molding-casting-composites

How to Mold and Cast [CRO-cast]

Molding:

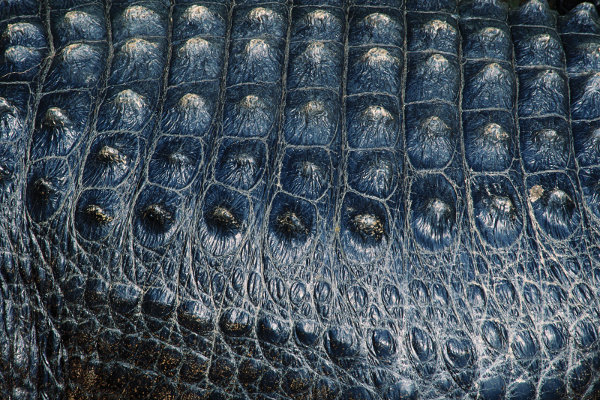

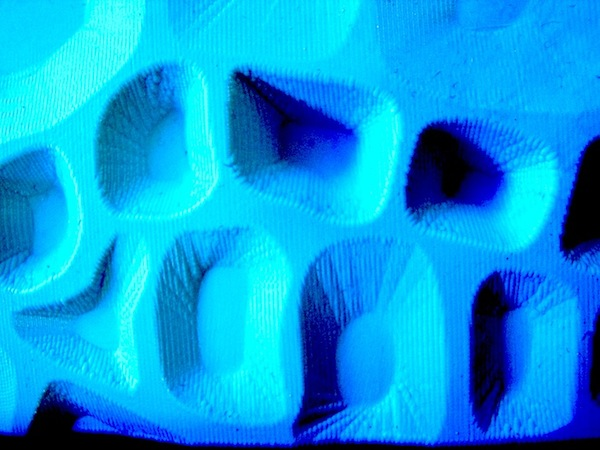

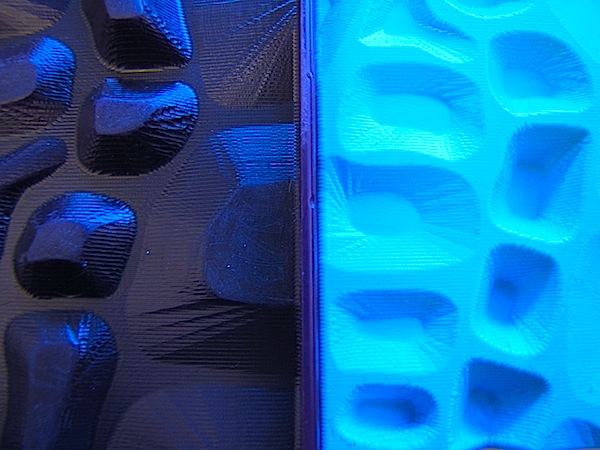

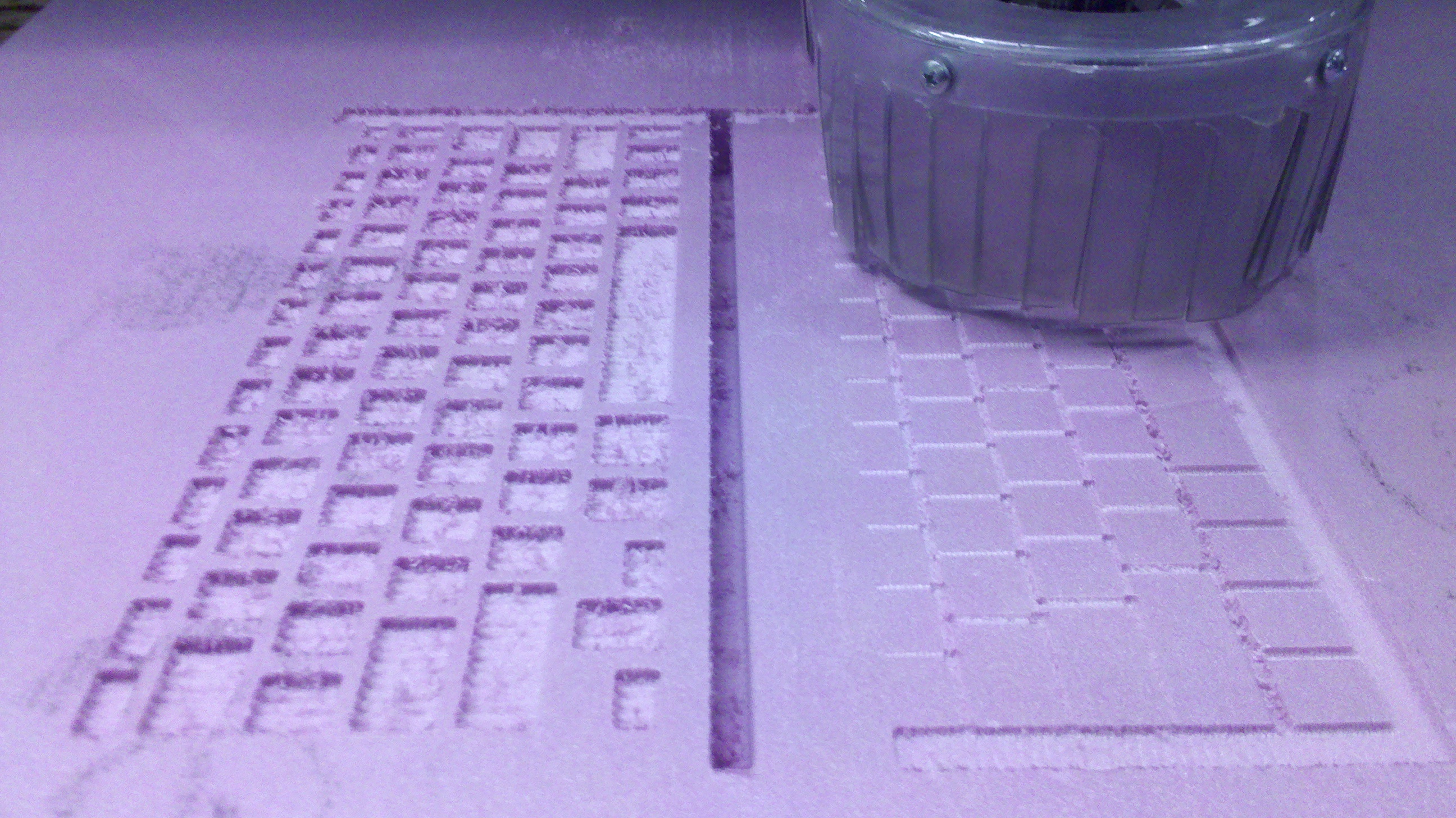

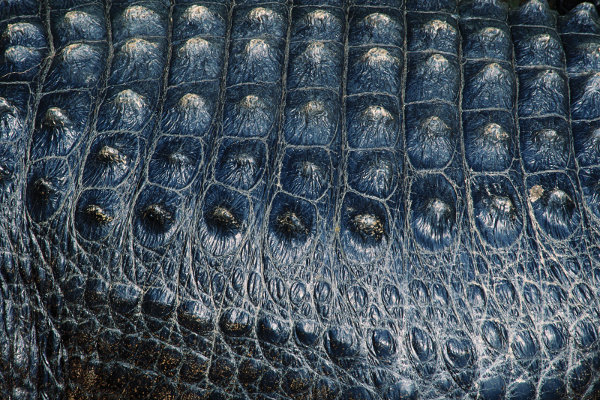

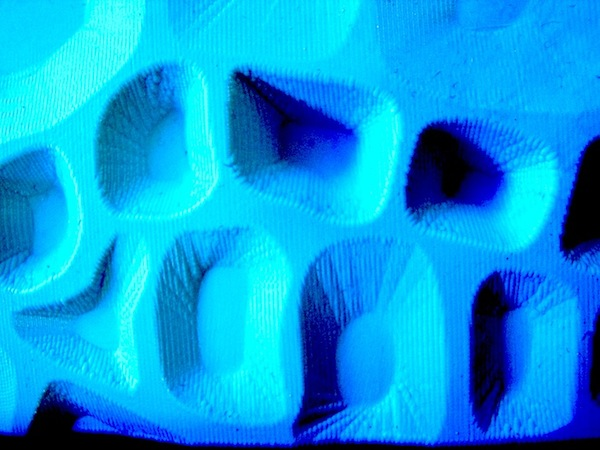

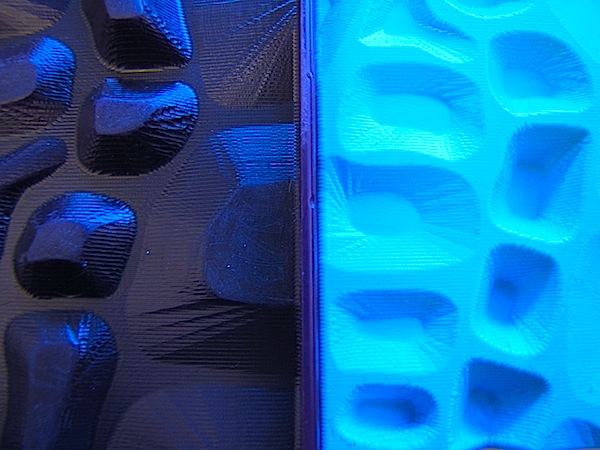

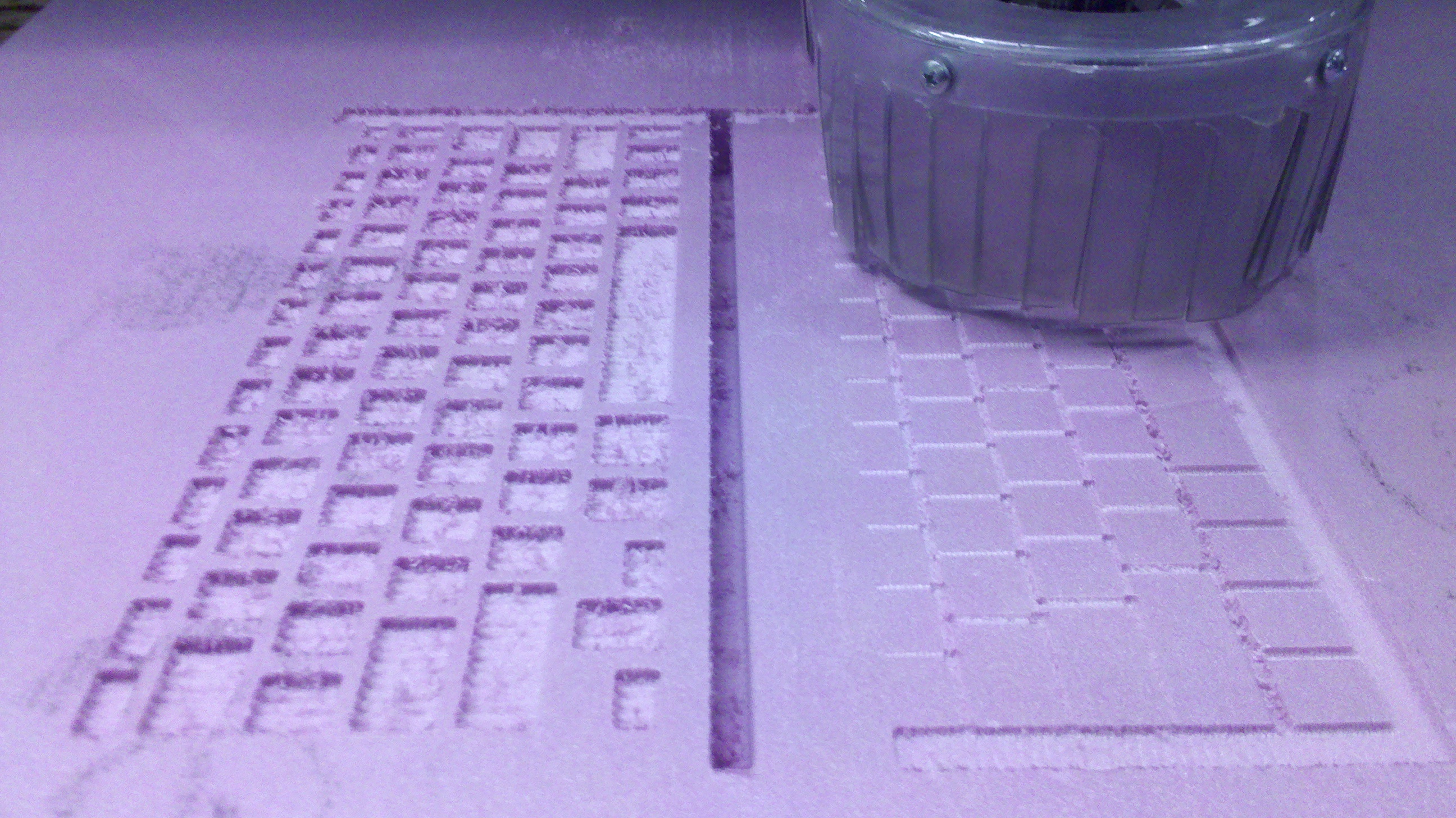

The two tests I conducted with molding and casting was one of a crocodile skin and a keypad cover I designed.For the crocodile skin, I cnc'd a positive of the skin, and then cast silicone to get a negative. The keypad example features a top and bottom two piece mold made out of cnc'd foam on the shopbot. The files took FOREVER to get right, because of the rough and final resolution, and the fact that there are sharp 90 degree angles in between areas that are not being cut plus narrow gaps...this needs debugging. The photos above are propellors that I cast out of a mold made by Kenny. I used natural fibers with drystone and hydrostone to get three different mixes.Molding is a process whereby a material becomes a pattern or framework for a future casting material. Molds consist of hollow blocks that are filled with liquid plastic, concrete, metal or glass. As the liquid cures within the mold(known as a casting), it takes the shape of the part it is set in, becoming a positive of a negative component. It is useful to use release agents to remove the cured component, otherwise casting of a hard material into a soft allows enough flexibility of one part to be able to remove the other. Types of molding include:

Compression Molding-a heated mold is forced into contact through applied pressure of another material in order to enter all areas of the mold, with the addition of heat until the materials have cured.This process can be used to mold thermoplastics and fiberglass.

Vacuum Forming- Similar to thermoforming, whereby a sheet of plastic is heated and then applied over the surface of the mold by applying vacuum between both the heated sheet and the mold surface. Critical issue to consider are draft angles, which describes areas of the mold which need to taper outward, to allow for ease in releasing the formed plastic from the mold.

Injection Molding- Material is fed into a heated area, where it mixes and is then forced through a mold cavity where it is simultaneously cooled and hardened as it exits the cavity and forms to the shape of the product. Injection Molding is best utilized when you have a component which needs to be produced in large volume.

Casting:

A process whereby a liquid is poured into a mold that has been preformed into some desired shape, allowing the liquid to solidify into a casting later removed from the original mold. Castings can be made out of metals or cold-set materials such as epoxy, concrete, or drystone.Castings can utilize a single-use mold or a multi-use mold for repetitive pours.

Composites:

Refers to a two or more material combination with different properties than those of its constituents.The constituents are in one of two categories: one constitutes the matrix and the other as reinforcement. The matrix supports and surrounds the reinforced fibers to keep everything in their position, and the fibers in turn reinforce the matrix by adding strength. Many composites we see today use a polymer matrix including epoxy, polymide, polypropylene.Depending on the process taken, a lay up usually contains more resin than fibers, while vacuum infusion ends up with more fiber than resin.

Kenny introduced natural fibers mixed with drystone, to make a propellar as illustrated in the latter half of the photos above. He used natural dried up fibers which were cut in 1cm pieces, and then mixed into a cup of already mixed drystone to reach a homogeneous mixture. Once mixed well, the mixture is poured into the mold to make a casting. Three different consistincies were experimented with above: drystone and fiber, hydrostone and fiber, and smaller sized fibers with drystone. The mixture with the larger chunks was a lot stronger, since the longer fibers made up a larger volume per strand linking areas together for added strength.