WEEK 6

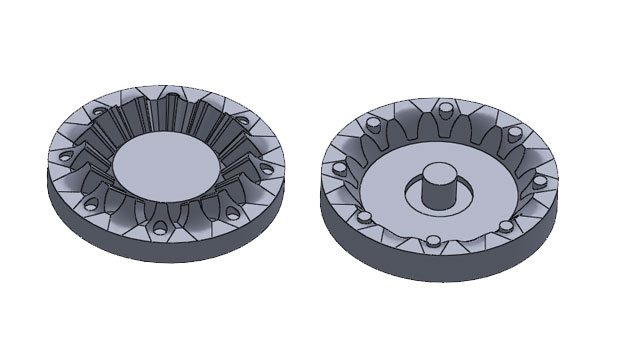

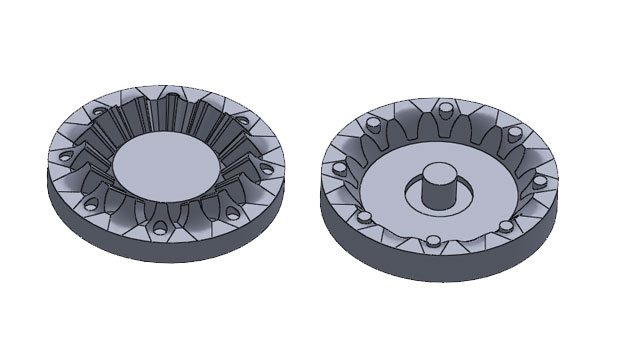

For this weeks assignment we had to design and make a reusable mold. I choose to explore this process by making a bevel gear. This ties into my final project, if I were to persue designing and making my own differntial (which requires bevel gears and pinions). I was also curious to see if I could make a mold with a complex splitting face.

First I made my gear with the help of the design library. This is a really powerfull feature and can be found at DesignLibrary>ANSI_Inch>Power_Transmition>Gears>Straight_Bevel_Gear.

I used the following settings:

I used the following settings:

-Diameteral Pitch: 8

-# of teeth: 16

-Pressure angle: 20

-# teeth on pinion: 12

After getting the gear I explored SolidWorks mold design tools which turns out are very powerfull, but a PITA to learn/work with.

First step was to define a split line, the line where the 2 mold halves meet along the part. There is a simple tool (Insert>Molds>Parting_line)which will determine the line based on a "pull" direction. Below you can see the result.

Next, you need to define a parting surface. Since I had a complicated object I could not use a simple plane, so I used the Solidworks feature yet again (Insert>Molds>Parting_surface), and also defined a "shut-off surface" for the center bore of my part. (these steps tell SolidWorks how I want my mold to be made)

Next, you need to define a parting surface. Since I had a complicated object I could not use a simple plane, so I used the Solidworks feature yet again (Insert>Molds>Parting_surface), and also defined a "shut-off surface" for the center bore of my part. (these steps tell SolidWorks how I want my mold to be made)

Finally, you can define a "tooling split" which will draw volumes in either direction of the parting line, and therefore define your mold (as it should be in oomoo). We still need to define the shape of the wax needed to make this mold.

Finally, you can define a "tooling split" which will draw volumes in either direction of the parting line, and therefore define your mold (as it should be in oomoo). We still need to define the shape of the wax needed to make this mold.

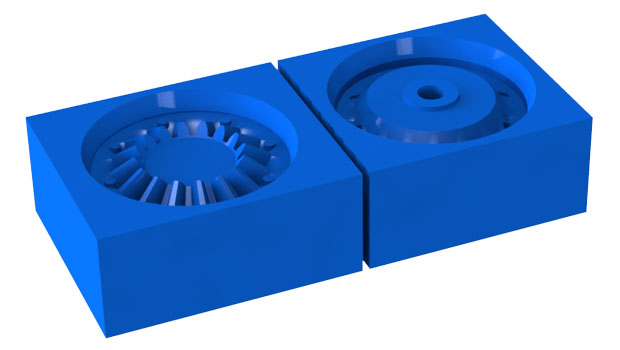

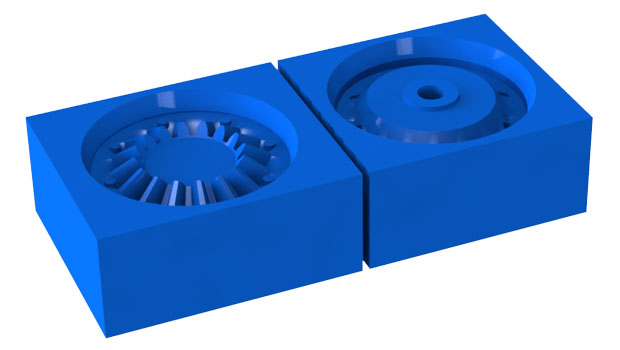

I'm not sure if I used the right work flow, but I ended up exporting the resulting "solid bodies" so I could work with them further. I did this by navigating to the solid bodies folder in the design tree, right clicking and choosing "insert into new part". I then did a subtraction or "cavity" of the mold into a block the size of the wax. This is what I got:

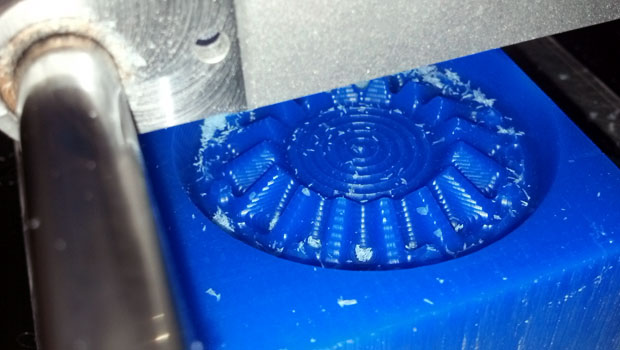

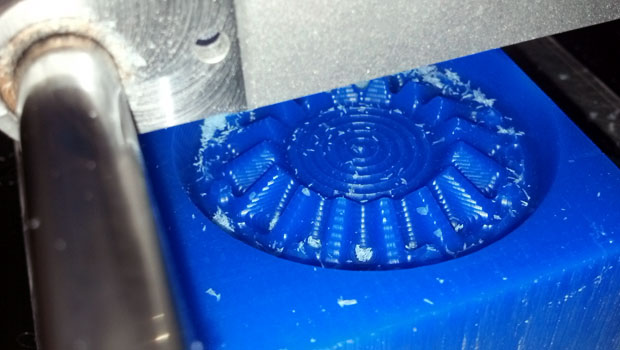

I then proceeded to actually cut the wax, I used a rough 1 pass with a 1/8 inch bit, and then did a final pass with a 1/32 inch bit with a 40% overlap, I will have more picture shortly, but so far I have only milled 1 side of the mold. (only had 1 block, so I could not mill while oomoo was drying)

Back