Rotem Abeles - How to make (almost) everything – Fall 2013

WEEK 9 – Composites

This week’s assignment was to design and make a 3D mold (~ft2), and produce a fiber composite part in it.

I wanted to build a balance bike for my daughter.

A balance bike is a bicycle without the pedaling system, so it can be used to teach very young children (2y old) how to maintain balance without the complication of pedaling (which is a skill learned much later, around age 5).

Balance bike design (example) from www.bikecad.ca

Most balance bike are made of metal or (ply)wood, so making a composite frame should be a nice challenge.

I used examples from the internet (such as the one above) to estimate the measurements for my design.

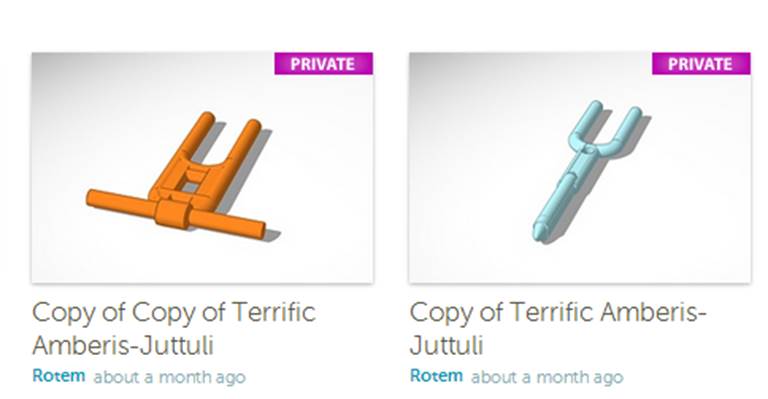

I used tinkercad to design a rear fork and a front fork. I also made a 12” foam wheel to see that it fits.

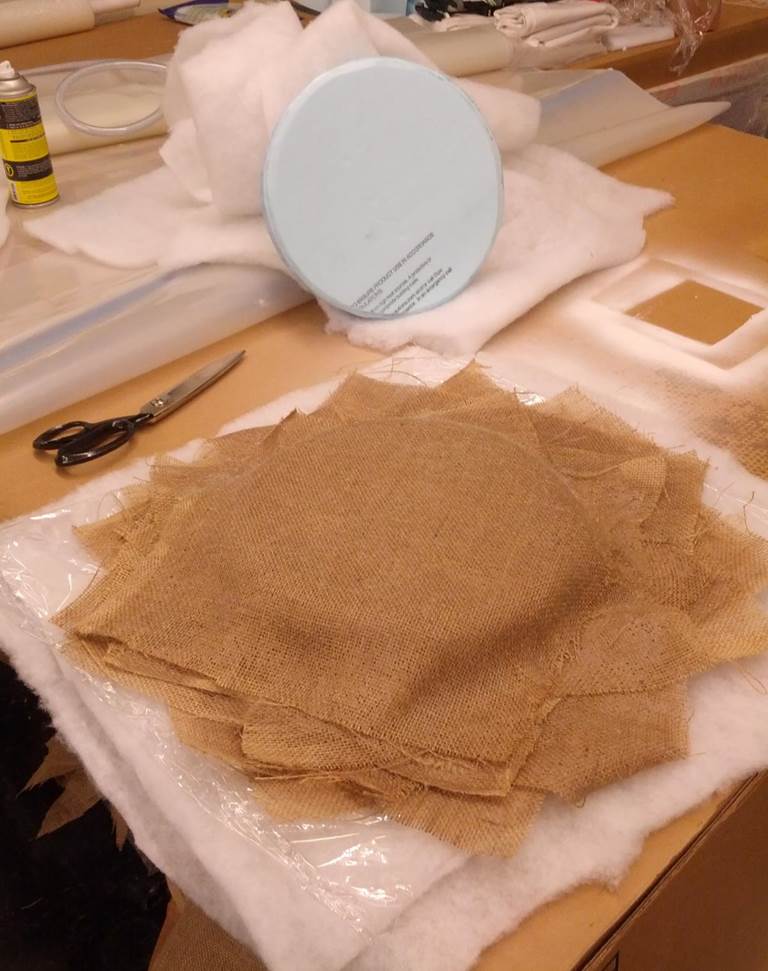

First I wanted to make the composite wheel to practice vacuum

double layer composite-making. I used Aquamarine epoxy (#300 and #21) in a 2:1

ratio, 4 layers of burlap (on each side!) and a layer of bleeder and breather

on each side as well.

After 24h in the vaccum bag it was ready to pull out.

Since I didn’t laser cut the

burlap, getting a proper finish was very difficult. I used a bunch of tools

from the machine shop, and it seems that metal sheers work best to remove

flashing.

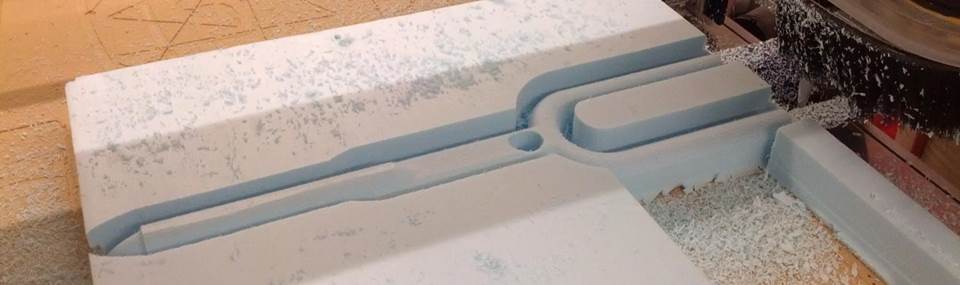

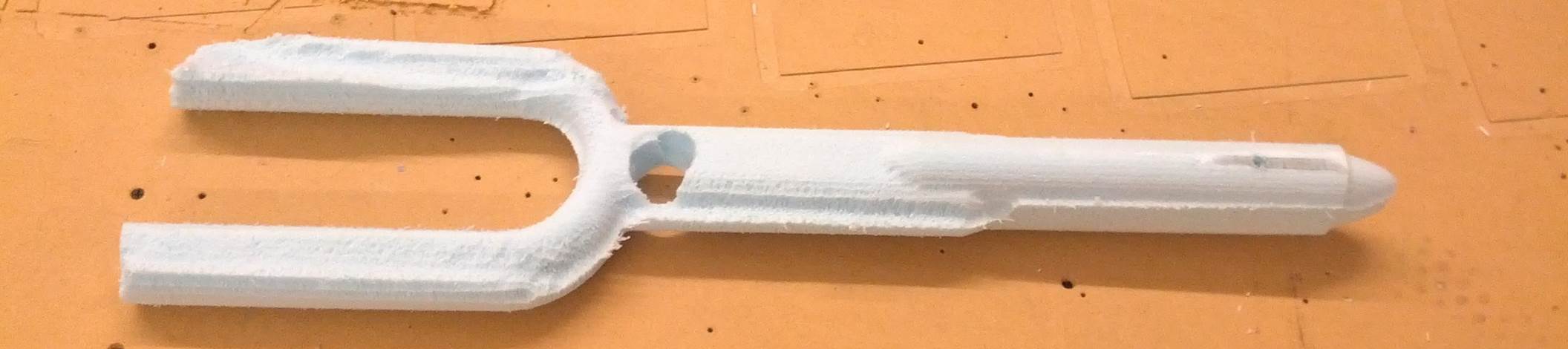

Then I went to mill the part of the frame on the shopbot. It was very fast and easy to get one side, but when I switched it over I could hold it steady due to the unusaual shape, and the shopbot almost tore it apart!

First side up

Flip sides

Catastrophe!

However, I did wanted to stress test the composite so I used the same vacuum bagging technic with this poor piece of foam. It turned out ugly and deformed, but surprisingly strong!

It seems if I could improve my design I can actualy make a bike out of this thing…