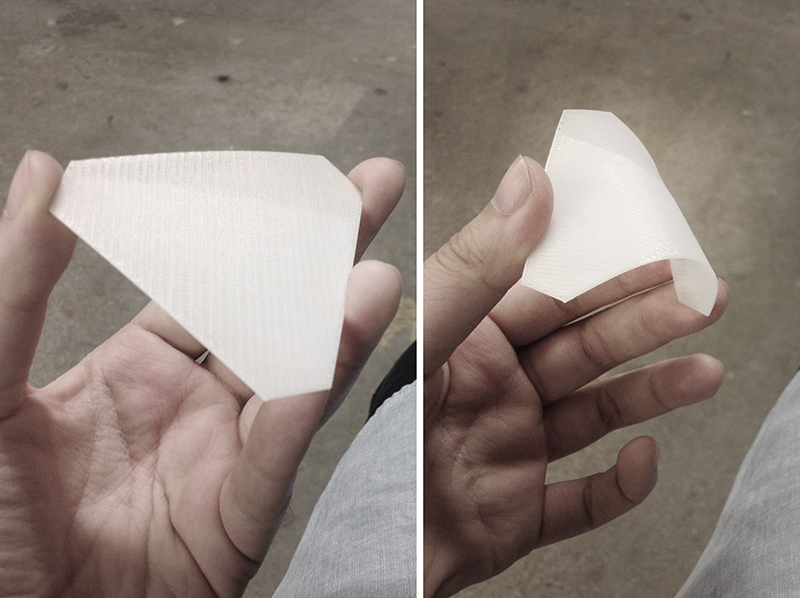

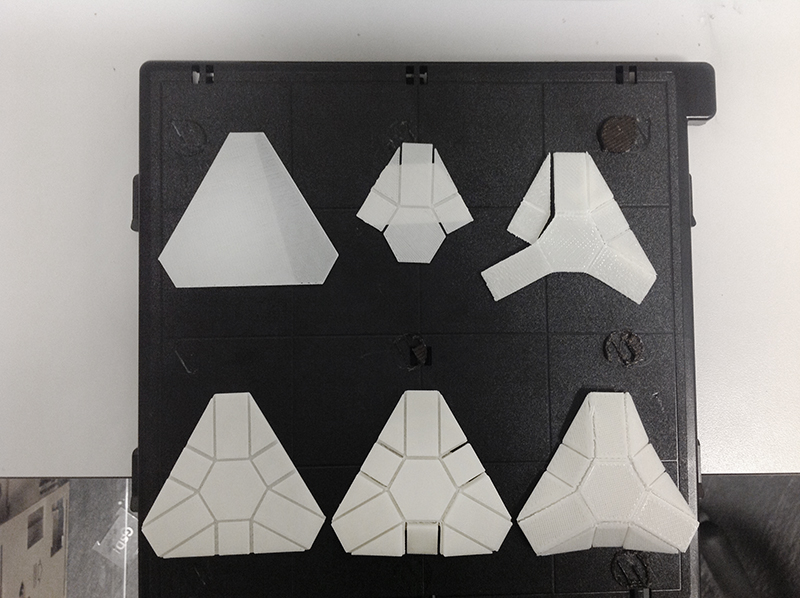

I start from very thin layer of ABS to test material effect, and realize it is bendable. I use U-Print machine in Harvard GSD for this time.

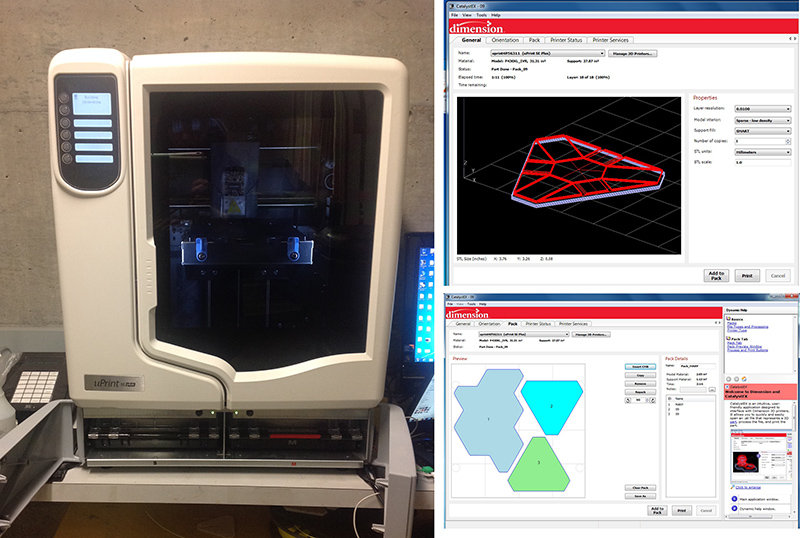

u-Print machine and interface / This is the only machine free to print in GSD now

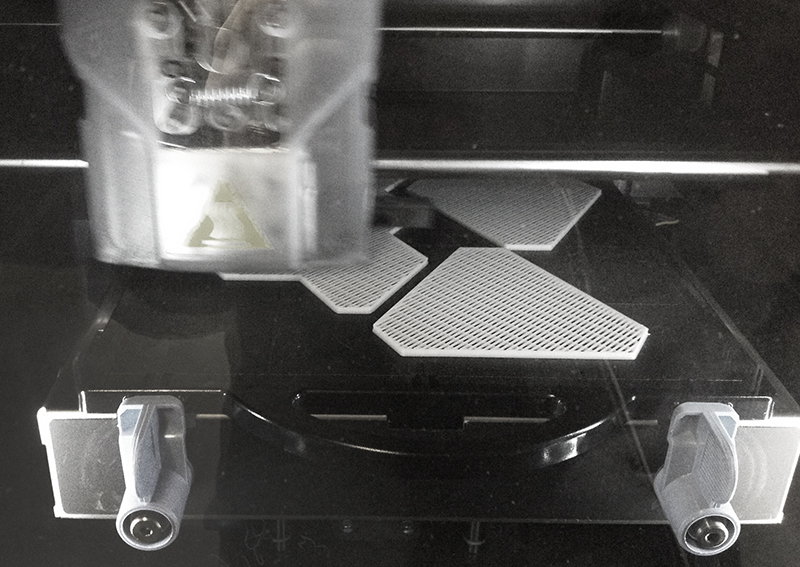

printing process

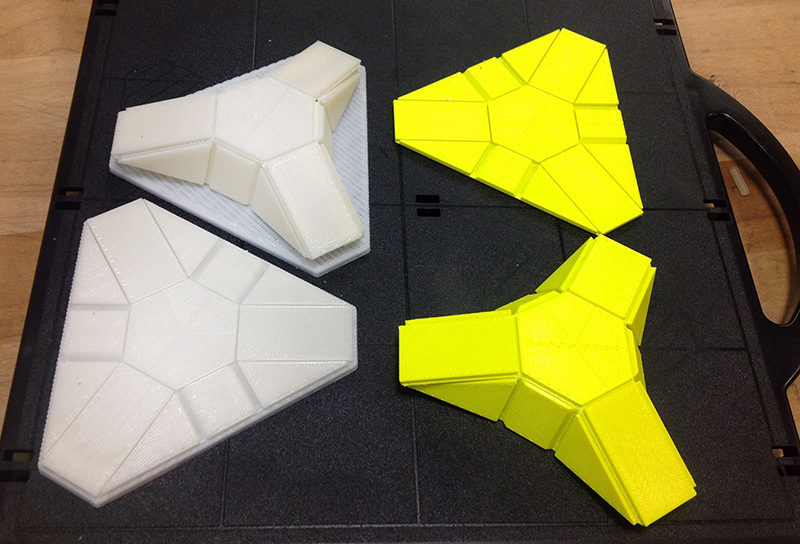

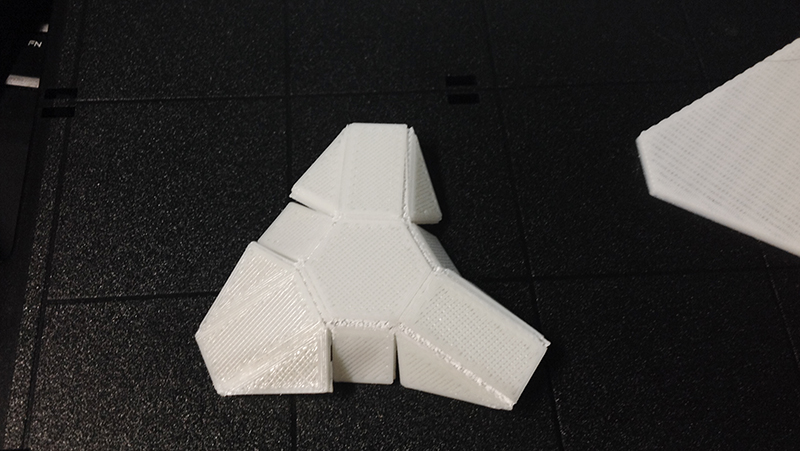

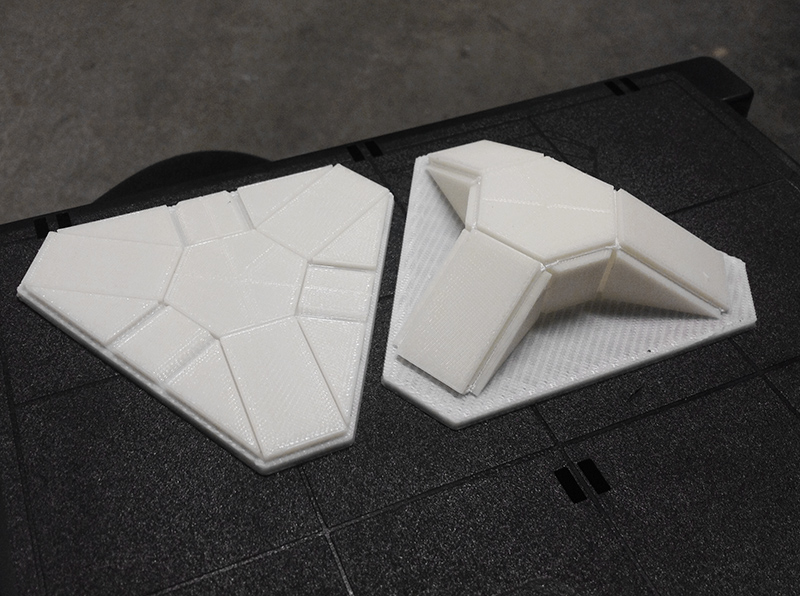

The first print is not successful. The joint layer is too thick and easy to break during the folding process.

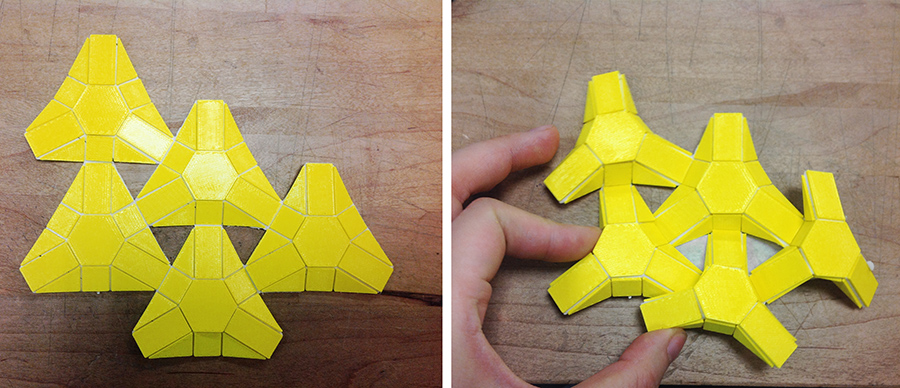

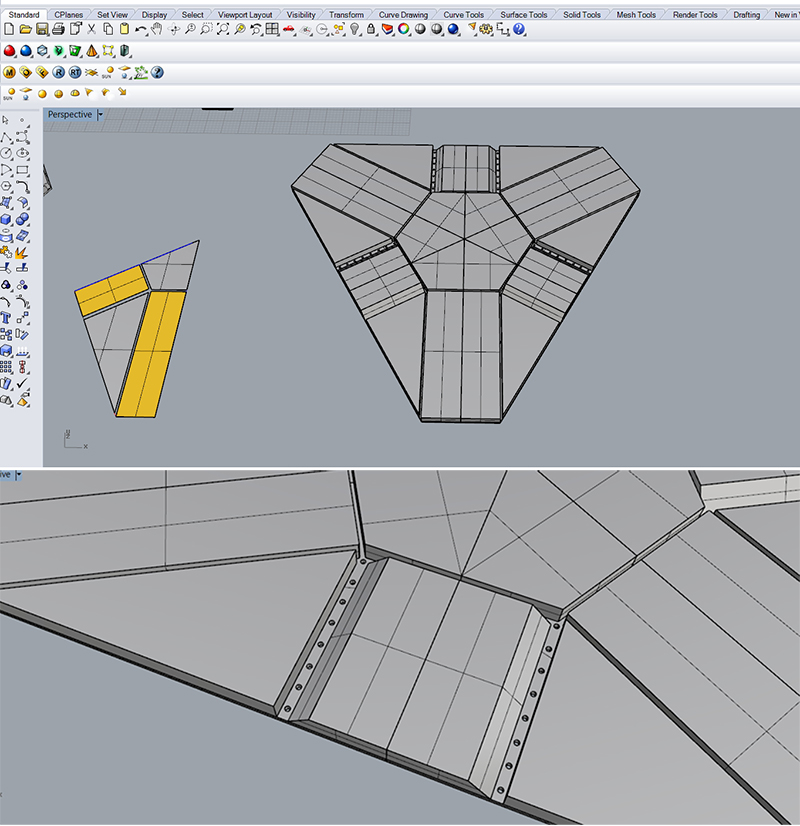

Therefore, I go back to change the thickness of joint layer, and reshape the edge to the panel.

After few tests, I figure out that the best thickness for joint layer is 0.5mm.

The final printing time is 18 minutes which almost 20% of time if we print the solid version of the folded version.