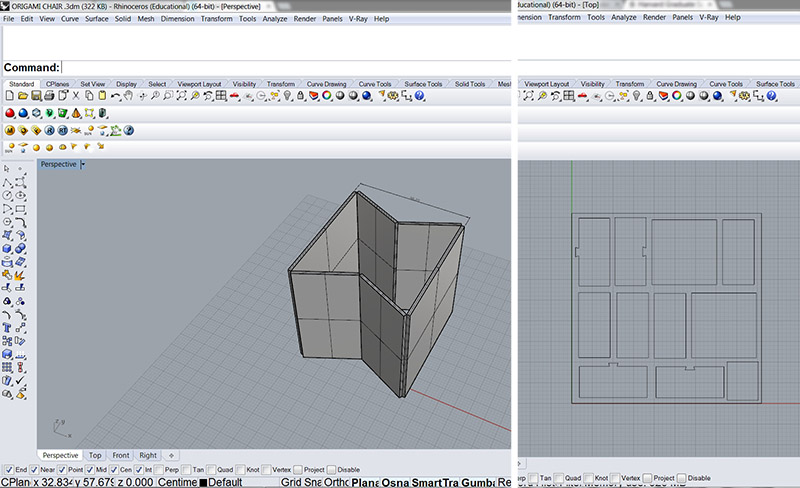

1. I started my geometry in Rhino /2. Unroll surfaces in pieces /3. Locate them with some distance in between inside 46”X46” square.

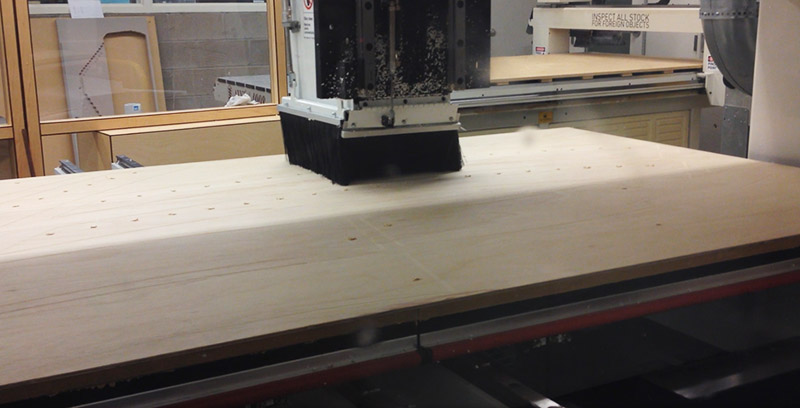

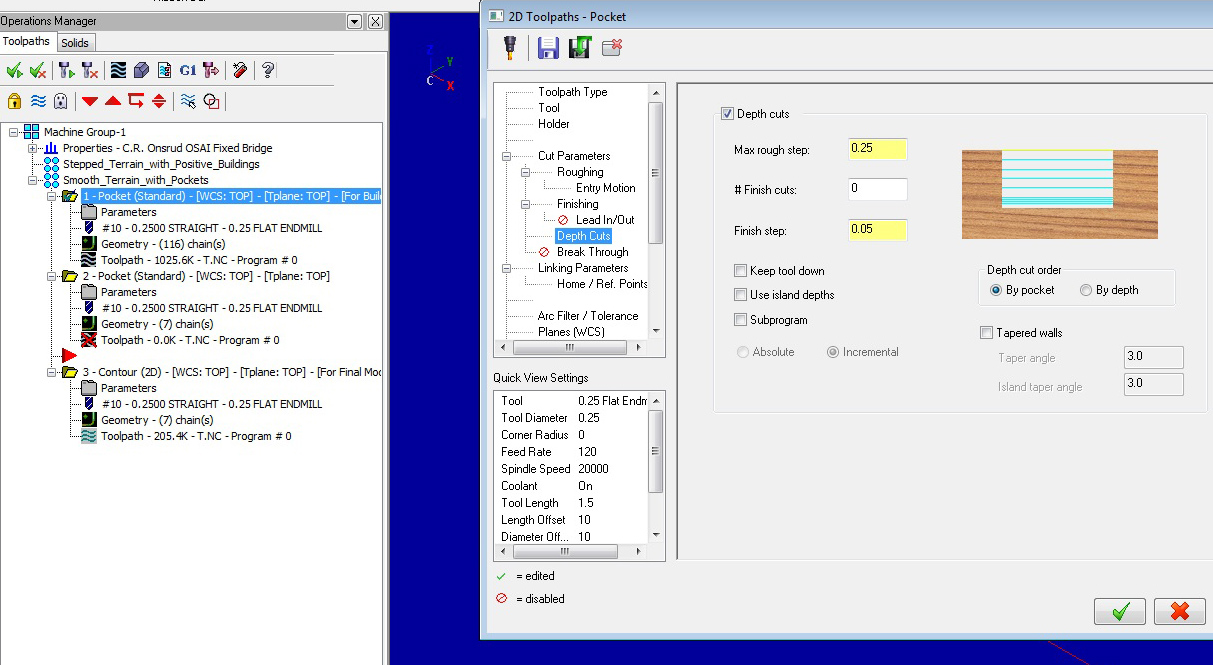

Import rhino file into MasterCAM to finish the milling setting. I use contour2D + Pocket (standard)

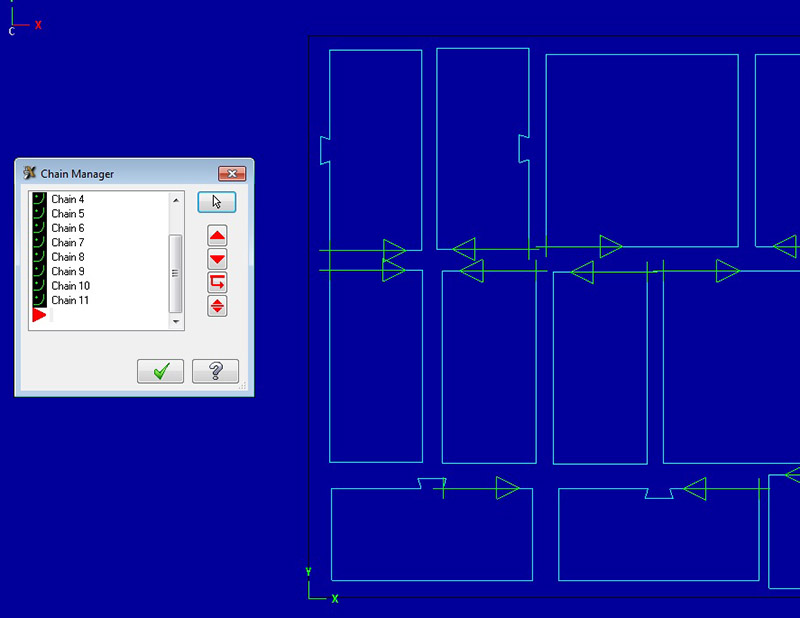

Select geometry chains and remember to add tabs to hold the material