Week Eight: Composites

I'm going to try to make a leg socket. Usually this would be made of carbon fiber, like this:

...but I'll use linen or burlap since that's what we have. One of my labmates lent me a plaster mold of our advisor's residual limb.

First step is attaching a release layer:

Then, cutting the material. I like how the linen looks. I'm using one large piece, which I'll fold over in five or six places so that it conforms to the mold and so that there's more than one layer of material, and then a second smaller piece that will reinforce the distal end (bottom) of the socket.

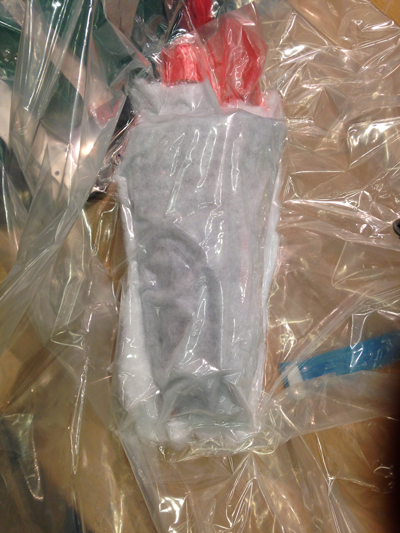

The bleeder is a piece of plastic with lots of small holes poked in it:

The breather is polyester gauze:

I couldn't take pictures of the next few steps because my hands were occupied, but I mixed one cup of the non-clear epoxy (2 pumps epoxy per 1 pump hardener) and spread it on the linen with a tongue depressor. There was just barely enough to soak through all the fabric, and I probably should have used more. Then I wrapped the mold (with the release layer) in the linen, then in the bleeder, then the breather, put everything into the vacuum bag, sealed the bag, and

The vacuum seems ok, but there's no epoxy coming through the breather. I probably didn't use enough.

Eighteen hours later, still no bleeding. (Theoretically this only needed four hours to set, but I left it longer.)

But let's unwrap it anyway. I trimmed the top edge with scissors--easier than I thought.

It came out cleanly, the epoxy is dry, and it isn't falling apart. But it's not stiff enough in the places where there's only a single layer of material. If I were doing this again, I'd use a second layer and more epoxy.