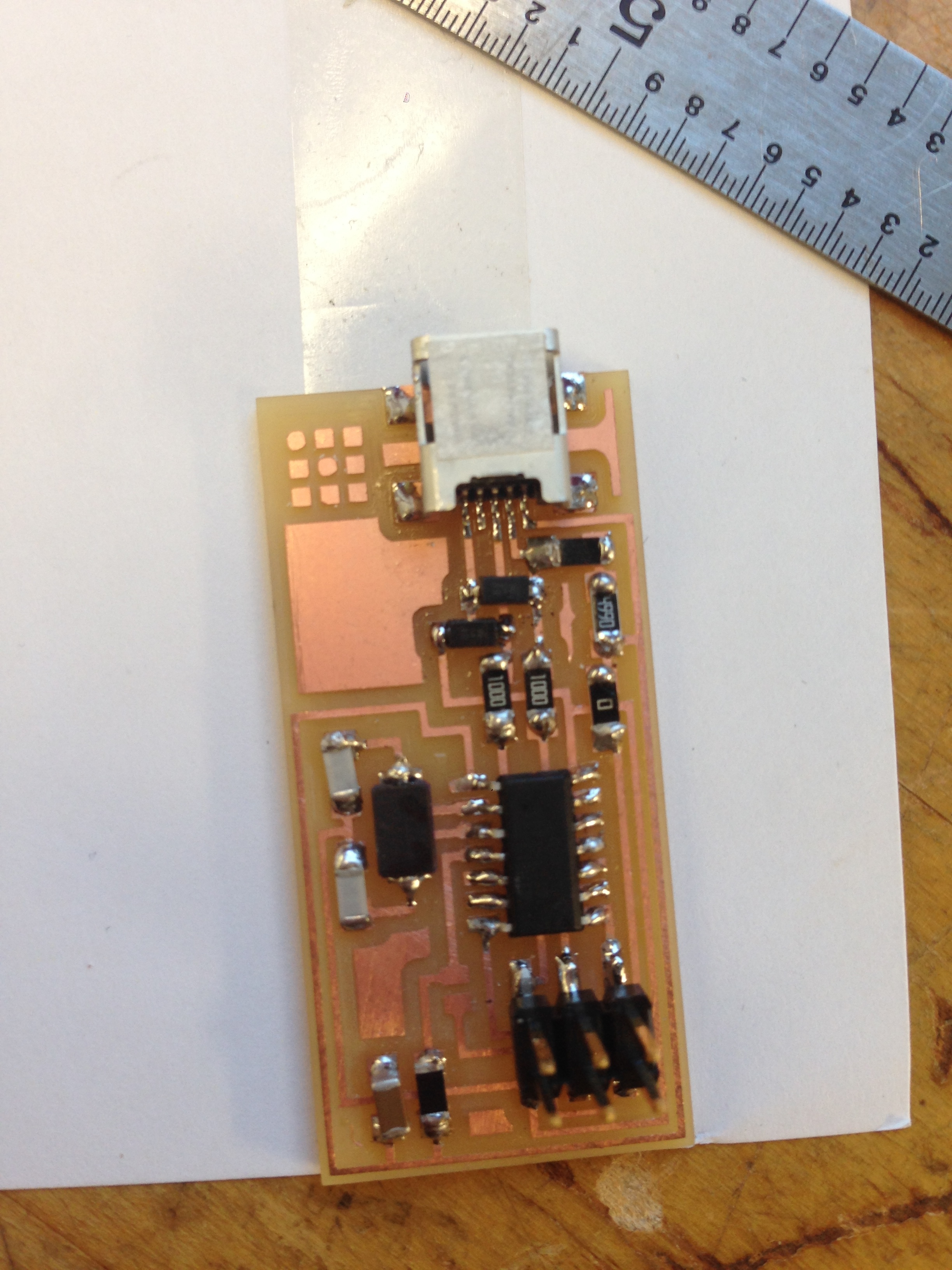

Since the traces were readily available, we just had to start by printing the board. There were a series of steps to be followed before starting out though. I had to be extra cautious with the xmin and ymin. My board just made thorugh with all the traces intact. 0.1 on either axes would have costed me the board and the machine time.

Soldering was quite intense. The job definitely needs firm hands. It took a while to get used to the workfllow. Here are the few things I learned with respect to PCB fabrication. Firt, its better to either use extra solder or use too less. Using extra solder makes things messy and two or more traces get connected inadvertently. Second, it is a good practice to look at the connections under the microscope every now and then. This will ensure that everything is going right and is a good way to avoid mistake in the future. Third, if there is extra solder, we will have to spend extra time cleaning up the mess using the copper braid. A good tip from Rob was to increase the temperature to 80 while using the copper braid. This was very effective as I was initially struggling to get the extra solder away. Remember to bring it back to 70 after getting the job done. Fourth, the trick while soldering is to put a blob of solder on the pad first and then place the part on the pad and rehaet the blob and the part together. This method is very efficient and gets things done faster.