How to Make (Almost) Anything

Project 03

Electronics Fabrication

Input

Parameters: PCB, Cutting Circuit Boards, Computer-controlled Milling, Soldering, Assembling, Programming, Computer-aided Manufacturing

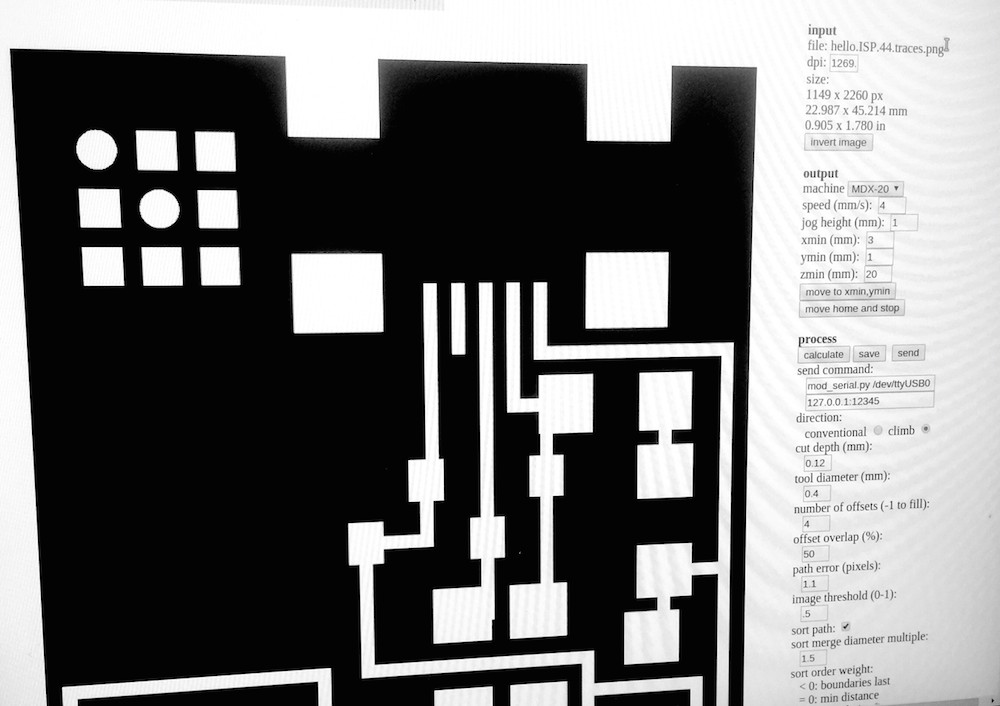

Tool: Roland MDX-20, Soldering Iron, Fab Modules by Neil Gershenfeld

Material: Copper Board, Components

Output

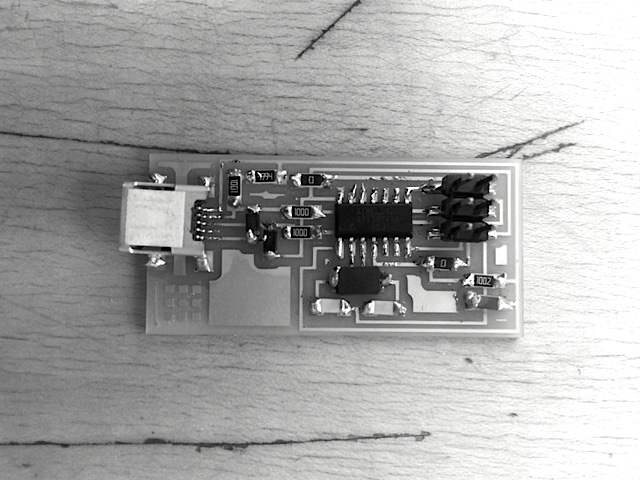

Description: FabISP: Fab-able In-System Programmer

This project explores the FabISP fabrication process:

1.Following the schematic of the hello.ISP.44.cad

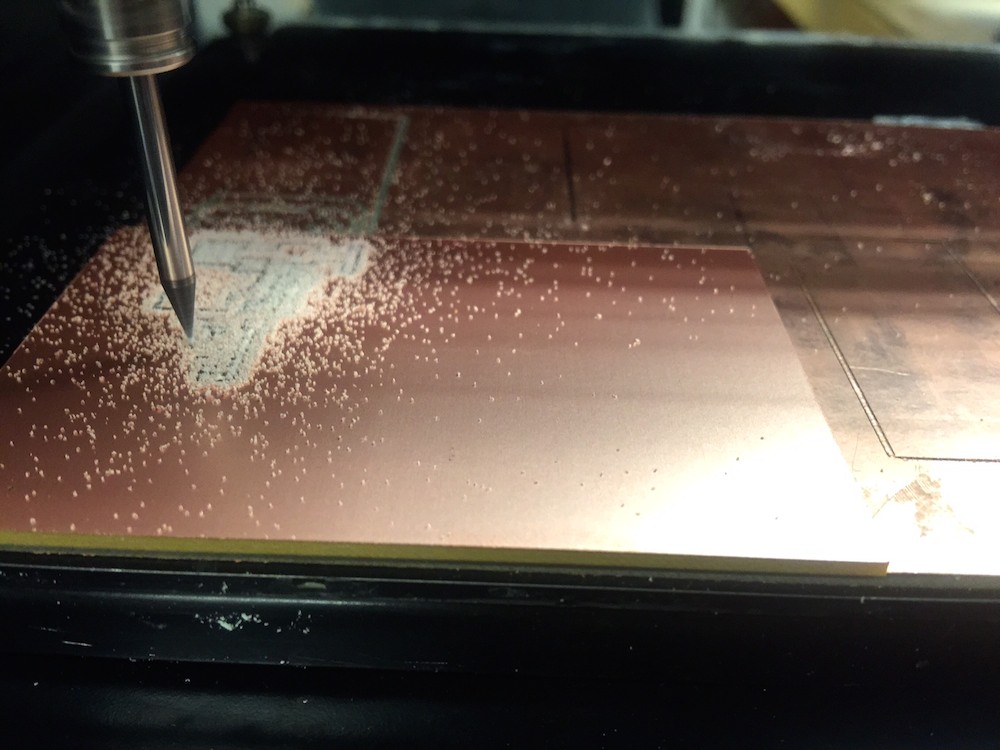

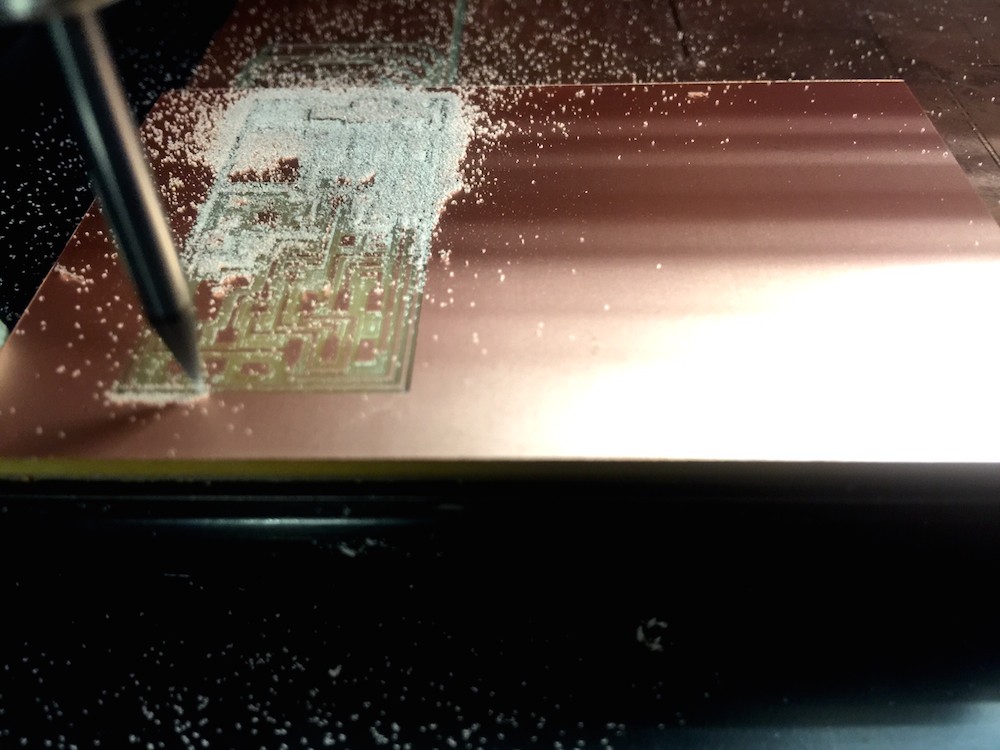

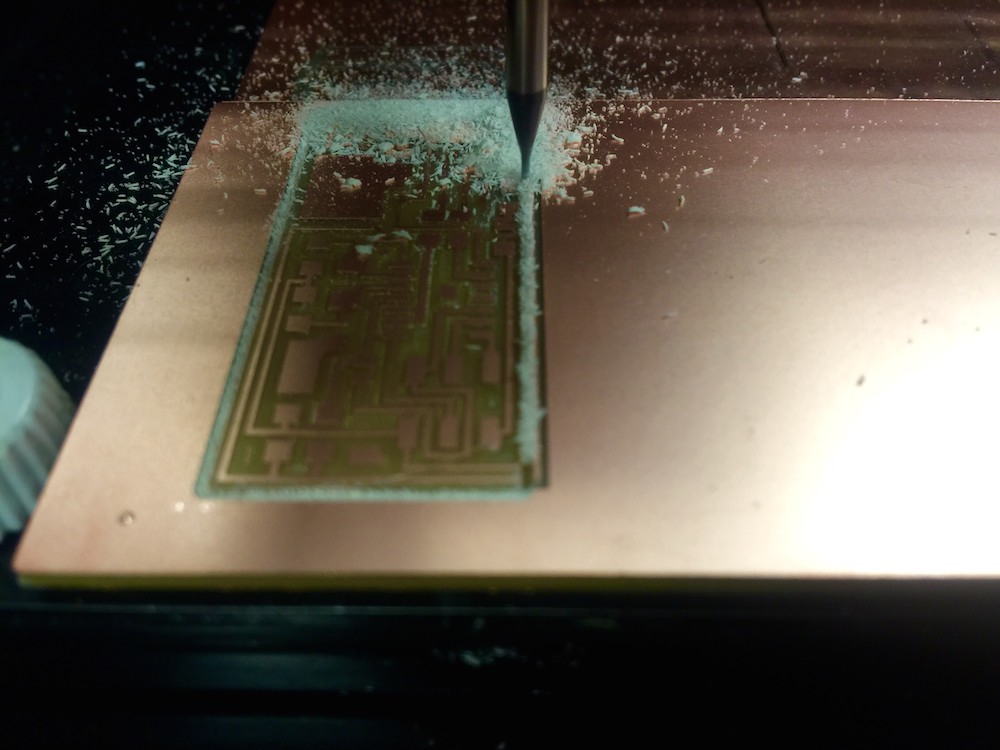

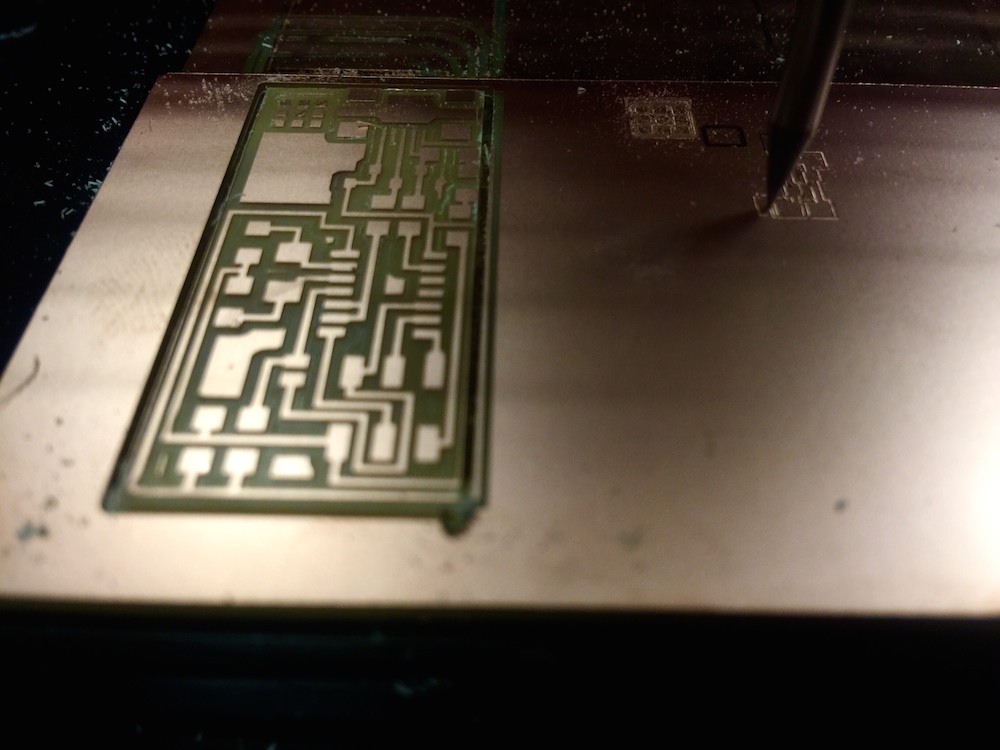

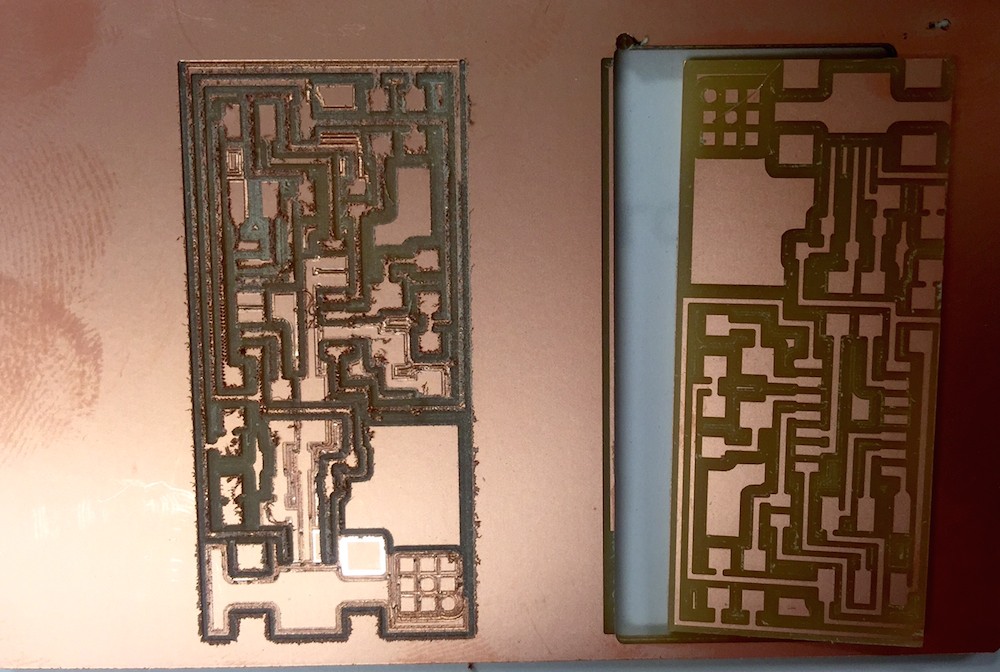

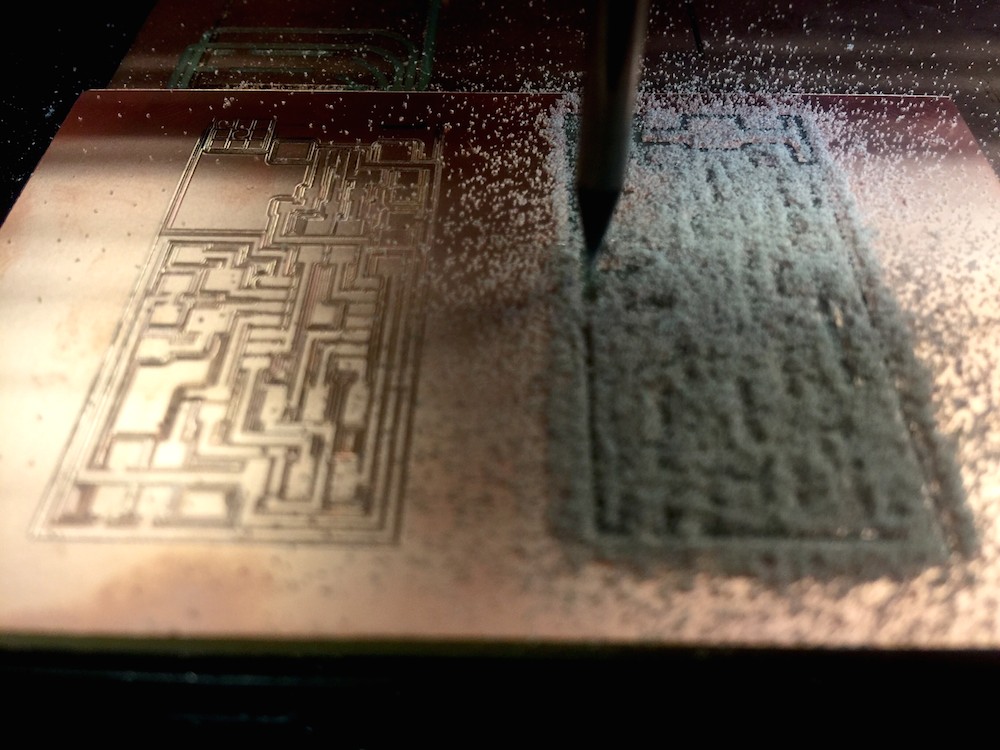

2. CNC Milling of Printed Circuit Board (PCB)

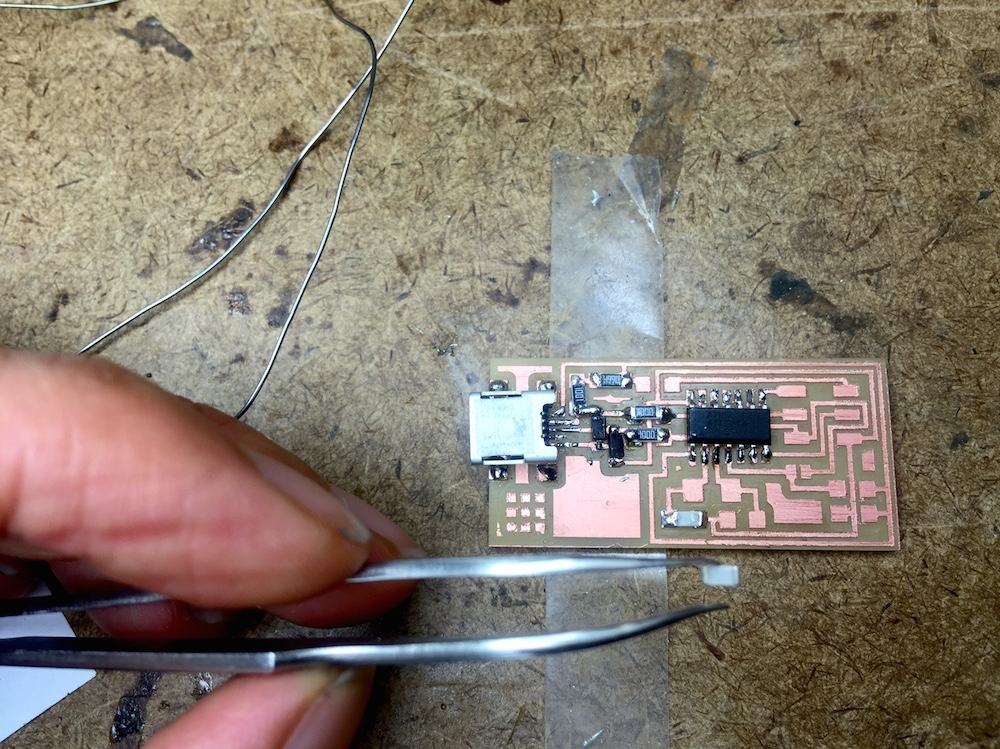

3. Soldering of Electrical Components

Fabrication Process

Milling the PCB: many failed attempts due to board not laid completely flat, wrong cut file, blunt endmills. Although I discovered afterwards that the borders of the lines didn't need to look absolutely, machine-like perfect, as long as they are not interrupted by a cut. The process of adjusting the endmill seemed endless on day 2, when I forgot my finished PCB home! Until fiddling prolifically taught a lesson in mechanics. One of the screws securing the endmill was missing

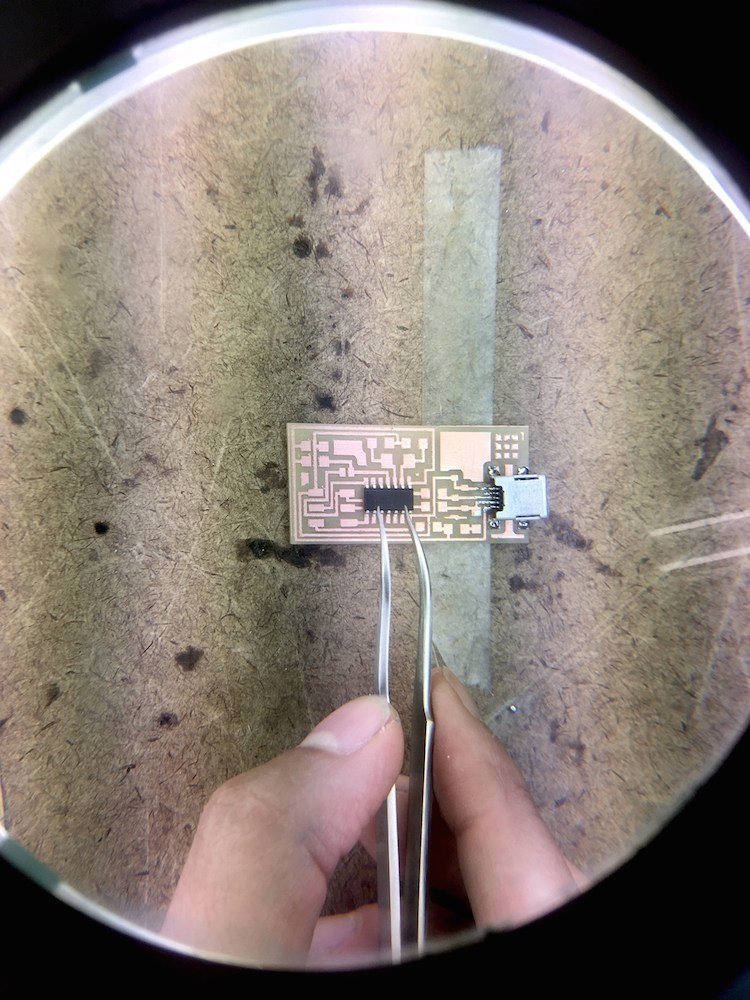

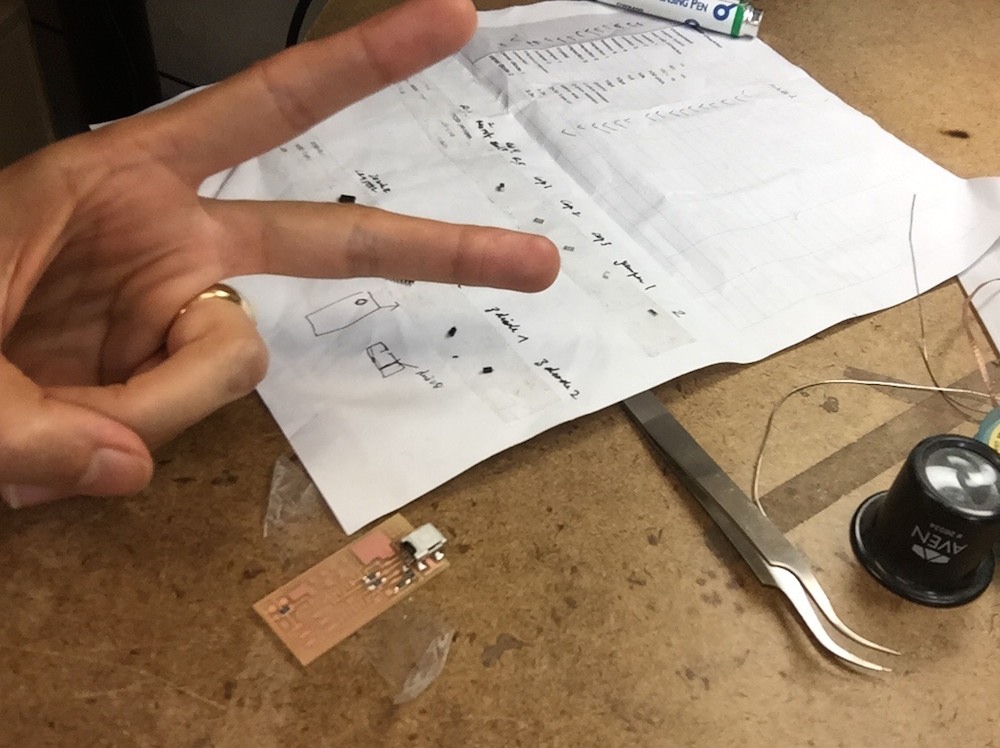

Soldering and Assembly: No major error. Putting a drop of solder on the wick to absorb any excess or misplaced solder.Proceeding from USB connector downwards. Respected the direction of microcontroller and diodes. The second board took 45 minutes. A small victory.

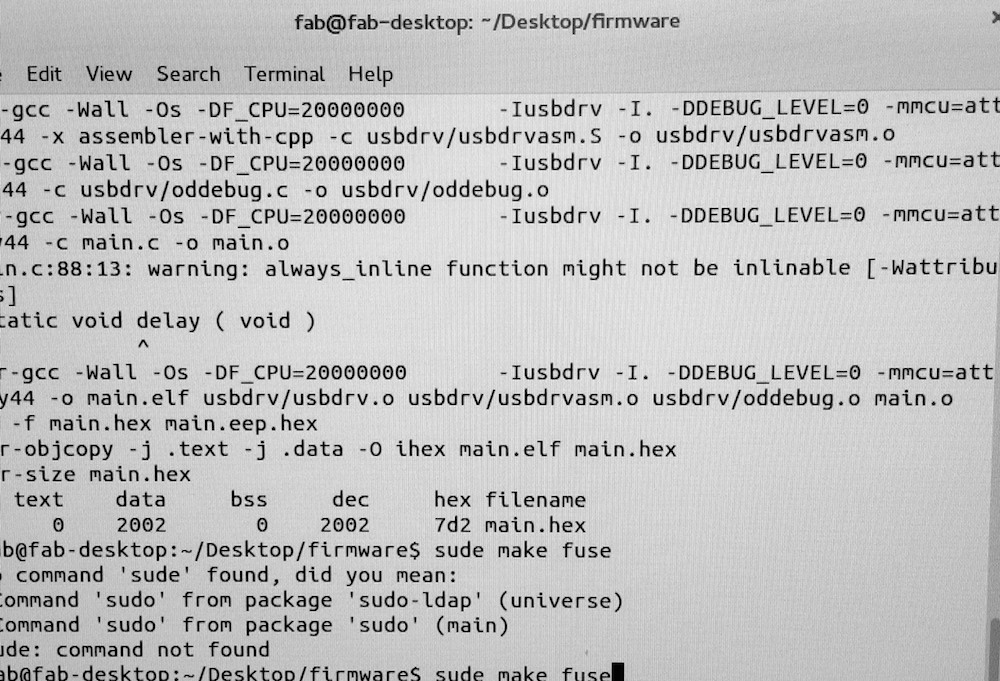

Programmation: Passed the smoke test. Remember to keep connected to USB while programming. Wonderfully easy install in 4 commands in Fab In-System Programmer (after I fixed the missing crystal)