Printing the Handle

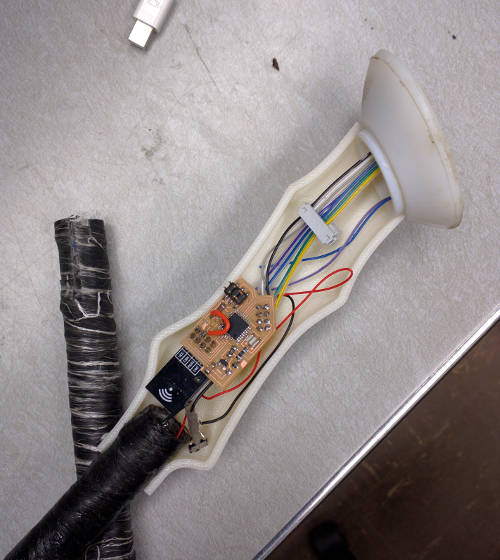

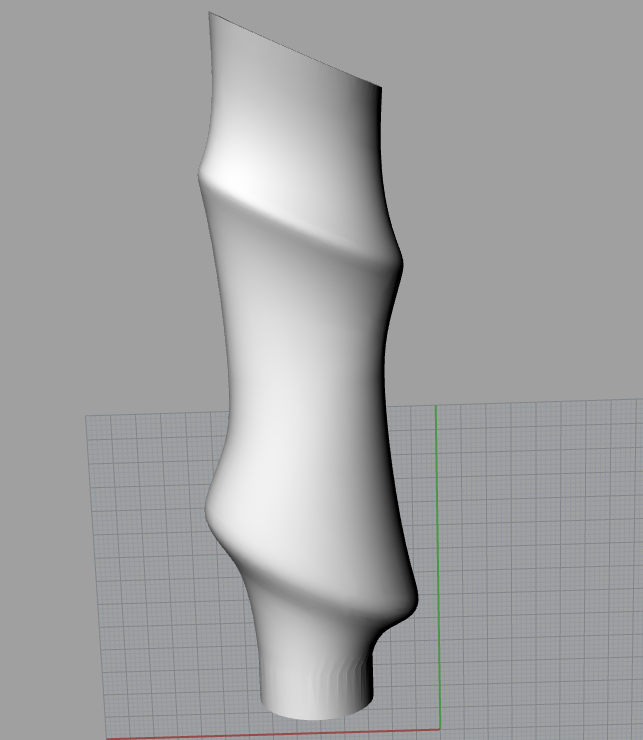

I first cleaned up the model I had designed for the trekking pole handle and decided to 3D print it in two halfs (rather than cast it as I had previously explored) as having two halfs that went together would be easier to work with to get the electronics in. This part also makes sense to 3D print as for now it is just a one off. If I wanted to make multiple it would make more sense to create molds that I could cast from.

The first print I attempted failed. While the shell was supposed to be 2mm thick, which was within the tolerances of the printer, the geometery did not play nicely with the printer software. I increased the shell thickness to 3mm, and also extended the bottom of the handle by 1 cm to make the interface with the trekking pole shaft easier.

This print was successful and the longer shaft worked quite well.

Printing the Top

I also printed the top of the trekking pole. This was originially meant to be a prototype of a top that I would cast in a hard rubber, but as is expected in this type of project I ran out of time. I used the objet 3D printer for this print, which ended up with a finish similar to what I was hoping to acheive.

The top of the pole has room for a screen and a button. The dimensions are a little weird because the circuit board that the screen is mounted to is quite large.

I considered casting the OLED screen into the top, but it seemed risky for a last minute attempt.