The Idea

I like to play chess. I’m not a great (or even a good) player, but the game is fun. A friend and I have been playing pretty consistently and we sometimes talk about how cool it would be to have a stylized chess set. We went back and forth with different ideas, but always rejected them as either A) being too expensive B) too stylized (i.e. no elegant for either of our tastes). After thinking about this project for a while, I decided to try to make a piece to see if we could use 3D printing to design our own set.

The natural place to start was the queen. She is the most important piece on the board.

Design

I am really starting to like Antimony. The interface is so slick and its such a natural environment to draw in. There is still some stuff that I have not figured out how to do. For example, I would have really liked to include some tapering effect, but just could not work out how to do it.

Design Tree

Design

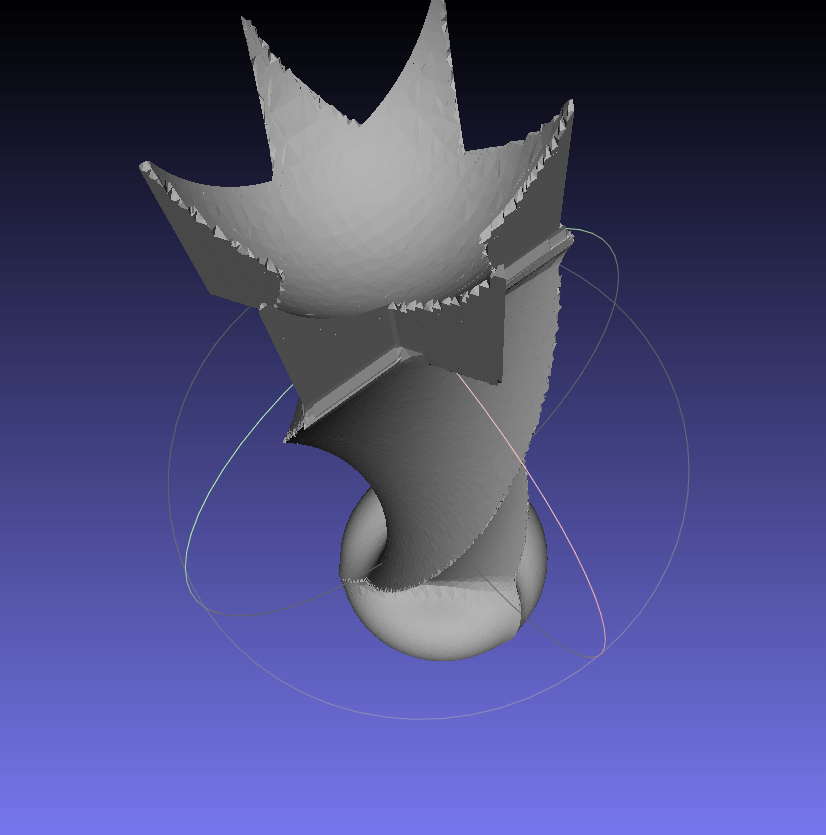

The design is fairly simple. The basic figure is an equilateral triangle rotated through 270 degrees. That shape is blended with a half toroid on the bottom for the base. The top is an extruded version of the equilateral triangle differencing with a sphere.

Preparing For Print

Here is where I started running into issues. I was unhappy with my first stl export out of antimony. I did not increase the resolution enough and I thought the output from the print would be jagged. I then went overkill by increasing the resolution by an order of magnitude and created a file that could not be utilized. I then went back and doubled the resolution and that worked very well.

First Export

Imported into Cura

Printing

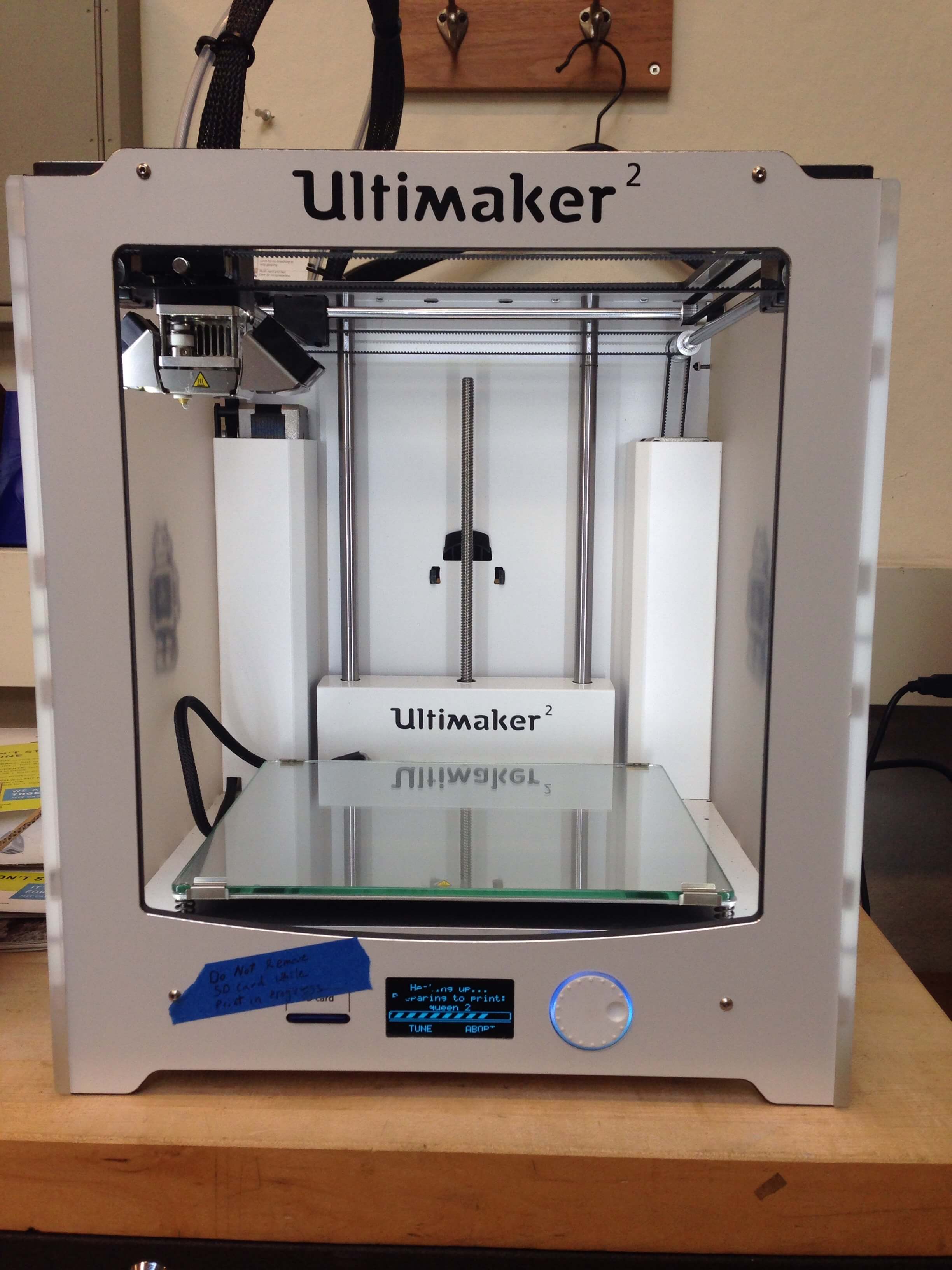

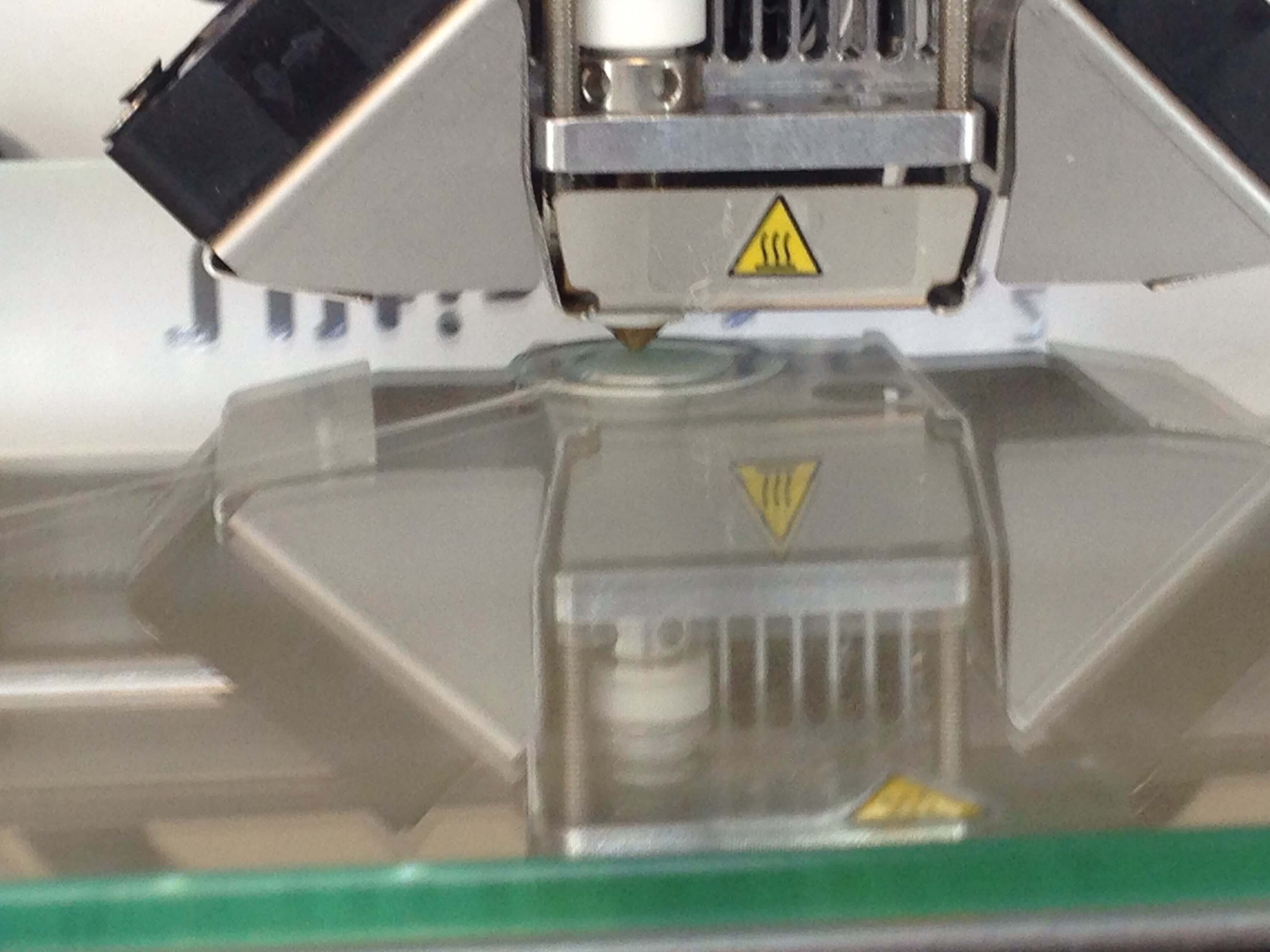

Printing started off poorly. I got everything prepared to print and then I noticed that the head was moving, but nothing was extruding. So I started to troubleshoot that. The first thing I checked was the motor in the back of the Ultimaker, it was working. Then I was stumped. Fortunately one of the shop managers came to help me and he noticed that somehow the filament had backed out of the head by about 2 inches. After fiddling with the menus on the printer for a bit, we were able to find a manual feed and get the fulminant repositioned. Then everything worked.

Printing was stalled in the beginning

. . . but we got it working

I underestimated how cool it would be to watch something I drew in CAD just come to life. I can see why there is so much hype around the technology of 3D printing: Its very satisfying to watch something from your mind be cleanly translated into reality.

Final Product

Next Steps

Scanning

For scanning I tried my trusty waterbottle with 123D print. It came out ok.