Objective

3D printing and 3D scanning.

Design

Everything in blender.

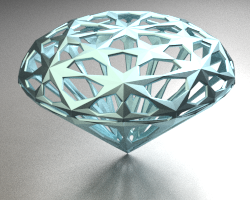

Diamond: I had no idea what to print, so I just started playing around with shapes in blender.

I shaped a diamond out of a cylinder and then applied to modifiers; wireframe (thickness 0.1) and subdivide (1). The result is a star-covered diamond.

I never printed this shape.

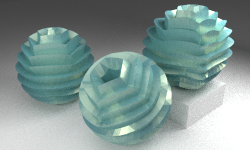

Penholder: A penholder is what I ended up printing. At first I started playing around with shapes.

3 random penholders:

I wasn't fully satisfied with how they came out. Second idea: I wanted it to look like the pen just fell into water/liquid. To get a realistic model, I used the fluids simulations in blender. Dropping a pen into a pool of water:

Then stop the animation at the best frame. Add a cylinder, put it over the area that will be printed. Add modifier - boolean - intersection with the splash. Then clean up the model (remove droplets, look whether hole for pen is clean, if not cut a cylinder shape out in the middle). Round and square holder:

I printed the salmon colored one on the Ultimaker 2 (in fast and normal).

I also looked at liquid dripping down and then addded a hole for the pen:

After cleaning off a lot of droplets and adding a hole in the middle (slightly tapered from 10mm to 9.7mm), I printed this shape on the Objet 3D printer.

General comments about liquid simulation in blender:

- You need a domain (liquid will be simulated inside this space) and some liquid. Either an object that is liquid or an inlet that produces liquid (faucet).

- Play around with the properties of the doman until you get what you want.

- To generate particles, set subdivision to 2 (in domain properties).

- World size is very important, larger: more movement, smaller: less waves/splash.

- Changing the resolution has a very similar effect to changing the real world size (higher resolution, more waves/splashes). For my final simulation I used 150, takes about 15min to bake 50 frames.

- The fluid presets are water, honey and oil. They behave very differently (I used base:5, exponent:5).

Printing

I used the Ultimaker 2 to print the round penholder.

After exporting the holer as a .stl file in blender, I opened it in Cura. I am not sure what the internal units of blender are. After opening the stl. file in Cura it becomes obvious that the model is downscaled a lot.

No problem, just scale it up again. Double check, that the hole will fit the pen and print. My first print was unsucessfull, the head of the printer was 1-2in away from the bed:

After aligning the printing bed (maintenance - build plate - then level the plate and move it close to the printing head), printing went really well.

I printed the same file twice; in fast and normal mode. In fast mode, it takes about 10min, in normal mode 1h05min.

There are several differences in quality between fast and normal:

- In fast mode, the floor of the model consists only of two layers, in normal mode several layers are layered to create the floor.

- The fill density in fast is lower than in normal mode:

- The surface is much rougher in fast than in normal mode and the surface of the fast print has several holes:

The change in quality becomes very apparent between my two prints. Probably due to the nature of the model (liquid, with very smooth surfaces).

The print from the Objet came out well. After dissolving the support material:

Scanning

NextEngine I tried scanning my Ultimaker print with the NextEngine 3D Laser Scanner. The scan did not come out that great, I think this is partly due to the shape and the color of the print:

From left to right: original 3D model; print is level (6 pictures, medium resolution), propt up (6 pictures, medium rsoltion); propt up (12 pictures, medium resolution).

Sense I used the Sense to scan my printed penholder. The resolution is worse, but the models have less holes:

Failed attempts I tried using Agisoft PhotoScan to generate a 3D model of my cat, but he was always moving a bit and the reconstruction software ignored the cat and only gave me a model of the background. I also downloaded and tried the 123D Catch app on my andriod tabley, but the app kept failing while capturing the data. I probably should have scanned the pen at one point.

Post processing

I wanted to smooth out the Ultimaker print. I tried flowing solvent vapor over the print (PLA) anbd submerging the whole piece in solvent.

Setup for flowing THF and CHCl3 over the print:

I submerged and evaporate3d the solvent in a fume hood! Don't use harmful solvents outside of a fume hood.

THF: THF vapor did not smooth the surface after 15min of exposure, submerging for 30min did not smooth the surface. The test piece completely fell apart due to stress factures after submerging over night.

Acetone: Submerging in acetone for 30min doid not smooth out the surface, submerging overnight did not smooth out the surface but caused minor stress factures.

Chloroform: Exposure to CHCl3 vapor for 15min slightly smoothed out the surface, dipping the print in CHCl3 smoothed out the surface (several times to completely eliminate the surface roughness).

I then treated my penholder with chloroform to smooth out the surface: