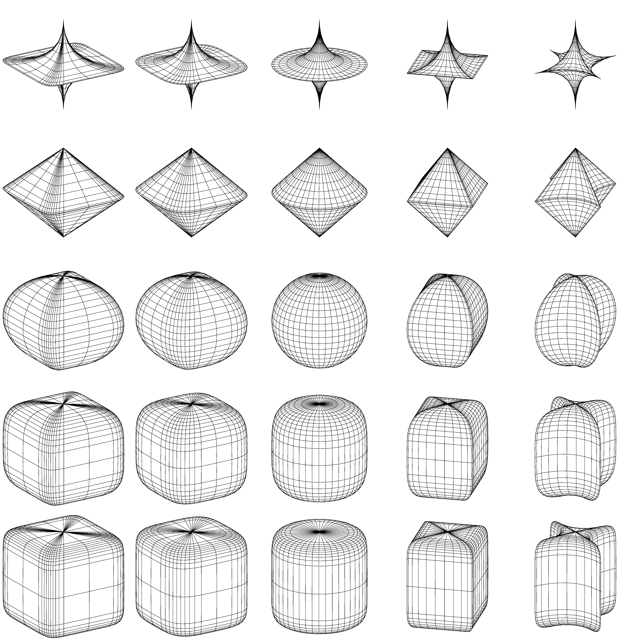

My first instinct for this week was to make a cylinder of rotating Reuxleux triangles, which can be used in a drill bit to make nearly square wholes. However, after some analysis, I realized that this shape is (barely) impossible using two molds. Instead, I decided to make a superquadric, which are sets of three-dimensional objects of the form

Reuleaux and Superquadrics, Courtesy of Wolfram Mathworld

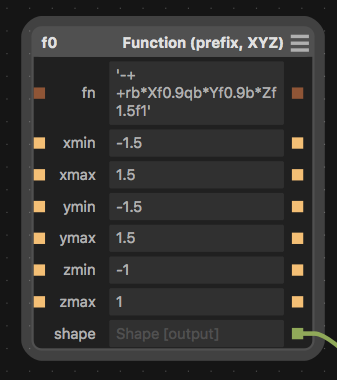

After settling on this formula, I coded this up in Antimony. In Week 3 , I coded up a completely new shape function with a custom shae script, but I realized that this could be done with a simple function in Antimony instead.

Antimony Nodes and Rendering

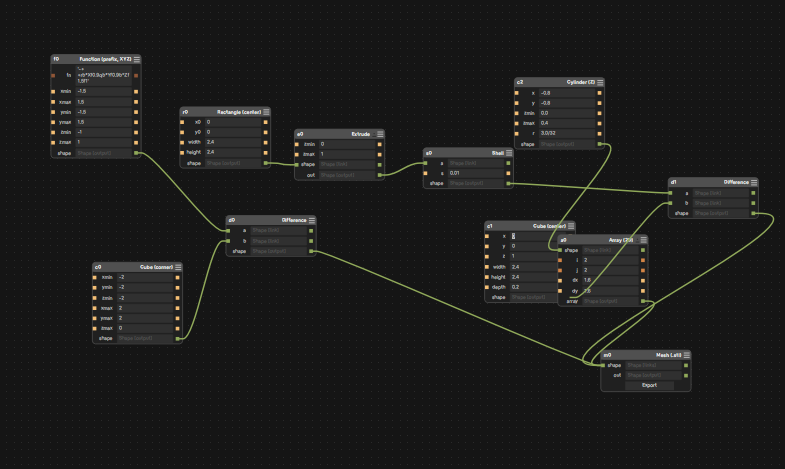

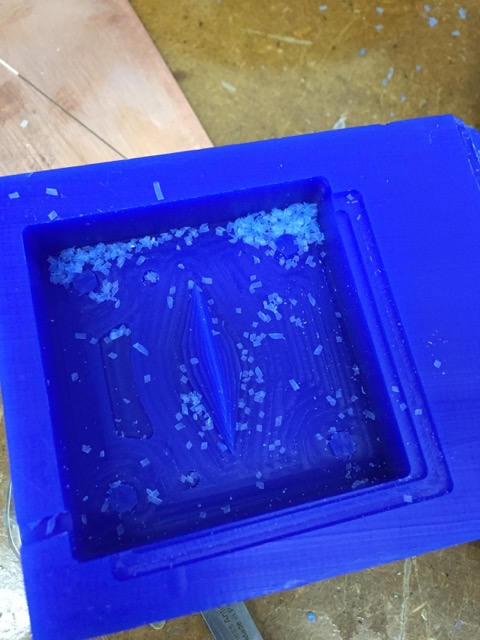

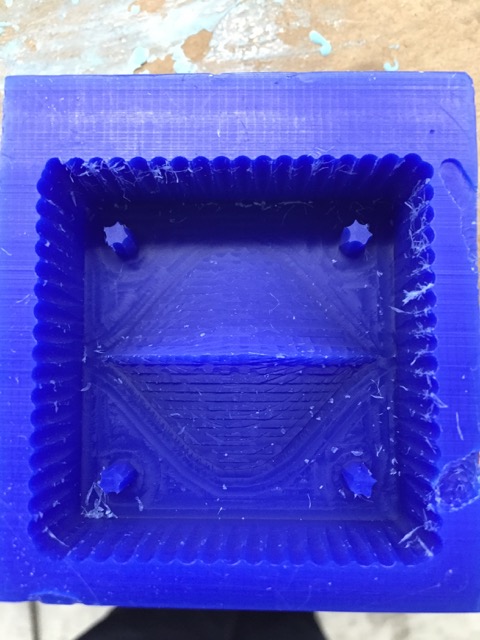

After this, it was time to create this in wax. Using the fabmodules, my onion was ready to go! However, printing was met with some complications. On my first cut, the machine stopped, and ended up cutting off a chunk of the wax and not remembering where zero. Thus, I had to get a new piece of wax to remake my mold, though this time, my final cut was still too rough.

Various stages of milling

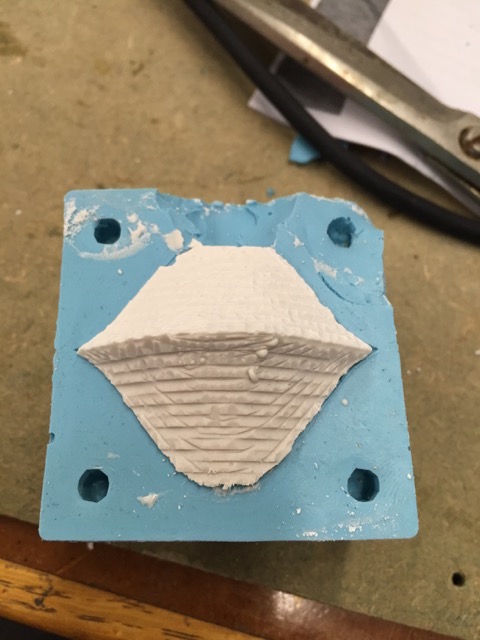

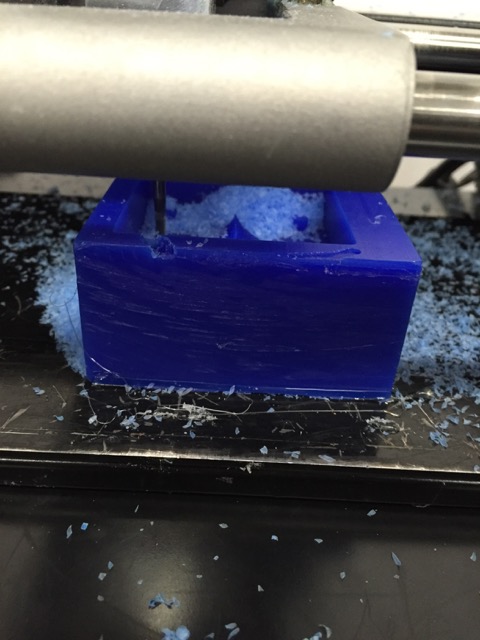

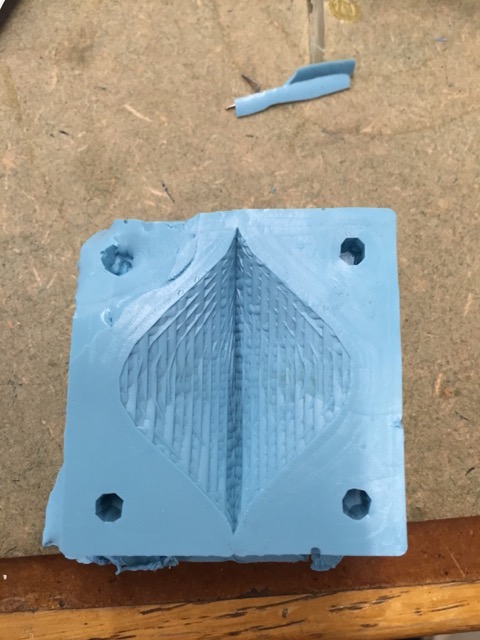

After this, it was onto Oomoo, a silicone-rubber composite material. On my first mold creation, I did not do a good enough job getting rid of air bubbles, and it ended up a little swiss-cheesy. My second attempt was without air bubbles, but I took it out a bit early, so it was slightly deformed on the corner

Fun with Oomoo

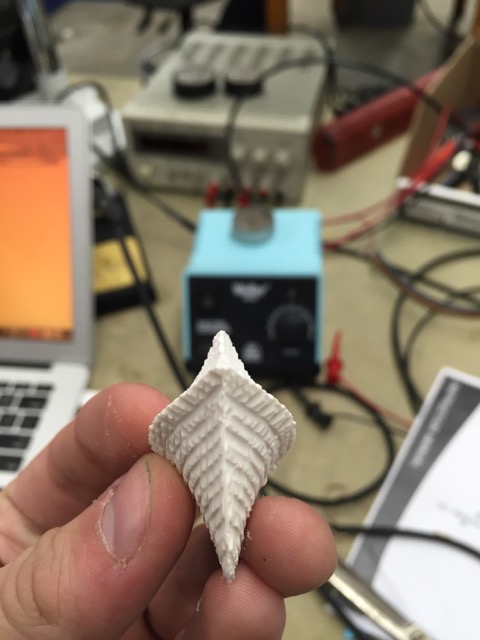

Finally, it was time to cast this in plaster. One thing I forgot in my design was a a funnelling system, so I had to cut some whole in the mold itself with scissors.