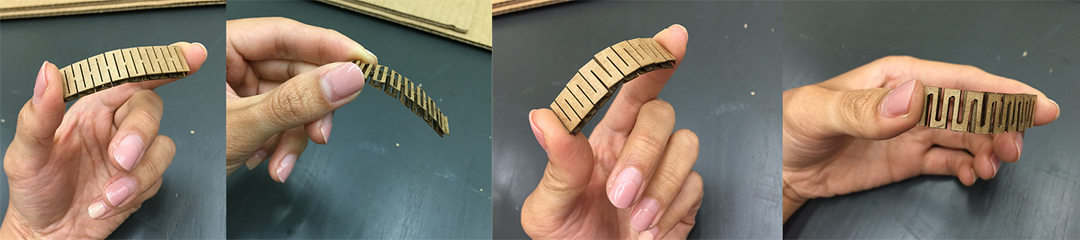

In this week's assignment, we were limited to 1/8th cardboard. Cardboard doesn't flex very well, so I tested various methods of making cardboard more bendable despite its corrugation. First, I used kerfing to do this and experimented with a couple patterns and spacing offsets. With a hairline width cut, it's still very stiff but starts to buckle nicely. I increased slightly the distance of the spacing and I think that's a good amount -- it bends without too much resistance and springs back.

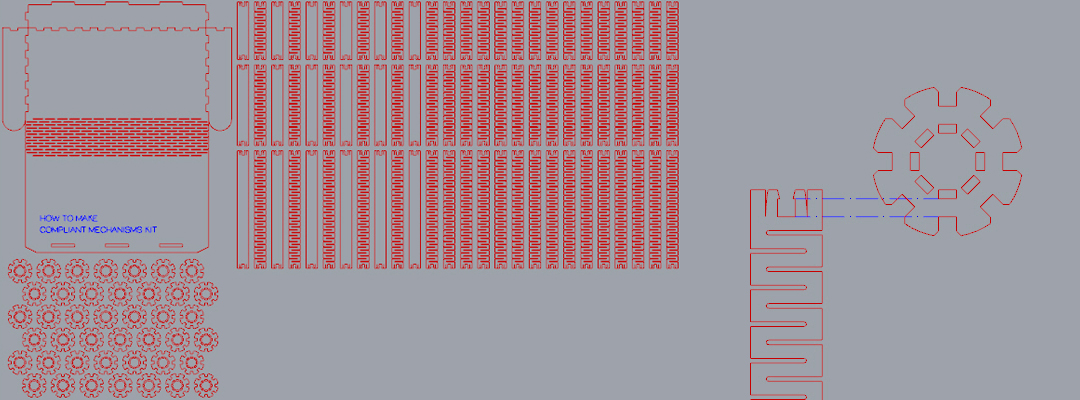

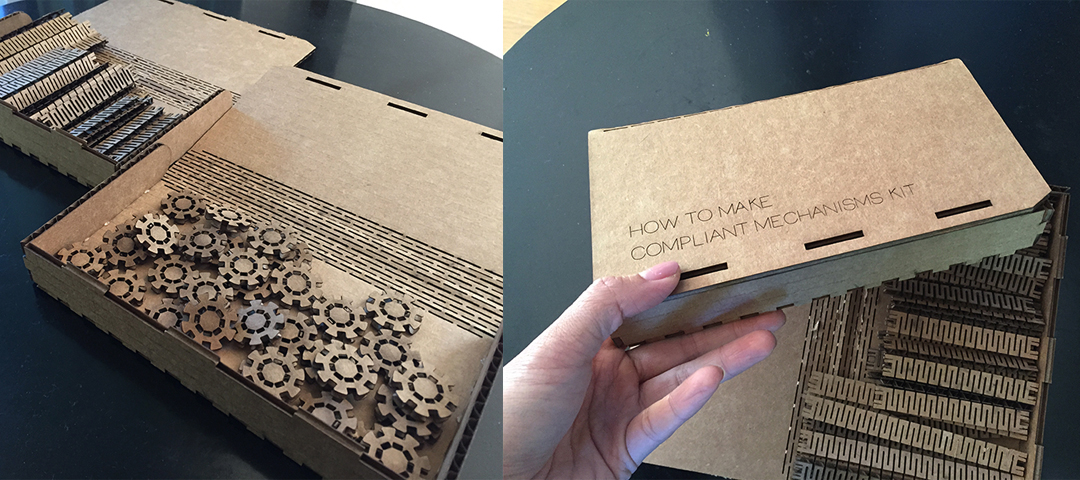

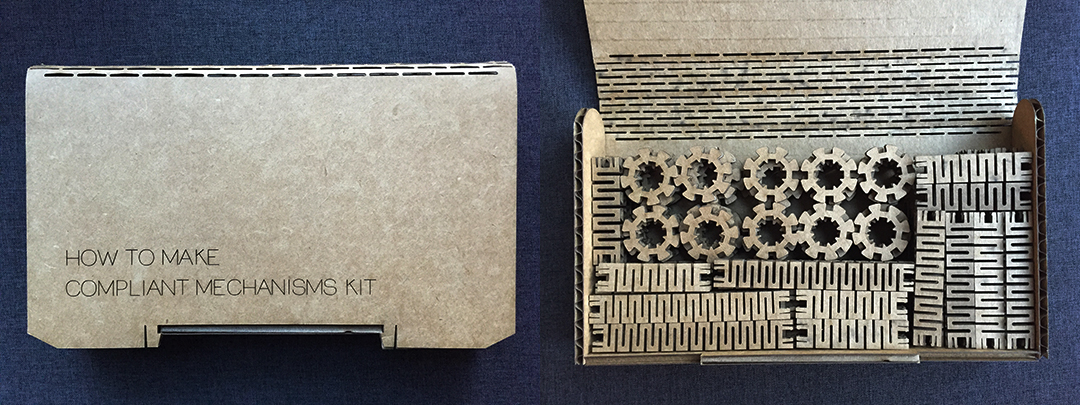

Next I designed a connector that could accommodate flexible beams in any of its 8 slots. The beam also has a slot with the thickness of the cardboard as well as crack shaped notches on both sides of the slot -- this helps to snap fit the two pieces into place.

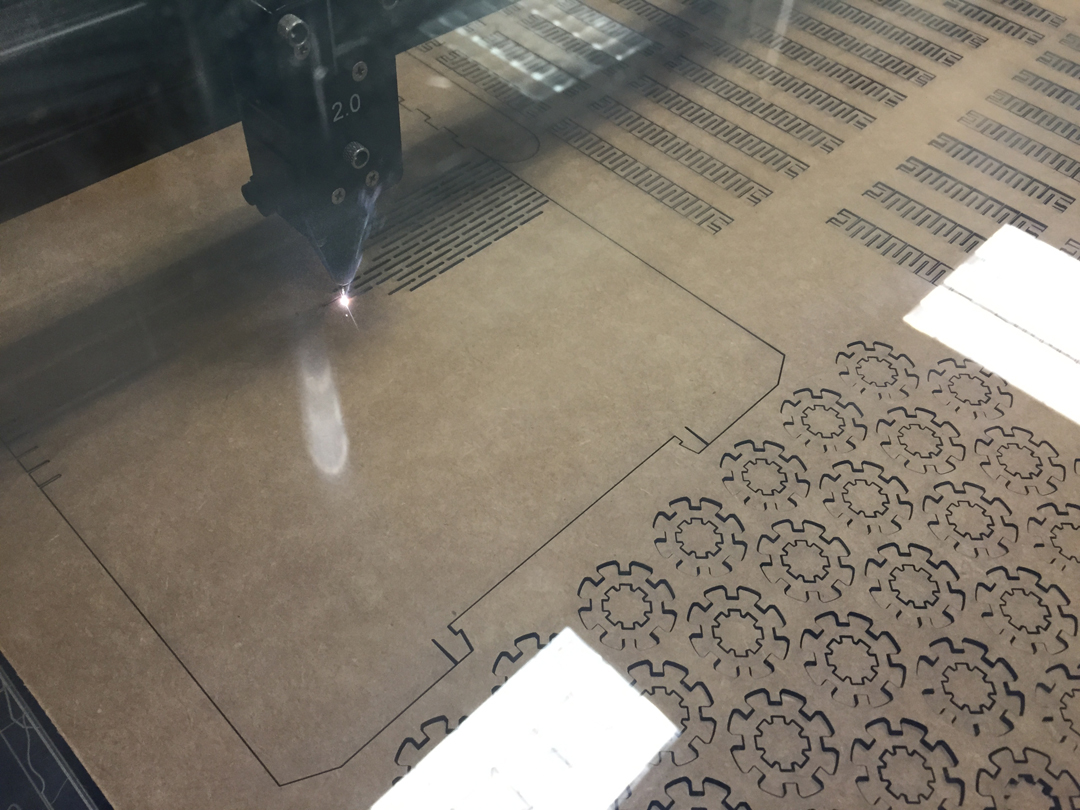

The best thing to do while waiting for your job to finish is to stare into the laser beam!

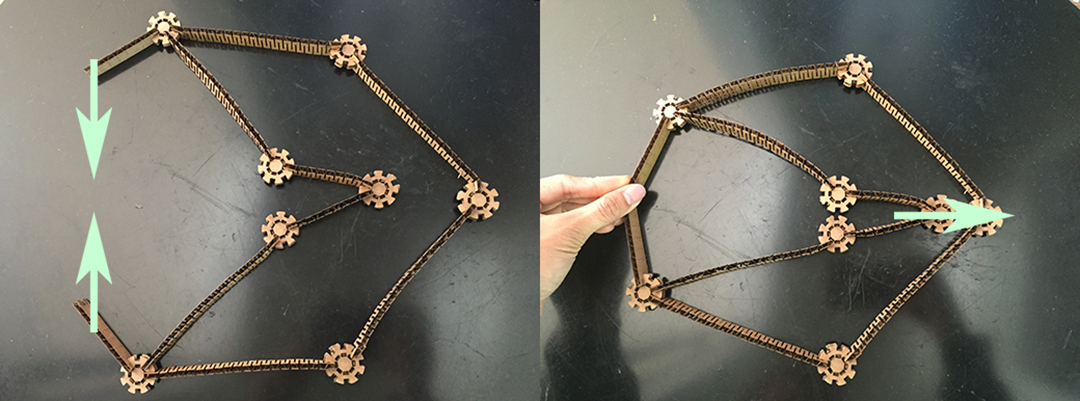

Here's a sample configuration of a compliant mechanism. On the left, I will apply a force from the top and bottom as indicated by the arrows; on the right is the output motion I get. It's very flexible -- but the beams are so long that they become weak and don't spring back. I will relasercut with shorter beams.

I also made a box with finger joints and a living hinge in which to store all my components. This makes it easy to transport to class, picnics, and parties. I went through several iterations of the box also. It works well, but I'd like the lid to lock better.

I went through 3 iterations and this is the final result. The motion is much more controlled with shorter beams (less floppy, more springy).

This is the 3rd version of the box; the lid stays in place better. I will make more compliant mechanisms later and photograph them!