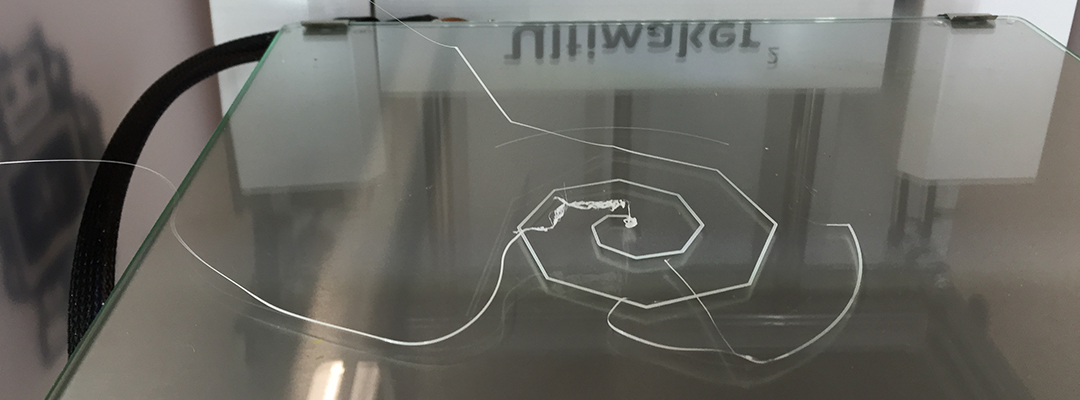

This was my first (documented) attempt. Actually, my actual first try didn't even extrude anything as I hadn't specififed the nozzle to heat up in my code -- oops. The above failed because it didn't wait until the correct temperature was reached.

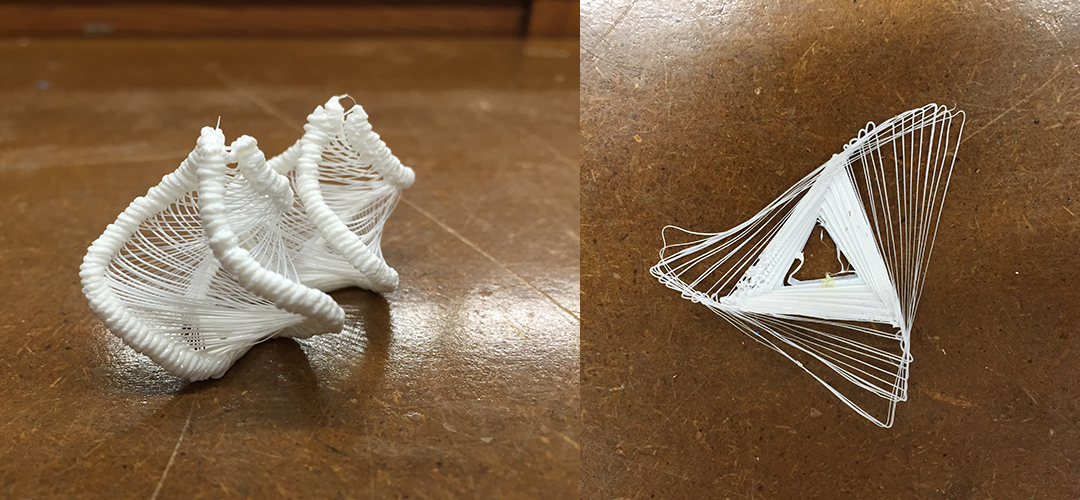

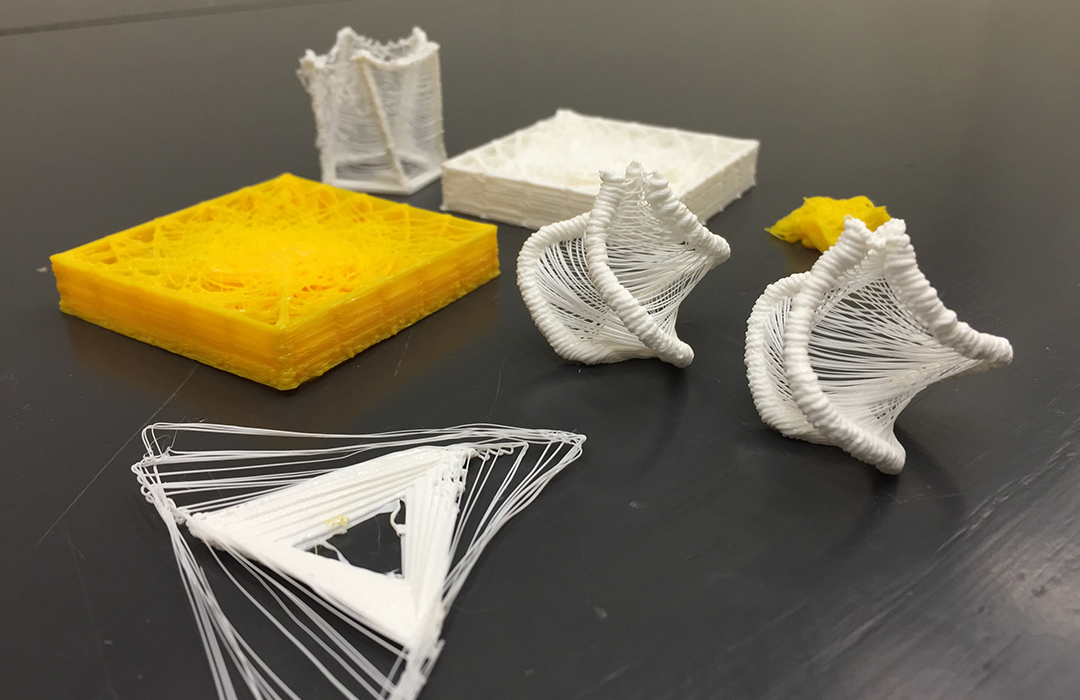

I tried to print really slow to get a truly 3-dimensional thing. This took about 3-4 minutes... You can potentially break out of the XY slice convention and build without supports.

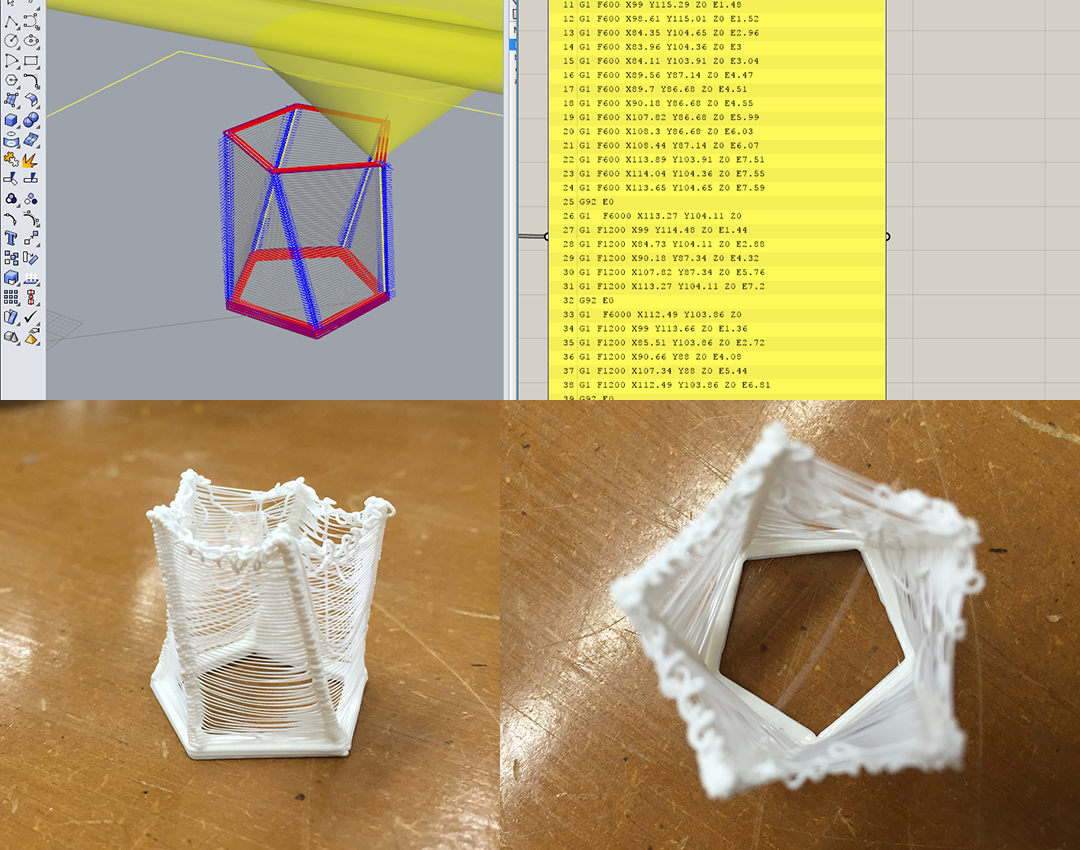

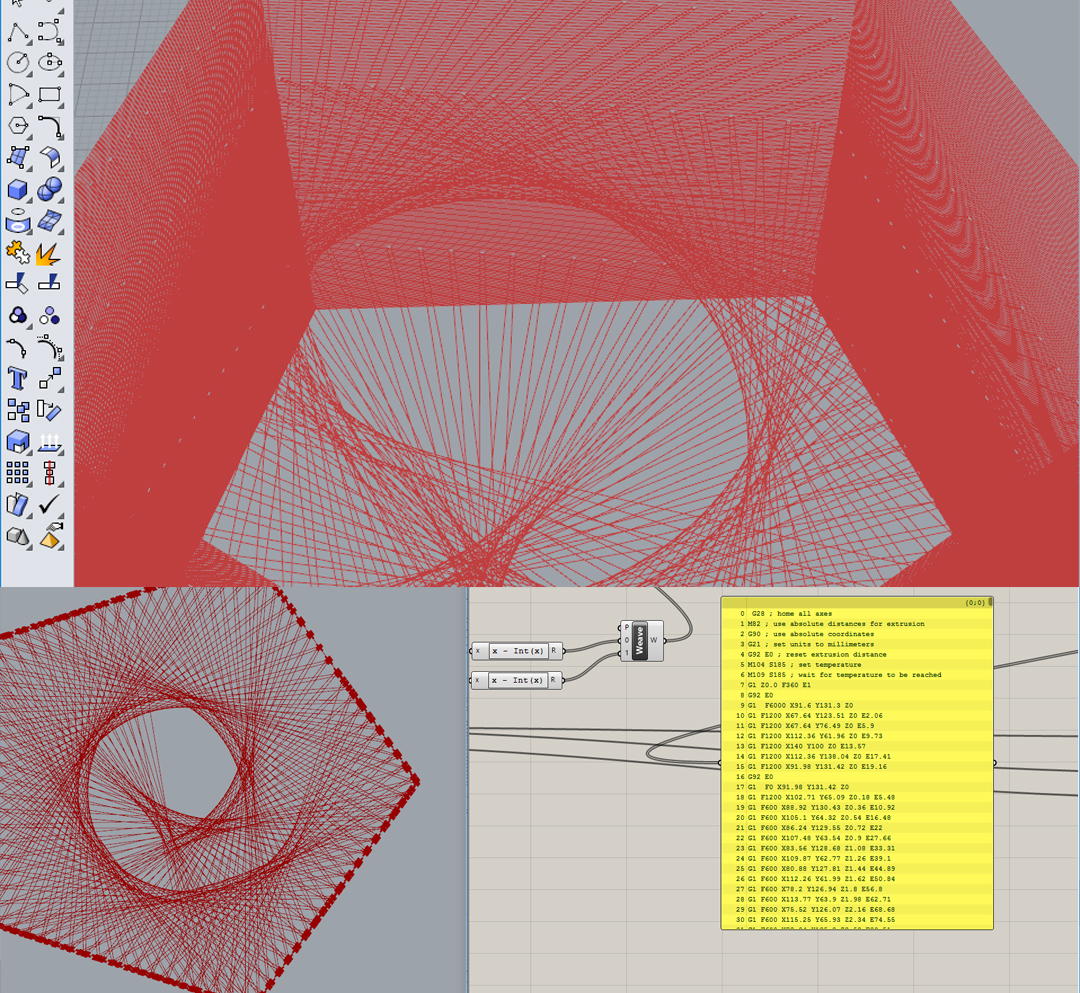

I designed some geometries in Rhino using Grasshopper to control flow/feed-rates, and used WebStorm the text editor to clean up any code. The result was stringy and kind of cool.

I designed another geometry -- with slightly more complexity -- tweaking the parameters until it printed properly. These would make pretty earrings! Plus another experiment.

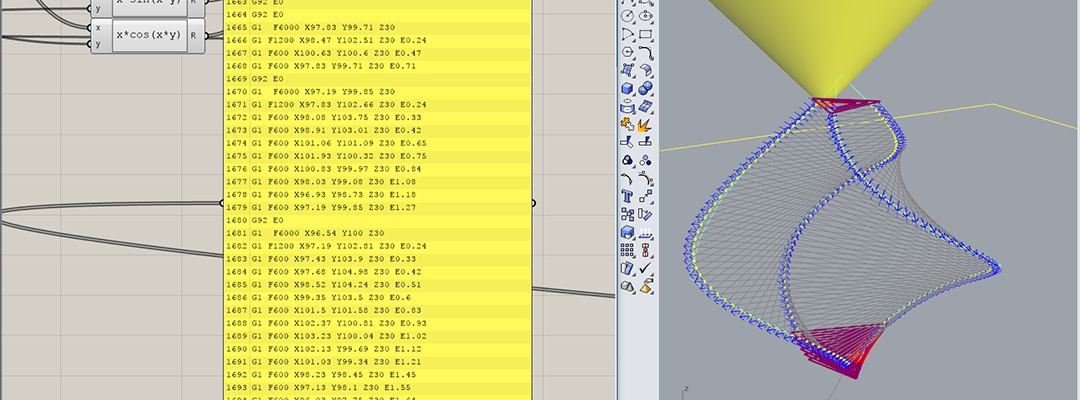

Here's another attempt at making 3-dimensional thing supported by walls. This hasn't been successfully printed yet.

A spread of prints that I liked.

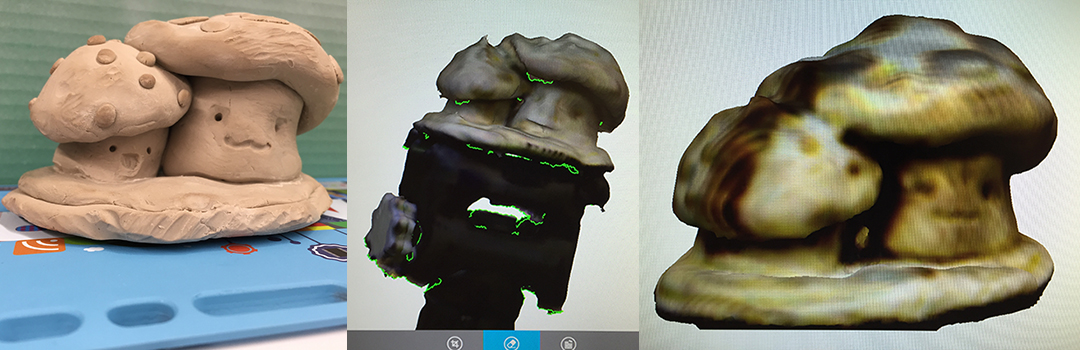

I heard clay was a good dull material -- optimal for laser scanning -- so I made shroom buddies. I want to figure out how to unroll and paint these guys, maybe rig and animate them as well.

Jacob Hamman, my classmate from the Harvard Section, scanned and printed me, which was fun.