This week was interesting, I guess. It's amazing that we can fabricate a fully-functional machine over the course of two hours, but I'm not covinced that actually doing it was particularly helpful. My efforts (as part of the laser-cutting team in my section) amounted to two hours of laser-cutting and folding cardboard. I am now excellent at folding. I'm also very proficient in scoring with exacto knives. Please enjoy the the images below:

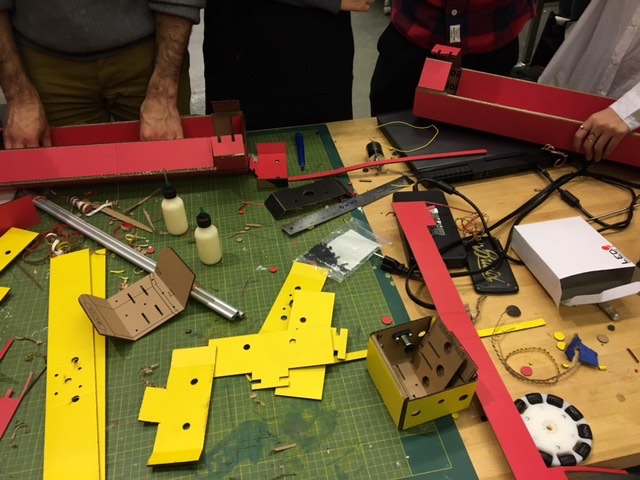

'This is not a workbench' ... We definitely weren't setting up our files here... not a chance.

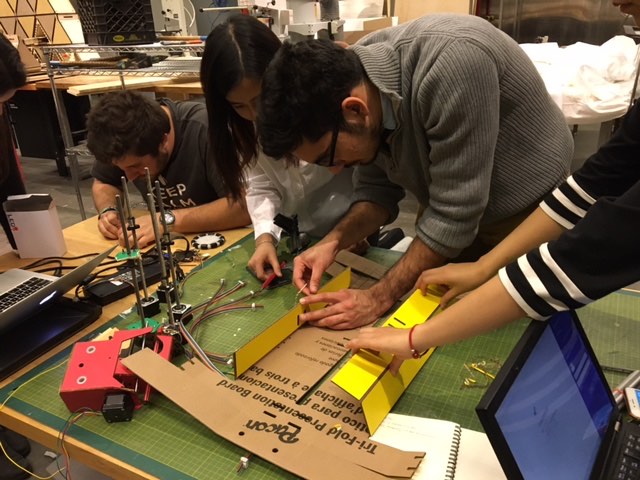

Document everything. Even people documenting everything.

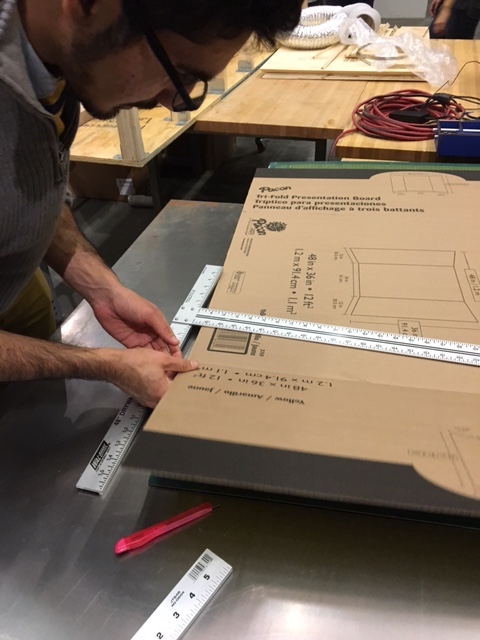

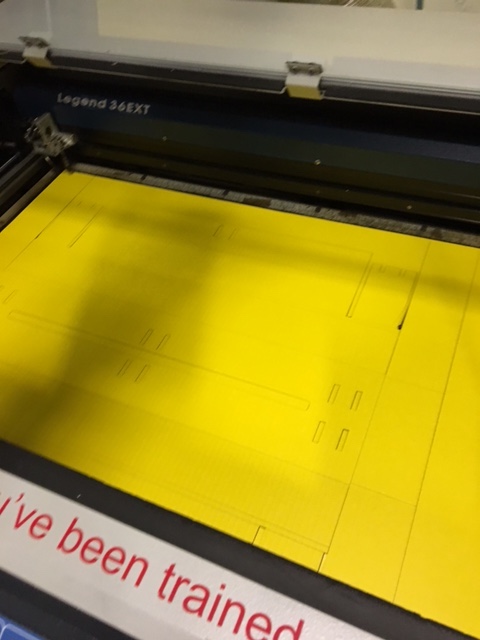

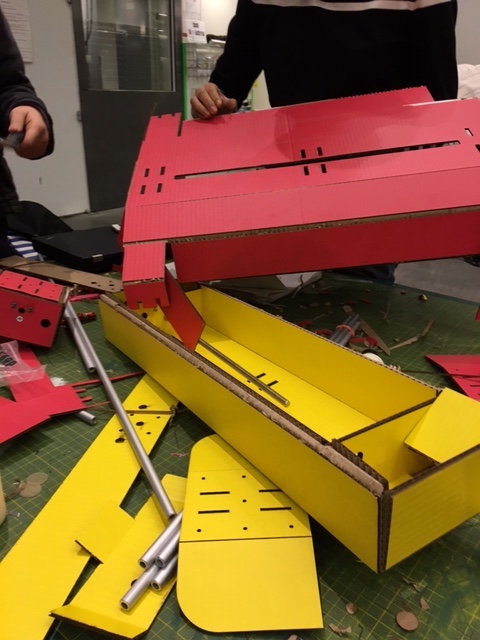

The scoring begins... (after 20 mins figuring out how to cut the cardboard, and scolding from the shop manager for trying to use the bandsaw.)

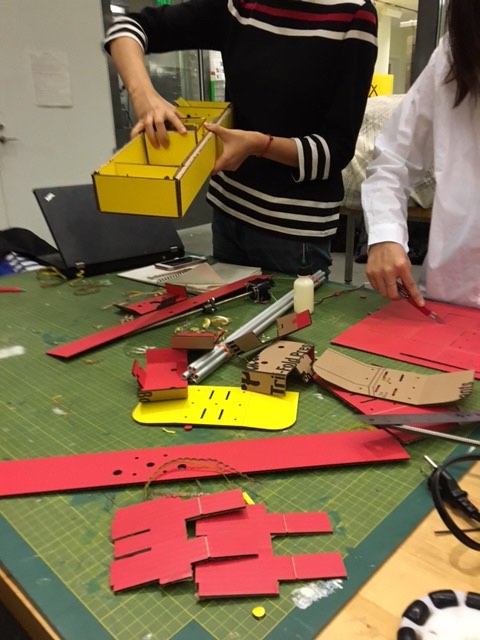

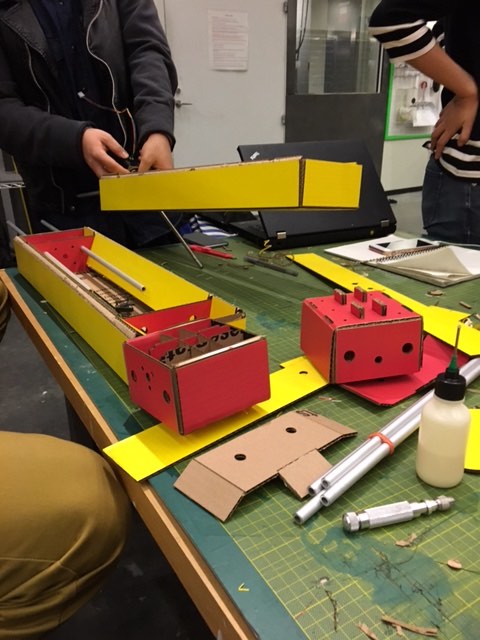

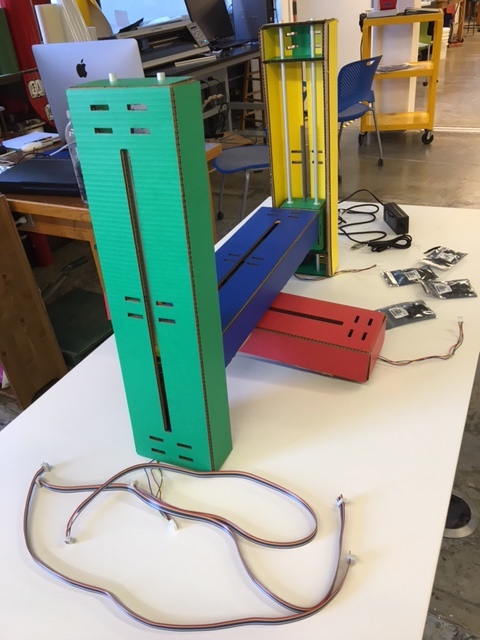

Motors that send things up and down (or left and right if the spindle is kept horizontal).

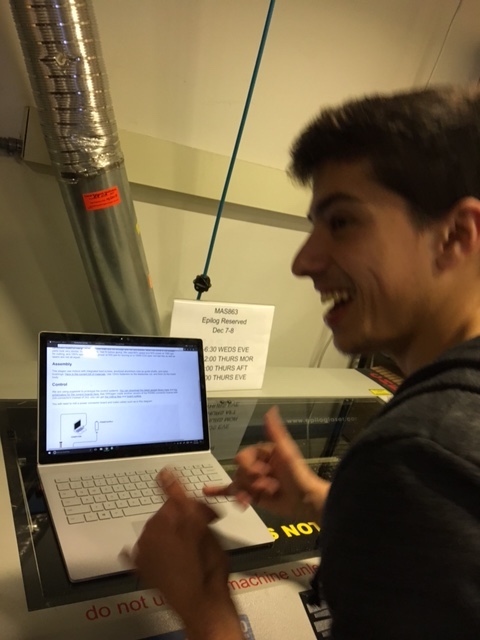

The cutting begins... (Nadya's comment being 'honestly, the laser cutting usually doesn't take this long')

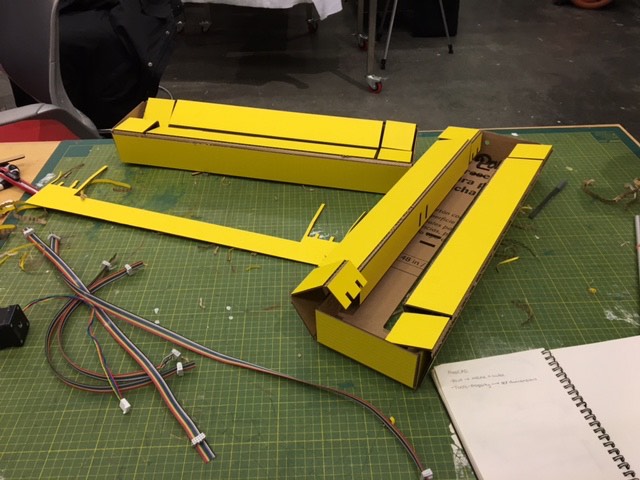

Looks like a cardboard box, doesn't it? ... That's because it is. But it's also yellow and will eventually be a machine.

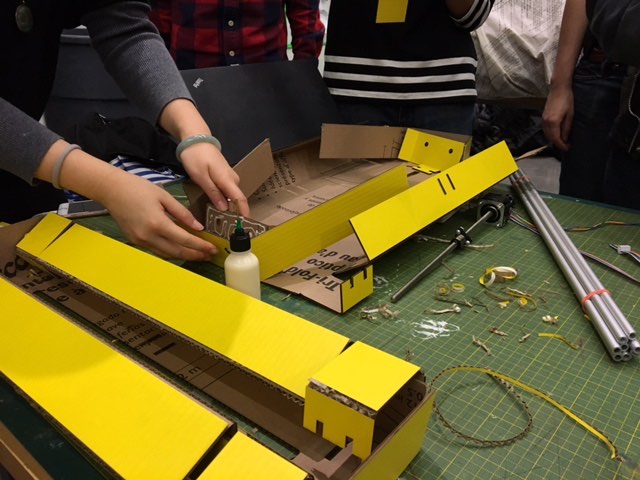

Pictured: Nadya's genius glueing contraption -- a bottle with a syringe on top.

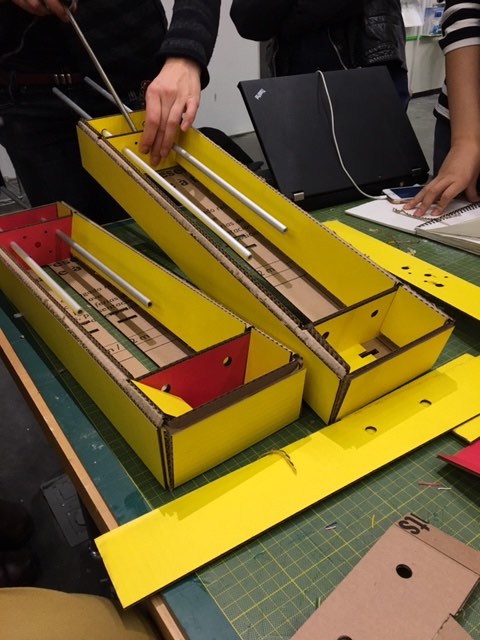

These metal rods stabilize the axes of the machine.

Aaand... Machine!