Week 10: Machine Team Project

This week was the team machine-building project, and I was pleased to be part of the highly competent and diverse CBA section "Makey Cakey." We started by deciding upon what to make. I gave up on the chocolate printer, since doing a full 3-axis machine was going to be way too tricky. My team was excited about food, though, so we quickly agreed upon a pancake printer that would be way cooler than PancakeBot. Then we can put it up by the Media Lab's Foodcam so everyone can print their own customized pancakes!

We divided up into three teams: software, hardware, and mechanical engineering. I joined the engineering team, which then split up further into the end effector group and the base machine group. I wound up in the base group, and we planned to meet up the next day to CAD but a few team members went ahead and completely modified Jake's machine design-- so our meeting turned into a ShopBot setup session rather than a CAD session. Which turned out to be perfect, because what appeared to be simple milling tasks on the ShopBot transformed into a series of epic endmill-destroying disasters.

I helped Yun out a bit with the 3D printer, which ran out of filament mid-print and then some of the filament got stuck up inside and we had to check the Wox website to troubleshoot. My main contribution, though, consisted of controlling, supervising, and troubleshooting the ShotBot from Friday through Sunday (or early Monday morning, to be precise). The whole sordid tale is on our team's documentation page, but here I've copy-pasted what happened in my subsection.

CAD --> CNC Milling

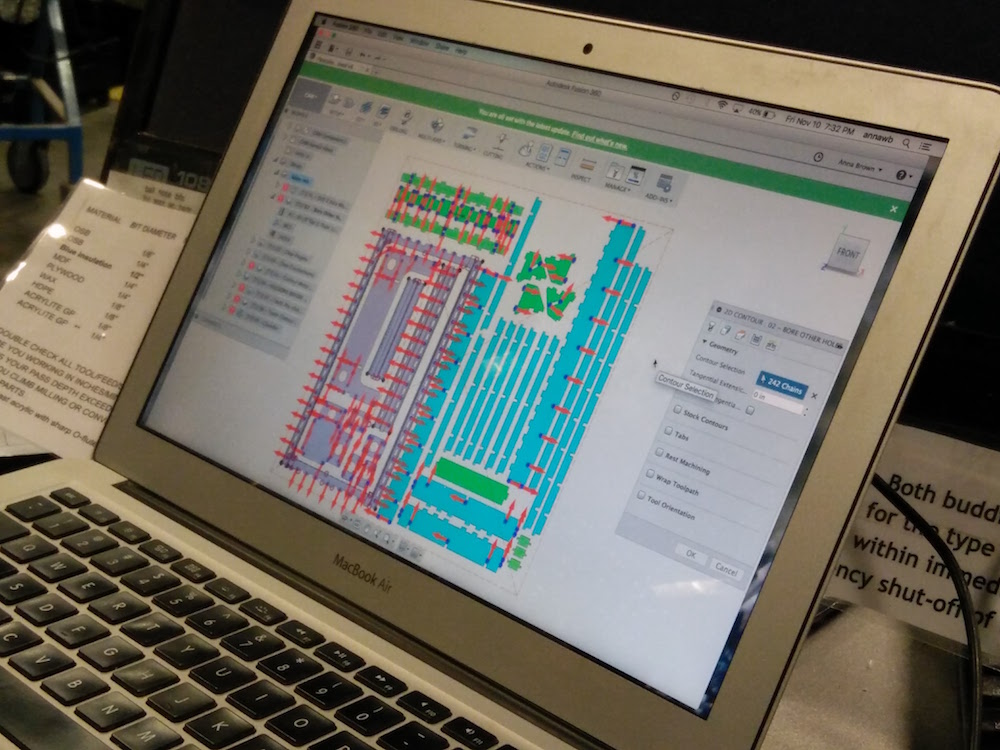

Preparing and then milling out the toolpath was far more exciting than we'd anticipated. First Oscar and George spent hours modifying

Jake's machine to fit our griddle, and then unfolding it in Fusion to create the layout of parts for milling. Then they painstakingly

created a bunch of CAM toolpaths, which involved clicking in the middle of hundreds of screw-holes on our model to ensure that the

holes all got milled before the main pieces-- only to find that we could just use Jake's original toolpaths for the most complex framing

pieces. We couldn't figure out how Jake made all the sketch-based toolpaths for the 45˚ angles, so it was an easy fix for Anna and Burhan

to just copy-paste Oscar's modified parts into Jake's more complicated toolpaths.

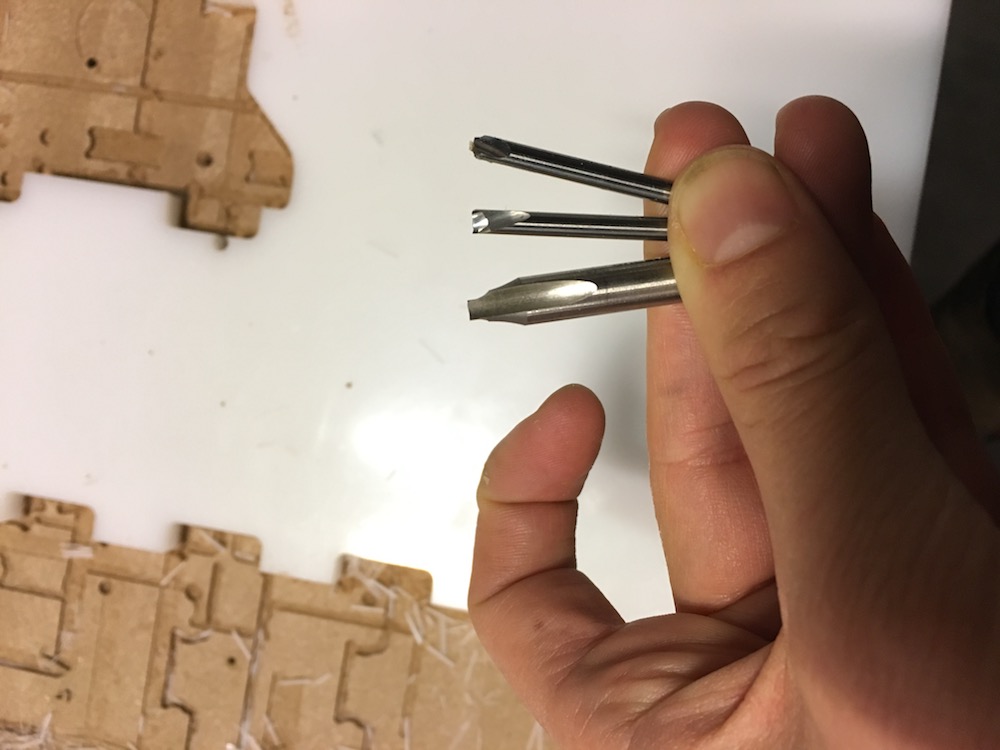

There were nine different toolpaths to mill, involving three different endmills-- because Jake is a freaking genius who foresees everything

and carefully optimized the whole milling process to mill the right things in the right order. Originally he even had four endmills,

but realized that he didn't need to be quite so precise about optimizing the right tools for the right jobs.

Burhan, George, Anna, and Vik then had a series of disasters learning experiences while attempting to mill out our model:

Lessons for the Future

I then skipped out on the rest of machine-building to catch up on life on Monday and Tuesday, and returned to the shop Tuesday night for the final preparations. Here are my personal takeaways from our weekend of ShopBot woes:

- Things can go wrong. Be prepared to go back to the original CAD file and redo toolpaths.

- Have one person in charge of the entire milling job, to facilitate change-overs when people need to sleep and to ensure that everyone knows where the most up-to-date CAD files live.

- Very hard plastic is hard to mill! Have the right bit and the right settings.

- Lower the RPM very slowly-- don't lower it by 500 all at once and expect things to be better. Maybe you can raise the RPM when things aren't milling out right.

- Make sure that all pieces are properly screwed down or have tabs! Even when they don't fly up and destroy your endmill, untethered pieces tend to slide around during milling and can mess up your machine's precision.

- The ShopBot has something against Burhan, who's otherwise a great guy.

- When the ShopBot is acting moody (i.e. not milling out as smoothly as before), first shut it off and on again.

- The ShopBot software hates everybody.

- Make sure you're selecting toolpaths on Fusion on the top layer, not on the bottom layer.

- The more milling programs you have, the easier it is to start over from the beginning of a program when something fails.

- It's not always email to just send the bits around and expect people to duplicate your project exactly, especially when there are lots of subsystems. There's a lot of tacit knowledge that's very hard to document and share.

- Jake is really incredibly talented. Thanks for all your help and brilliance, Jake!