Composites

Week 12: Composites

This week, we learned how to fabricate a resin and fiber (fabric) composite.

Composite Training

|

This is what we are going to make for this training session. Grace showed the composite demo to make a bike seat!

Prep: materials and tools

|

|

|

|

|

|

|

|

|

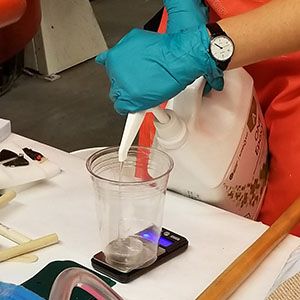

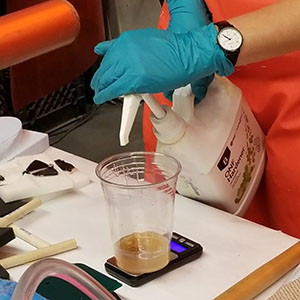

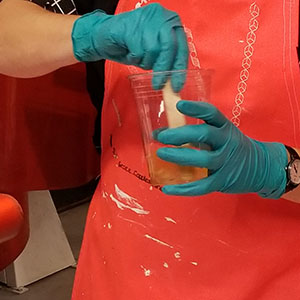

Stirring well to mix the two parts (A:B = 100g : 42g) of epoxy. She told that if the ratio does not match well, the epoxy mixture generates great heat so that make the plastic cup melted. So be precise!

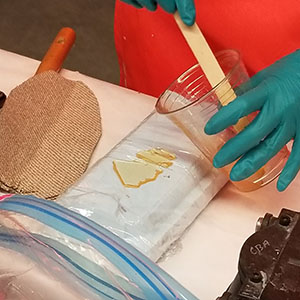

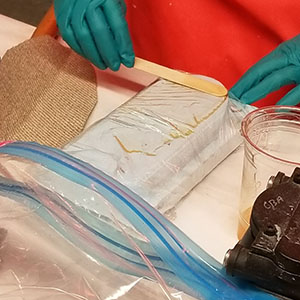

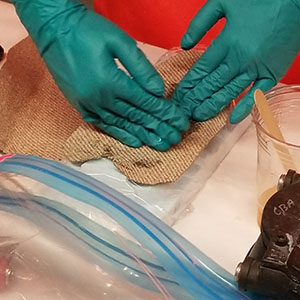

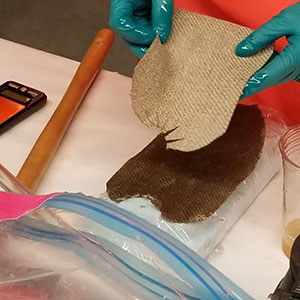

Applying epoxy to fabric layers

|

|

|

Used burlap fabric and more than 3 layers

|

|

|

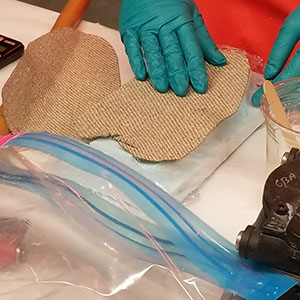

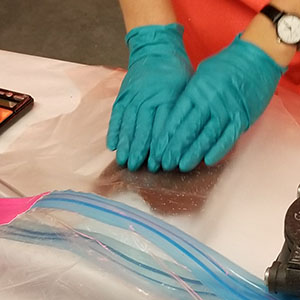

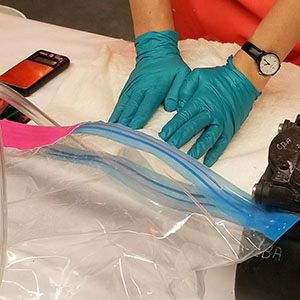

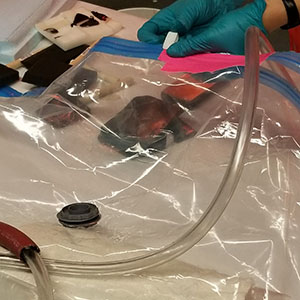

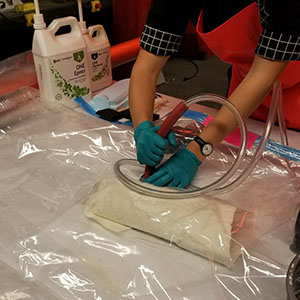

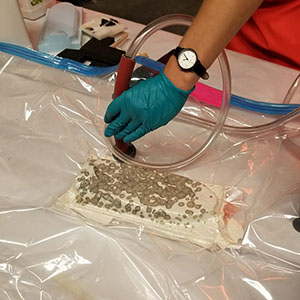

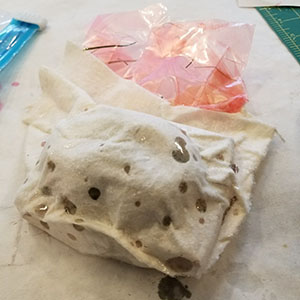

Vacuuming

|

|

|

|

|

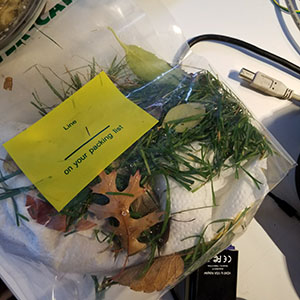

🍂 Leaves Composites 🍂

Picking up the fallen leaves

|

Before the winter comes, (even though 2 days ago there was the first snow fall) I went out for grabbing some fallen leaves to use them as a fiber-like material for the composites. I wonder how would it work, how stiff would it be, how would it look.

|

|

|

👄 CAD a Mold 👄

I just drew a mouth to make a tray and thought it would be beautiful to have a lip shape wrapped with some nice colored leaves.

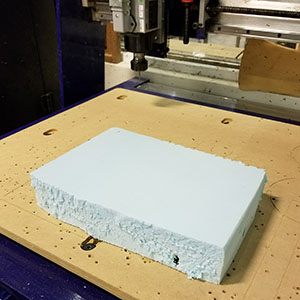

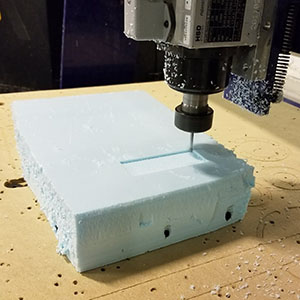

Milling a Mold

|

|

|

Fixed the foam on the ShopBot (screwed the machine screws diagonally) and started to mill!

|

|

|

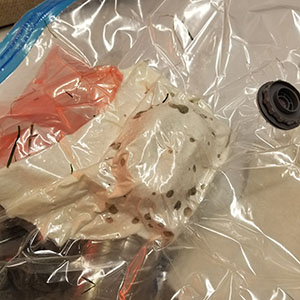

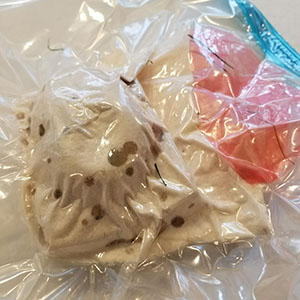

Resin and leaves

|

|

|

|

|

I put the composites vacuumed about for 12 hrs and it seemed cured perfectly!

|

|

|

Unwrapped all the film and clean wrap from the composites and its aftermath.

|

|

|

|

|

|

|

|

|

|

|

|

|