Final Project Log and Description

"Priyanka Learns HOW TO MAKE a Programmable Shoe"

I want to take this exciting opportunity to be in the How to Make Almost Anything Class this semester to fulfill on an idea that I have been mulling over for many years previously. The project called MorphWear, is a vision for a universal wardrobe where you can have one pair of shoes, one pair of pants, a shirt, etc. that can

The idea of MorphWear came to me when I was in Singapore the summer after graduating with my bachelor's degree from MIT in Mechanical & Ocean Engineering. I was working on a water project and leading a leadership workshop at the Singapore University of Technology & Design, when I realized that I was constantly distracted by the very fashionable clothes in the country. As a petite woman visiting a country with my petite women, I was bombarded with an enticing plethora of options for fashion. I realized I could get clothes, shoes, and accessories (all finally in my size, ahhhh! :D) in all sorts of colors, shapes, patterns, designs, etc., oftentimes with many of the same form factors, but with either the specific screen-printed design or a specifc hemming detail different.

This got me thinking.

Unfortunately, our current apparel (and similar consumer goods) consumption rates are beyond the resource capacity of our planet, and I must say that I too am no stranger to excess:

Figure 1: My Shoe Collection

Yet I also feel a strong sense of personal responsibility, as an engineer and aspiring policymaker, to be an integral part in reversing our society's trend in excess consumption and resource degradation to help protect our resources for future generations, and protect our communities and environment from the deleterious and already-present effects of climate change. Although just one small, potential solution to the continuously mounting problem of waste and environmental harm, I believe a transition to programmable and personalized apparel items can limit our desire for excess material and thus limit our need to excessively tap into our planet's finite resources, and yet still allow for (and potentially enhance) personal expression and creativity.

Week 1 Thought Log

My goal for the class is to create a customizable, programmable shoe that connects via Bluetooth to an App on my phone and that sends commands to the shoe to then make it morph into different colors, shapes, and patterns. I would like the final project to be a a first iteration of a product that can one day replace the above number of shoes you see, to (ultimately) just one pair that satisfies all my shoe-related needs. And if possible, it would be awesome to have a chance to take next semester’s How to Make Things that Can Make Almost Anything as well, to build upon this project to actually build a machine that can make and remake shoes of many different varieties using minimal resources.

I am beyond excited for this project and looking forward to seeing how it follows through!

Week 2 Thought Log

Updates

- What if I built a shoe reassembly machine that can take different fabric patterns, and put them together into diferent types of shoes of different designs?

- Can even be used for other apparel and accessory types/applications

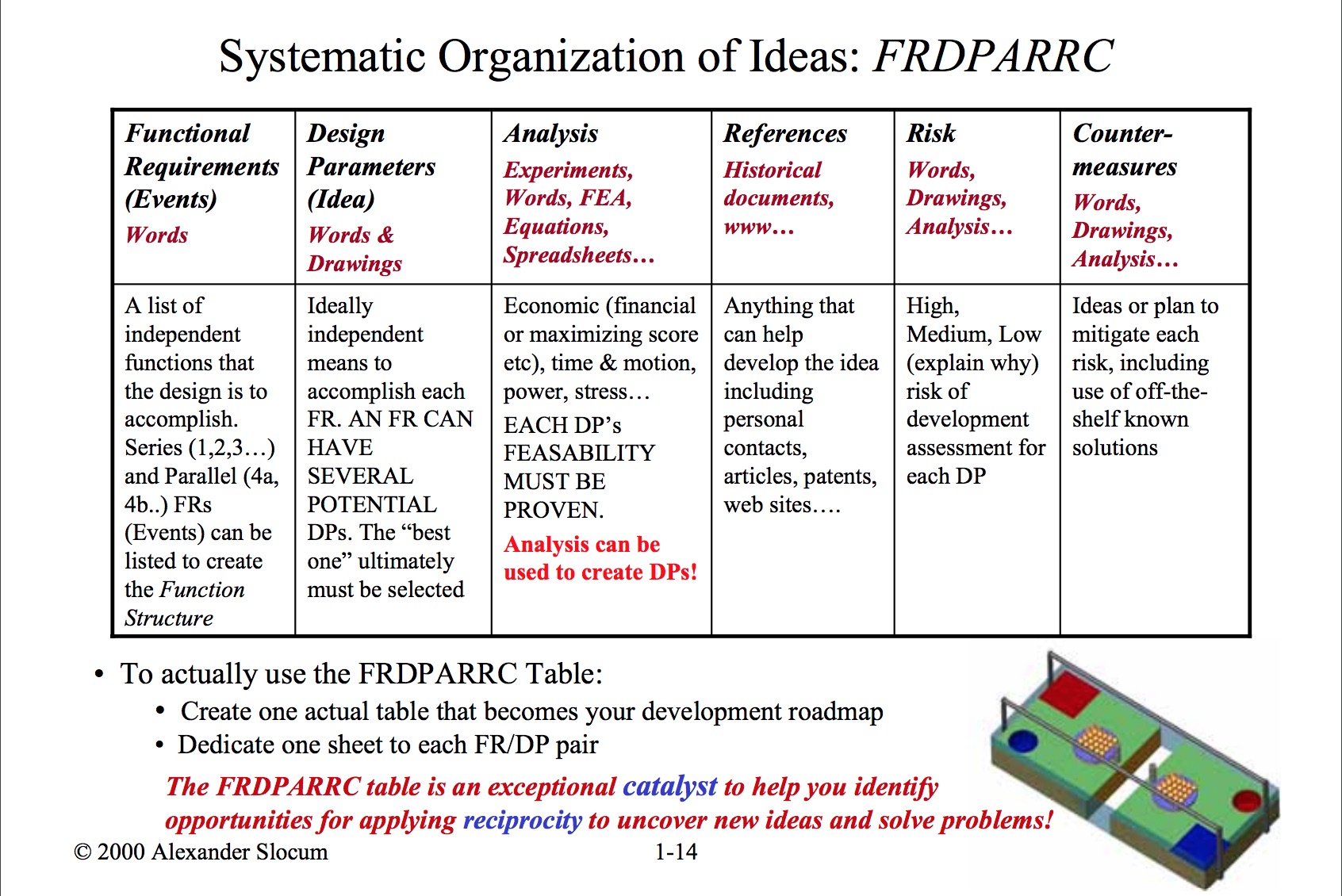

- From Alex Slocum's class --> Ceate a FRDPARRC Table for 3 Different Strategies for the Machine

- Looked up past HTMAA Fashion Projects and analyzed their performance, pros, cons, and market potential

Figure 3: Explanation of a FRDPARRC Table from my 2.77 Class Notes

Week 3 Thought Log

Updates

- Machine Strategy Chosen

- 3 Concepts Created from Strategy

- Scanned my Foot

- Used Mesh Mixer to fill in my foot on the software UI

- Converted into CAD File and prepared to 3D print, but ran out of time

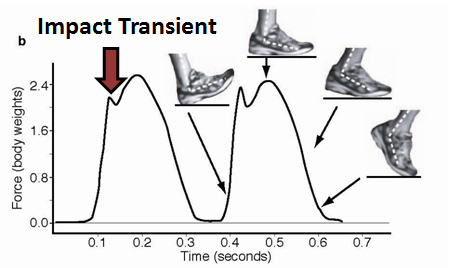

- Current goal: Have a machine create fully custom shoes to match my feet exactly. Time do do a foot dynamics/biomechanics force body diagram, and simulation.

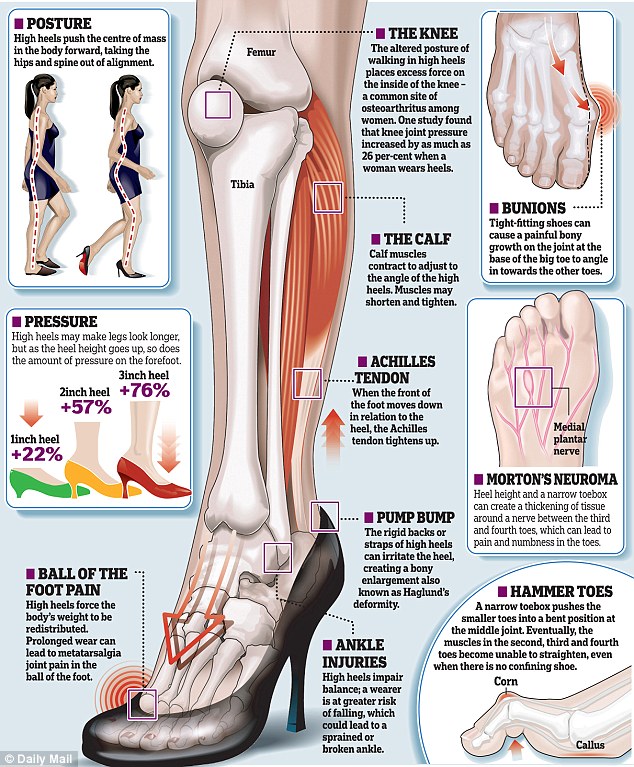

Figure 4: Understanding the Biomechanics of Foot Movement Picture Link from Harvard Study on Podiatrics

Week 4 Thought Log

Updates

- Realized I have a lot of learning (and practice not being scared) of electronics design and programming to do before I can realiably make a precision machine

- Nevertheless, Came up with a Concept for Machine --> Sketch Drawing

- May need to narrow my scope to something more individually doable

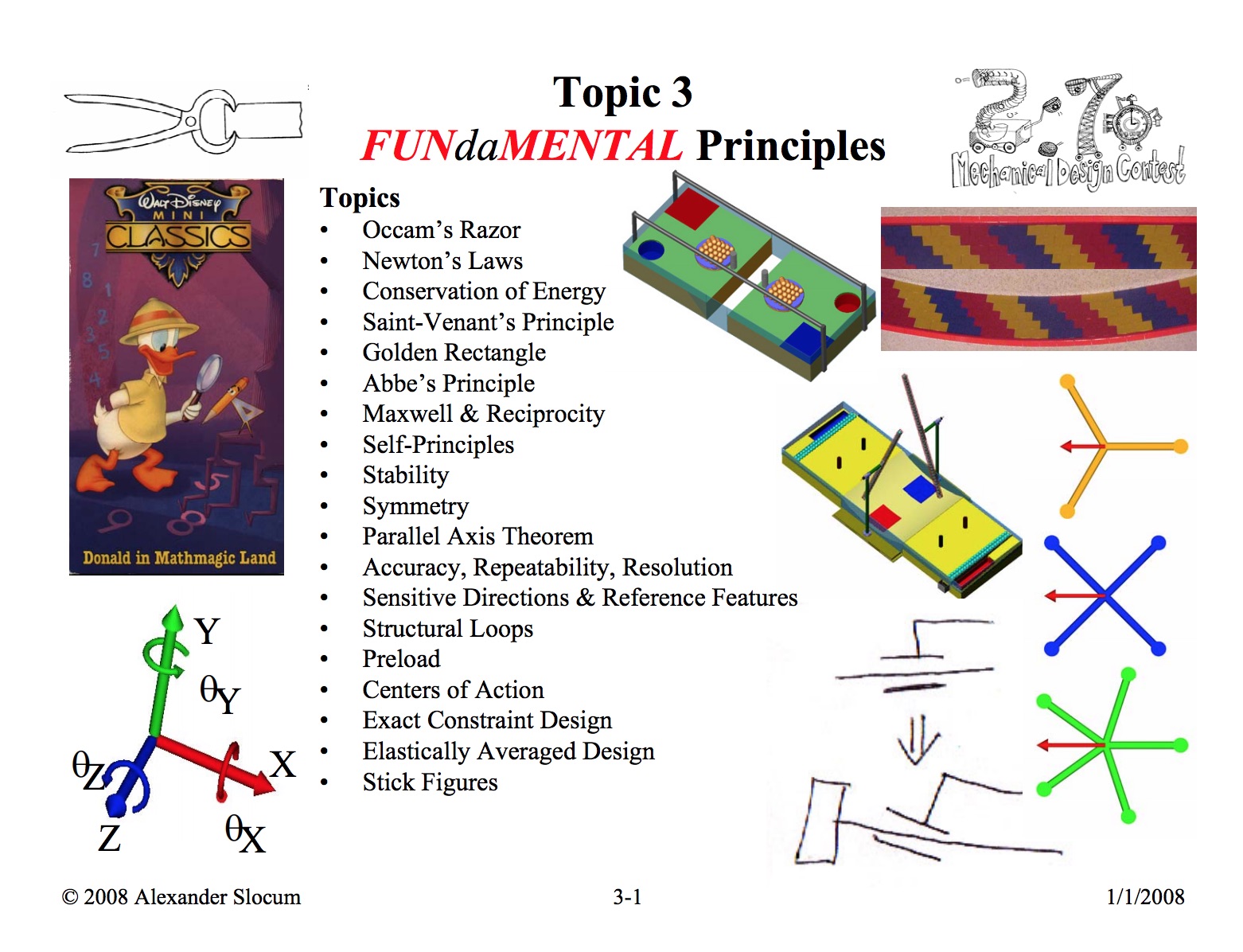

I came up with my initial sketches based on teh following "FUNdamental Principles" that I learned in Alex Slocum's class:

Figure 5: Fundamental Principles of Precision Machine Design

Week 5 Thought Log

Updates

- Realized that creating a "Shoe Making Machine" may not be feasible for me to complete by the end of the semester

- Decided to just stick with designing an "embedded" shoe

- CADDed a circular, revolving 3-story shoe rack & milled some of the pieces (ran out of time) and features on ShopBot

- Thought up 3 Different Strategies for how to design the shoe.

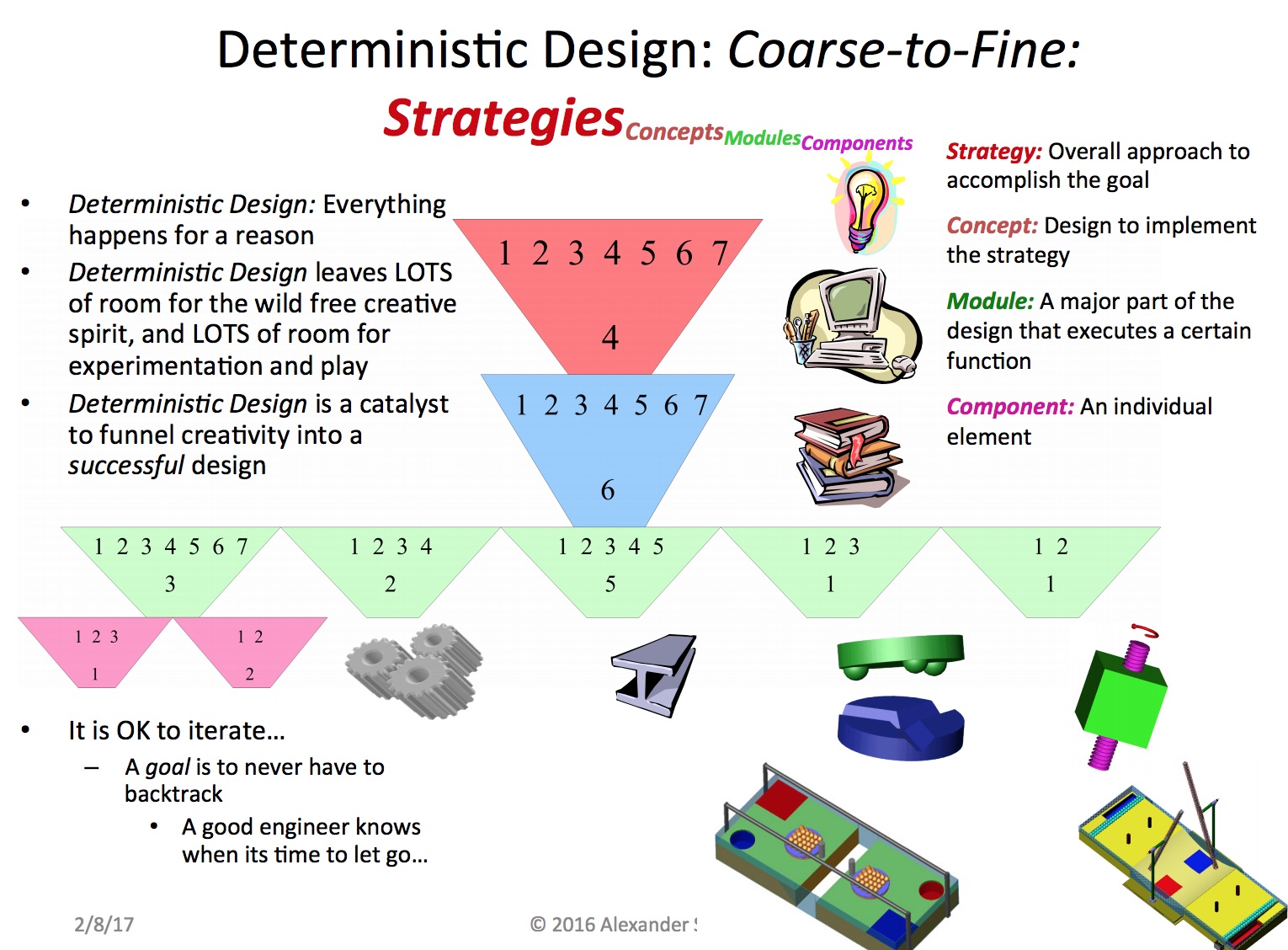

Here is a breakdown of how I plan to go from thinking up strategies of how to build a shoe to then designing for the process and executing on it. (Again courtesy of Alex Slocum's class website). I would like to follow through with the "Deterministic Design" methodology due to its robustness to failure in real-life products.

Figure 6: Methodology of Deterministic Design

Week 6 Thought Log

Updates

- Signals/Inputs to the Software from the Hardware -- How does that work?? Really cool, but really daunting...

- What is the difference between Embedded Programming and just regular programming? --> from what it looks like, embedded programming is programming that "syncs" to a hardware device and gives it commands

- What kind of embedded programming will I require for my shoe? I guess there will be an output hardware device on my shoe that will get signals from my code based on signals from an input device. Ok, so this is my goal!

- I also learned the extremely important reason for data sheets and why it's so important to read them!

- Goal this week: Create FBD and FRDPARRC Table of Shoe to Make (3 Concepts)

Here I came upon a really cool website on all things embedded systems: <,a> I also found a great link on Adafruit's website on various "wearables" fashion technology hardware that can be used for embedeed systems programming:

Week 7 Thought Log

Updates

- Considered the Mold for the Final Shoe Design

- Designed First Iteration of Shoe Outsole on Onshape

- Attending Sewing Recitation From Tom Lutz and got intrigued

Realized after going through the Molding and Casting training and practice, that it will be quite useful for my final project, and I can even create rubberized casts and then reuse the wax mold again and again! I think I will make a simple ball-of-foot comfort pad for my shoe. Here below is the type of material that we have in the lab that I plan to use for the final project:

Figure 7: Sorta-Clear Rubbery Silicone Casting Material to Use for Project!

Week 8 Thought Log

Updates

- Created Heel, Insole, Rubber Outsole, Shoe Vamp + Counter Modules

- Sketch drawing of different heel cavity/housing designs

- The shoe heel needs to act as both a statement, be able to support the loads/forces from the wearer's body weight and from her motion, but also act as the HOUSING for the PCB + Battery

Decided on a HEELED SHOE. Even though I created a more general machine idea, a heeled shoe seems more practical at this time. I would like to attach a USB port on the inner part of the Shoe Heel.

Figure 9: Diagram of What Wearing High Heels Can Do to the Body

Week 9 Thought Log

Updates

- Layout of the Shoe Module components for Each Class Module

- Created a Bill of Materials document (living document to add and subtract in)

- Focused on the Group Machine Build mostly this week.

SUMMARY HERE (and next steps) Having now gone through the Output Devices class, I am realizing that I may need to rescope and limit the number of features that my shoe can do. It is currently a bit too far fetched, but I'll see just how far I can go. Here below is a link to a useful video of how to create and export a cohesive BOM list in Autocad Fusion 360:

Week 10 Thought Log

Updates

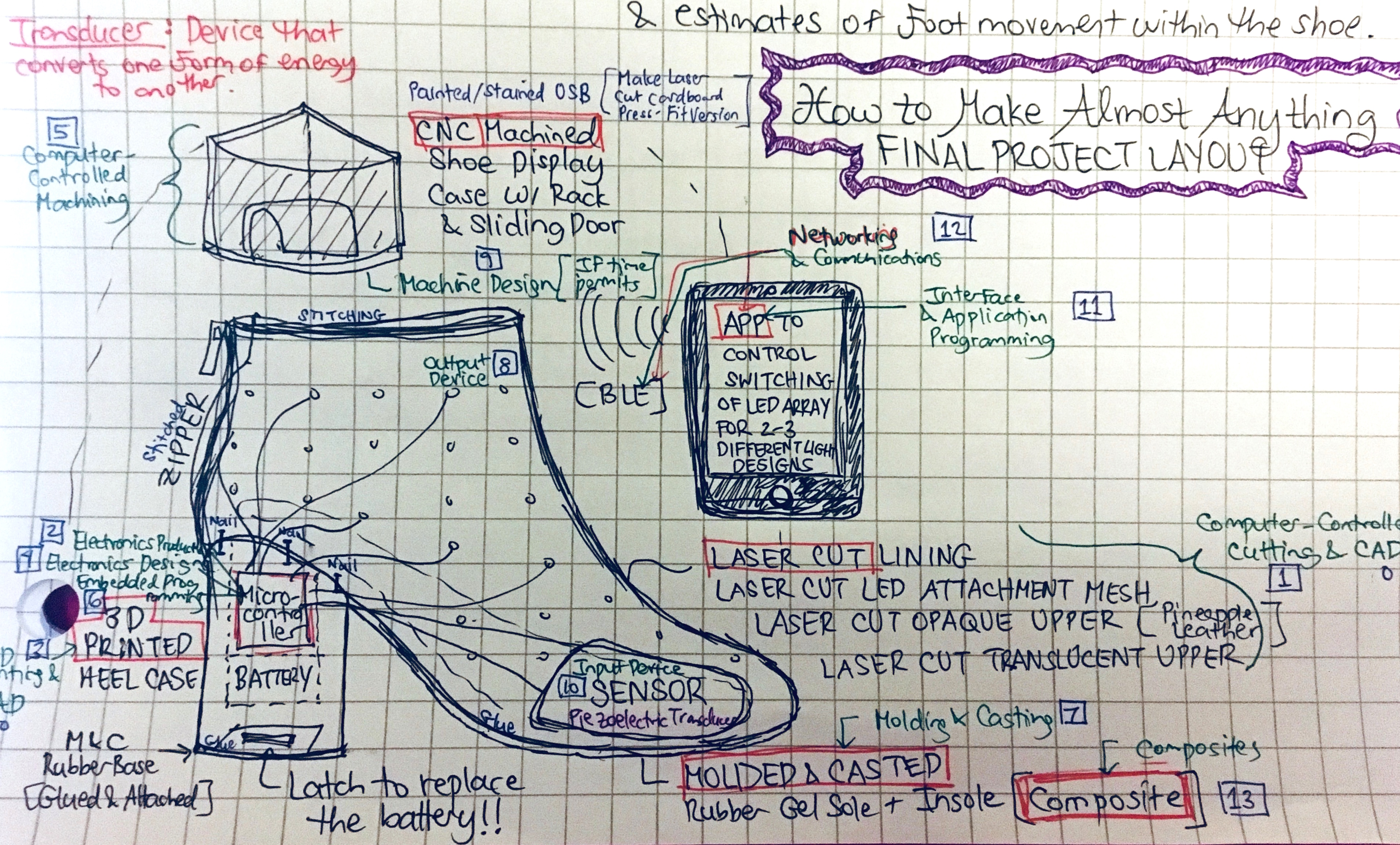

This week, I finally came up with the final design with all the modules incorporated for the class! Take a look at the sketch below:

Figure 11: Final Project Diagram

I now have a clear picture of what components need to be made and which components correspond to which weekly modules that we have/are doing in the class.Here below are my final project's components that correspond to each week's module in the class:

Components corresponding to Weekly Class Modules

- Week 1: Computer Controlled Cutting -- Shoe Outsole

- Laser Cut Lining

- Laser Cut Opaque Upper

- Laser Cut LED Attachment Mesh

- Laser Cut Translucent Upper

- Week 2: Electronics Production -- Milling and Stuffing Embedded PCB

- Week 3: 3D Printing -- 3D Printed Heel with Cavity for PCB Board & Battery Pack

- Week 4: Electronics Design -- Choosing Components & Designing Layout of PCB

- Week 5: Computer Controlled Machining -- Shoe Display Case w/ Rack & Sliding Door

- Week 6: Embedded Programming -- Software integration with PCB Microcontroller

- Week 7: Molding & Casting -- Wax Molds for (Casted) Rubber Gel Sole + Insole

- Week 8: Output Devices -- LED Array Embedded & Stitched in Sewn Shoe Upper

- Week 9: Machine Design -- Automated (Convex) Sliding Door for Shoe Display Case

- Week 10: Input Devices -- Switch and Piezoelectric Transducer Sensor inside Shoe

- Week 11: Interface and Application Programming -- App to Control teh LED Array switcihing for 2-3 Different Light Designs

- Week 12: Networking & Communications -- Bluetooth Low Energy System connecting the App commands to the Microcontroller that controls the ouput of the Shoe's LED Array

- Week 13: Composites -- Developing a Composite Insole Material for Added Comfort

I am finally starting to feel a better sense of what needs to come together this week. One of the or

Week 11 Thought Log

Updates

- Redid the Week 3 module for 3D printing and practiced making a Block High Heel

- The Heel, its Cavity, and the Battery Housing Lid were Dimensioned on Paper

- The Heel's coponents were then CADded in OnShape (and exported into) Fusion360

- The CAD file was exported onto the SHINDO 3D Printer and Printed with ABS(?)

SUMMARY HERE (and next steps) The picture of what the final product will look like is finally coming together and I feel like a lot of progress is starting to be made. This week, I started one of the more unique components of my design for the LED shoe -- the heel!

Week 12 Thought Log

Updates

- Embroidery Tutorial using thread, conductive thread, and LEDs (get from shop) with Tom Lutz

- CADed the heel and attempted a 3D print

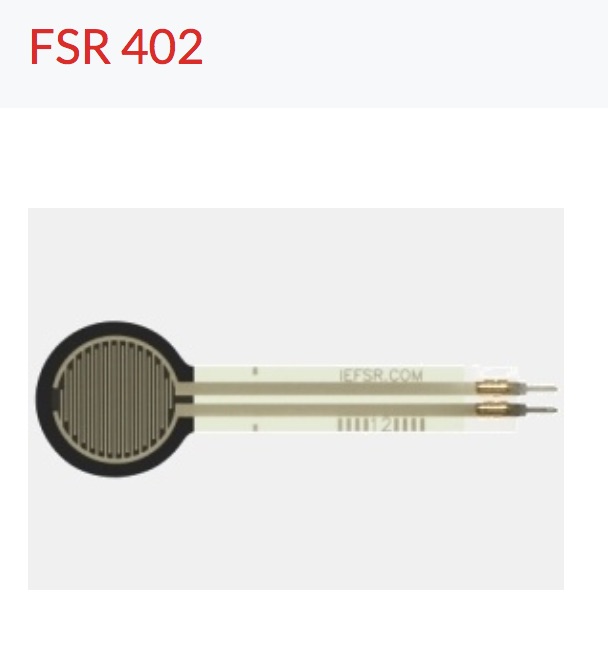

- Decided upon Resistive Force Sensors that act as the input device to modulate the output device of an the LED array

Here is a great website (Neil recommended) for getting Force Sensitive Resistors: Here below are pictures of two specific ones that look interesting: the FR402 and FR406

Figure 16: FSR402 Circular Force Sensitive Resistor that Works in a Circuit as a Voltage Divider Component

Figure 17: The Same Idea but a Little Bigger and Square-Shaped FSR

Week 13 Thought Log

Updates

- Designed my Shoe using a Tutorial on YouTube!

- I created the left and right meane forms for my right foot using a nylon sock, duct tape, and foam board

- Created a Composite Outsole so that My Shoe can actually be made as a High Heel!

Here below you can see the composite outsole made from light guage burlap and epoxy with my 3D printed high heel to get the height:

Figure 18: My General Shoe Design Bottom Form

Final Week Thought Log

Updates

- Mad rush to finish the electronics!!

- Creating and routing the board took longer than I expected and lots of mistakes were made!

- Not sure if I can get the electroncis and programming to work out this week, but I plan to keep at it and see what I can accomplish to the finish line and thereafter!

Even though I learned more than I could have ever imagined in one class, I am still feeling quite in need to upping my game in electronics and plan to take an electronics design course next semester! But for now, back to work completing my embedded shoe! Lots of mistakes and triumphs to come!

Figure 19: A Very Fitting Meme for the Class :P