Composites

This week's mission is to design and fabricate a 3D mold and produce a fiber composite part in it, with resin infusion and compaction.

Composites

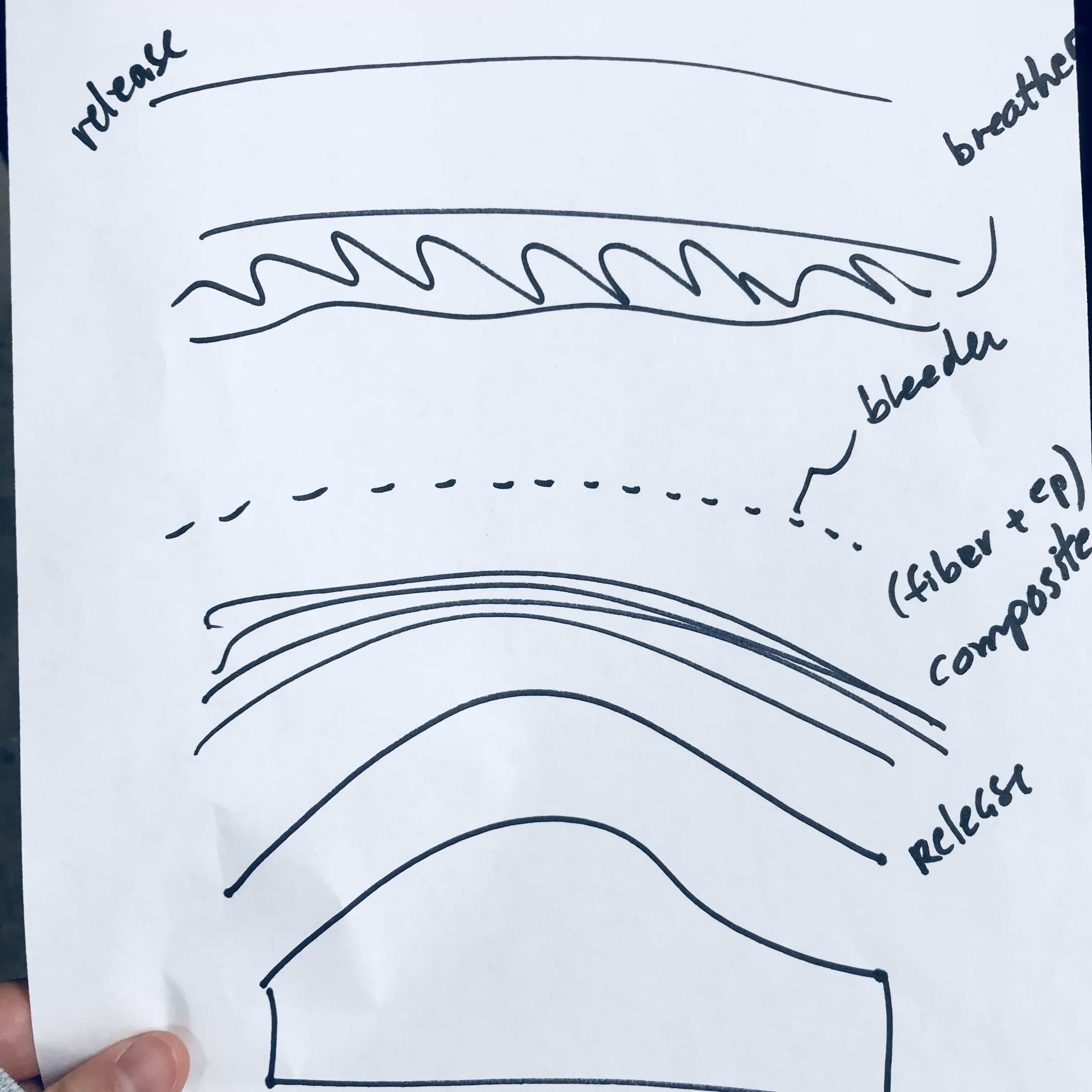

Layers

Top to bottom: release, breather, perforated bleeder, (fiber + epoxy) composite, release, mold

Hat & Mask

I planed to make a composite to make the AR hat stand on the head. So I started with this head.

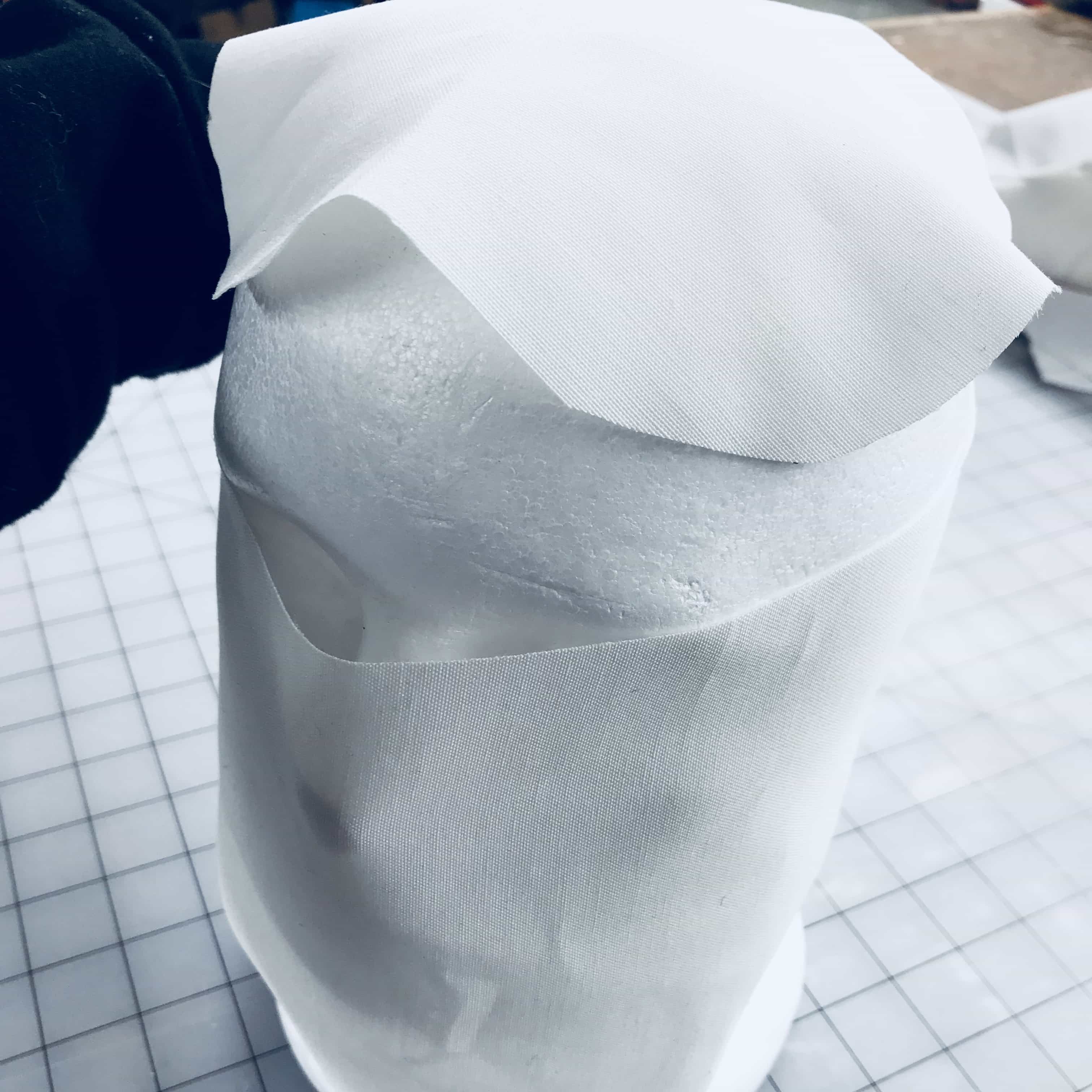

Cut the fabric

I wanted to make it soft but steady. So I chose this thin fabric, and only applied two layers.

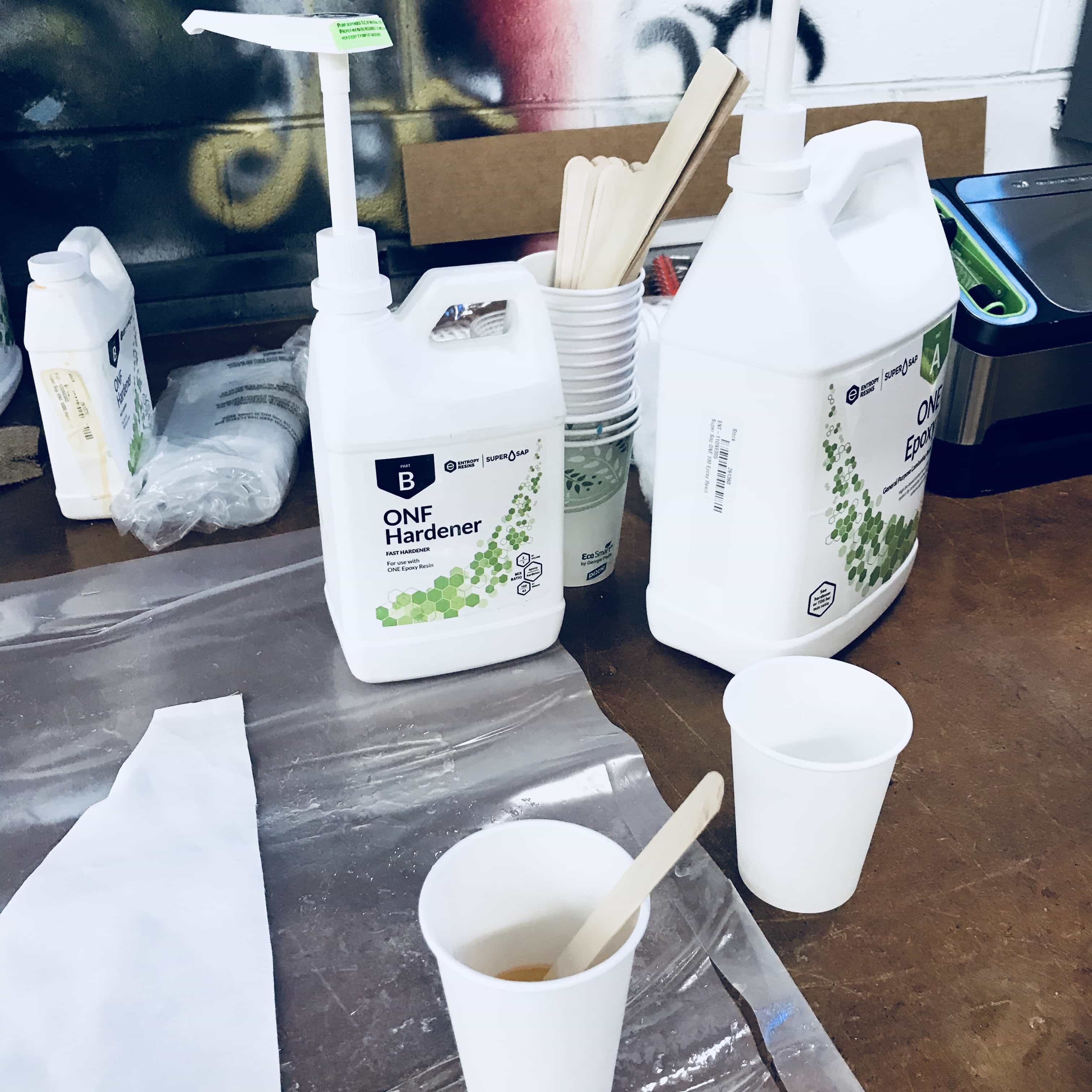

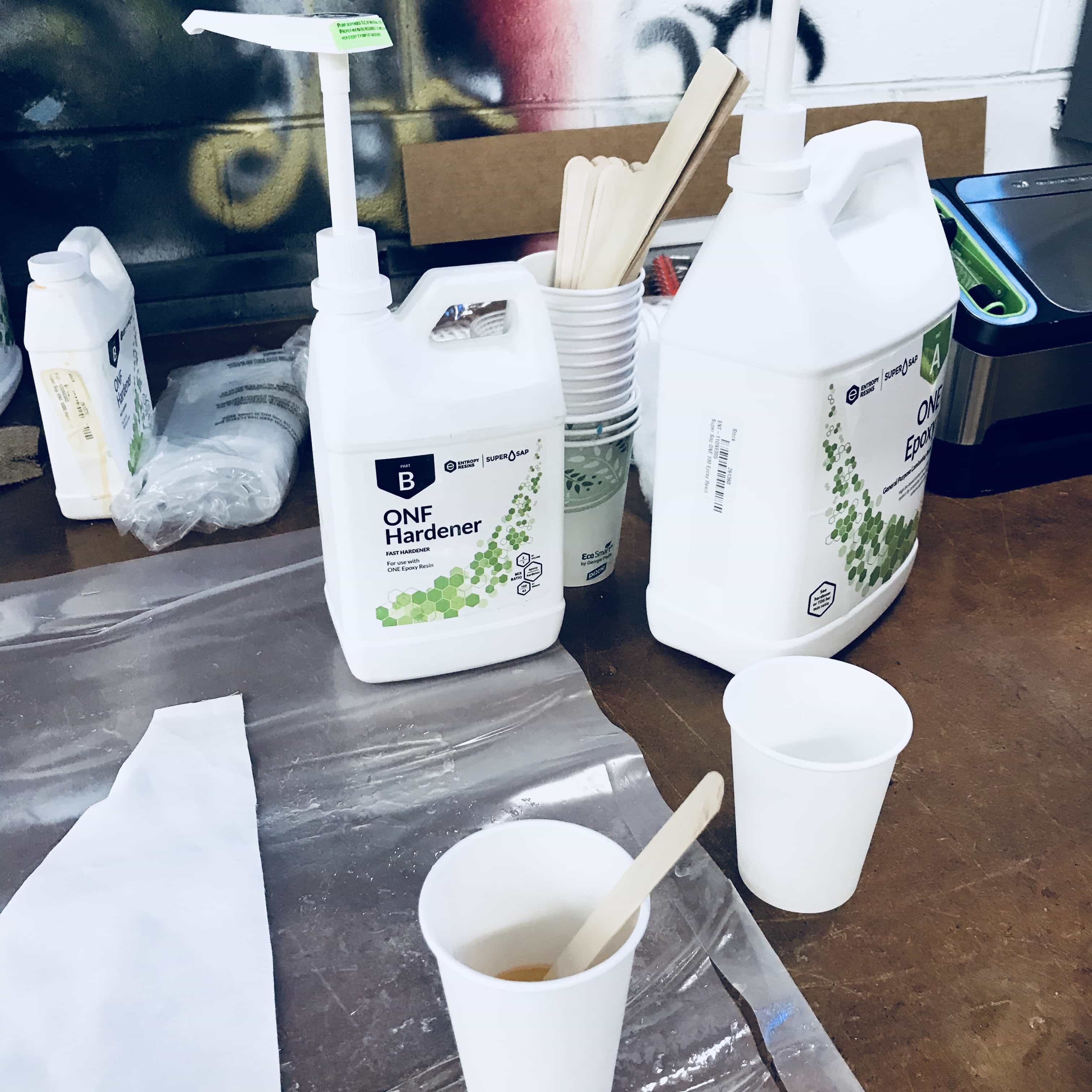

Mix and Pour Epoxy

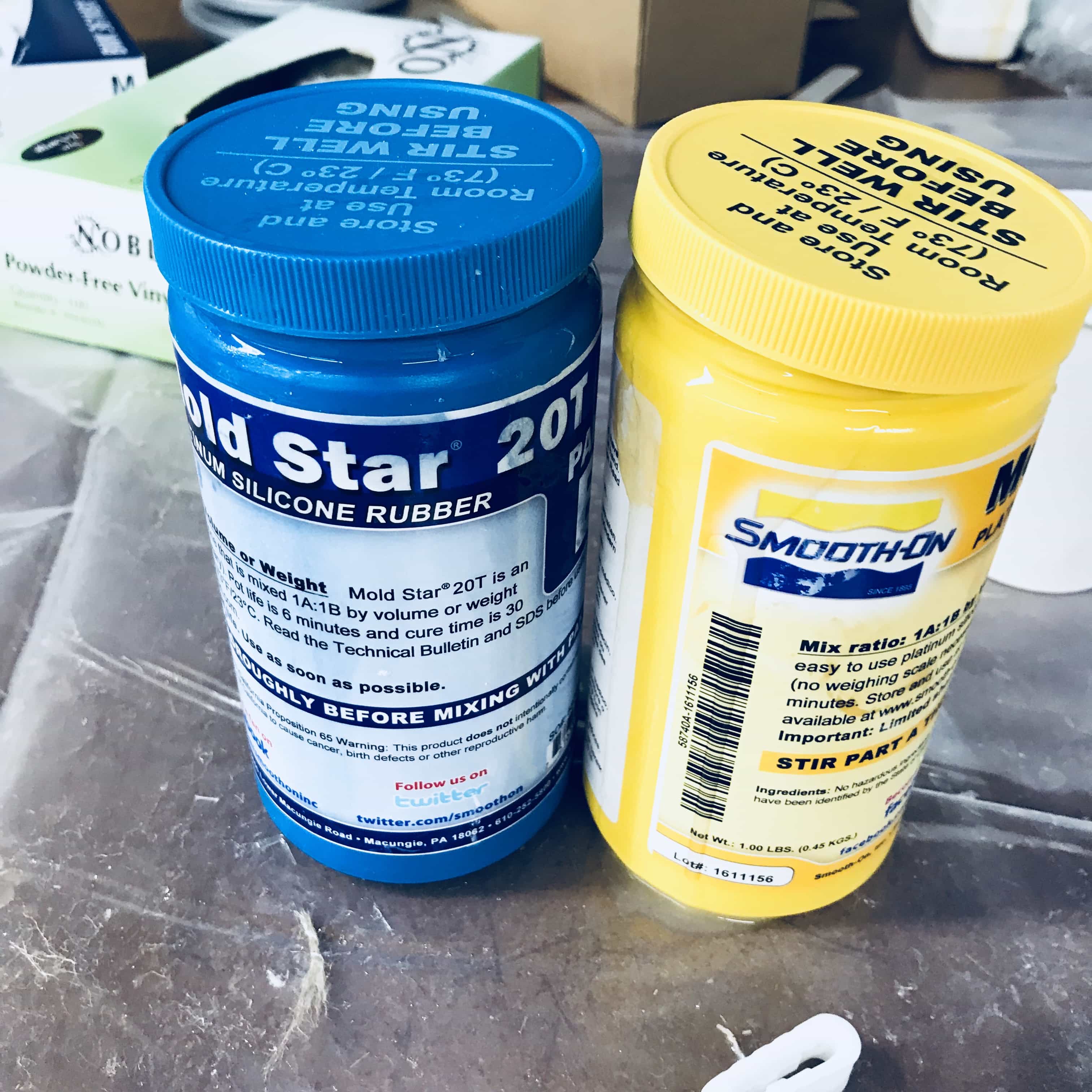

Try Silicon

Rob suggested that I could also try Silicone to produce soft composite. So I used Mols Star 20T on the mask.

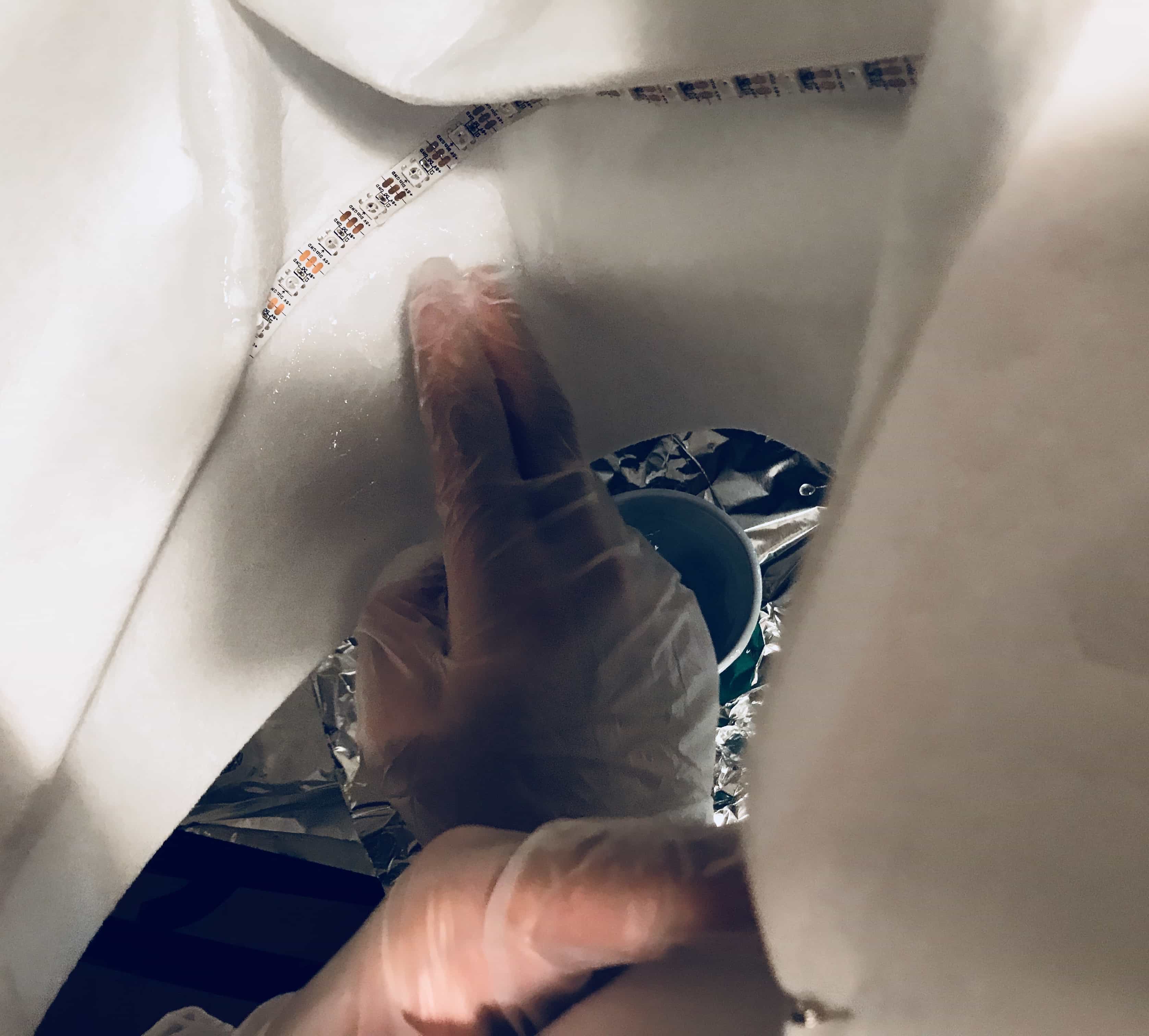

Wrap bleeder

Torture the head

.......To let it breath

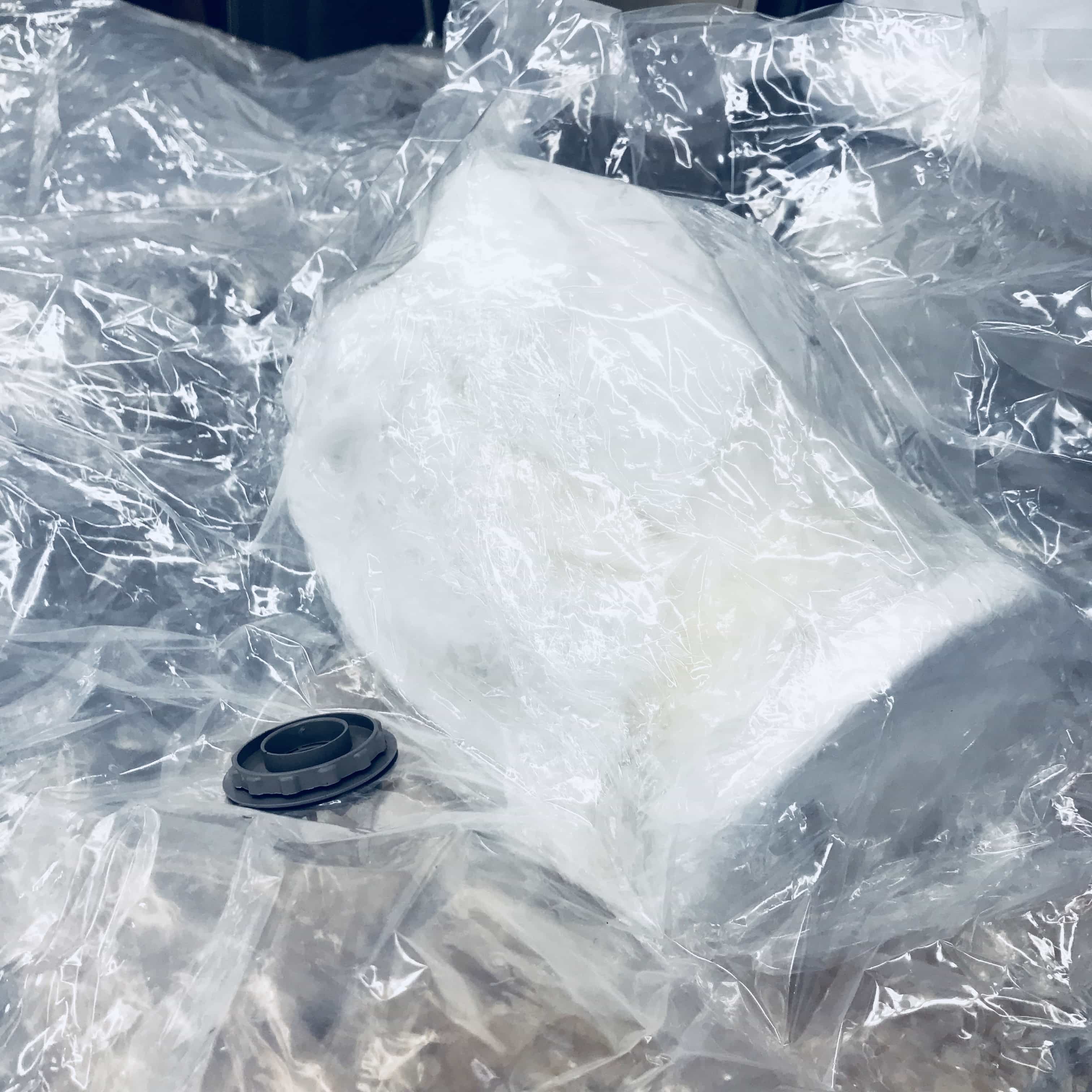

Vacuum bagging

The cap..

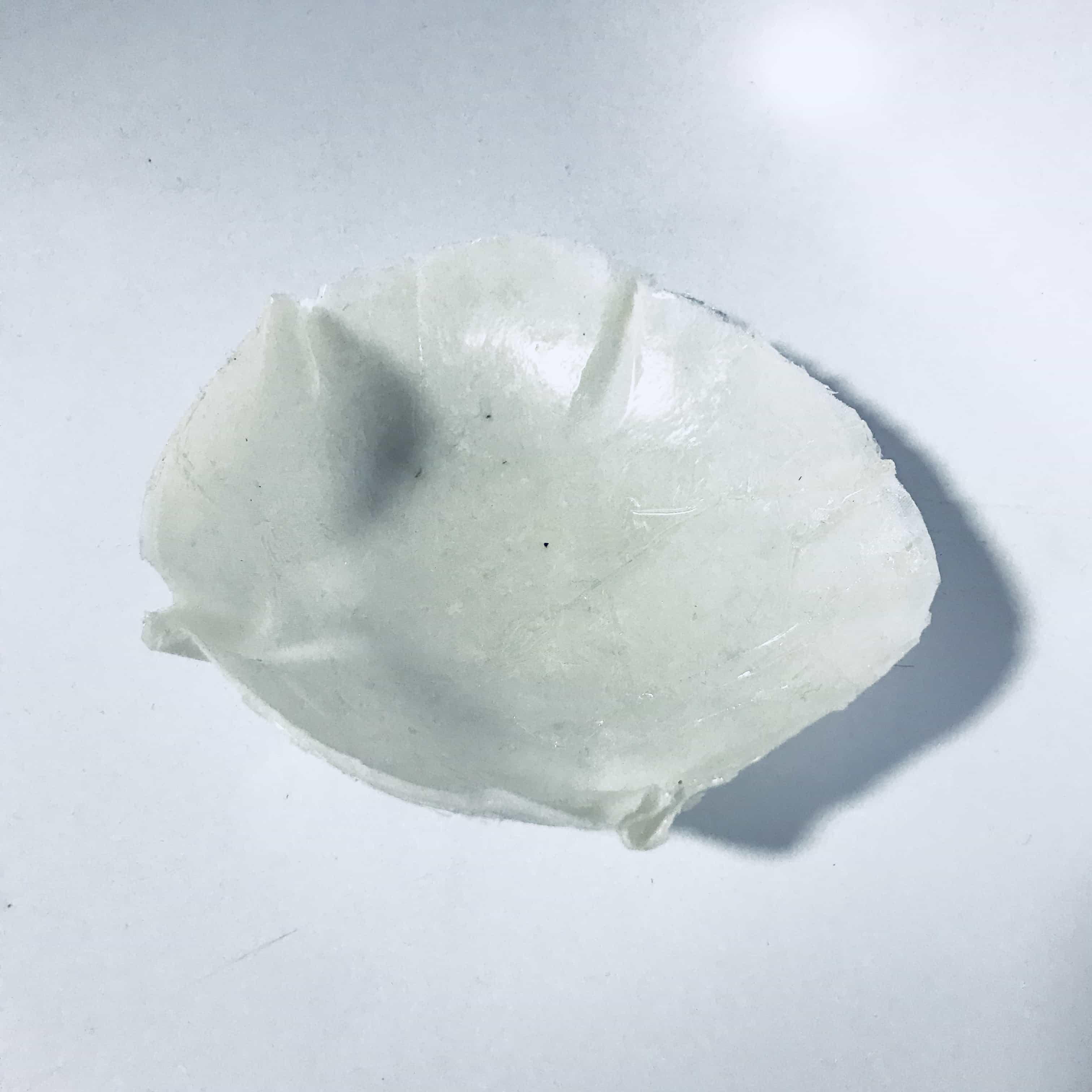

The silicon mask failed to dry

Try apply epoxy directly on fabric

Hardened after one day, faster with higher temperature

Another version, stiffer

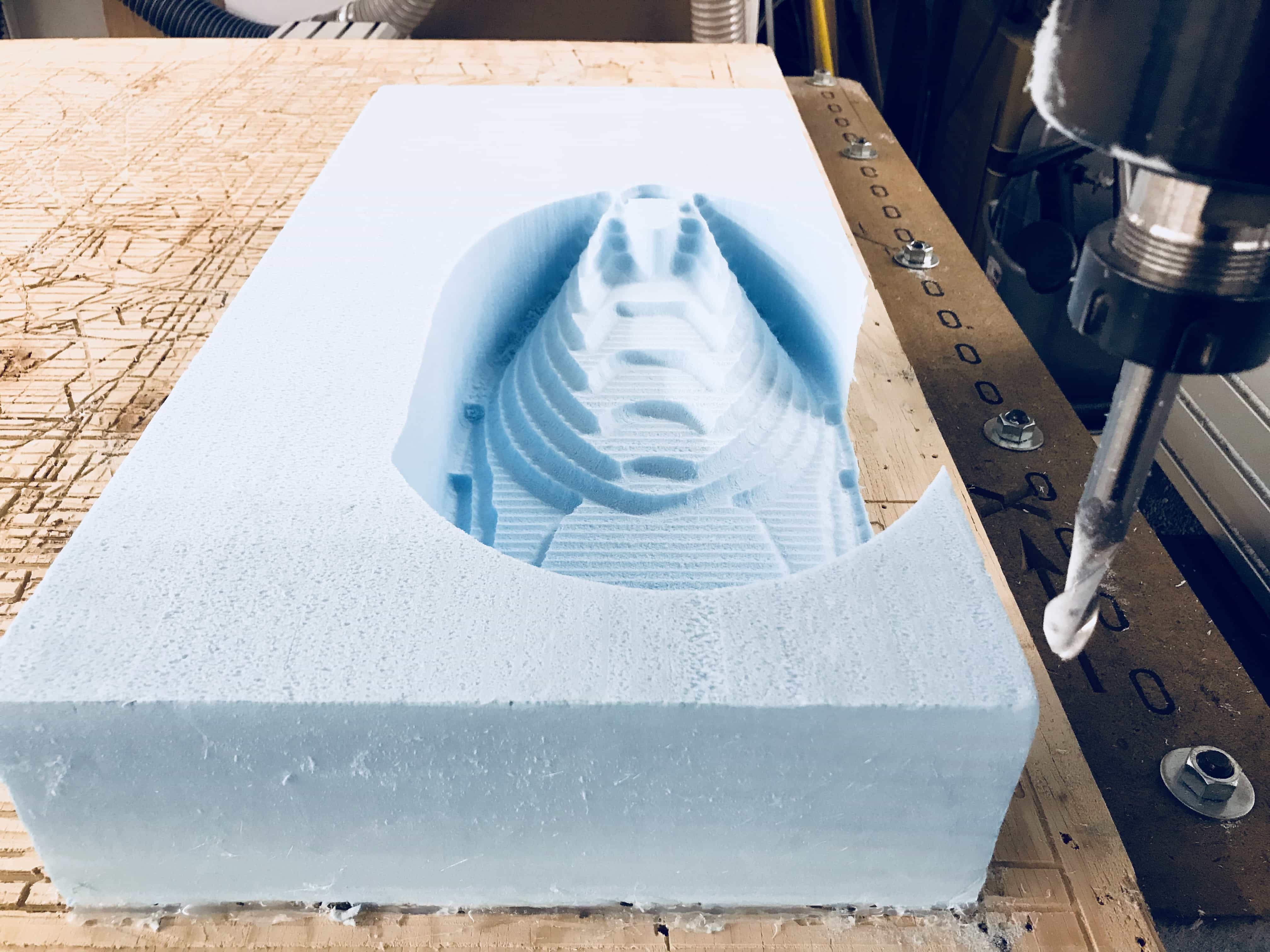

Try to make a composite AR Hat

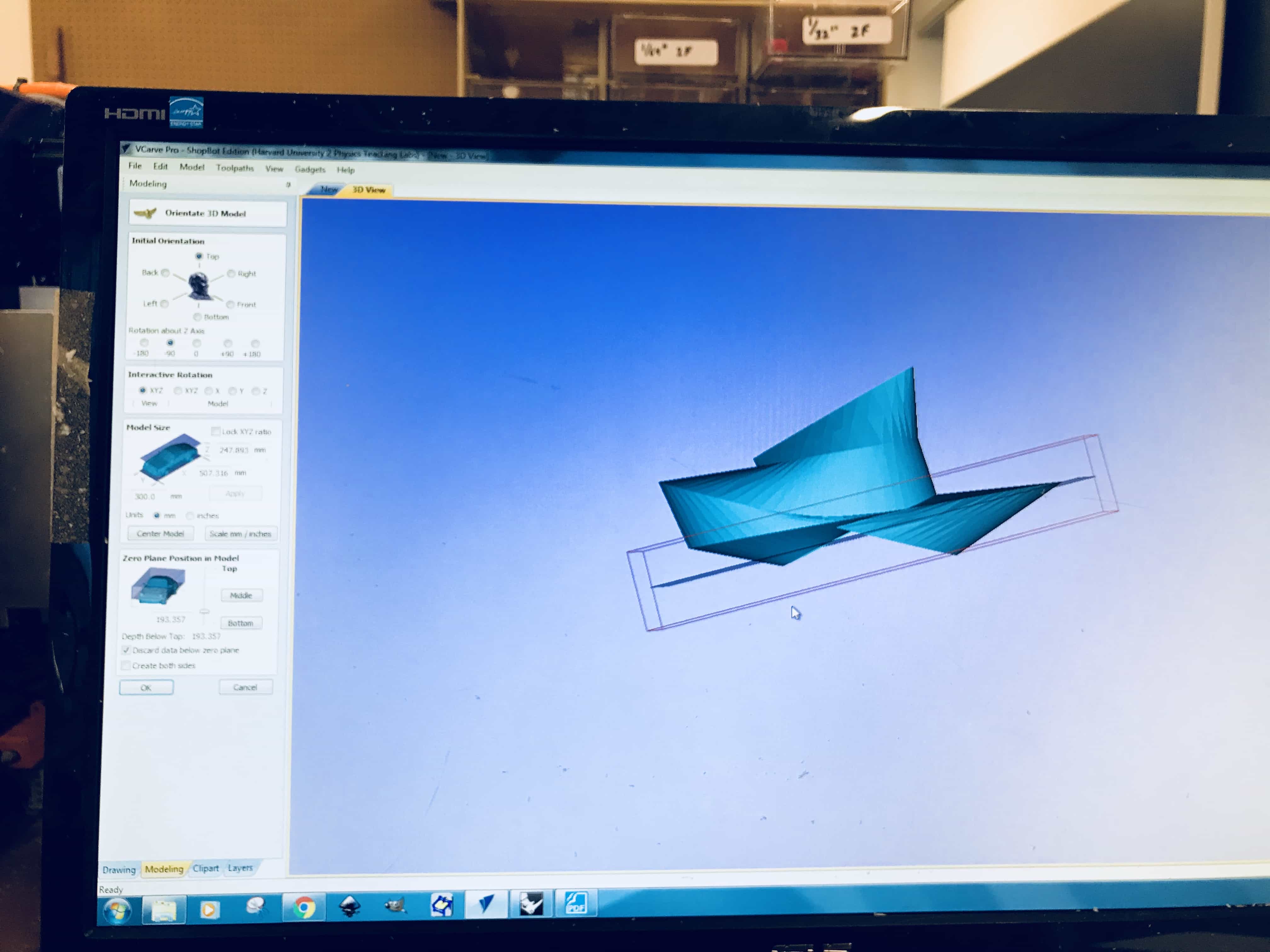

Within the constraint of the optics

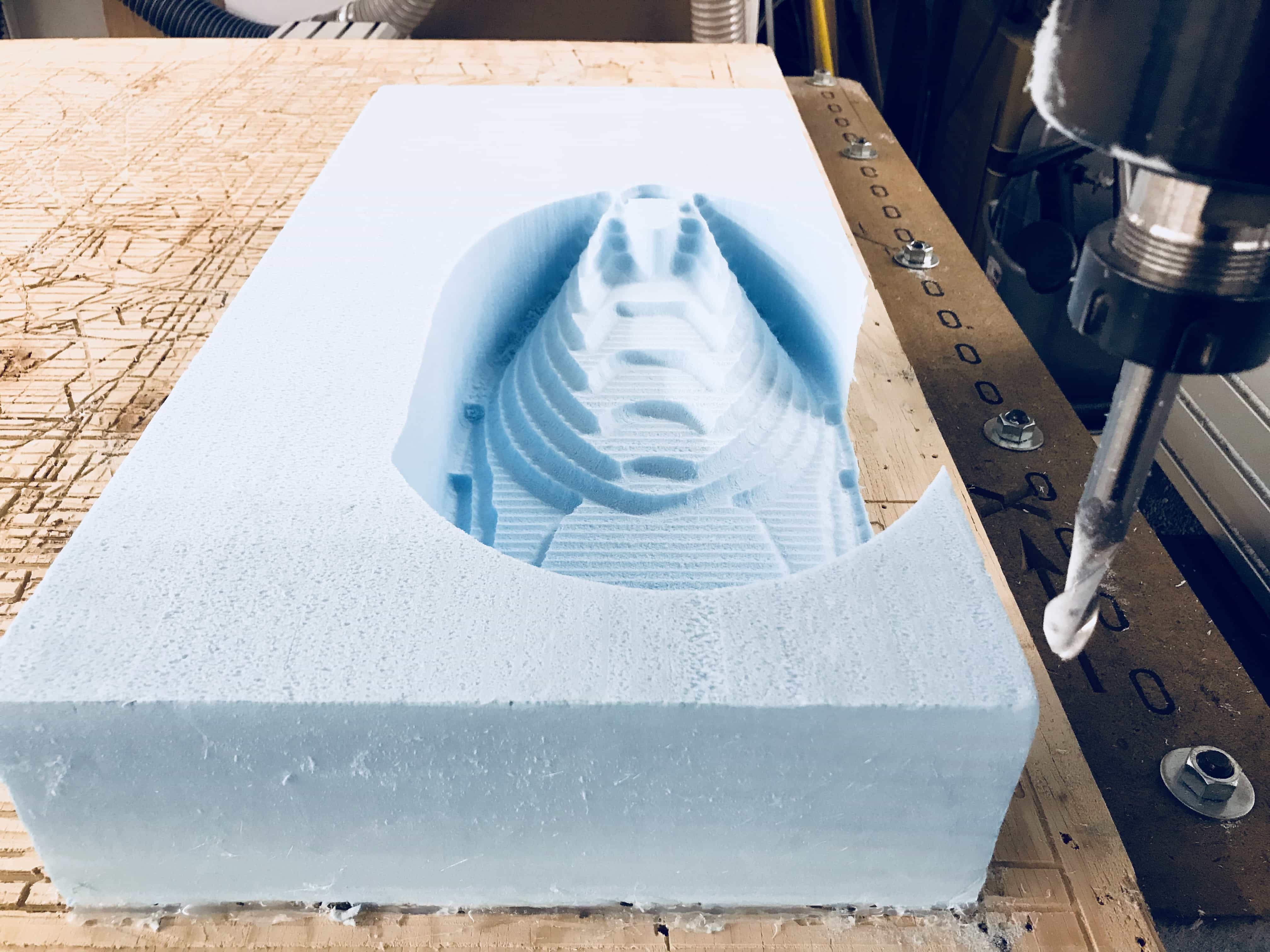

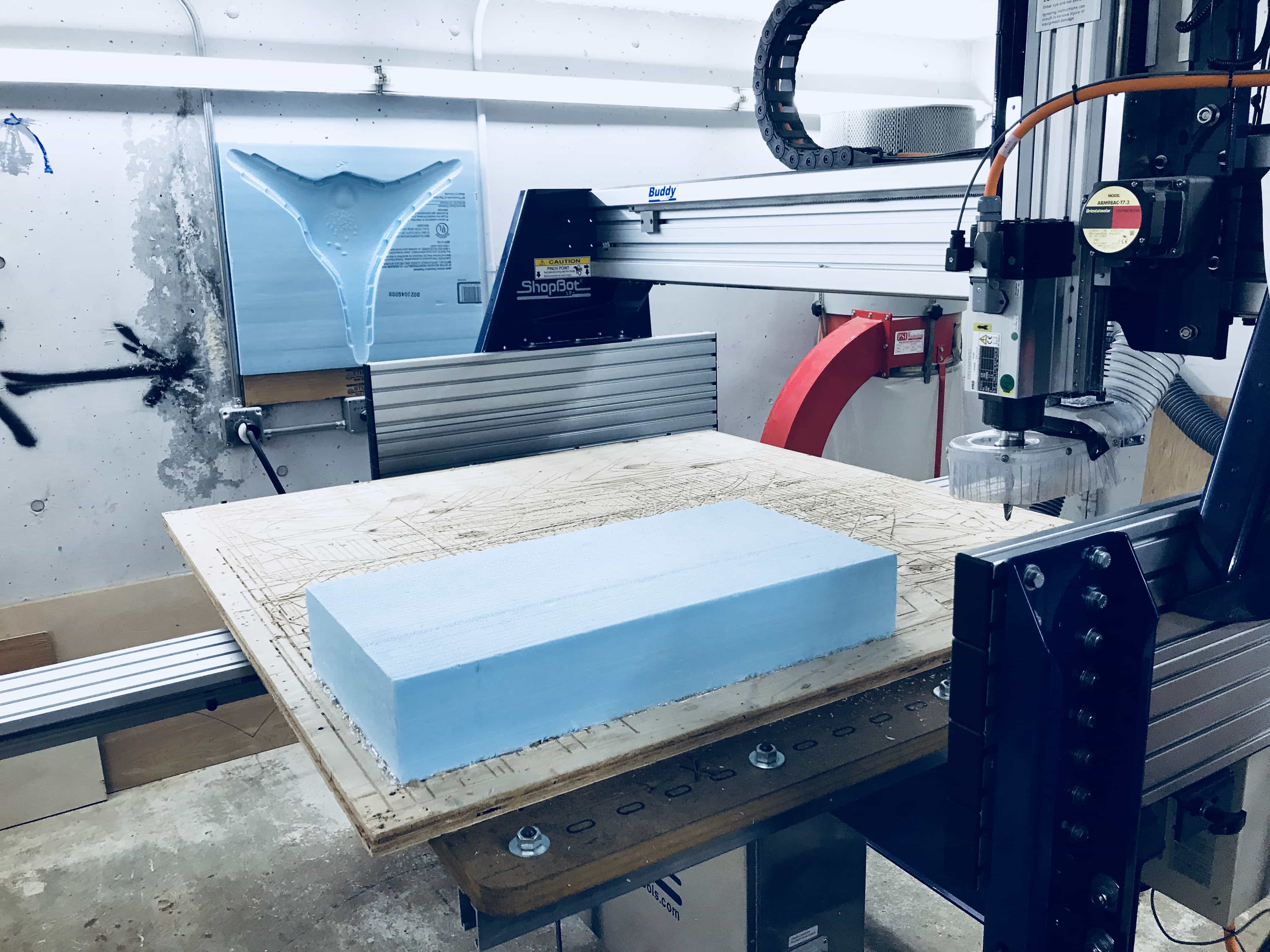

Mill the foam

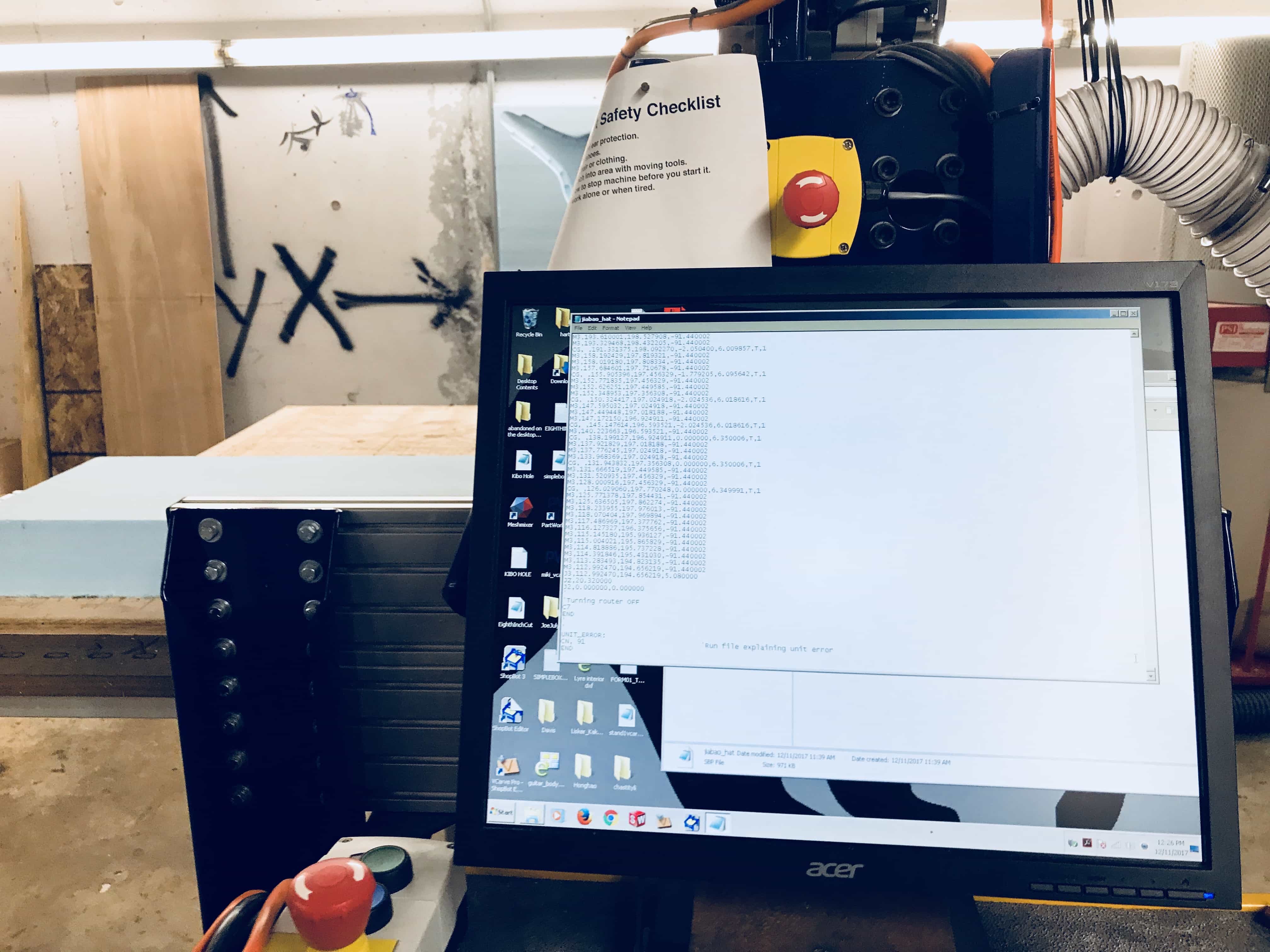

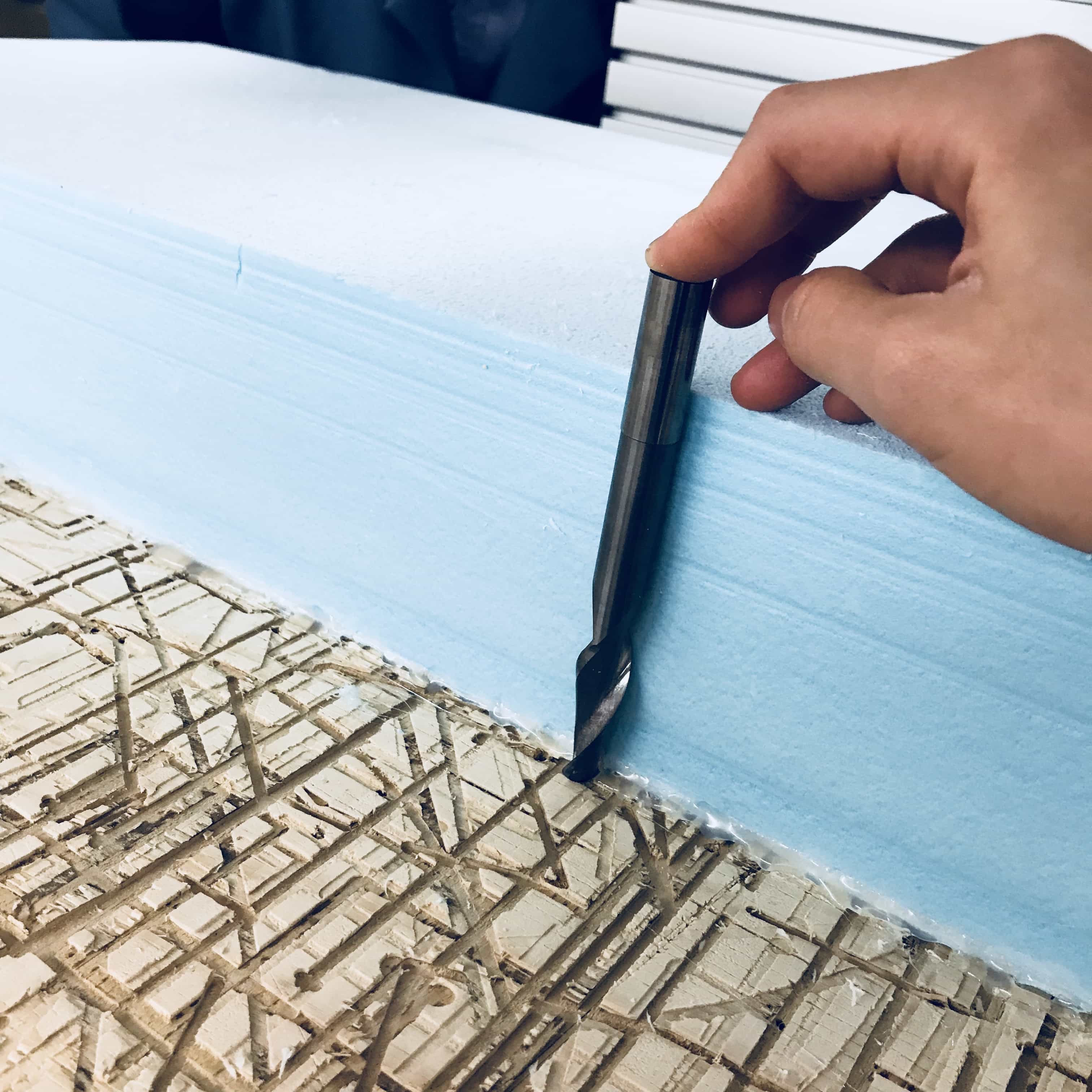

Ckeck the toolpath

Make sure the end mill is deep enough

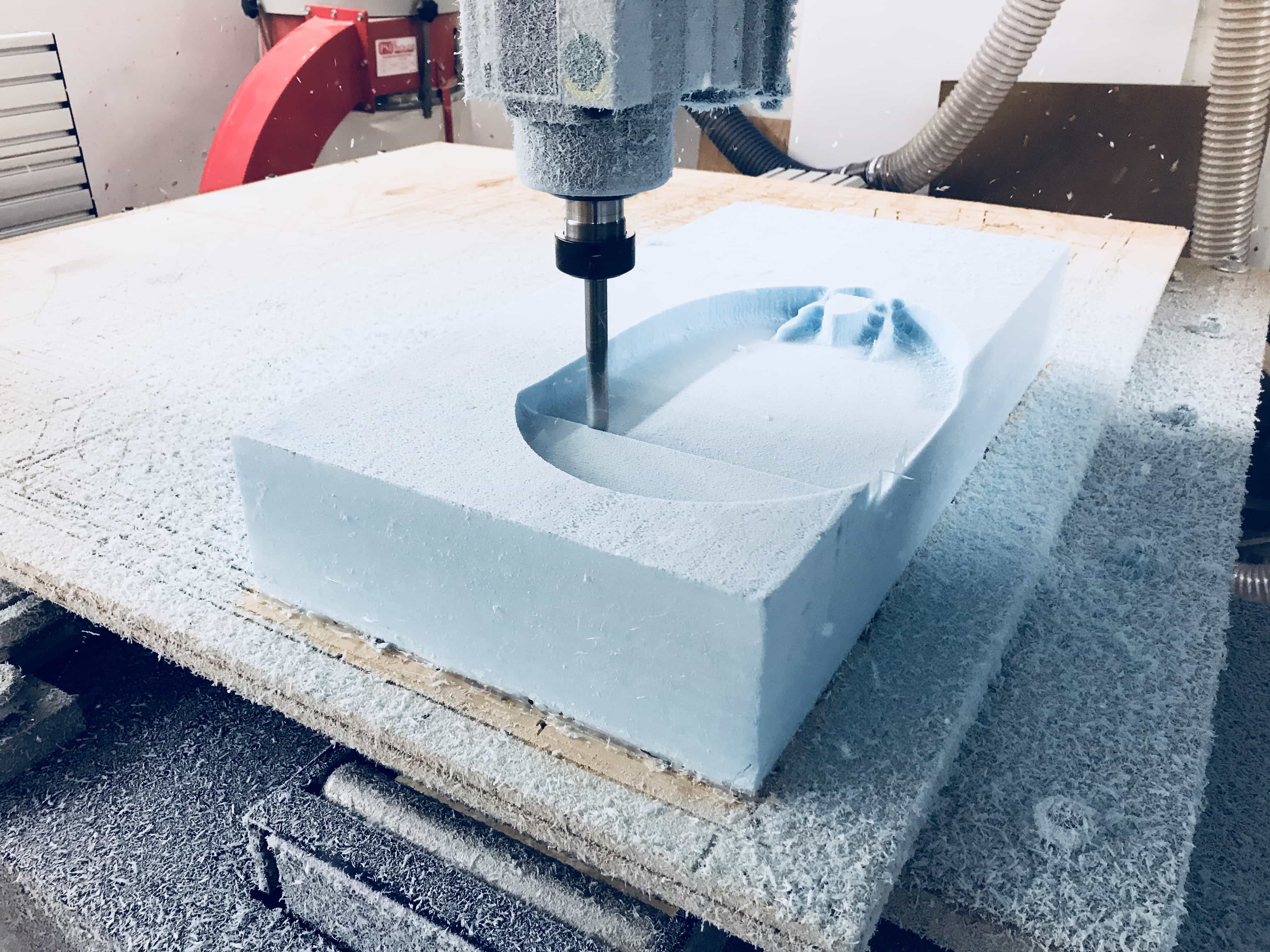

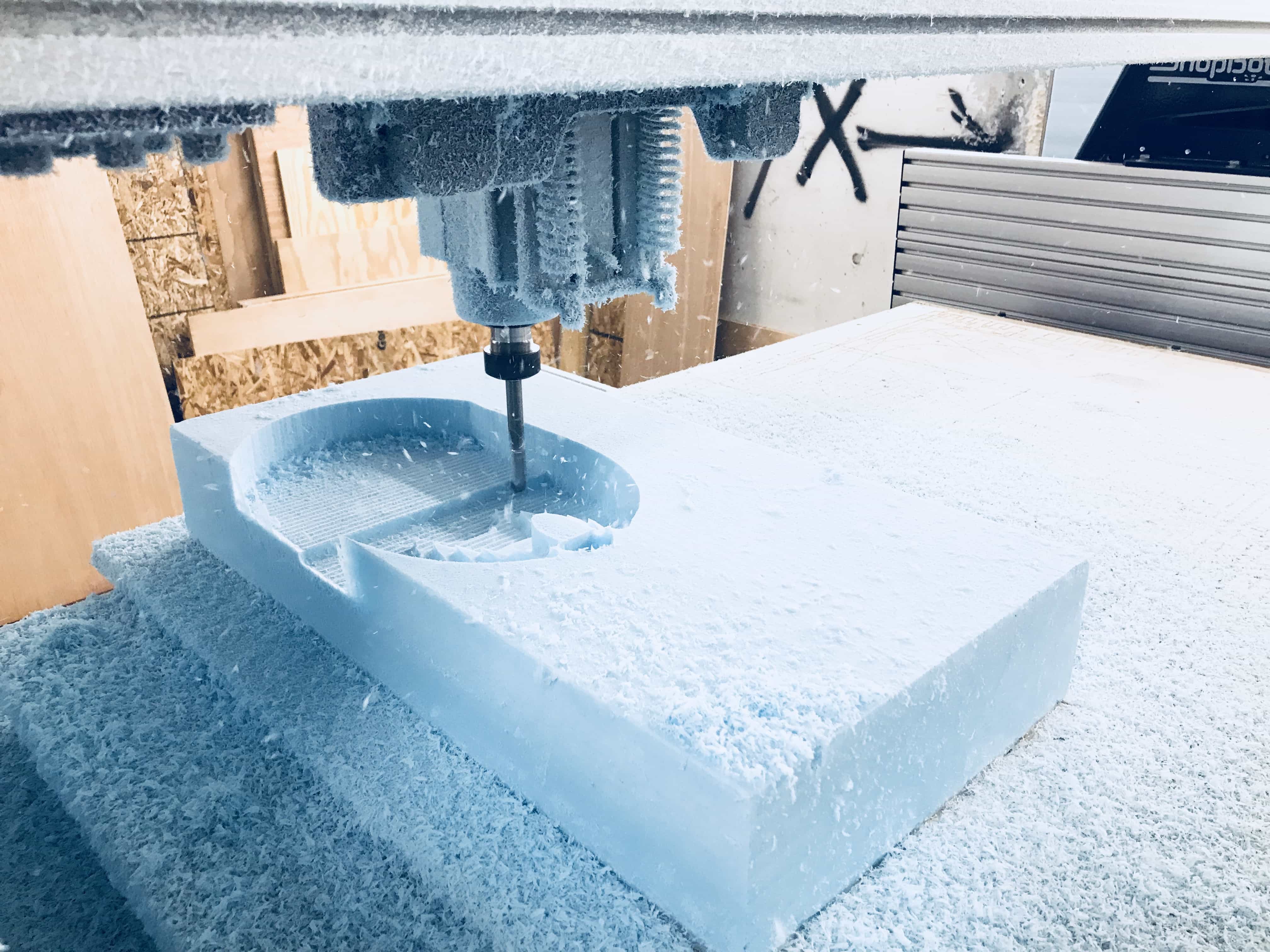

Because the end mill is too short, I had to take off the vacuum to avoid it gets into the mill. That's why here you see foam dust everywhere.

This simple milling had lots of problems and caused me almost one day. The end mill turned out to be still too short. It kept hitting the top of the foam. Milling off the right side of the foam caused the foam to move as well.

😡

The milling is finally done! But then... hours and hours of work became Corbu's chewing toy!!!