I had fun with the laser cutter, so I’m making more things.

This week we worked with cardboard for the assignment, but laser cutters can cut a lot of things. And my roommates and I take up way too much of our limited cabinet space with spice jars.

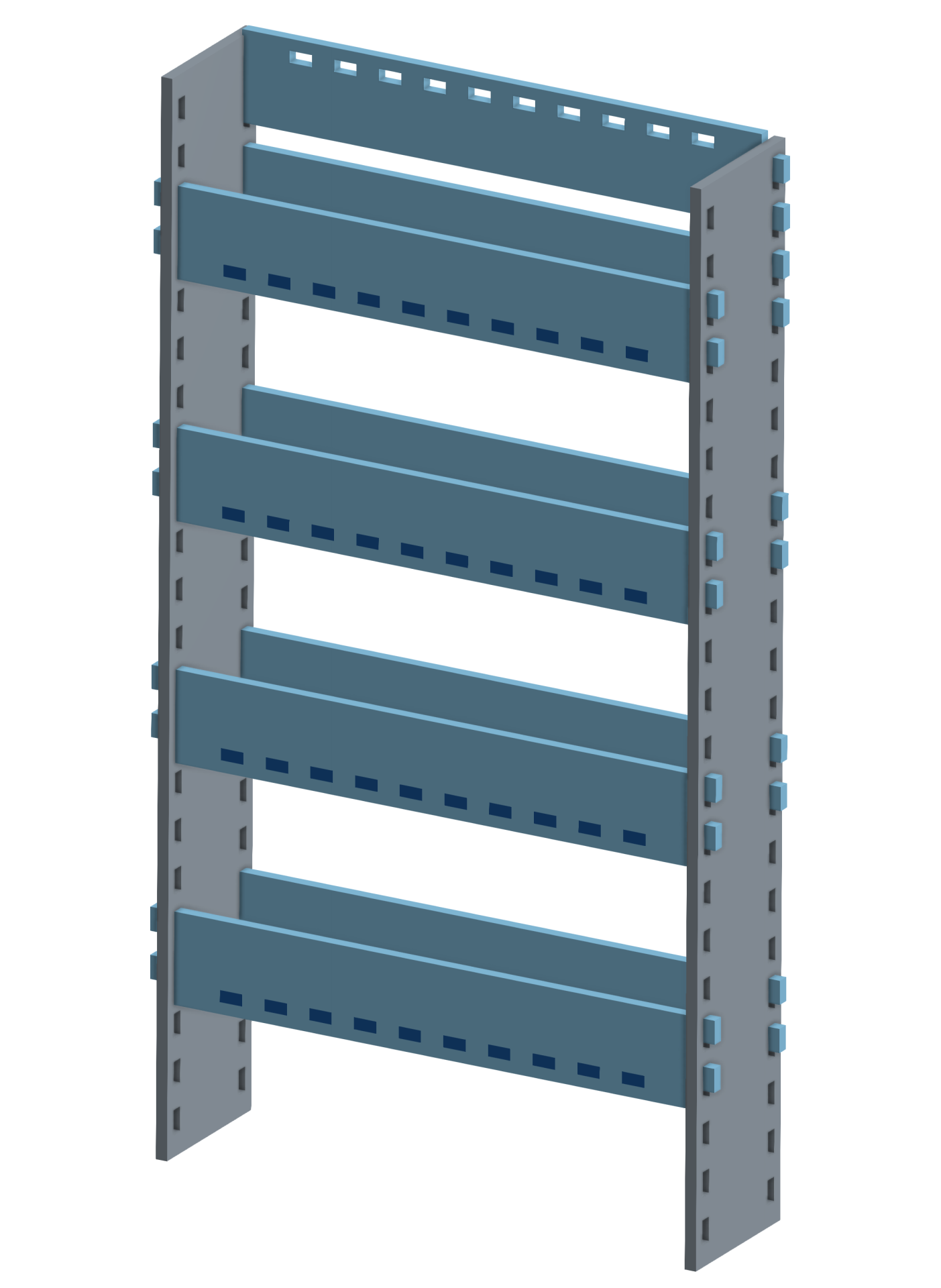

I designed a modular hanging spice rack in OnShape (which gave me a chance to learn how to create and use linear patterns). It has three different parts: side panels, rack bottom panels, and rack front/back panels. The rack pieces can be assembled and hooked in at different heights within the side panels, depending on the desired spacing. The front/back panel can also be flipped upside down and be used to hang up the rack on the wall.

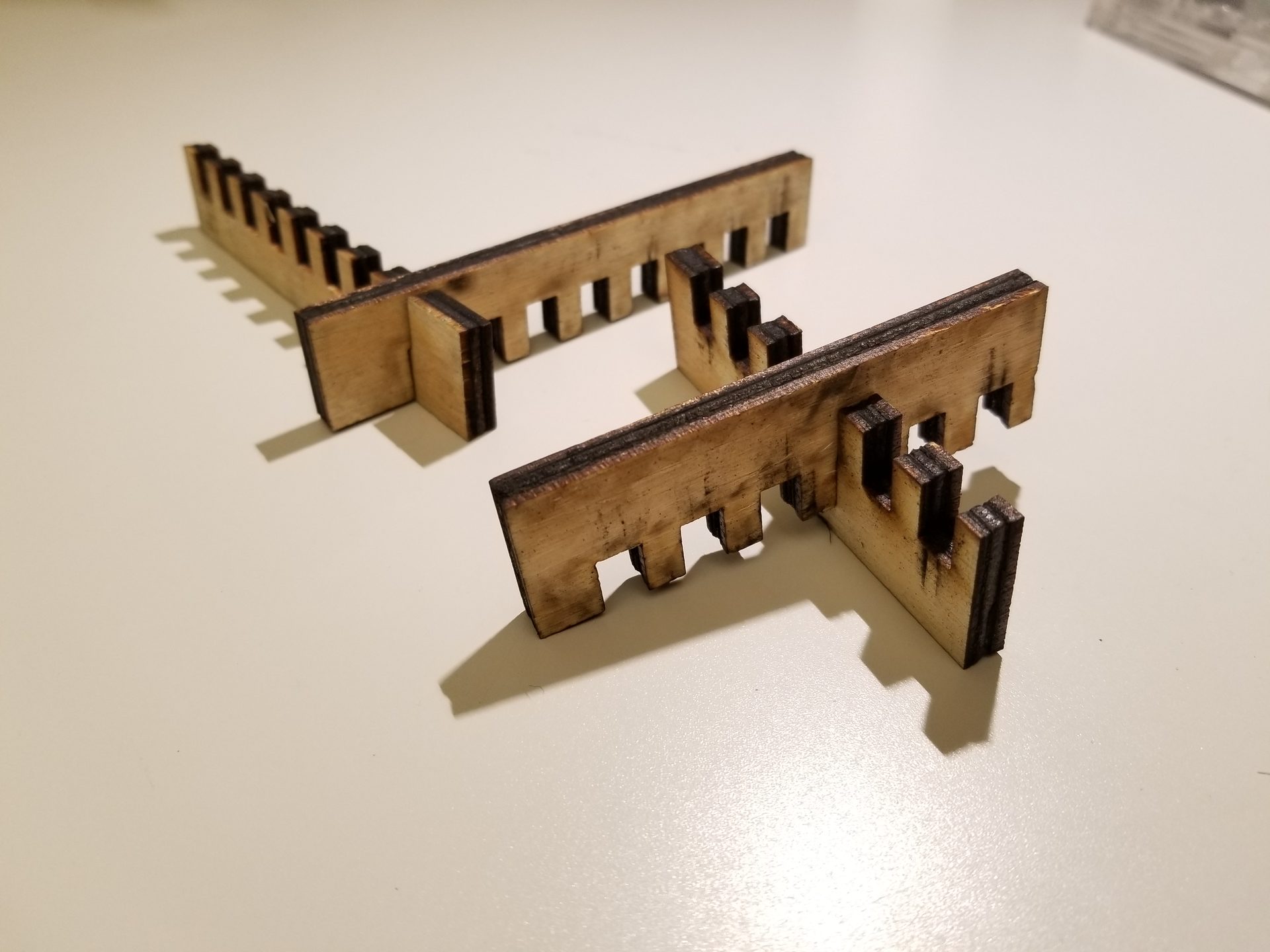

Laser cutting the wood wasn’t quite as straightforward as the cardboard. For one thing, I didn’t know the thickness to start. I had some scrap plywood I was using in Active Learning Labs at Project Night that claimed it was 7/32” thick. This was a lie. The calipers measured it at 6.8 mm, which is actually closer to 9/32”. I made a pair of combs with notches of different widths, from 6.65 to 7.00 mm and laser cut them. First I had to do a lot more fiddling with the settings to actually cut through the wood properly. On the 75 W Epilog laser cutter, I ended up using a speed of 12, power 100, frequency 500 Hz, and 2 passes of cutting to get through it. On the first comb, all of the slots were too big and wobbly. Another comb! On this one I went smaller and ended up settling on a stock thickness of 6.45 mm. There was soot everywhere, but minimal fire.

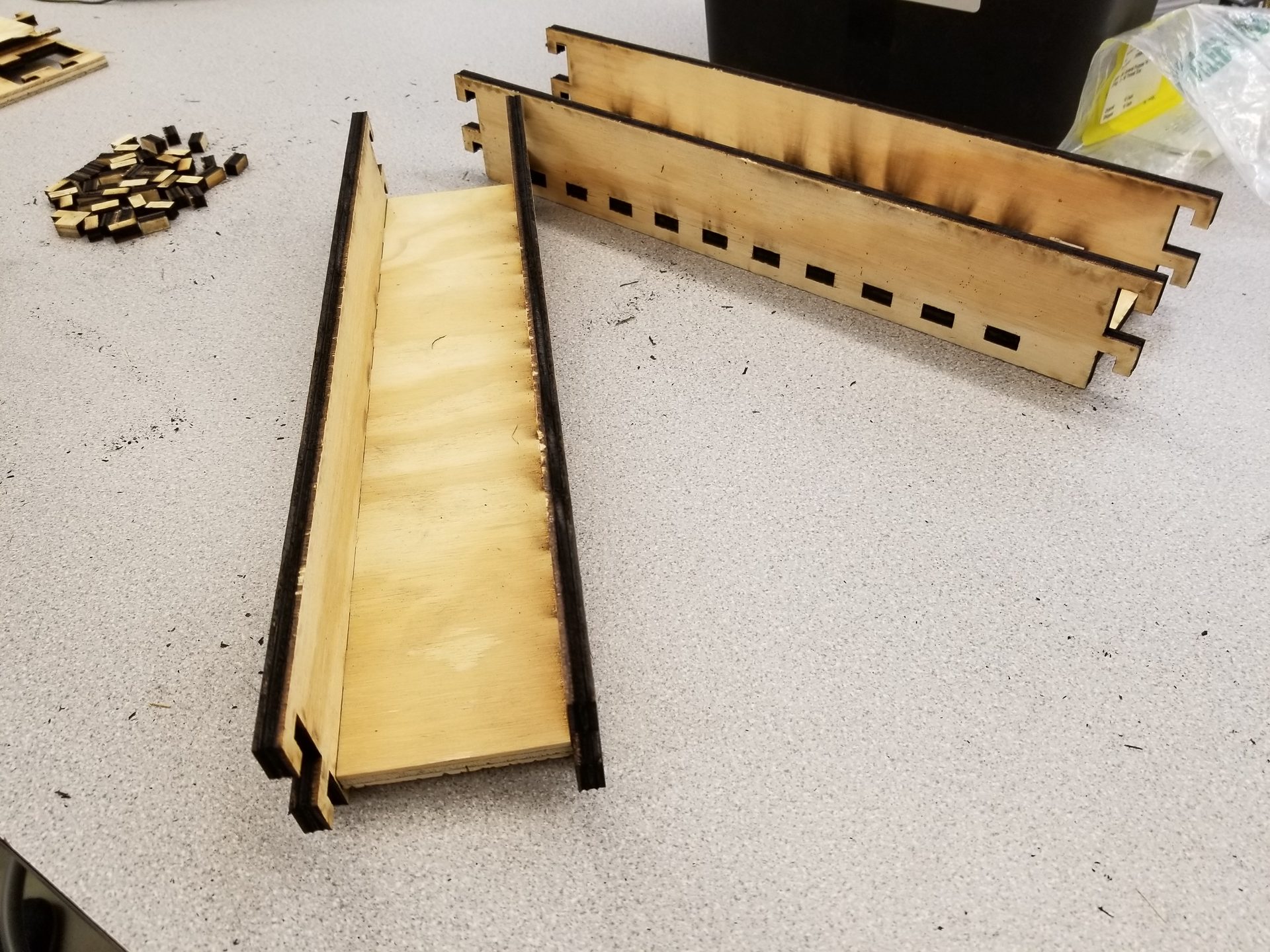

With the thickness set, I could export the CAD faces to DXF files and lay them out for cutting. I started with the rack pieces. Even with two passes, some of the holes didn’t pop out properly. There was also some warping from (I think) the cheap wood and multiple passes. This meant I had to use a rubber mallet to get the rack bottoms connected to the front and back. So much for easy modularity, but these parts generally wouldn’t need to be taken apart anyway.

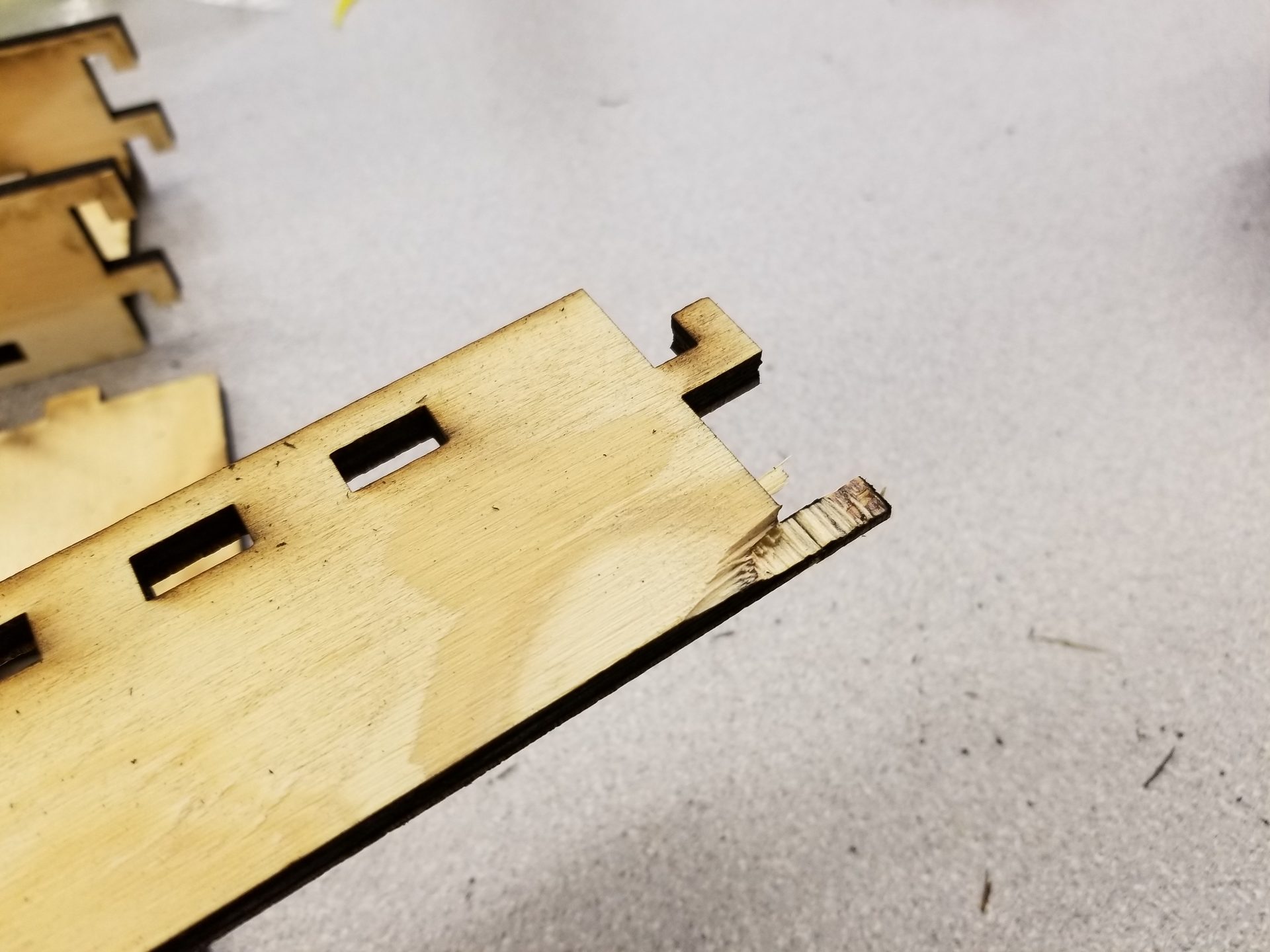

The crappy wood and pieces getting stuck resulted in a sad ending for one of the front/back panels:

I already knew the hooks were a weak point, and apparently this is kind of common. Oh well - there’s more scap wood, and this is kind of a prototype anyway.

At this point, I ran out of time in Project Night, and they didn’t let us use the laser cutters on our own late at night. Until I can get back to the laser cutters, I’ve got a few sooty parts that will hopefully one day clear out cabinet space in my kitchen.

Eventually I returned and finished cutting my pieces and took it home to assemble. It end up being a pain to fit all those tiny parts together, requiring a rubber mallet borrowed from my roommate. It’s not the prettiest spice rack, but it’s getting the job done. The biggest problem: I still have too many spices to fit them all in the rack.