3D printing and scanning

The group assigment was to test design rules for the 3D printer. We had our text file printed with the Eden260vs and were pretty much impressed with the resolution, sharp angles, and precision of the machine.

This week's individual assignment was to test the design rules of our 3D printer, design and print an object that cannot be made subtractively, and 3D scan an object.

I've never tried out 3D printing before, and I'm excited about the possibilities it offers. As part of the CBA shop, we could use the Sindoh 3DWox, a pretty accessible printer, which works with diverse filaments such as PLA, ABS, ASA, PETG, among others; we had also access to the Eden260vs as well as to the Dimension, which are more robust machines intended to operate on an industrial scale. Since we had the possibility to experiment the different results the printers produce, I decided to try two of them, the Sindoh and the Eden.

For the selection of the object to be printed, I couldn't yet image something related to my final project. Therefore, I decided to design objects that would in a way be an experiment of the possibilities of 3d printing organic shapes, besides being convenient objects for my daily use.

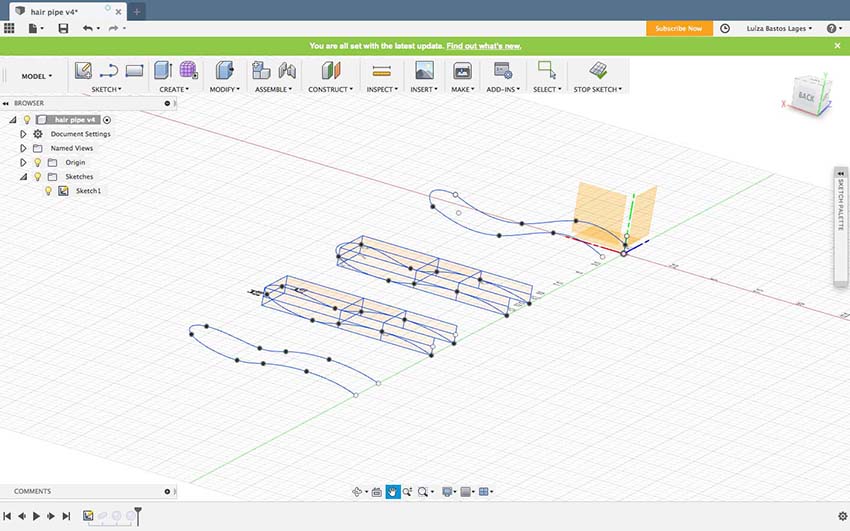

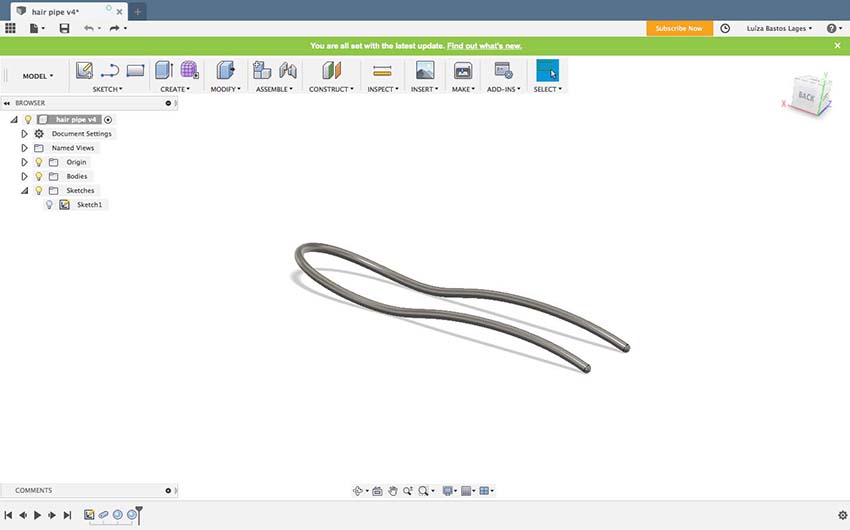

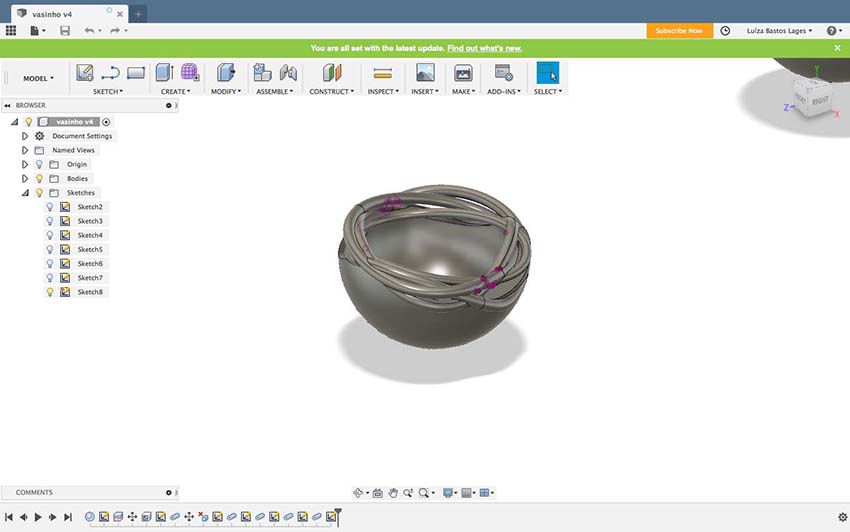

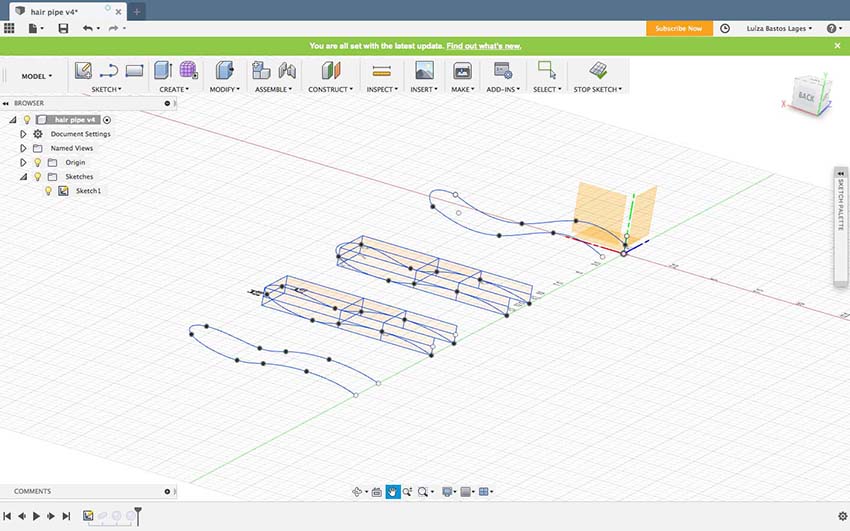

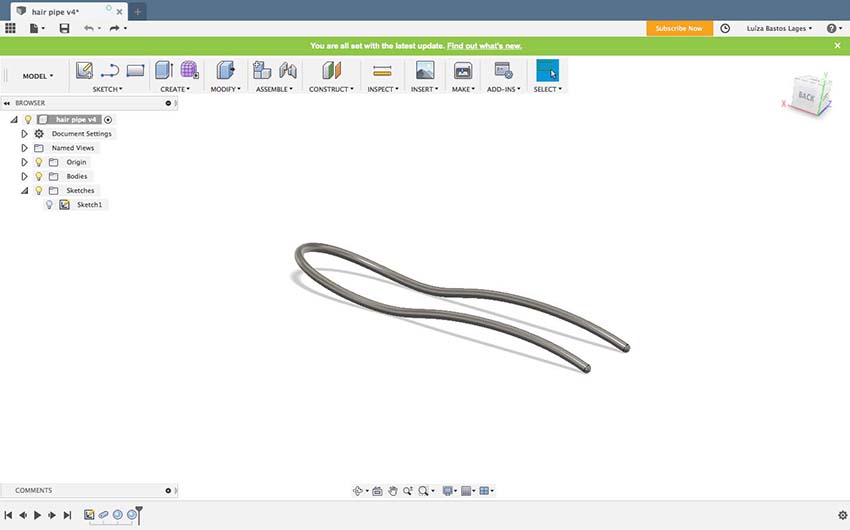

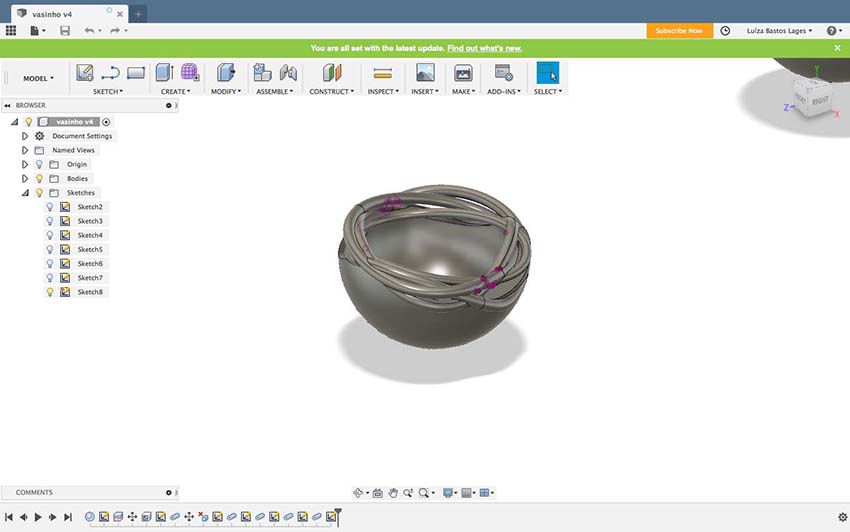

Regarding the Sindoh 3Dwox, I was interested in experimenting how much the machine could print organically entangled forms while regarding the Eden260vs, I was more curious to experience the quality of the finishing and the effect of the translucent material. So, I designed two different objects, using fusion 360. The first one can be used as a hair clip, and the second one - which would also be awesome printed in the translucent material, if I have the chance - was initially thought as a candle holder.

With the help of John and Tom the process of 3d printing was smooth and everything worked well. However, since we wanted to optimaze the space in the machine so that all students could use it, the candle holder printed in the Sindoh 3Dwox was reduced two times in scale, so even before I had it done I new it would not work as I imagined it to.

The candle holder endep up being so small that it completely lost its initial function and the entangled tubes just did not came out with a good finishing. It was quite hard to remove the support material from the vacant space in between the tubes and after doing so they just keep this rough texture.

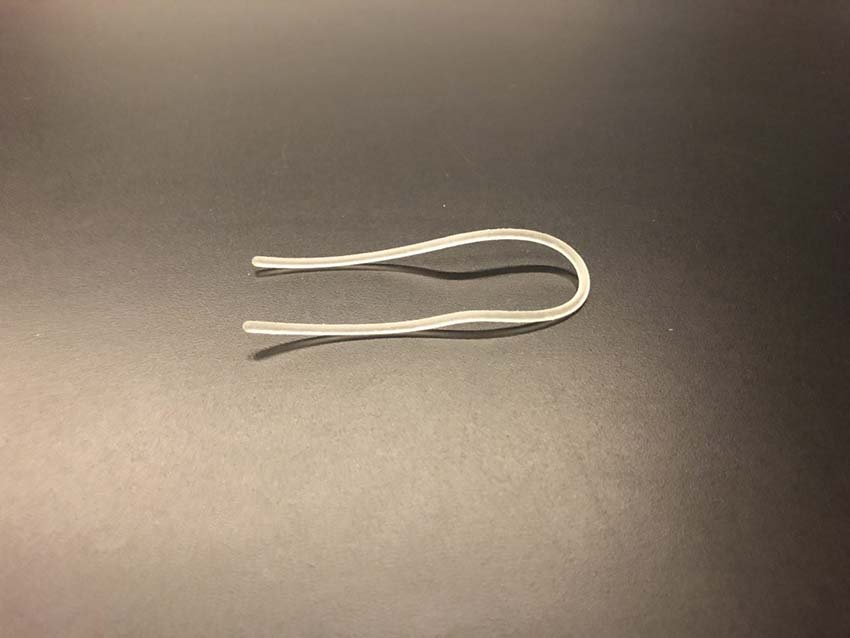

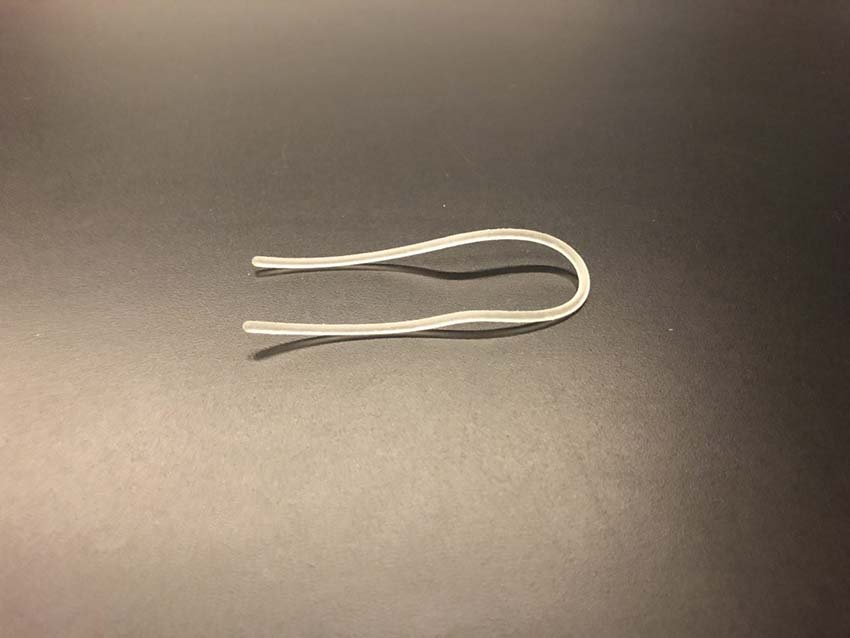

The hair clip was printed in the Eden260vs, which is a printer with a much better quality and resolution. Since my design was a pretty simple tube performing some curves, I did not have unexpected surpreses with this one. However, I have tried it on my hair before photographing it for documentation, and since the material is flexibel it bent a bit. So the following photos are do not show how it came out of the machine, precisely as I draw it.

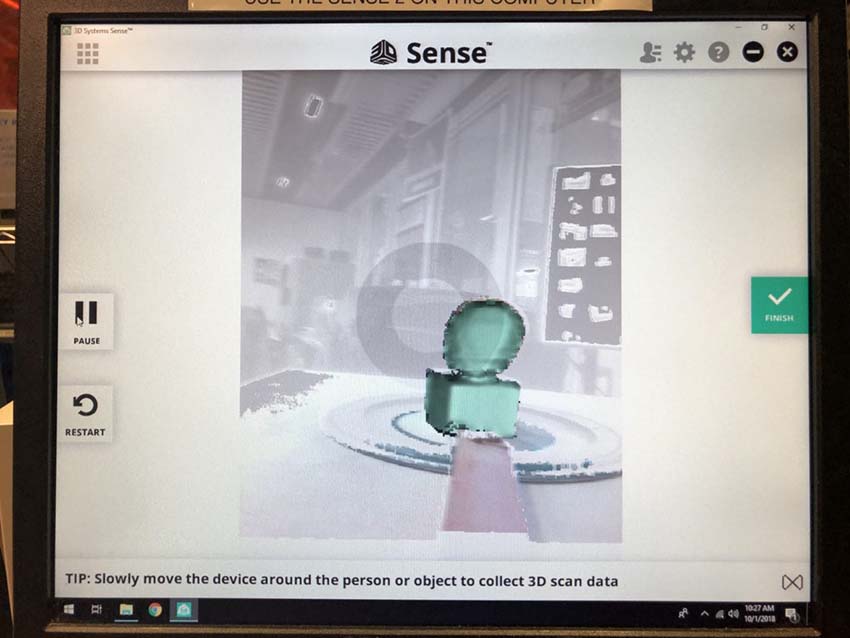

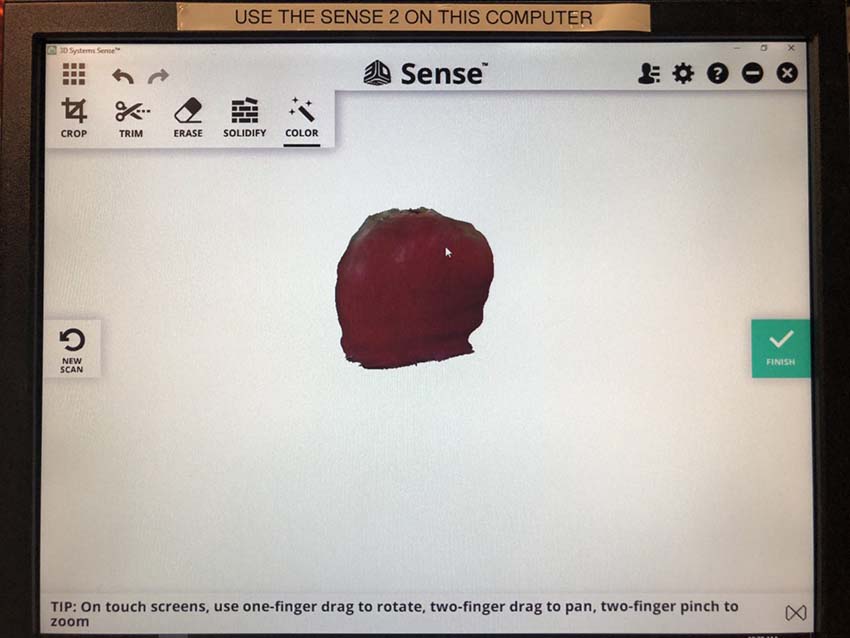

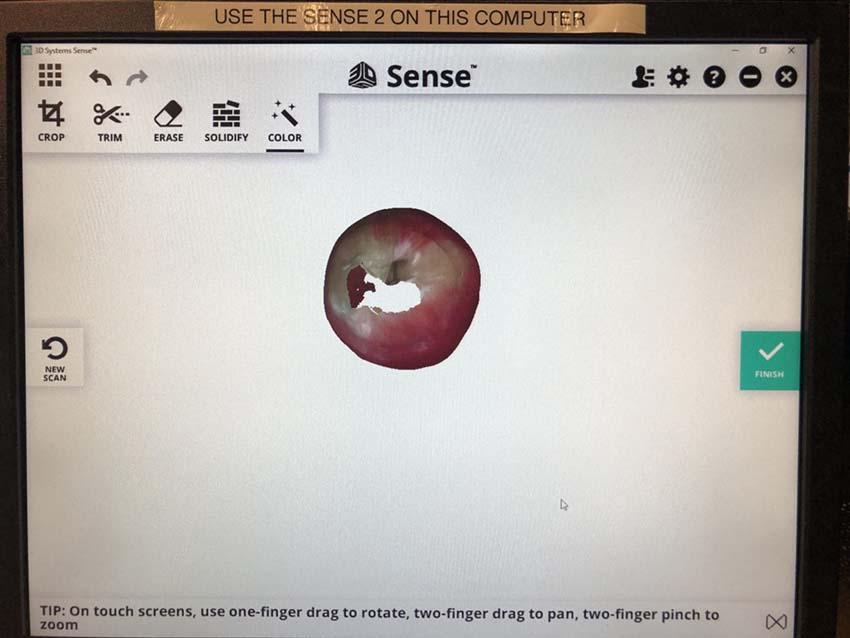

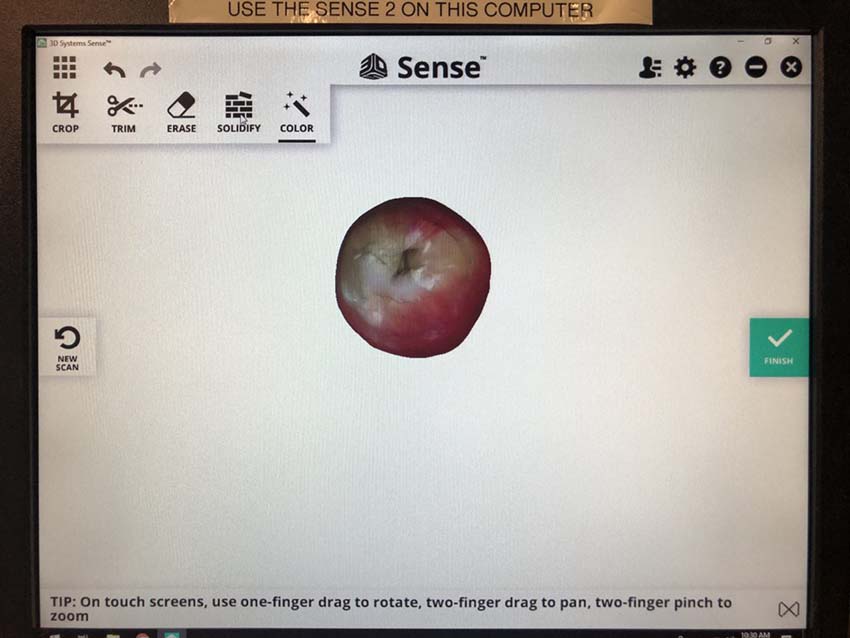

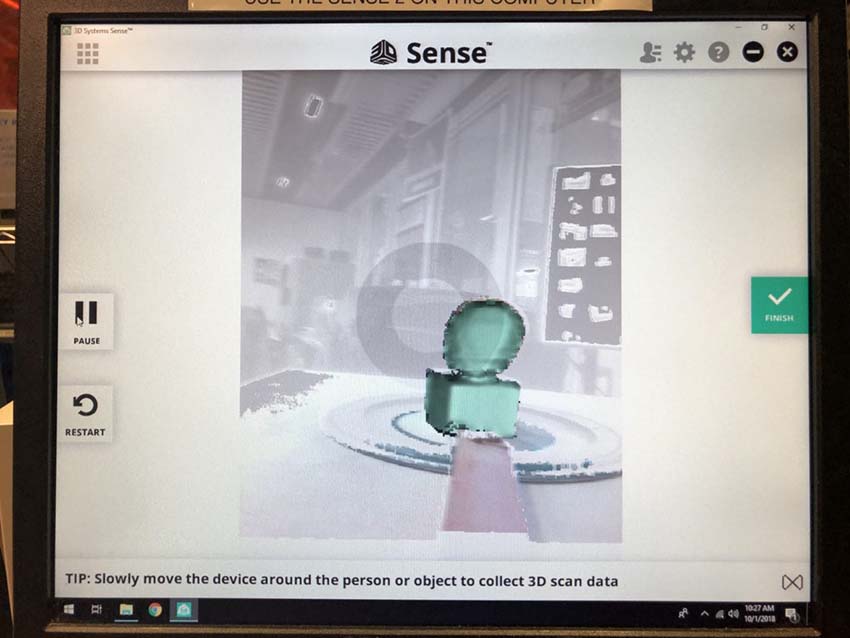

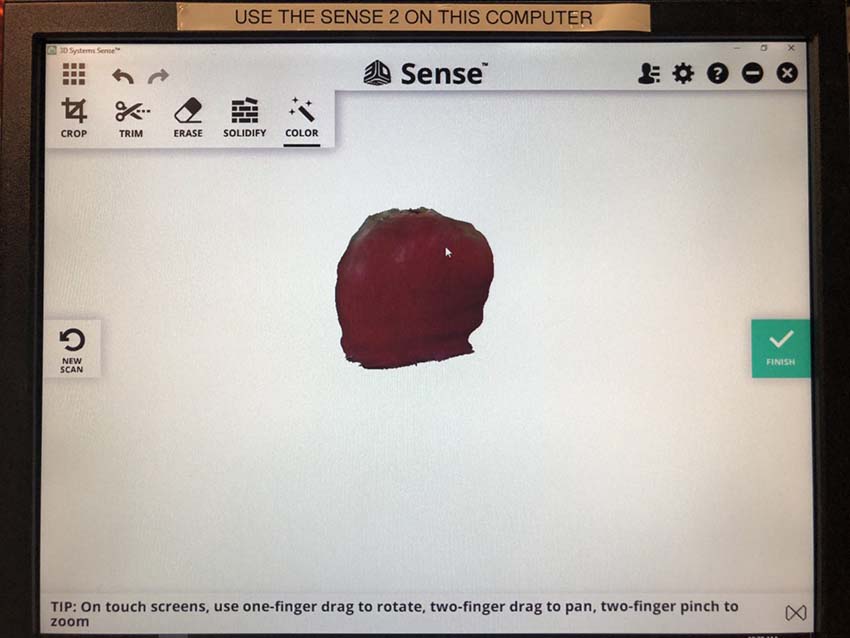

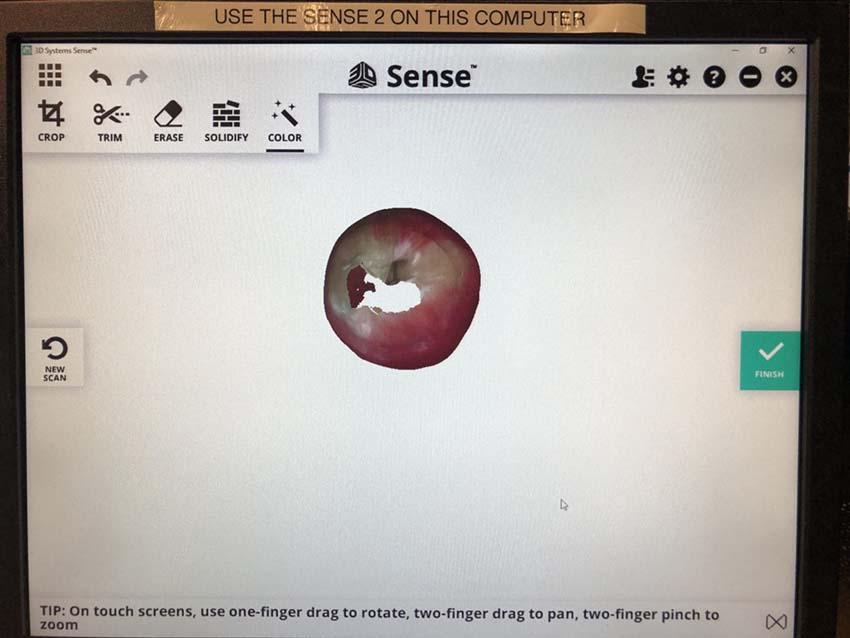

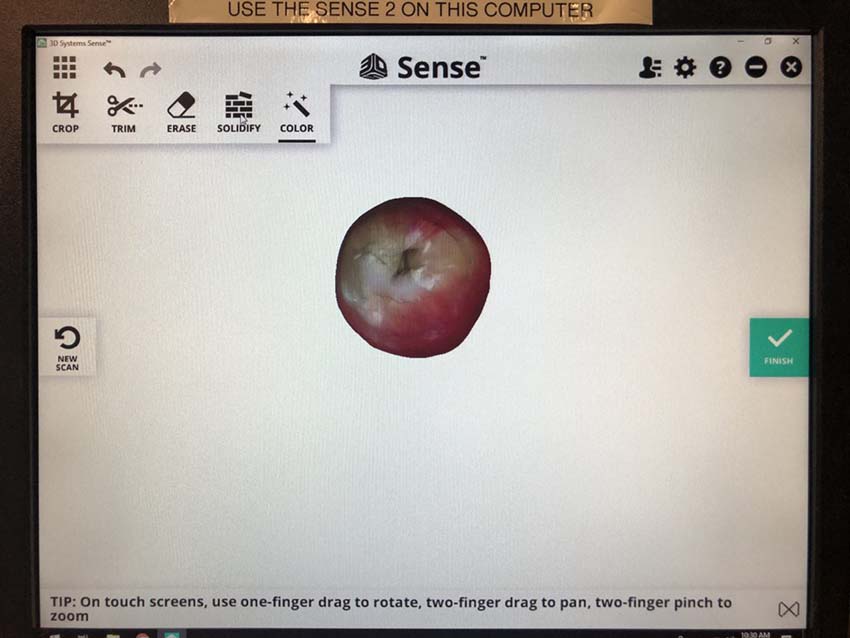

For 3D scanning, I attempted to use the Sense 3D scanner. This machine is a great possibility for having a quick (almost instantaneous) visualization and communication of an object or product. It works very easy and fast and has interesting features to edit the scanned object. However, for such a fast process, as expected, the quality of the final model is not really good, so it might be proper for very specific purposes as a fast visualization or for further editing in other 3d modeling software.

The group assigment was to test design rules for the 3D printer. We had our text file printed with the Eden260vs and were pretty much impressed with the resolution, sharp angles, and precision of the machine.

This week's individual assignment was to test the design rules of our 3D printer, design and print an object that cannot be made subtractively, and 3D scan an object.

I've never tried out 3D printing before, and I'm excited about the possibilities it offers. As part of the CBA shop, we could use the Sindoh 3DWox, a pretty accessible printer, which works with diverse filaments such as PLA, ABS, ASA, PETG, among others; we had also access to the Eden260vs as well as to the Dimension, which are more robust machines intended to operate on an industrial scale. Since we had the possibility to experiment the different results the printers produce, I decided to try two of them, the Sindoh and the Eden.

For the selection of the object to be printed, I couldn't yet image something related to my final project. Therefore, I decided to design objects that would in a way be an experiment of the possibilities of 3d printing organic shapes, besides being convenient objects for my daily use.

Regarding the Sindoh 3Dwox, I was interested in experimenting how much the machine could print organically entangled forms while regarding the Eden260vs, I was more curious to experience the quality of the finishing and the effect of the translucent material. So, I designed two different objects, using fusion 360. The first one can be used as a hair clip, and the second one - which would also be awesome printed in the translucent material, if I have the chance - was initially thought as a candle holder.

With the help of John and Tom the process of 3d printing was smooth and everything worked well. However, since we wanted to optimaze the space in the machine so that all students could use it, the candle holder printed in the Sindoh 3Dwox was reduced two times in scale, so even before I had it done I new it would not work as I imagined it to.

The candle holder endep up being so small that it completely lost its initial function and the entangled tubes just did not came out with a good finishing. It was quite hard to remove the support material from the vacant space in between the tubes and after doing so they just keep this rough texture.

The hair clip was printed in the Eden260vs, which is a printer with a much better quality and resolution. Since my design was a pretty simple tube performing some curves, I did not have unexpected surpreses with this one. However, I have tried it on my hair before photographing it for documentation, and since the material is flexibel it bent a bit. So the following photos are do not show how it came out of the machine, precisely as I draw it.

For 3D scanning, I attempted to use the Sense 3D scanner. This machine is a great possibility for having a quick (almost instantaneous) visualization and communication of an object or product. It works very easy and fast and has interesting features to edit the scanned object. However, for such a fast process, as expected, the quality of the final model is not really good, so it might be proper for very specific purposes as a fast visualization or for further editing in other 3d modeling software.