background

group assignment:

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

individual assignment:

design a 3D mold around the stock and tooling that you'll be using,

mill it, and use it to cast parts

"the glory is fallen out of

the sky the last immortal

leaf

is dead and the gold

year

a formal spasm

in the

dust

this is the passing of all shining things..."

ee cummings

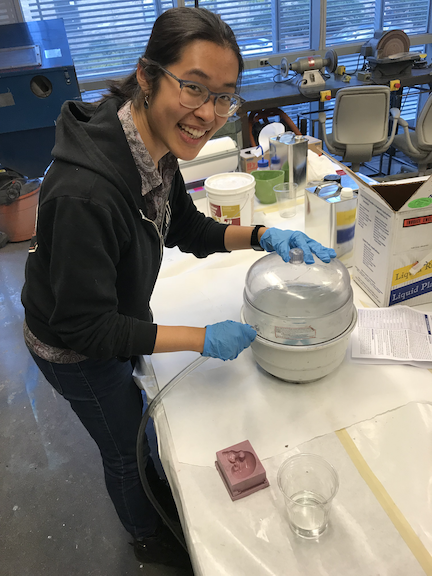

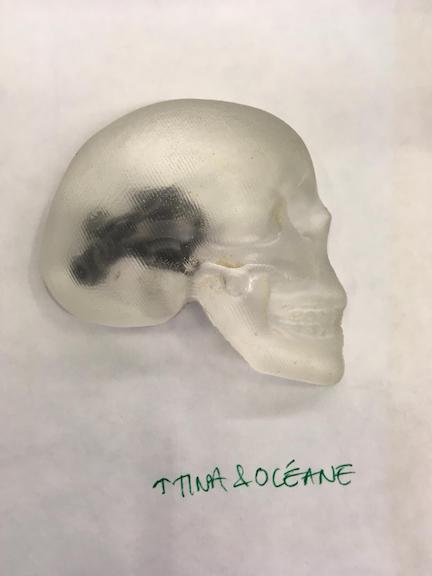

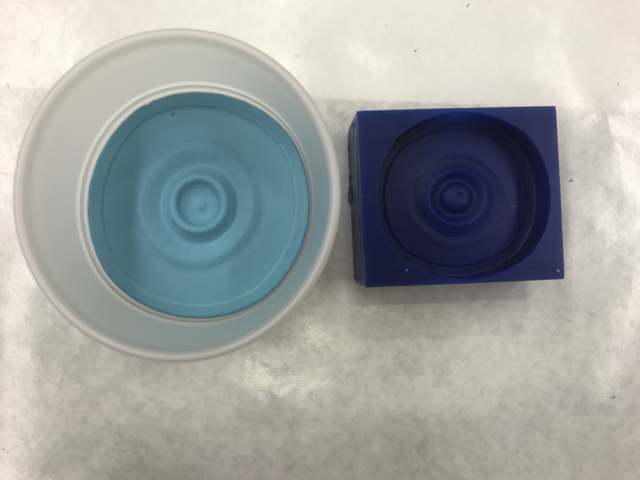

testing casting materials & molds

Tina and i were looking forward to experimenting with materials we had yet to use. SmoothOn Epoxy 202 was a fun place to start. we were so dern excited, that we forgot to read the saftey guides.

notably, "Crystal Clear™ 202 is intended for casting in thin sections. Developed for casting thicknesses of no more than ½" was a guide we missed. regardless, our pieces came out a-ok.

time to begin machining! this week I wanted to capture fall (this is my first fall and it is simply magleafique). since i'm running out of pages to store them in my journal, it's time to lock one of these leaves in an O2-less environment as a leafsake.

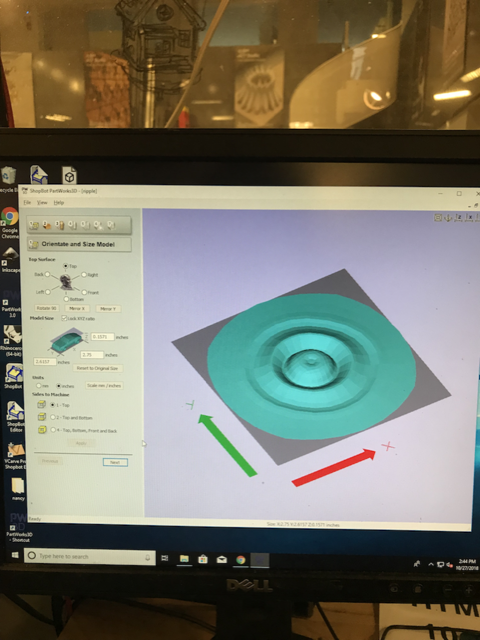

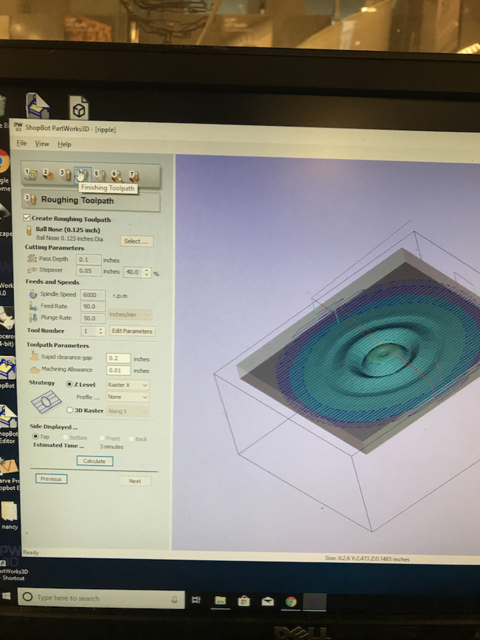

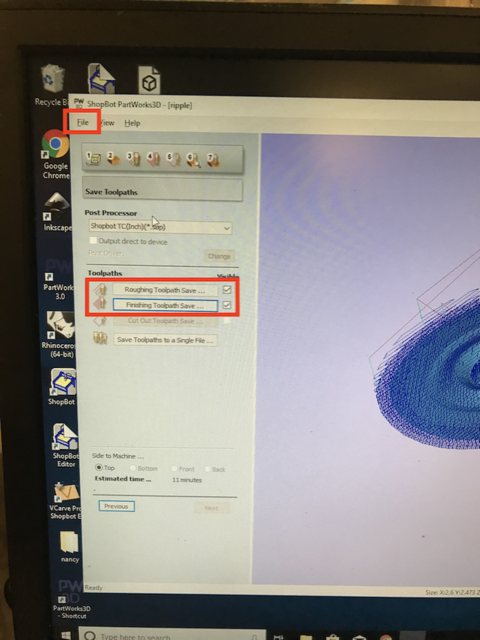

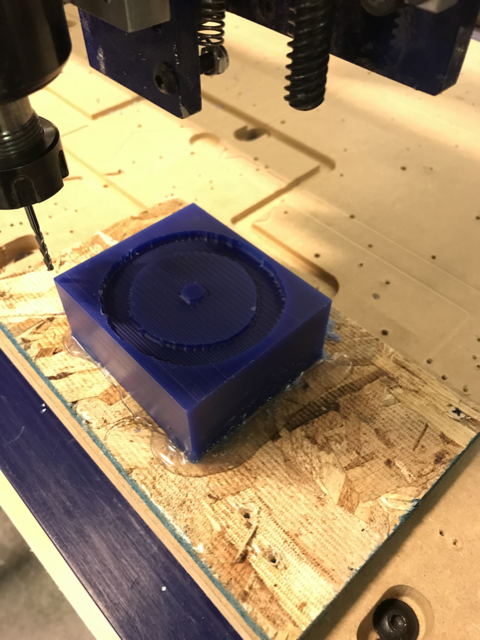

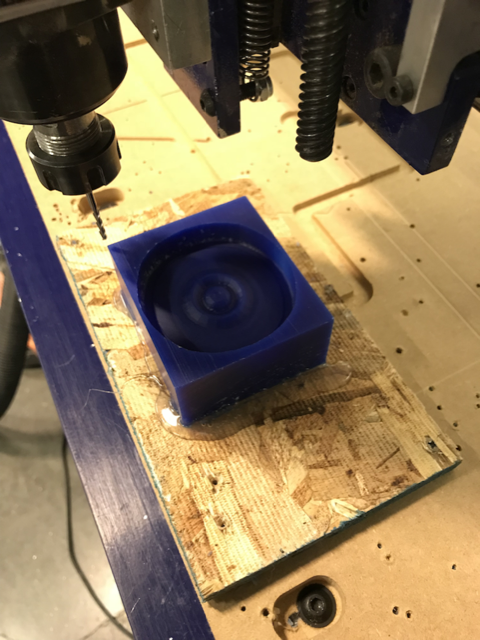

mold machining

3D Model Docs

off to the ShopBot3 we go...

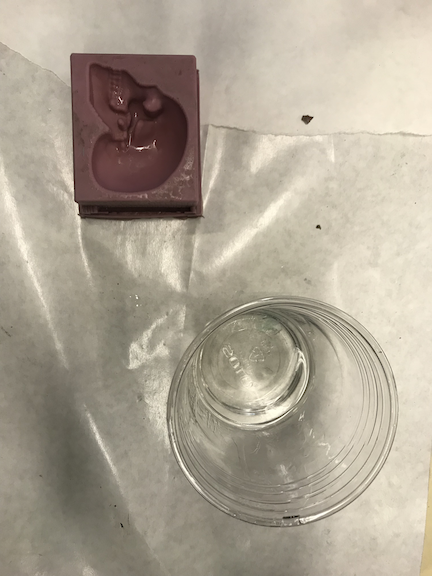

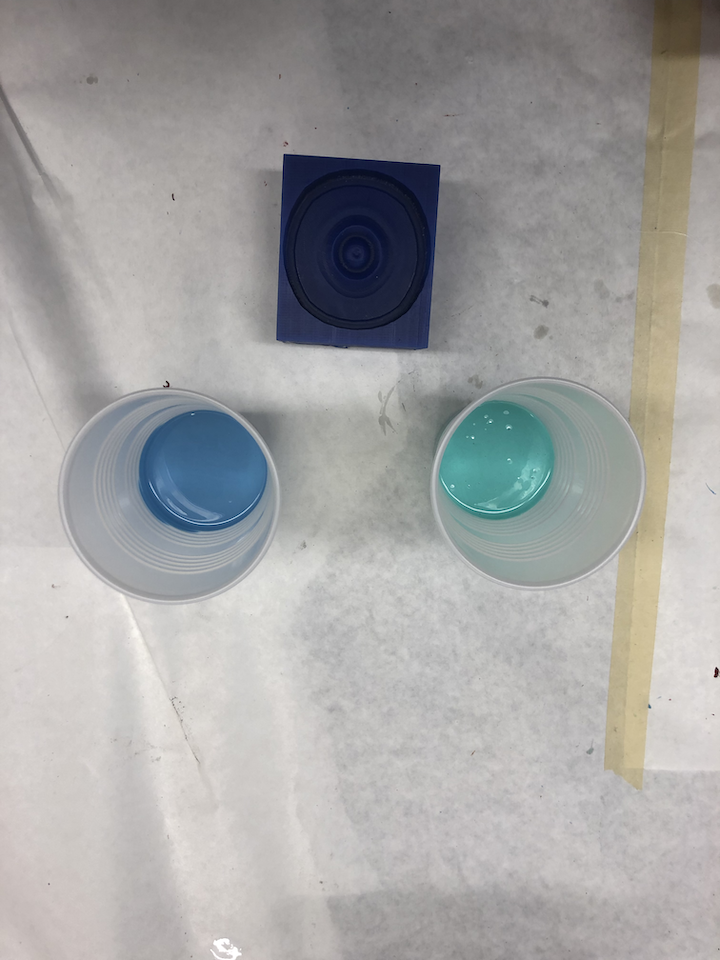

mold casting

mix mix mix

after about 2ish hours it should be ready. since my mold was very shallow, it was probably finished curing after an hour or so.

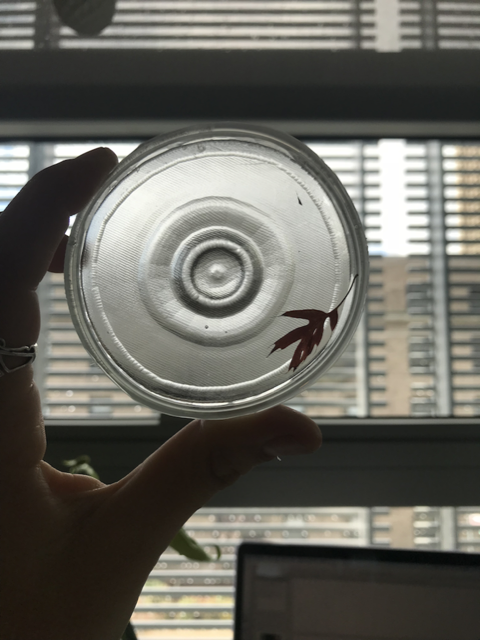

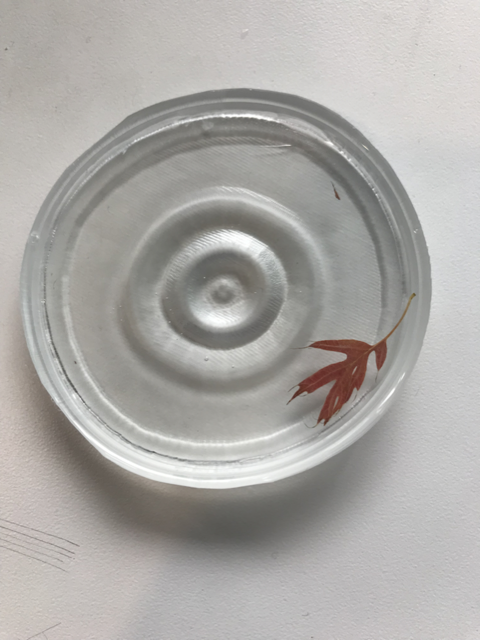

resin casting

placing the leaf inside the resin in the cup (note to future self: wear gloves). a few hours later and voilà...