avr isp programmer board

This week, we learned how to mill a trace and solder the appropriate components given the layout. We each applied these skills to create a AVR ISP Programmer board. Upon the class staff’s recommendation, I followed Brian’s awesome documentation which contain the files for milling and the schematic and layout for soldering.

Tools:

- Roland MDX-20 Mill

- Double-sided tape

- Sacrifical board

- Isopropanol (for cleaning off our oils that oxidize the copper)

Materials:

- 1x Milled board

- 1x ATtiny45 or ATtiny85

- 2x 1kΩ resistors

- 2x 499Ω resistors

- 2x 49Ω resistors

- 2x 3.3v zener diodes

- 1x red LED

- 1x green LED

- 1x 100nF capacitor

- 1x 2x3 pin header

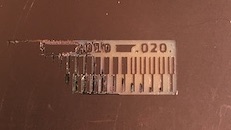

Milling

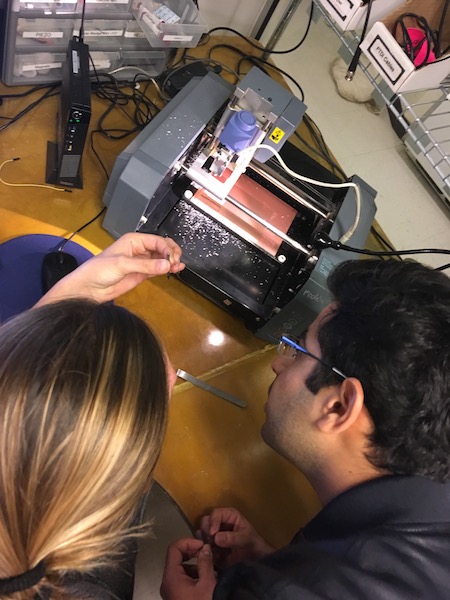

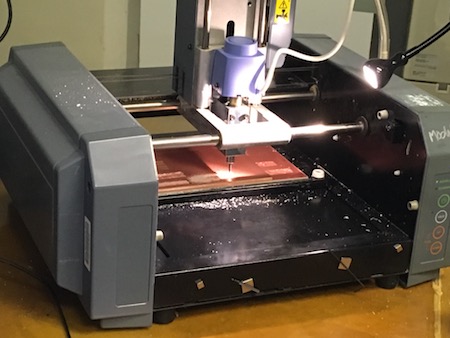

We used the Roland MDX-20 with a 1/64” endmill to mill the trace and a 1/32” endmill to mill the board. Our adventure began with training from Tomas and was continued with a group of us (Nicole, Oceane, Ravi, Caro, Erik and me) characterizing the 1/64” endmill.

Setup

- Double-sided tape a sacrificial layer flat onto the bottom of the mill

- Double-sided tape the sheet you will mill onto the sacrificial layer.

Setting up the Mill

- Turn off “view” mode.

- Make sure you put in the proper endmill. Be careful not to let the endmill drop and break. The tip of the endmill needs to touch the material (which should be lying flat)

- Lower the head of the machine such that it has the range of motion to cut as deep as is needed (the max depth parameter passed to the machine).

- Once the bit has been loaded and the z-axis has been manually set, we can move to the software.

It’s important to mill the traces before the outline because milling the outline could result in a loose part that could then wreck the sacrifical layer.

Using the Mill

- Upload the traces file

- Set the x,y origin from which to start the job. The x,y coordinate is deterministic and consistent per use of the machine.

- Calculate the toolpath given the settings (below).

- Ensure that there is a serial connection between the computer and the mill (so that the job information can be sent).

- Send the job over!

Mill Traces Settings

- tool diameter (in): 0.0156 = 1/64”

- cut depth (in): 0.004

- max depth (in): 0.004

- offset number: 4

Note: the offset number corresponds to how many passes are made to increase the width of the trace.

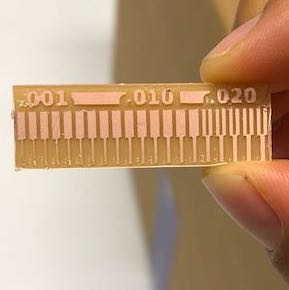

Mill Outline Settings

- tool diameter (in): 0.0312 = 1/32”

- cut depth (in): 0.024

- max depth (in): 0.072

- offset number: 1

Note: Since the max depth is 3 times the assigned cut depth, the mill will make 3 passes going .024 inches deep with each cut. This exists to prevent the endmill from breaking. The offset number is 1 because we only want to basically cut the pcb out from the plate. The cut doesn’t need to be wide.

Soldering

This was my first time soldering, and I didn’t realize how hard it was! Tomas (one of our TA’s) made it look so easy!

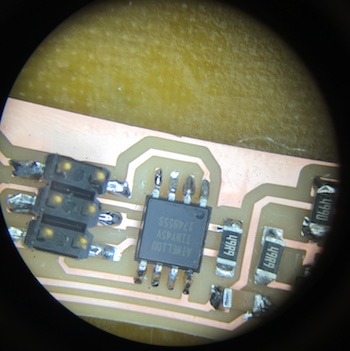

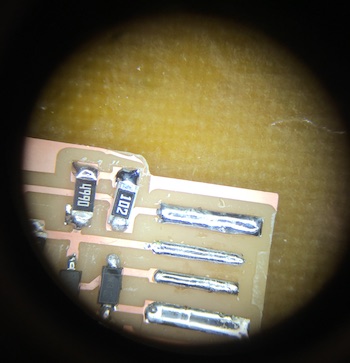

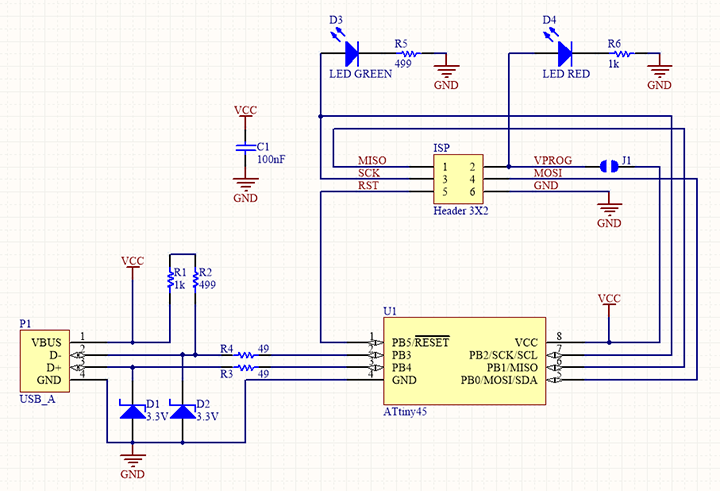

Anyway, I basically followed Brian’s advice and referenced the schematic and layout:

The layout tells you where to particular components go. The schematic is tells you information about the parts of the circuit and you can use it to figure out what it does.

Some things I learned:

- Let the solder flow. In the beginning, the solder would ball up and become a big glob and when I saw that happen I’d immediate move it away from the board instead of letting it flow.

- Clean the solder tip. It reduces the likelihood of globbing.

- Keep the board steady It’s hard to keep the board steady when both of your hands are in use. I used doublesided tape to keep the board in place, but I later learned there’s a clip to hold the board down.

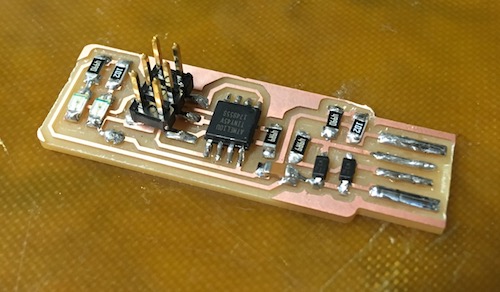

Here’s the final result!