Mechanical Machine Design

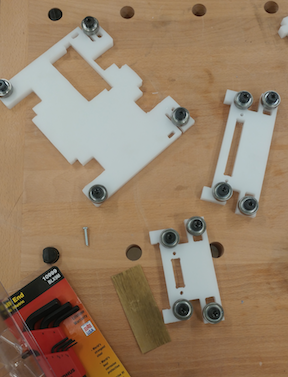

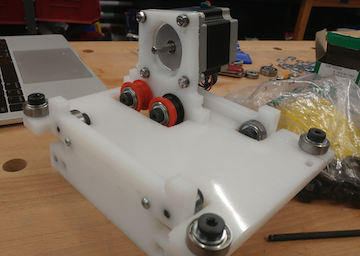

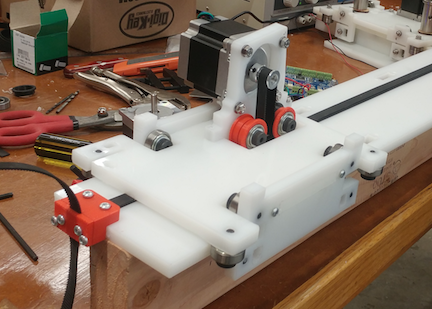

This week, the entire Harvard section collaborated on a machine that takes long-exposure and panoramic pictures. We divided the project into several stages and our section into several focus groups. As a member of the assembly team, I first helped build a gantry and track modeled after jake's, assembling acrylic parts with fasteners and tensioning the belt on the track. Many of the parts in this project are very specifically sized, and this initial assembly was fairly tim-consuming and involved a lot of consultation of Jake's diagrams and instructions. We found that the lateral bearings meant to guide the gantry down the track bound too tightly with the lower portion of the "I" shape of the track, so we ended up mounting the top acrylic board on a milled 2x4. We used the table saw in the GSD woodshop to rip-cut the rail to an acceptable width. With the guidance of the design team, who gave us their specifications for the camera mount, we designed a way to house the camera and rotational module on top of the lateral-axis gantry so that weight would be well-distributed. The camera housing was slightly longer than the surface of the gantry so it extends off the edge slightly, but is otherwise as stable as possible.

see our final project website