This week we learned how to use our first machine - the laser cutter. All prototyping this week was done in cardboard, but this machine is capable of cutting plastics, resins, and even plywood. Our assignment was to make a press-fit construction kit. At first I thought that press-fit furniture would be fun to design, but quickly ran up against the limitations of my extremely basic knowledge of Rhino. I decided to go with a set of simple interlocking shapes that could be used like building blocks to build ... well, almost anything.

As a group, Lins, Nicole and I worked on testing different kerf sizes, hoping to find the tightest fit that didn’t deform the material. I ended up using a kerf size of 3.6mm in my pieces. The GSD cutters post suggested speed and power settings for thin balsa wood - I found that these worked fine for cutting cardboard.

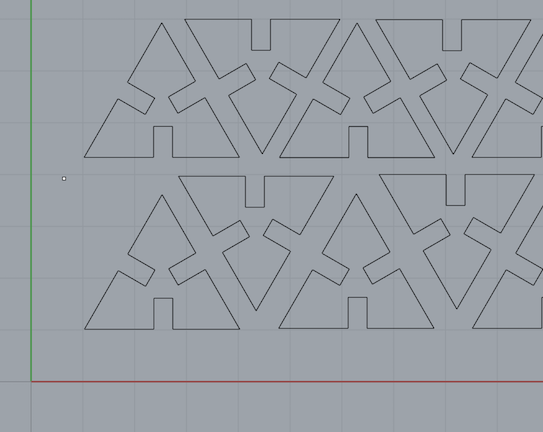

I created an array of triangles with properly sized kerf cutouts in Rhino but did not get to cut it this week. I felt really overwhelmed trying to learn an entirely unfamiliar CAD software, and by the time I figured out how to make basic parametric shapes it was already Tuesday night. I hope to return to the laser cutter to finish this project.

I returned to Rhino modeling to design the shelf I made during Make Something Big Week, and furthered my knowledge of the software. I also returned to the laser cutter to make an acrylic box for my final project. This went smoothly thanks to generous help from GSD TAs.