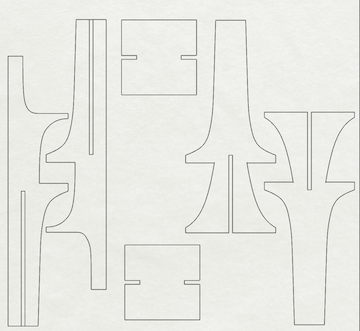

This week our assignment was to make something big - an assignment I felt really confident about because of my background in furniture making. I knew that my ability to design in CAD would be a limiting factor here. I decided to make a small shelf using one piece of 4'x4' OSB to test the design before cutting a full-sized piece. I made a simple interlocking design that I'd had in mind for some time, in which the shelf's vertical rails are cut away to provide support for the shelves.

Two flat vertical supports interlock at right angles; shelves with slots cut into their sides fit halfway across the support. Our CAD design was to be exported as a .dxf file and translated into a toolpath on a shop computer. After making this translation, I added tabs to secure the cut pieces in their places until we were ready to move them. I also added screw holes with which to secure the 4'x4' board to the sacraficial layer of the ShopBot. Rob and I laid a fresh board onto the bed of the shopbot, installed its cutting head, and zeroed its coordinates at the board's corner. We cut the screw holes and installed screws to secure the piece. The first time we ran the cut file, a piece came loose before the tool's final (tab) pass, and we paused the cut. We realized that the board was cupped towards the middle. Rob installed an extra screw along the inside edge of this first piece. This closed a noticeable gat between board and bed, but unfortunately proved to be in the toolpath when we resumed cutting. This required us to install a new endmill before proceeding. The remaining pieces stayed securely in place until I cut through the tabs with a mat knife.

I realized that the first cut piece, which we'd removed from the cutting bed, had been scrapped while I was cutting the rest of the design, so I reassembled it with screws and tape. This shelf was meant as a prototype rather than a functional design, and, as I soon realized, this wasn't the limiting flaw of this run.

As soon as I'd fit the pieces of my shelf together I noticed a huge flaw in my design - in reducing the width of the shelves to fit on the 4'x4' board, I'd made them too short to accommodate the 5" extensions on the vertical supports. The shelf needs 2" on either side to fit around the supports plus 10" length across the span of the wider supports. When I make the full-sized shelf I will definitely change these proportions.

Unfortunate design oversight.