Working Towards a Distiller

Week 9: Throughout the semester there was nothing that came to me where I was like 'I have to make that'. I kept waiting to have the epiphany moment but I haven't, so I'm going back to my distillation idea and committing because the final project is getting close. Also, there can be a lot of very different componenents in a distiller/distilling system so I feel like it is a good tool to show my knowledge of different types of fabrication.

I am challenging myself (tbd if this is a stupid challenge) to not look at the design specs of pre-existing distillation devices for the time being. HTMAA is a time when you have the liberty to try something crazy like that. My thinking is that sometimes if you don't know pre-existing designs then you can sometimes come up with something better because you aren't stuck in tradition.

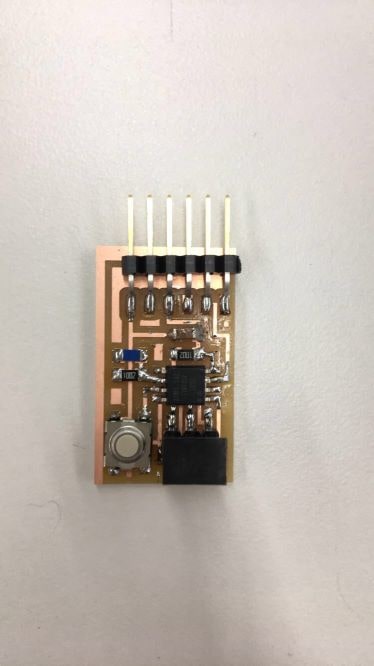

This week I built a temperature sensor that turns on when you press a button. This is for when the device is turned on (button) and I want to measure the temperature of the heating plate so it doesn't get too hot or also so I know if the water temperature isn't reaching boiling. There will be another separate circuit yet to be made that is like a thermoresister but for wetness sensing so the whole system turns off when there is no more water in the original chamber, similar to an electric kettle. Anyways, here is a photo of my temperature sensing circuit for this week.

Week 10: I had a lot of development this week and had a good talk with a fablab representative from (Brazil/Spain?). More pix and videos to come but here are 2 videos that inspired me- one is a diy heating element coil and the other is how to measure water levels with capacitance. The circuitry for this I'm realizing is going to be tricky, mostly because of safety. While I was messing around playing mad scientist with different distiller designs I burned myself more than a couple times and I soon realizd how careful I have to be with this project because I'm creating really hot stuff.

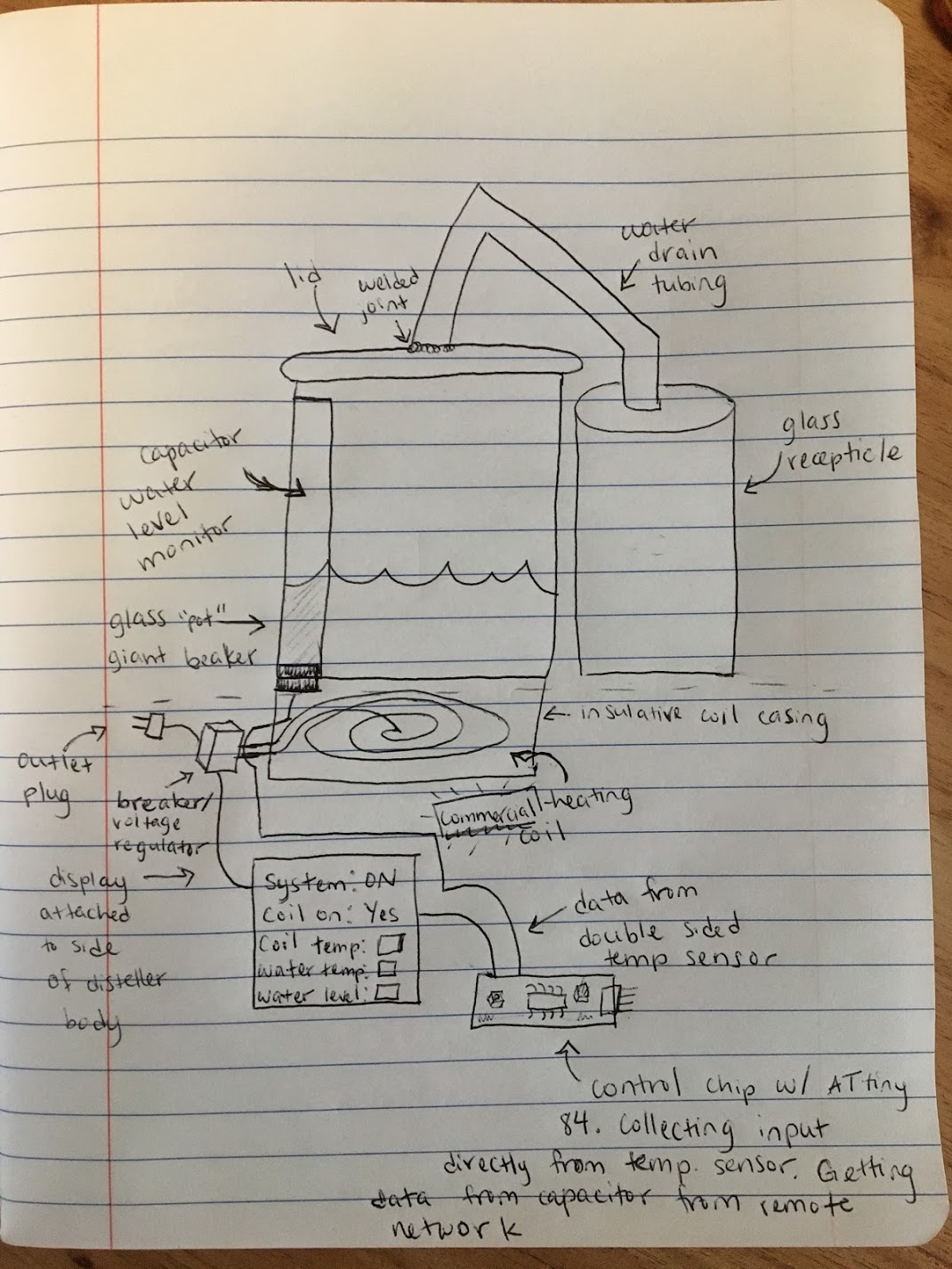

Week 12: Below is a diagram of what I'm thinking for the full distller. Also, I tried heating tape Rob gave me from the lab and almost burned my apartment down. I originally thought I might DIY the heating element but it's definitely commercial from here on out

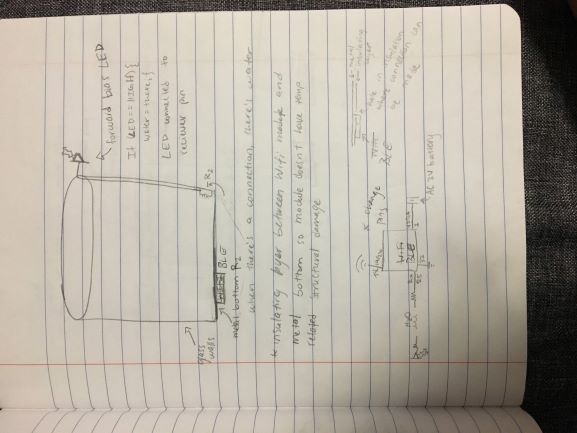

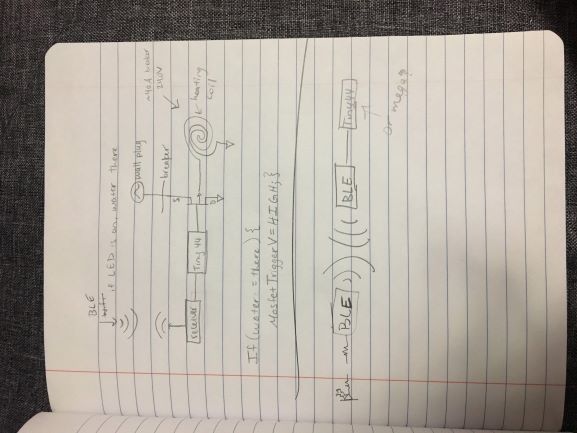

Week 13: Below is a drawn diagram on how the BLE system will work with the distiller. For a while I was thinking of making a water level sensor with a capacitor, but then I realized I dont actually need to know what the water level is, just if there is liquid or not. I decided I would put one resistor on the side of the container and one resistor on the bottom and when there is water, the circuit is connected and an LED lights up to let us know. When there isn't water, the circuit is broken. The bluetooth sensors will be constantly checking whether this micro-circuit is connected or not and relaying this so that the system knows when to turn off.