The Structure

For the structure I made the lid and the heat housing.

For the lid, I orignally had a cone, whose shape I had calculated to be good for funneling off the steam and it had holes for the water sensor leads. After two days and 6 failed 3D print attempts, I changed the design just in case being conular was the problem (it wasn't). I made it as simple and flat as possible so I could be sure to get something printed. If I'd had an extra week I would have loved to remake the cone. Also, I was able to get one layer of silicone sealant on the inside of the lid but had planned to do more. However, time was an issue and the sealant was the most acrid, horrible smell. I added a layer of Oomoo at the top of the lid as well as an extra precaution for insulation on the part where steam would be hitting directly. Below are photos are the desired conular design, the flat design, the inside of the lid with its insulation, and the lid in action

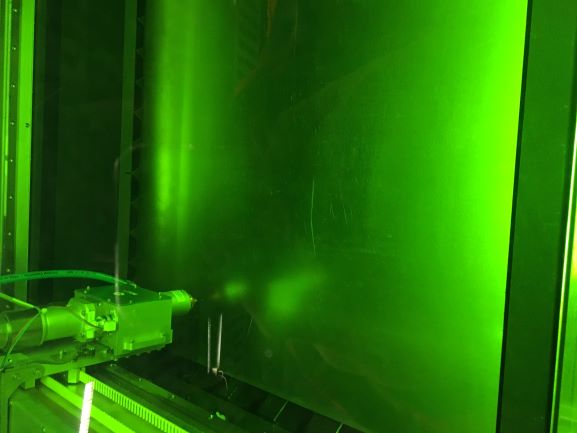

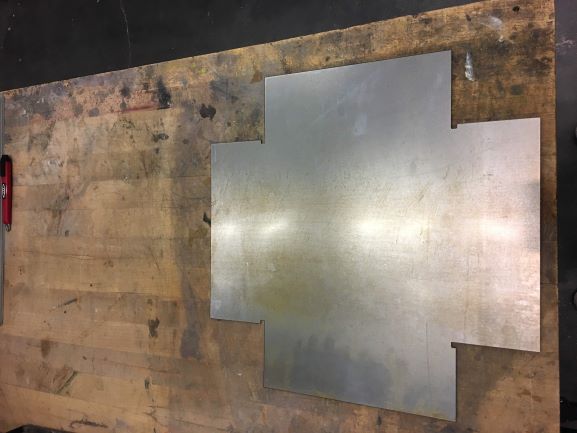

The heating element housing was originally made with this in mind. There were going to be little tabs for the heating element support to sit on and then it was going to be insulated. However, the heating element didn't come in until Monday and I didn't have time to finish everything else and also make sure the system safely worked with the coil burner. I ended up using the heat housing box as 'packaging' for the heat source I did use though. Here are photos of the fabrication and final product of the box.