Wildcard Week

Sheet Metal

I made the outer box that would house the heat elements of the distiller. Originally I had planned on making a smaller box that would be snug on the heating coil and adding more working outwards for insulation and covering. However, since I didn't have the actual heating element yet I made the outer box and will be working inwards. Below is a photo of the box.

We used the fablight machine which is basically a laser cutter for sheet metal. It's awesome. To use it you create a CAD file of what you want in 'sheet metal' mode. Then you export the DFX and open it with the fablight software, convert it to a .fab file and upload to the fablight cutter. It's really a spectacular device and I'm amazed that it was made in house.

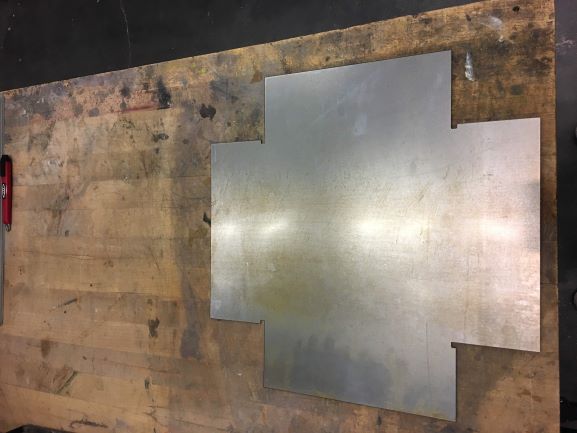

Below is a photo of the original cutout of the sheet metal

After cutting out the metal I went to the steel bender. There were some complicatons because of tabs that my CAD had automatically put in the design. Having never worked with sheet metal before though, I didn't know any better and figured the CAD program knew what it was doing. The tabs go in the way of bending a little so I had to remove some of the teeth from the bender. Also, sheet metal bending is an imprecise art. Because steel, and other metals are springy, you have to overbend a little, and I kind of had to just eyeball what I thought was right. It turned out fine though. Below is a photo of bending in progress.

After the bending was welding. I started out with MIG welding- I had the clamps in place to create perfect right angles, did my practice welds, everything. The video below explains more

After burning several holes through my box, even when I pressed the button for 1 second, I decided MIG is not the answer for my box in that moment. Sara very kindly offered to fill in my holes but Sam had metioned I could just cut some extra pieces of thin metal and spot weld the box together and I decided that was a safer route. Below is a photo in the process of covering up the holes and one of the final product

More to come on this box because now that the heating element is in I have to add tabs to the box to support it and I also have to add a cover to the top and an insulative layer on the bottom and sides so you can touch it while the distiller is in use.