Electronics0 Week03

how to make (almost) anything

Electronics Production

Week 03

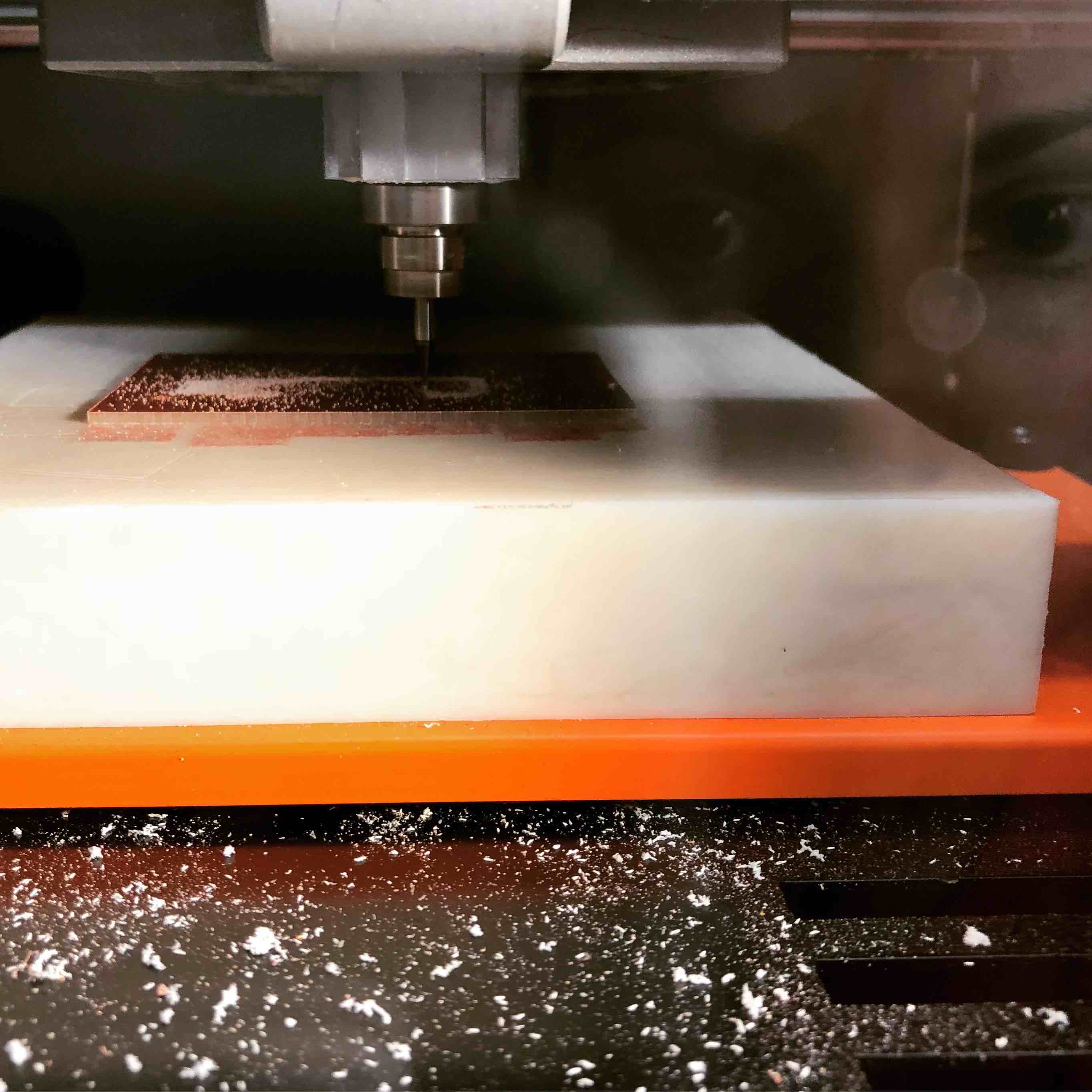

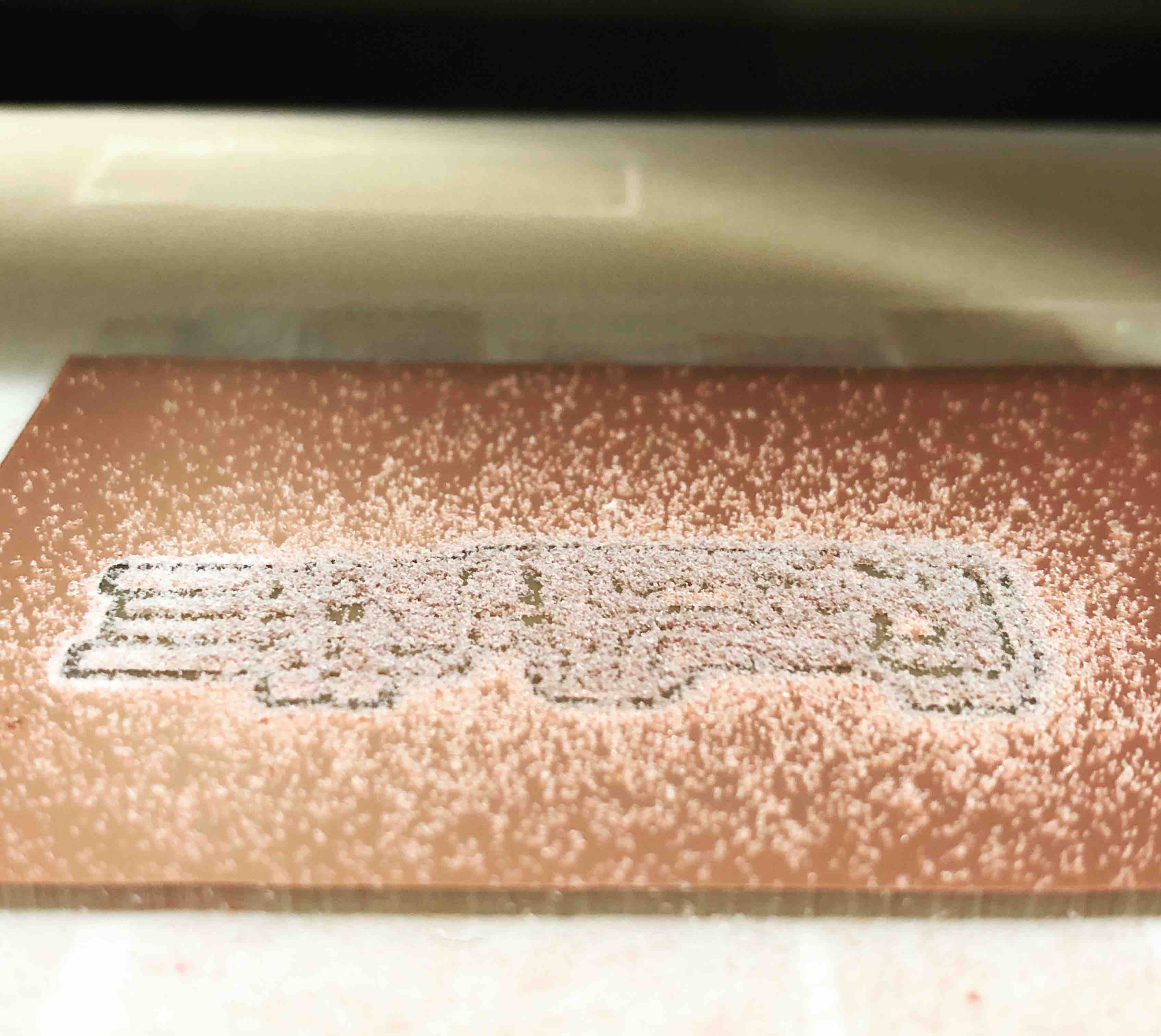

This week’s assignment was to make an in-circuit programmer by machine milling a printed circuit board (PCB) then soldering onto it electronic components.

The assignment was slightly less intimidating thanks to Brian, a former guru (TA) of How to Make (almost) Anything. For the milling of the PCB, I imported Brian’s .png files to the mods.cba.mit.edu roadmap for the SR20 mill. Then for the soldering, I followed Brian’s diagram that clearly laid out where each component went.

Brian’s manual: http://fab.cba.mit.edu/classes/863.16/doc/projects/ftsmin/index.html

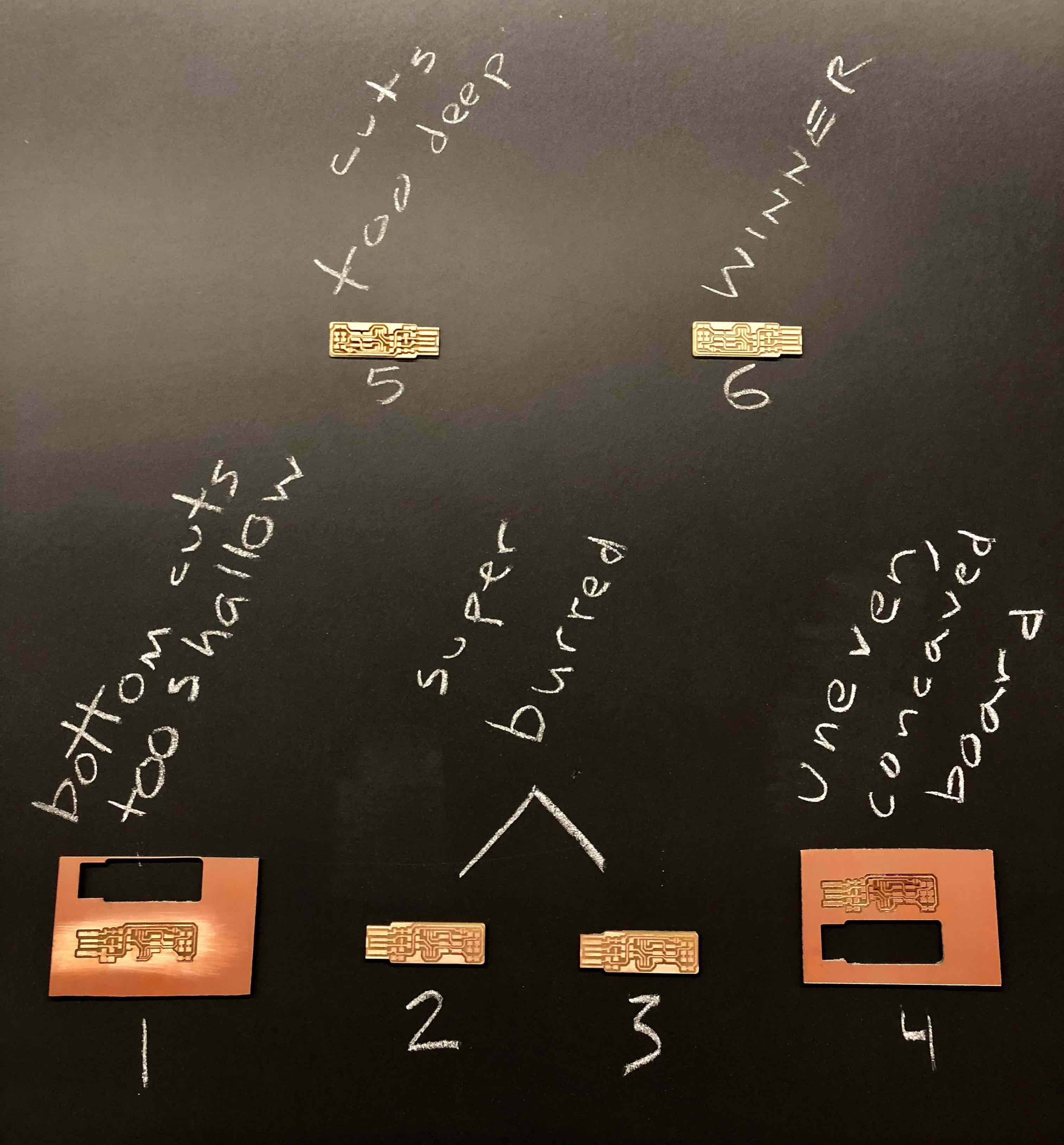

While I blazed through the milling of my first PCB immediately following the Harvard section on how to mill and solder, the next day when I returned to replicate the process, I was greatly held up. Between user-errors and technical difficulties, I spent several hours learning how to perfect the milling process. The following checklist emerged:

Firmly press down the board to prevent bowing; make sure the drilling bit, png file, and mods settings are all coordinated; when drilling bits die, replace them; adjust the cut depth and maximum cut depth incrementally.

Technique is useless without an accompanying intuition or sensitivity about how to situationally apply it. Learning to solder was learning to become a craftsman where technique and intuition are married in the maker’s hands.

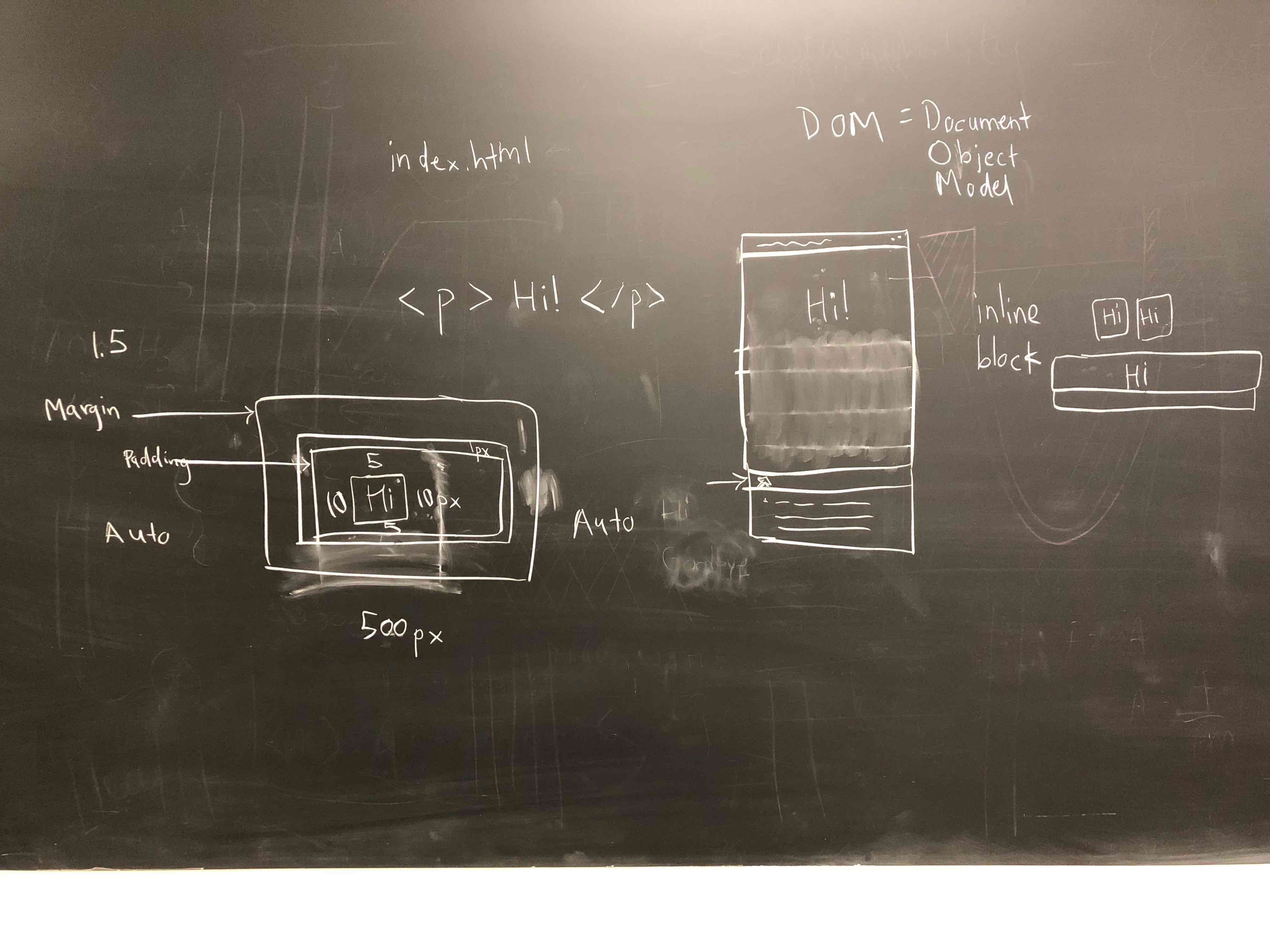

This course is all about karma management. Last week, I was indebted to Michelle for teaching me how to maneuver in Rhino. This week, I passed on a few milling and soldering nuggets to Jackson. The karmic circle immediately kept cycling when Jackson returned the gesture with teaching me a few things about HTML and CSS coding.