Chloe Nelson-Arzuaga

How to Make (Almost) Anything

Documenting my time trying to learn how to make (almost) anything

Foldable Shelter

Final Project

Foldable Shelter

For my Final Project I made a model of a shelter the size of a twin size bed that can fold into the size of a suitcase.

- Date Updated: 17 Febuary 2020

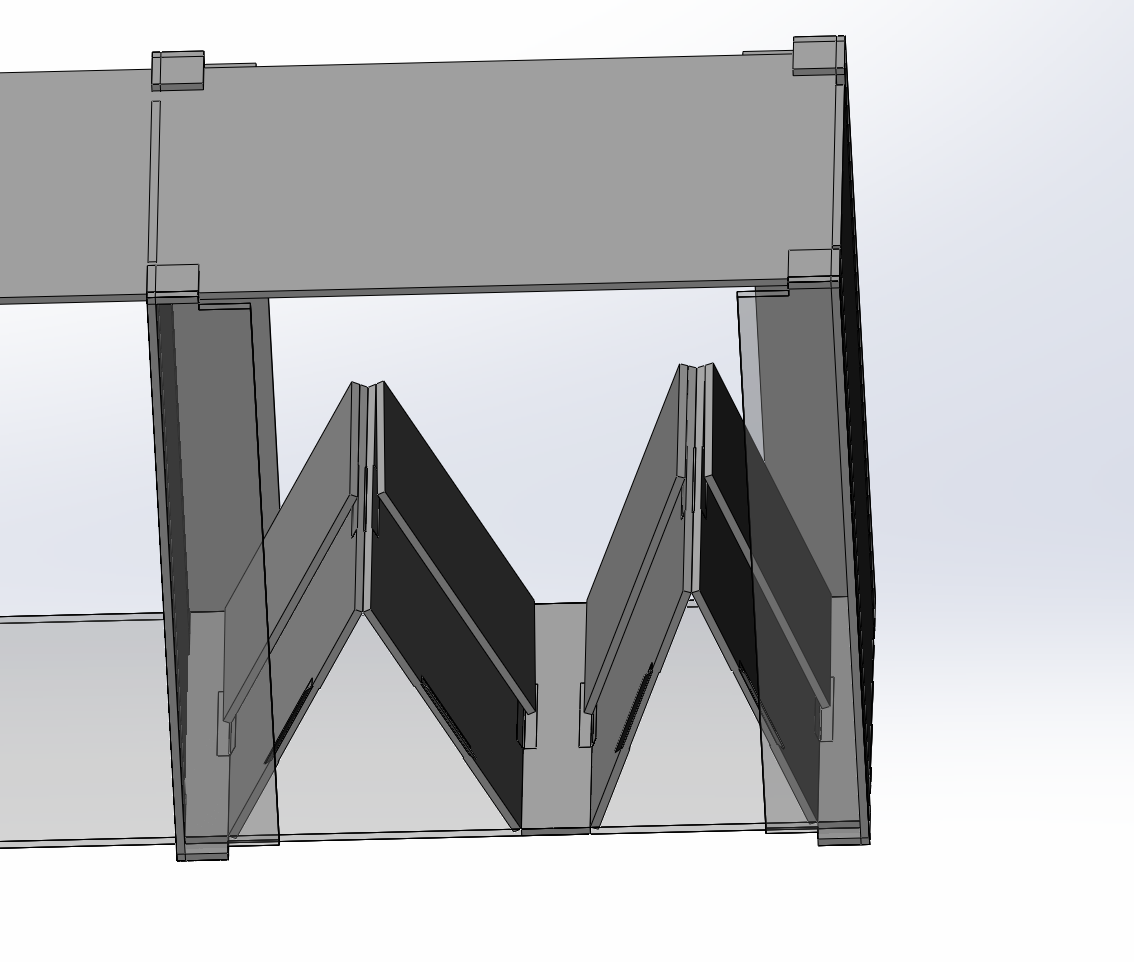

CAD Design

Week 1

Colapsable Shelter

This week our assignment was to start designing our final project. For my final project I decided to try and create a shelter that folded from the size of twin size bed into the size of a suitcase.

- Date Updated: 17 Febuary 2020

Computer Controlled Cutting

Week 2

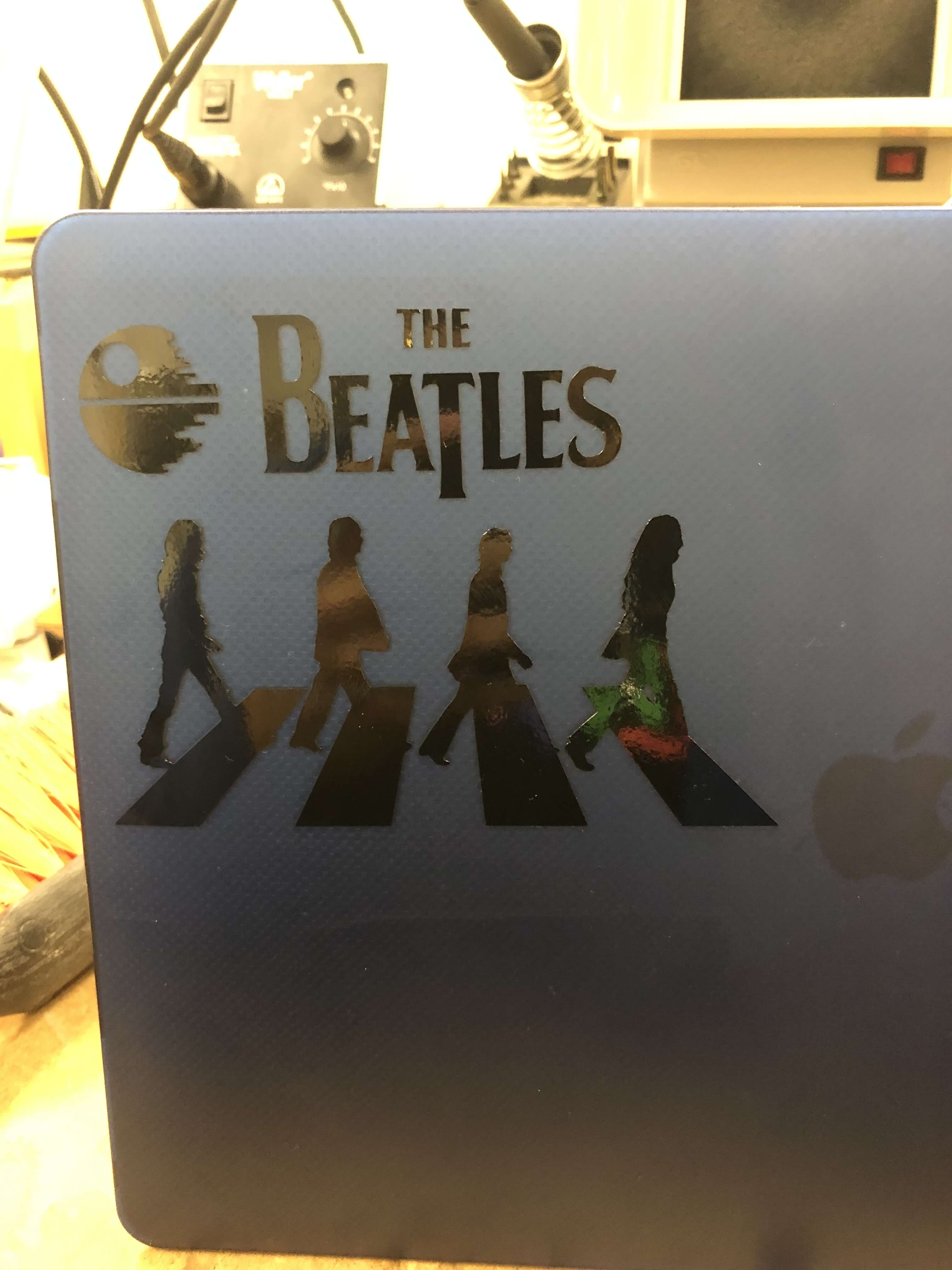

Creating a Laser Cut Tree and Vinyl Sticker

For this week we were tasked with making a laser cut construction kit and a viynl cut sticker.

- Date Updated: 17 Febuary 2020

Electronics Production

Week 3

Creating a programer

This week we were tasked with creating a programer and programming it ourselves.

- Date Updated: 17 Febuary 2020

3D Scanning and Printing

Week 4

Scanning and 3D printing chainmail

This week we were tasked with scannning an object and 3D printing something that could not be manufactured subtractivly. This was to learn about the advantages of additive (3D printing) processes.

- Date Updated: 17 Febuary 2020

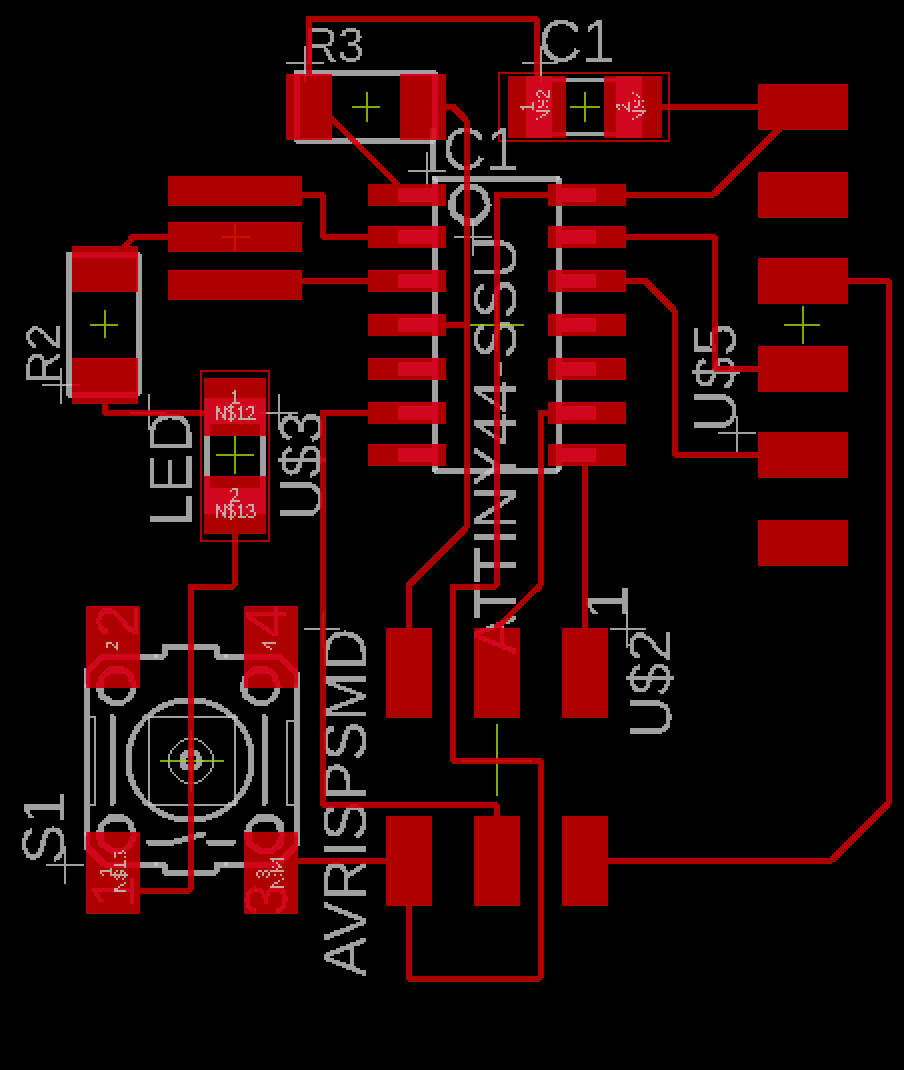

Electronics Design

Week 5

Creating a Hello World with LED and Button

This week we were tasked with recreating the Hello World Board and adding an LED and Button to it.

- Date Updated: 17 Febuary 2020

Computer Controlled Machining

Week 6

Creating a Foldable Shelter

This week we were tasked with making something big. I decided to try and make a foldable structure.

- Date Updated: 17 Febuary 2020

Embedded Programming

Week 7

Programming a Hello World with Button and LED

This week our assignment was to program our Hello World Board so that the Button togles the LED.

- Date Updated: 17 Febuary 2020

Molding and Casting

Week 8

Molding a Pumpkin and my Brass at

This week we were tasked with CNCing a mold and then using it to cast something. I decided in the spirit of Halloween to create a pumpkin.

- Date Updated: 17 Febbuary 2020

Input Devices

Week 9

Motion Sensor

This week we were tasked with creating an input device. I created a motion sensor that displayed if there was motion by flashing a blue LED.

- Date Updated: 17 Febuary 2020

Output Devices

Week 10

LED Strips

This week we were tasked with creating an output device. For my output I wanted to create a strip of LEDs for the interior of my final project.

- Date Updated: 17 Febbuary 2020

Networking and Communications

Week 11

Communicating Between motion and lights

For my final project I want to have a motion detector trigger a strip of LEDs. This week I created the networking structure between the motion detector and a single LED.

- Date Updated: 17 Febuary 2020

Mechanical Machine Design

Week 12

1D Claw Machine

This week we worked in teams to create a machine. My group created a 1D Claw machine and I was specifically in charge of all of the wiring to make sure none of the wires got in the way of movement.

- Date Updated: 17 Febuary 2020

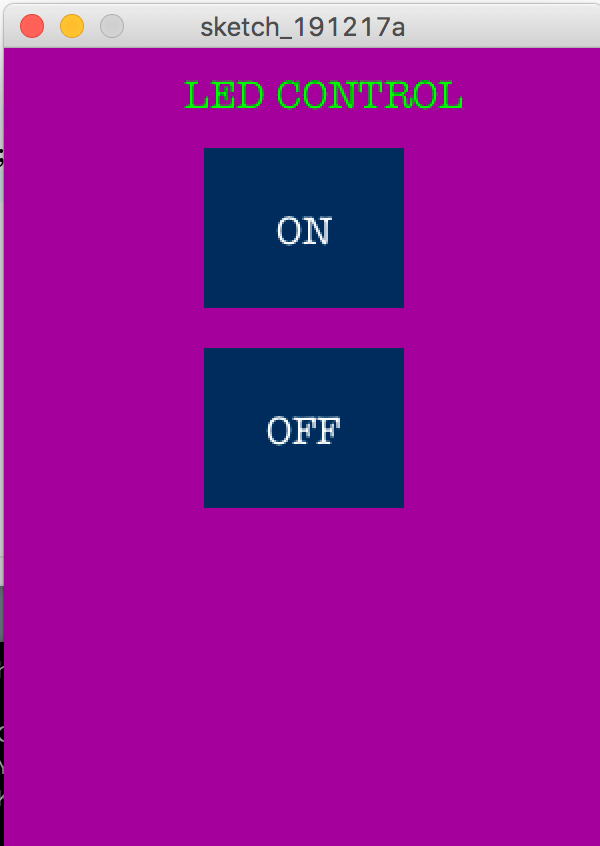

Interface and Application Programming

Week 13

Creating an LED toggle app for arduino

This week we were tasked with creating an app to interface with our boards. I chose to make a simple app that had on and off buttons for an LED.

- Date Updated: 17 Febuary 2020

WildCard

Week 14

Knitting a scarf

I decided to be part of the knitting wildcard group. We worked on designing anything we wanted and getting it to knit on the knitting machine. I chose to make a scarf with pockets for my hands.

- Date Updated: 17 December 2019

About me

Consumer products should be functional and elegant. Since I entered the world of 3-dimensional design, I have strived to create this balance in my research and coursework. I am currently double majoring in Mechanical Engineering and Art and Design at the Massachusetts Institute of Technology. My path has exposed me to multiple types of design and processes that allow me the flexibility to reach beyond the scope of traditional design while applying engineering fundamentals. I have learned how to create a designs in Solidworks or Rhino, prototype with 3D printers and laser cutters and create final products with heavier machinery such as mills, lathes or injection molders. These skills have led me to become a published researcher and successful student as well as aided me in my endeavor to merge mechanical and aesthetic design.

Beyond research and courses, I have also learned how to create ancient Damascus steel and learned how to forge from a Japanese master smith. I am always interested in learning new ways to create as well as sharing my knowledge with others. Whether it is in a group project creating toys, or teaching STEM enrichment to faculty and students in Boston and Miami, I believe the sharing of knowledge is a worthwhile endeavor.

- Location: Cambridge, MA

- Email: chloen@mit.edu

- Résumé: resume.pdf

- LinkedIn: www.linkedin.com