Chris Lloyd

MAS.863/4.140/6.943

How To Make (almost) Anything

2019

Week 6: computer-controlled machining

I wanted to make a planter for my fiddle leaf fig plant as it's sat in my living room for six months in its original container, on top of an old antique platter my grandmother gave me, on top of a chair. My mission this week is to give this plant a proper home.

I visited the Architecture Shop to look at the machine and material, which is a 4'x8' sheet of Oriented strand board (OSB) with 7/16' thickness of oriented strand board (OSB), a very poor quality particle board. Based on some feedback from the shop manager, I knew that I wouldn't be able to make small notches or other thin features in my design or the material would crumble like a cookie. It also would be very challenging to practice flecture with this size of design for the same reason.

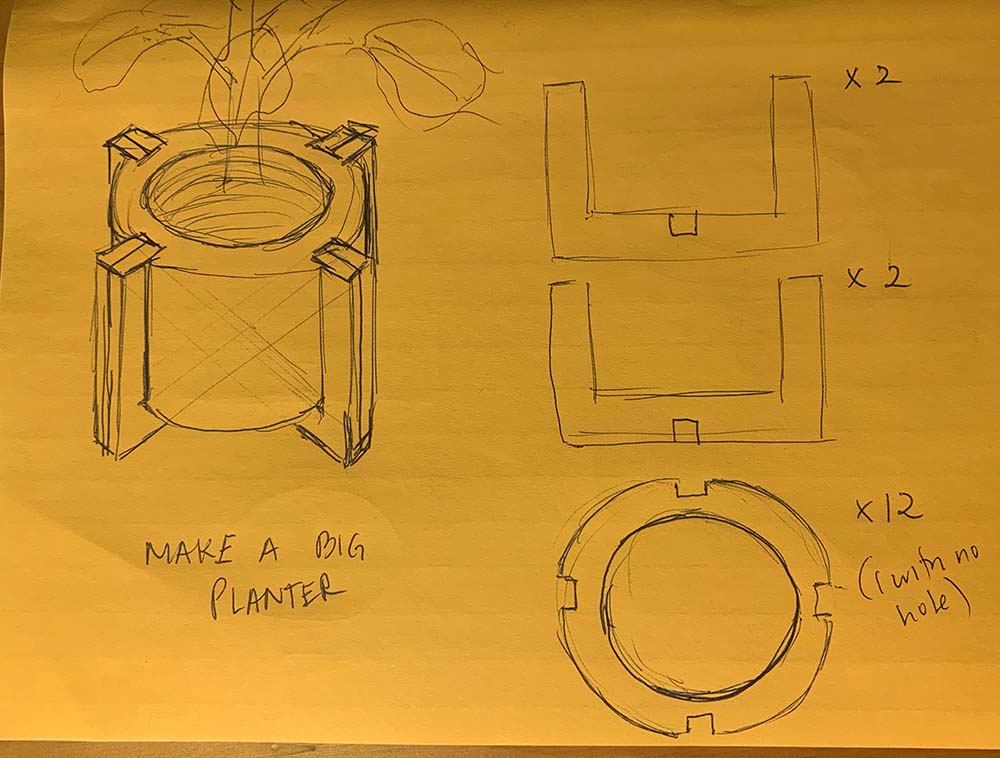

I sketched some ideas and came up with this concept. Circles would be stacked over cross-hatched container piece. I decided to double-up on the container pieces (total of 4) so the notches on the circle pieces wouldn’t be too small and potentially break.

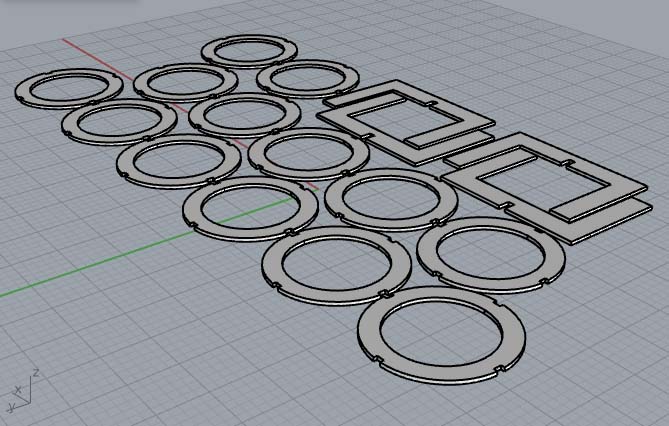

Based on the thickness of the material, I designed the sliced version of the pot using RHINO. I'm still having some issues with moving objects in a 3D space, so I never assembled the design. I'm hoping I got the math right for now and will do more training on this in the future.

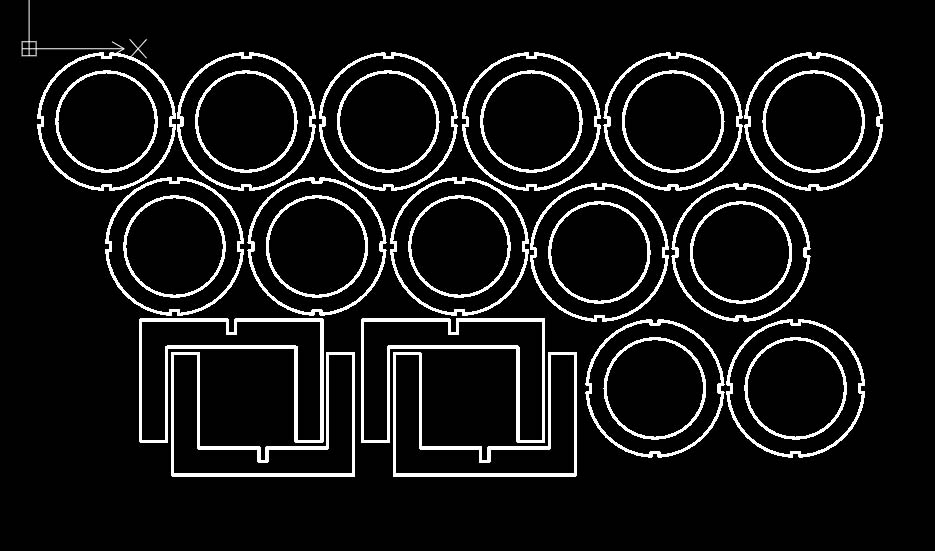

Next, I needed to create a 2D dxf file, which can be sent to the Onsrud CNC Router. DXF files can easily be exported from RHINO and even Adobe Illustrator.

With the help of Chris in the architecture shop, I used mastercam to create the tool path and use the onsrud to cut the OSB. First you have to choose your tool. 1/4" endmill. The you set up the chains. A tricky part was making sure that the cut was on the right side of the various circles I was cutting to get thr correct geometry.

Here is the final product. I did not need any nails or glue as the circular rings keep the two-axis frame in place. Now I just need to find a plant!