3d printing and scanning

-----------------------------------------------------------------------

printing

this week, for the 3D printing assignment, i wanted to make a small glasses easter-island-moai-esque holder to place on my desk, because i am notoriously known for losing my glasses when i take them off. i was inspired by this image i found online shown below, so i tried my best to re-create it.

i started in Rhino, where i attempted to build the model of this piece. i think in theory, it should have been fairly easy, but because i am still new to Rhino and modeling (thought i would love to get better, therefore the practice), it took me way longer than it should have. i was also having a lot of trouble getting my objects to boolean, because i was creating them and then exploding them and then moving them around, which did not make for the best workflow. i think in the future, i will definitely try to plan out a better workflow, whether that be subconsciously or on paper to make the modeling process easier for myself.

i think overall, the model turned out pretty well, i kept in mind the additive mindset, and tried to create interesting elements. so at the base of the cylinder, i chamfered the edge to test how far the 3d printing could extend without needing supports. i had the nose of the face jut out, and the mouth boolean-differenced from the truncated cylinder.

we did a test piece to characterize the printer — the wall thickness parameters of the print.

then, i was set to print the model. i imported the file into the Sindoh 3d printer 3dwox software and adjusted the scale, infill, and support settings to my liking. it was fairly simple and intuitive to use. i then converted the model into g-code, saved it onto a flash drive, and plugged it into a Sindoh machine.

i didn’t realize, even though i should have because the entire process is melting plastic, but the machine and the bed they stand on get extremely hot!

i plugged in the usb and started the print! the printer took off, started to make the base, and then when i knew the print was going fine, i left until the print was done. which i now slightly regret, because i would have liked to have seen how the infill was placed within the object, but i’m sure i’ll be printing something else and be sure to inspect during the process.

voila! my print was done!! but the supports were still attached

so i carefully detached and sanded a little. i noticed that the back piece that jutted out to hold the glasses wasn’t as thin and straight as i liked — a limitation that we tested earlier for the machine, but i thought i had accounted for.

the texture of the piece also changed going up the object — it was much coarser on the bottom and then smoothed out at the top. i am assuming that has to do with the supports or diameter? since the angle does not change from bottom to top.

i wished i had made the nose holes and mouth holes larger, but i can still clearly tell how the additive process was also able to create these subtractions.

i now have this uber cute piece on my desk to place my glasses whenever i need!

scanning

for the 3d printing assignment, i first tried to 3d print a ganesh keychain. i thought it would be a great idea to try to recreate that because I got it several years ago, love it, and would be devastated it if I were ever to lose it or break it.

however, when i opened Sense and started to 3d print the object, i think the keychain was too small, because it was being very finicky and not wanting to focus on only that object. i credit that limitation to having to be at such certain distance away from the object. i think i will be trying to 3d scan the keychain with the phone app later.

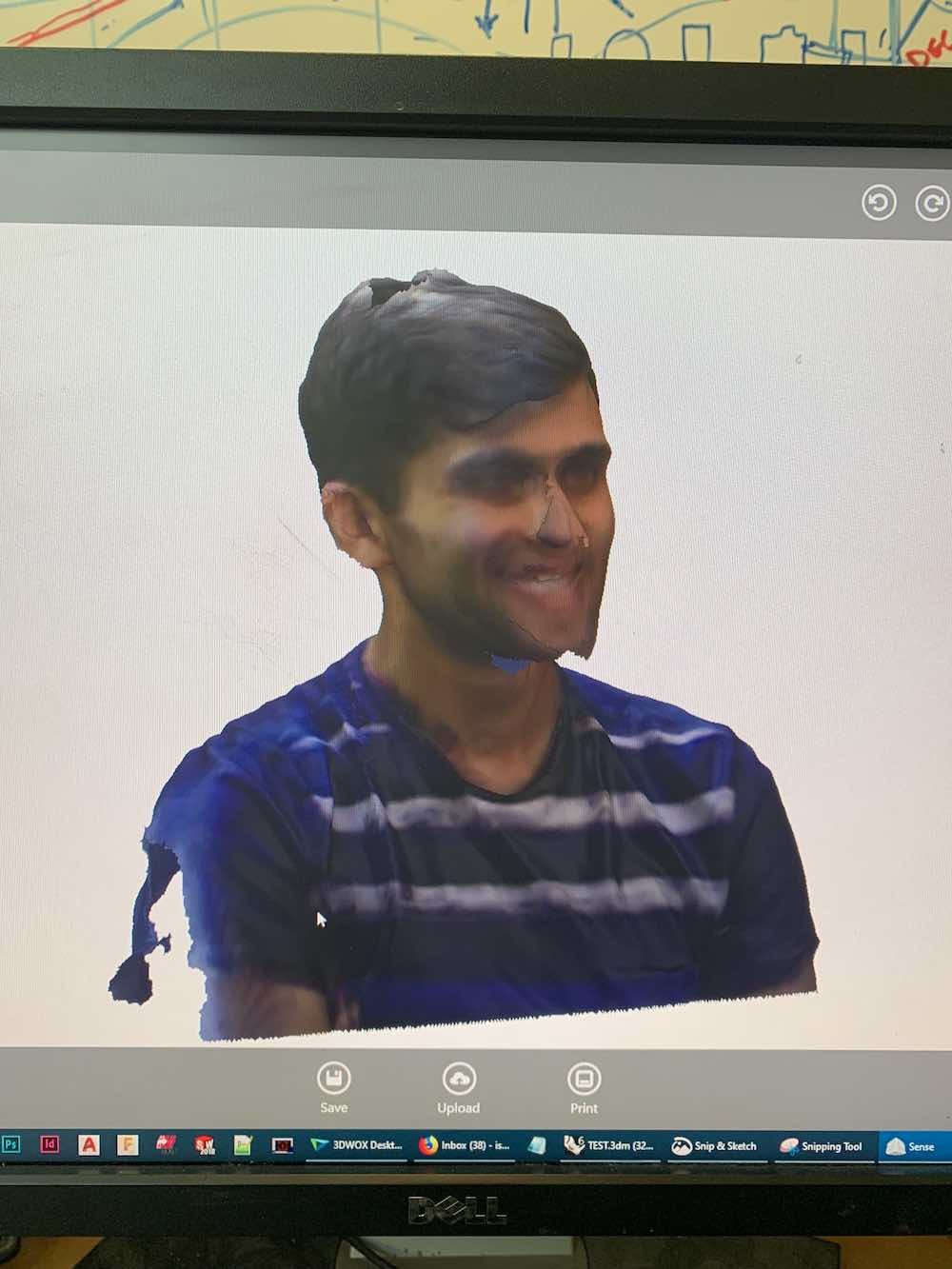

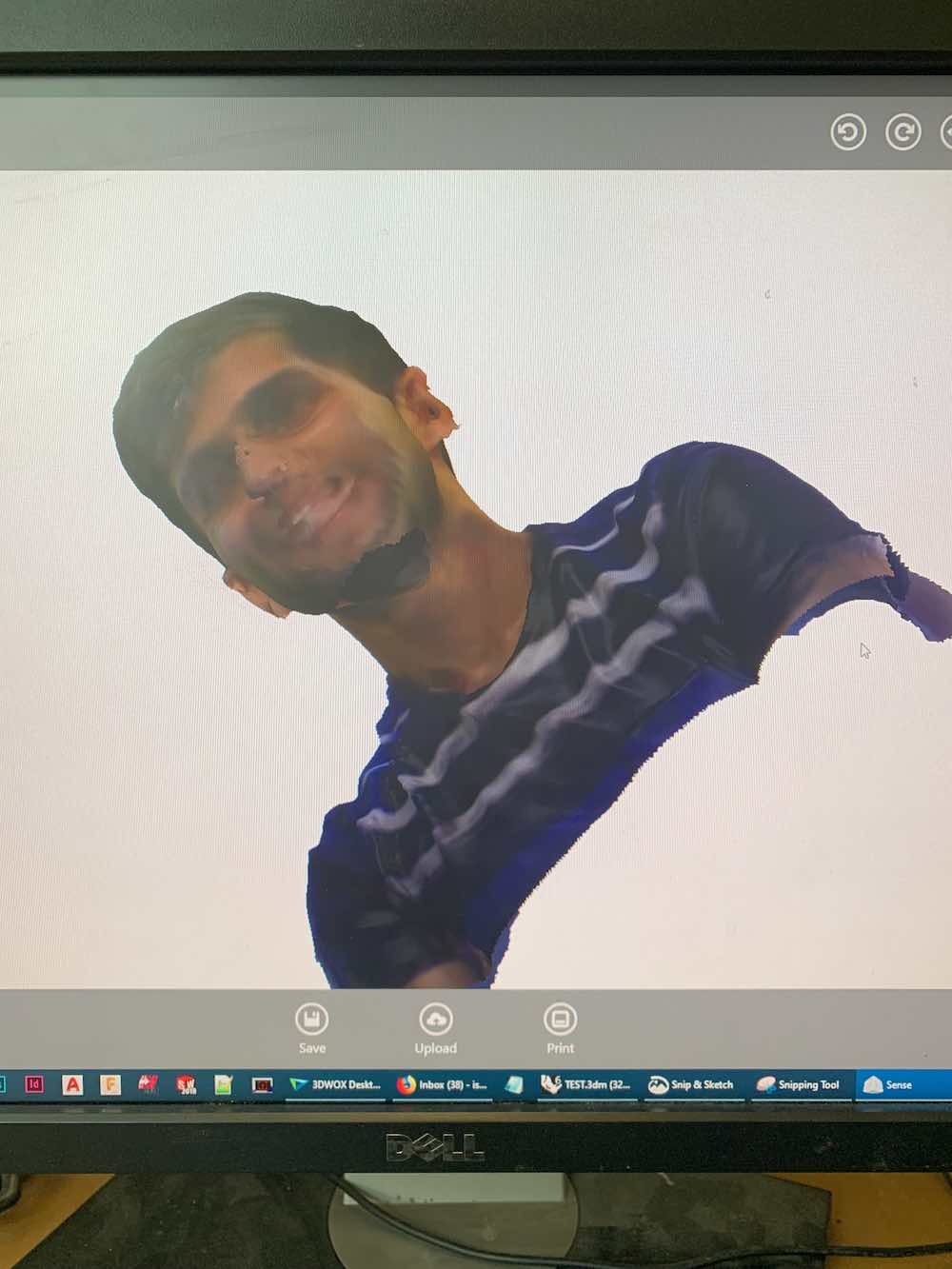

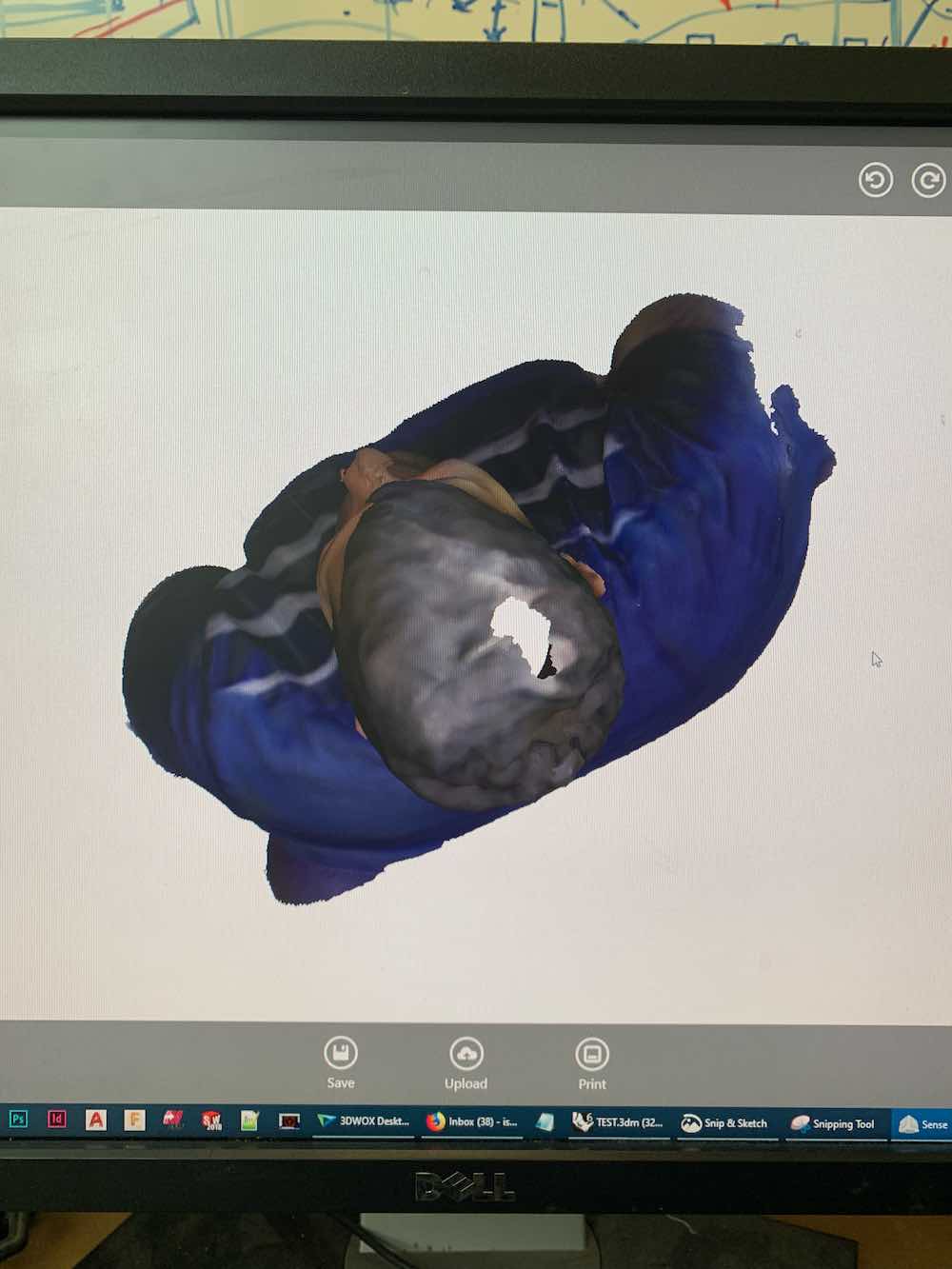

instead, i decided to 3d print my boyfriend’s face, which was super fun. it took a couple tries to get the hang of it and try to get all the nooks and crannies of his face, and eventually i almost got it. it was interesting how when he had glasses on, they just melted into his face rather than being a separate object.

i didn’t end up printing his face, but definitely will look into 3d scanning other things in the future.