For the wildcard week, I signed up for soft robotics. Ali gave a really nice tutorial about the overall idea and the details regarding soft robotics. Here is the wiki page for this week.

The main drawback of the soft robotics is that it is extremely difficult to have precise control over the system.

It is also very difficult to fully simulate the material behavior because there are thousands of variables involved.

I thought why not try simulating it in Rhino Grasshopper. I might get at least an approximation of the actual movement.

I was intrigued by the work by prof. George M. Whitesides

(link)

at Harvard, and tried to simulate it in Rhino and Grasshopper.

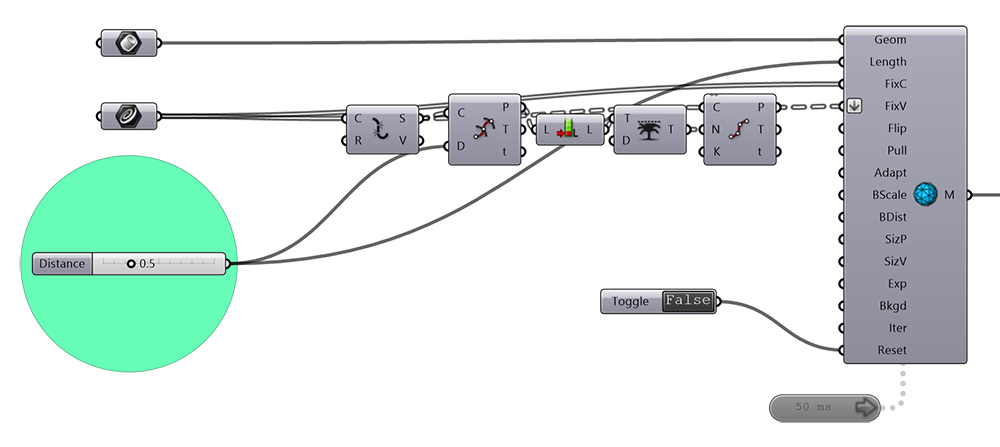

Grasshopper script is composed of two parts. One, discretizing the design domain effective enough to mimic the actual

material behavior, and two, doing the physical simulation using a few constraints.

For the first part, I used the

MeshMachine

component to do the remeshing to have fairly uniform edge length of each mesh cell. By controlling a

slider in the green bubble, you can change the target edge length of mesh faces.

Meshing the domain using MeshMachine component. 2,463 triangles were created.

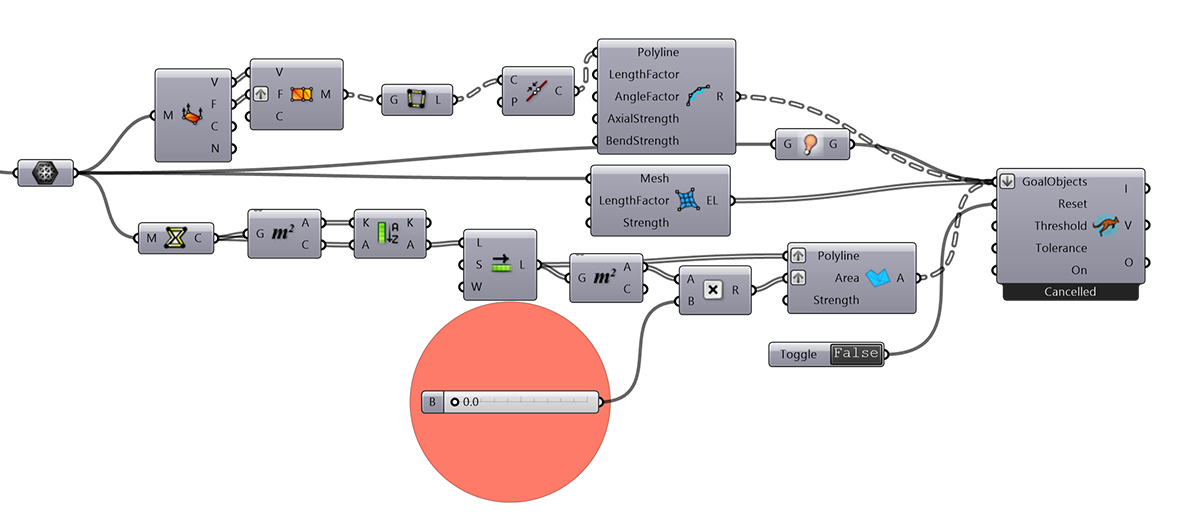

For the second part, I used Kangaroo simulation engine in Grasshopper. If you move the slider in the red bubble all the way down to 0.0, you're telling your model to decrease the area in the cavity, resulting in the contraction.

Physics simulation using polygon area constraint.

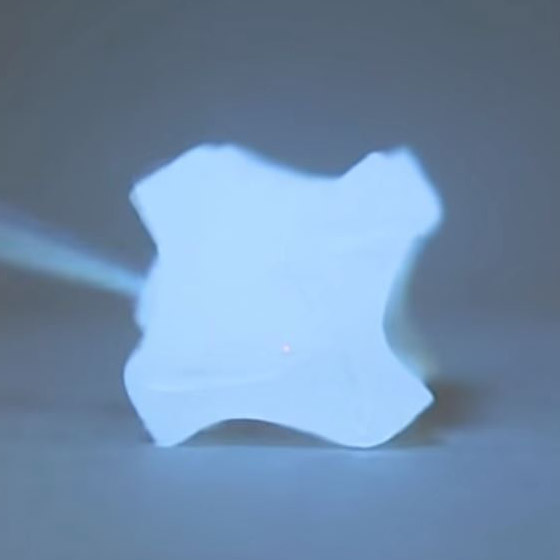

It surprisingly resembles the behavior that you can see from the actual video.

Elliptical shapes with varying orientations makes the shape contract into

a rectilinear shape of different directions, which in the end makes the

rotating effect.

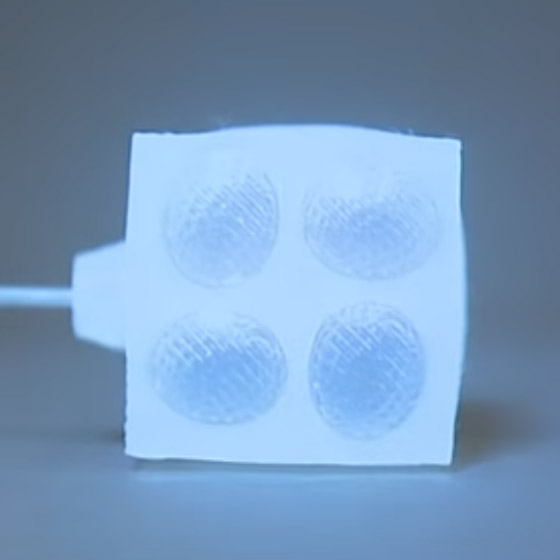

Few things to keep in mind when designing the mold. The interior edges

should be filleted with the radius of at least 0.25mm to prevent the silicone

from tearing and bubbles getting trapped along the edge.

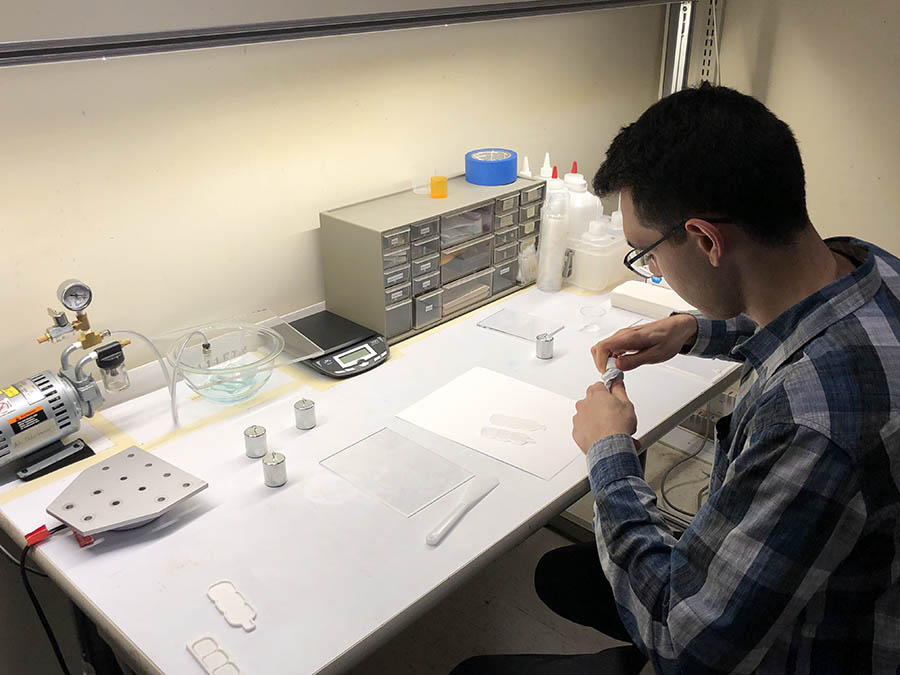

Ali had his own workspace optimal for working with silicone!

Equipments include:

- Vaccum chamber

- Desktop compressor

- Heatbed

- Mixing Container

- Transparent Cover

- Electronic scale

I printed the mold with Original Prusa i3.

I used 50% infill with 0.15 Optimal settings in the slicer.

.jpg)

.jpg)

Then I used Dragon Skin 10 NV to cast.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)