Sometimes I am really really stupit - I admit. I knew I had only two days to work on my Big Thing -

because I was about to leave for a studio trip for a week, but still was ambitious about my design.

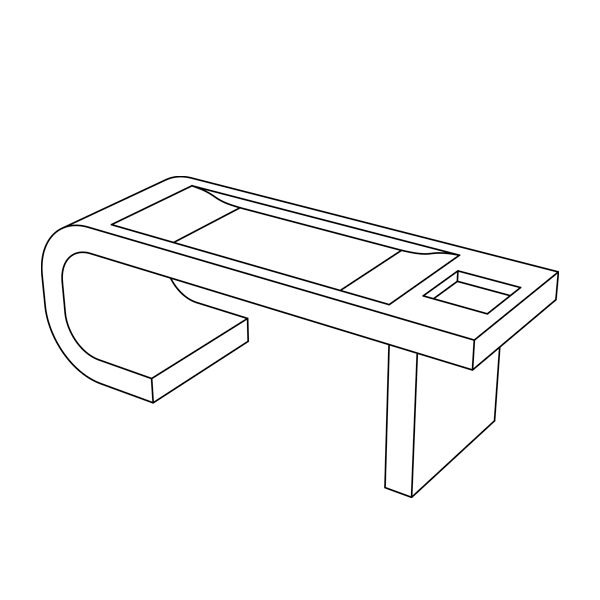

I designed a bench that is made out of plywood attached to each other and one stock.

I wanted it too be chunky and heavy, and to creat a bench that looked like one big plywood thing.

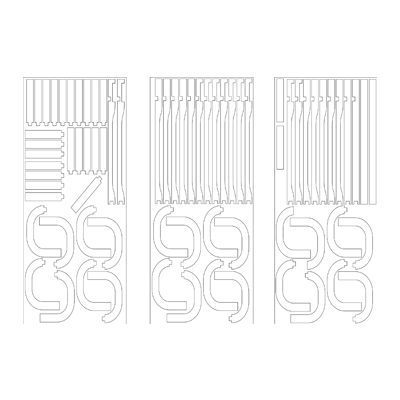

At first, I thought I could do it from one piece cutted over and over again - but this kind on bench

could only be possible if using around 15 sheets of plywood, and spending arout 1,000 dollars.

I decided to take it aprt to make the cutting more efficent, althought the assembly would be much Harder.

Obviously that was a mistake and I needed to design something small out of the OSB and not spent time and money

on a too big bench. I also had to shrink it so it wasn't even my originle design.

So it took me a while to cut the three sheets, although I came really early to the woodshop - waiting

that Chris will be available to help and that the machine will be available too was extremely time consuming.

The machine was also not calibrated right, so it didnt cut the plywood all the way through, and I needed to spend a lot

of time on sending the pieces. In one of the sheets the parts were moving, so I had to stop it in the middle.

I started to glue the parts, but it took a while and it is still in the shop waiting

for me to assamble it. I will do it tonight!

It took forever to glue all the parts together, and I needed chris's help

in trying to fit the legs together since it was too tight.

I sanded the pieces for a long time, and with a lot of effort it finally worked!

I oiled the piece and took it to my house, where my cats are enjoying it.