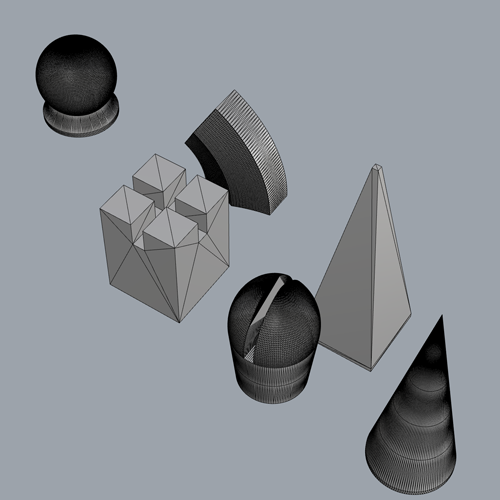

I wanted to make the chess set Man Ray designed in 1920. I found a 3d file online, but the tools were too

complicated meshes and super heavy, so I needed to reduce the meshes and change it a little bit in Rhino.

The tools were also too big to fit in just one wax block, so I scaled them down and didnt put the The rooks.

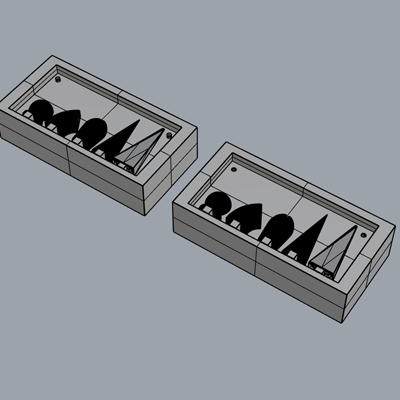

That was the easy part. The next part was to create the MasterCam file. Because I didn't know excetly how to

set the file, Jung was helping me. We did four tool paths: first was rough cut, than a cut on the inner edge

the third tool path did the finish cutting and the last one did the fitting elemnts and some geometry fixing.

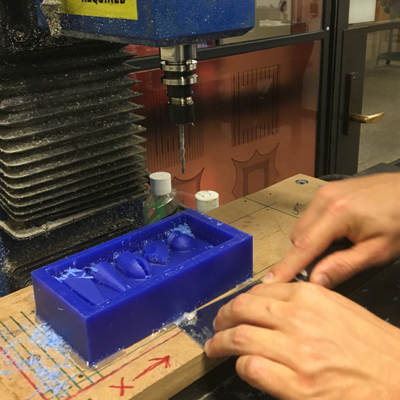

The day after I milled the wax blocks with the Intelitek. Operating the machine wasn't hard, but than the bit broke

Aparently the definition if one of the tools weren't right on the machine software - oops.

So after Jen fixed the bit, and defined new tool in the machine software, I was able to try again.

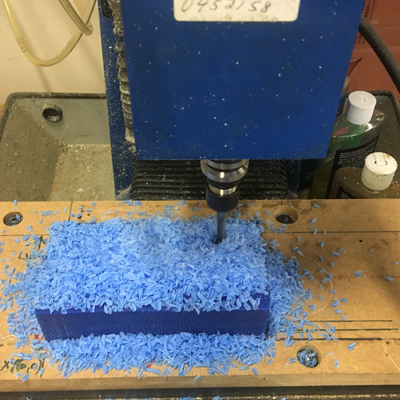

This time it worked! I milled two blocks, mirrored geometries, and it took about one hour for both.

one of them wasn't perfect, I don't know why, but it was already too late so I needed to give up and cast

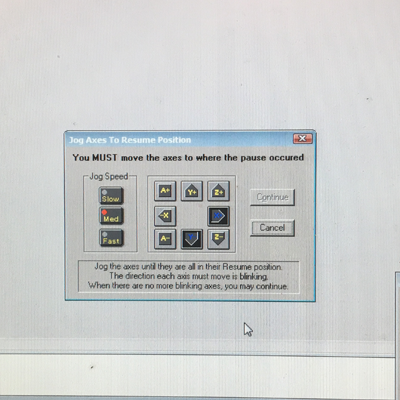

One thing that was weird about the machine was that when I used one G-code for all the tool paths, it

kept asking me to move the machine to the point where it stopped before changing the tool. so in the

second time I milled I used 4 different G-Codes.

Casting the silicon was super easy and straight forward. I left it to cured over night.

It was surprisingly easy to remove the silicon from the was mold. I wish I had time to expiriment

with metal casting, or even just cast the set in two colors - but maybe next week, we will see.

The plaster casting wasn't that easy. It was too liquid and it was hard to keep it stay inside the mold.