Week 6: Computer-Controlled Machining

Designing Giraffe Stilts

For this week's assignment to Make Something Big, I decided to make Giraffe Stilts.

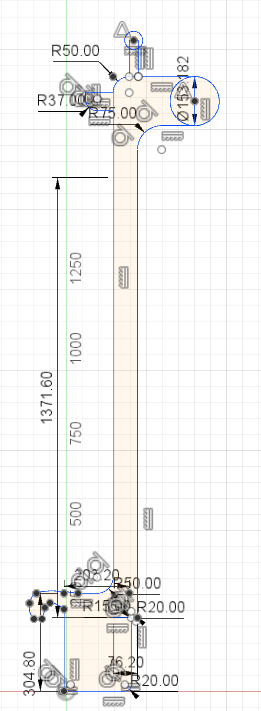

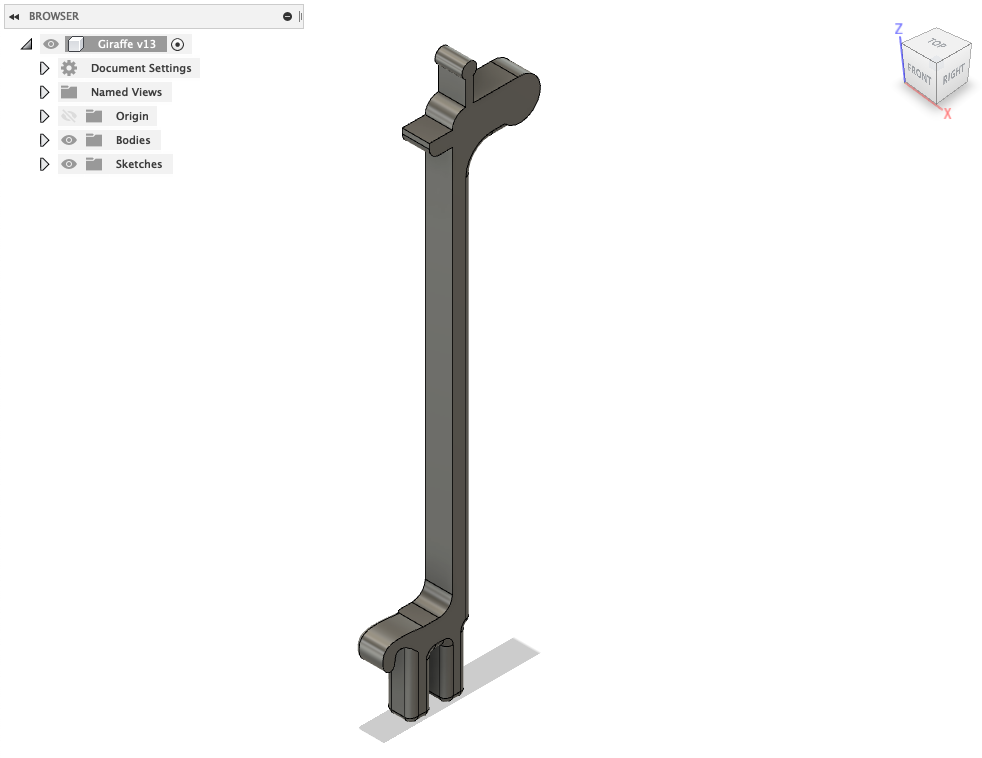

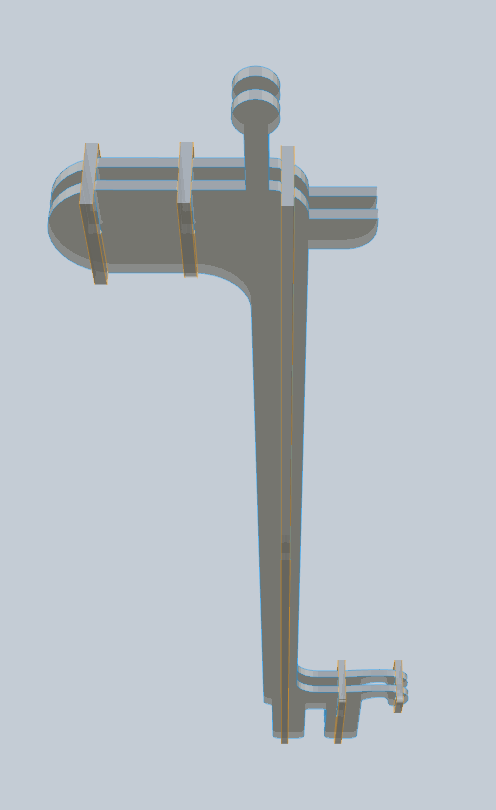

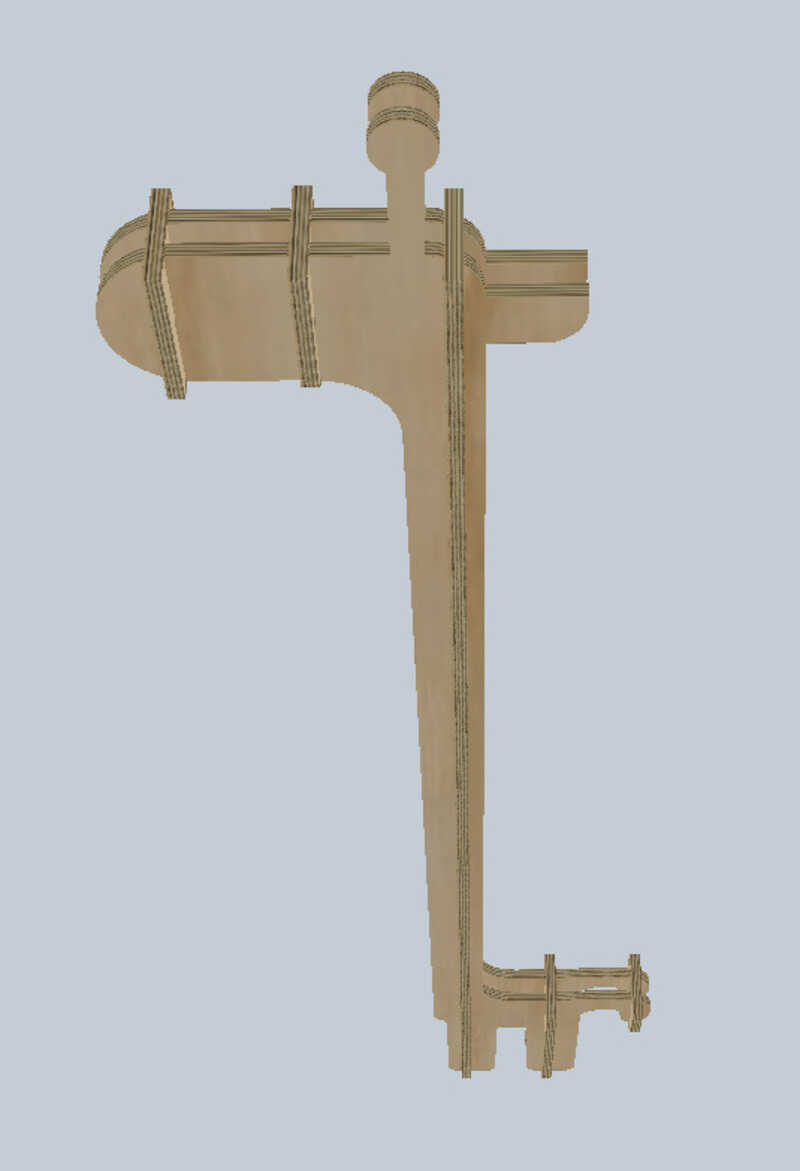

I began by designing a 3D volumetric version of the giraffe-stilts using Fusion 360.

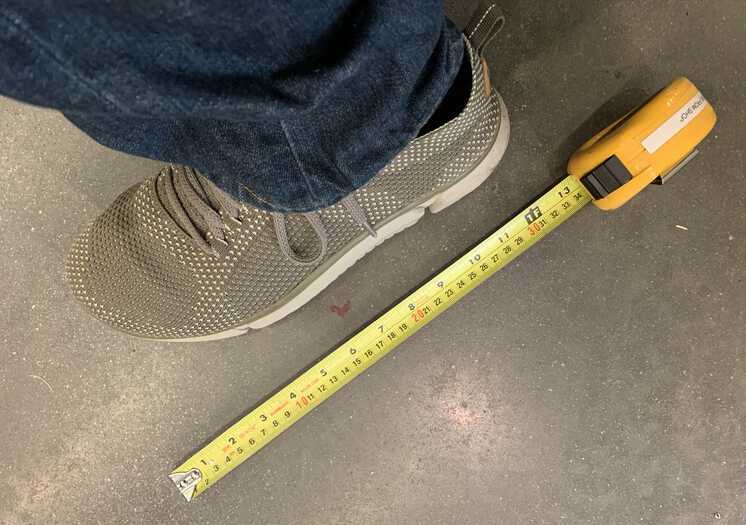

For the bottom part of the giraffe, I wanted to make sure it would accommodate my shoe across the width of the giraffe.

I was pretty happy with the model I put together, though I wish I had punched out an eyeball.

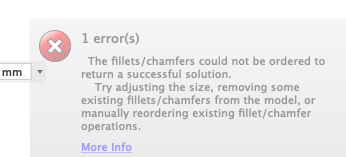

I wanted to do a fillet of nearly all of the edges of the giraffe, but trying to do a mass filleting of the two side faces ran up against certain parts not allowing a larger radius fillet.

I wanted to do a fillet of nearly all of the edges of the giraffe, but trying to do a mass filleting of the two side faces ran up against certain parts not allowing a larger radius fillet.

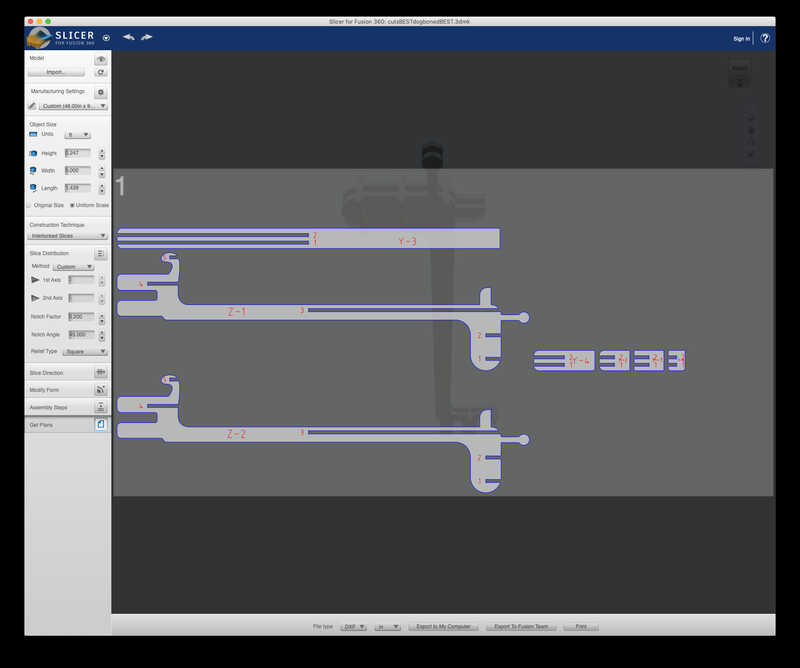

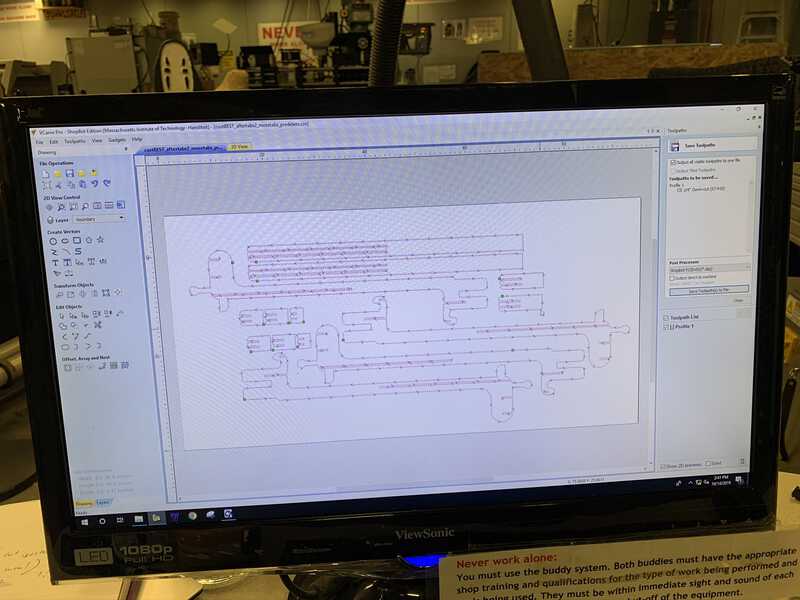

I then used Slicer for Fusion 360 to generate slices to make on the machine.

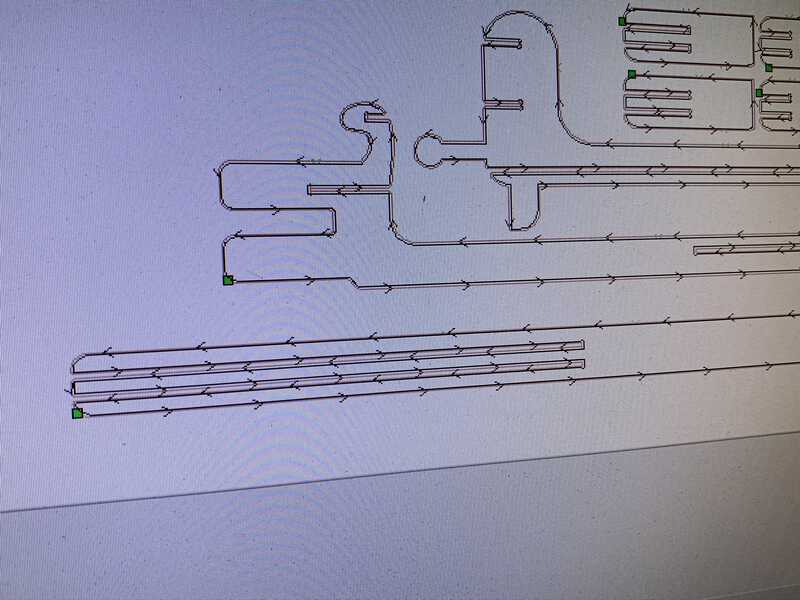

And then converted that to cuts.

I carefully packed my cuts such that two copies would fit.

I worked with Patricia on making the cuts!

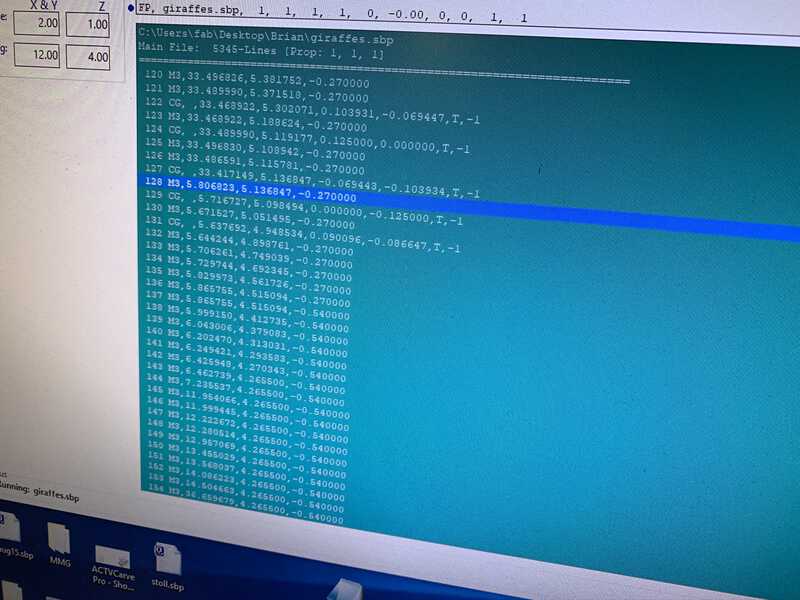

Since there were some super long cuts, the output on the ShopBot screen moved relatively slow!

There was an issue with the longest piece that went down the giraffe's neck. It was too long to cut, and because there were three prongs, it didn't have enough room to its right or left to properly attach tabs along the way.

I was careful to stop the machine immediately when the vibration began. When we realized the design could not be salvaged with this type of wood I removed the remaining pieces from the print route.

After that first cut failed, we assumed I must just need more tabs on the legs. I re-laid out my pieces to fit with that first piece deleted, and got the machine going again. I also screwed down the loose pieces remaining from the failed portion.

Unfortunately adding more tabs did not help. And adding a giant tab such that the legs would be attached at both the top and bottom did not do the trick either.

One of the half-cut long pieces still worked OK for one of the stilts. We were out of time by then, but I was told I can come back later this week, find a scrap of one of the harder pieces of wood, and try to print those remaining pieces then.

Then I used the belt sander to smooth out some of the pieces. The giraffe was long, which made getting the right orientation challenging! I found sanding the outside of the whole giraffe was a bit more stable than sanding the individual wobblier pieces.

Adorable!

Cuts source files: