This week we needed to mold and cast a design. In Mexico we play this game called "toma todo" which is in ways a kind of gambling game like craps. The objective is to put down as little and take as much of whatever is being wagered, normally being penies or pesos. The one shown below I bought in Guanajuato, Mexico and is made of metal and wood.

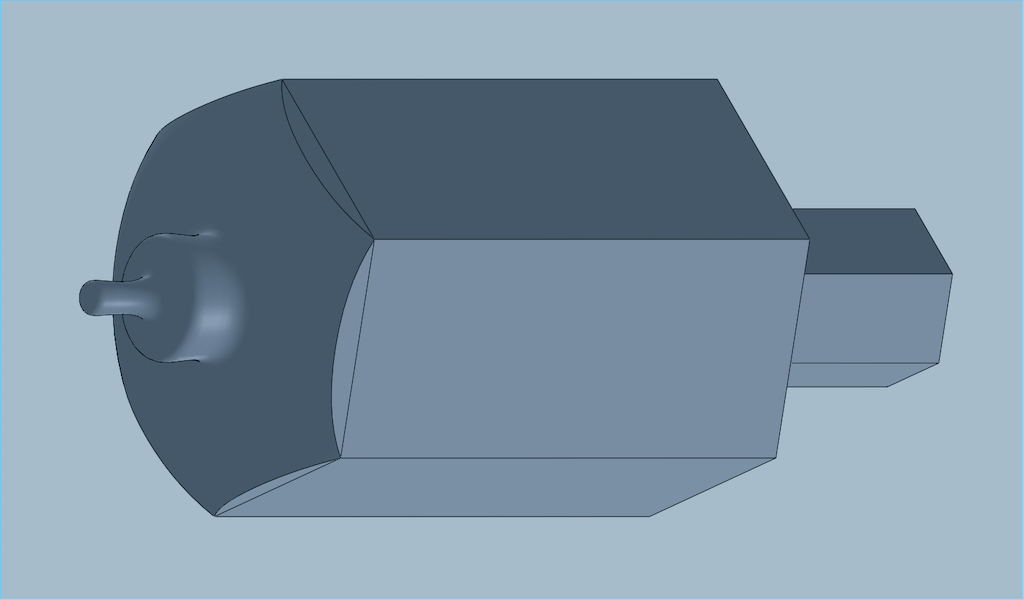

I designed the top as 3 pieces. They were the head which contacts the surface to spin on, the main body, and the tail to grip. Then I assembled them into one piece and saved it as a part.

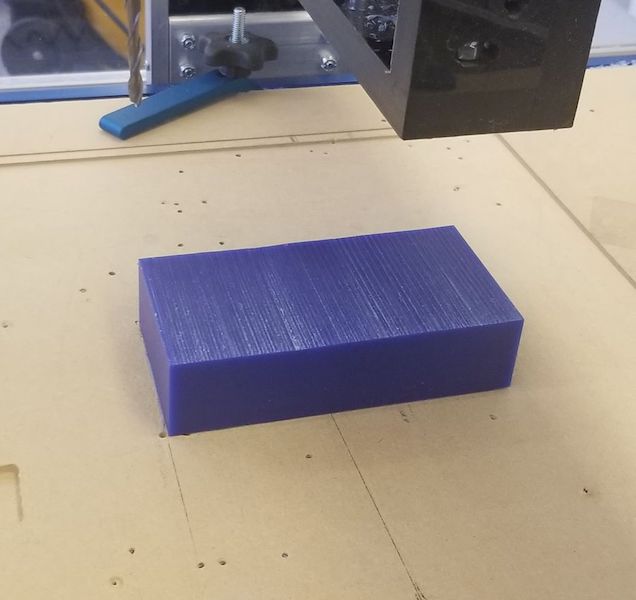

The main feature is that I used a 3D adaptive clearing instead of 2D. I also used parallel and perpendicular passes. Then I used a 1/4" flat end mill. The rest of the instructions can be found on this google docs for reference. HSM gave me the toolpaths and the code to put into the mill.

Using a 3x6x6 wax box to begin, I used the mill to make my design. It came out pretty well and similar to the cad design. I sanded down some of the sided to get clearner and smoother results.

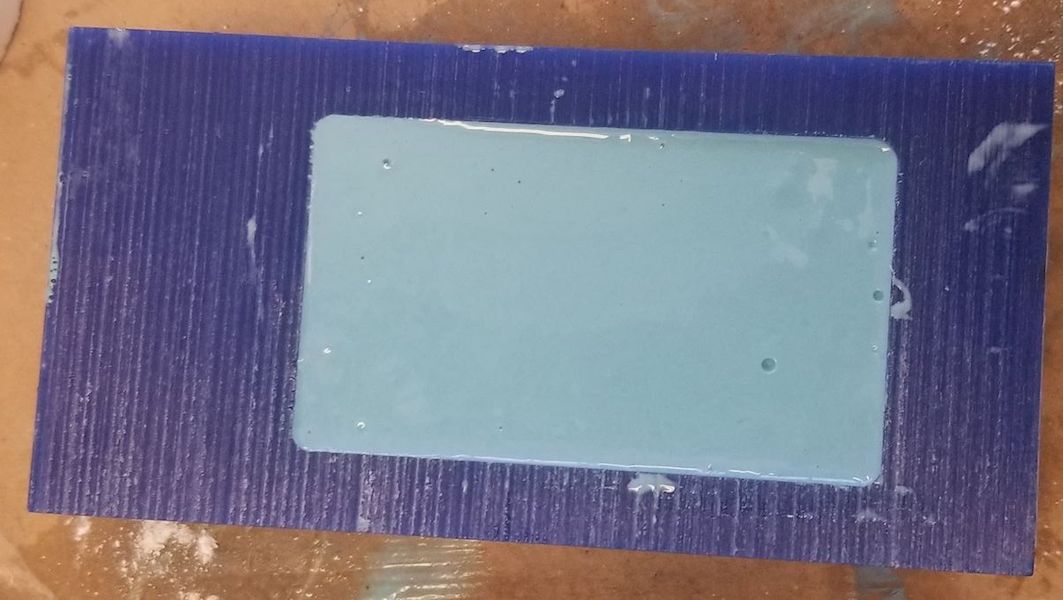

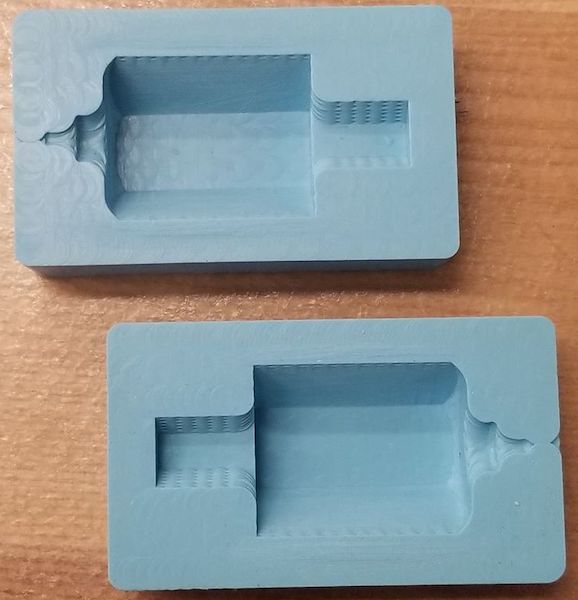

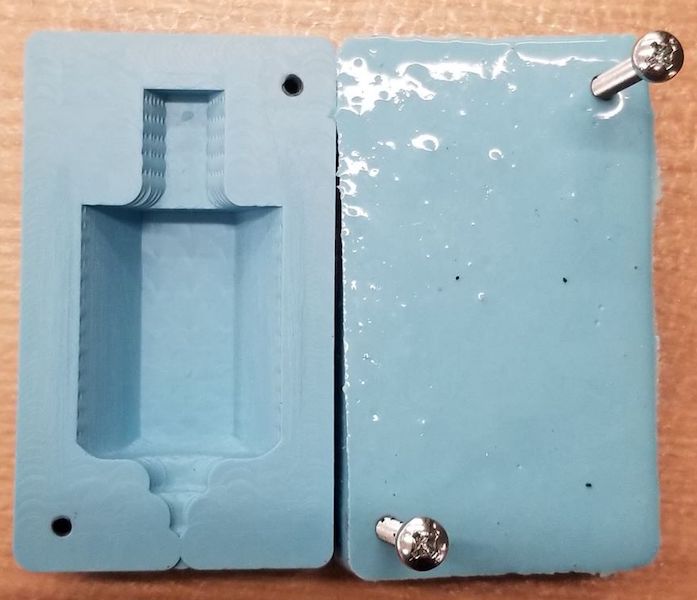

I used Oomoo part A and B mixed 1:1 and poured into my wax mold. The instructions said to let rest for about 90 minutes but I let it sit for an average of 2 hours, since after their time it was still somewhat squishy and too bouncy. I also drilled some holes into the Oomoo to get better allignment when adding the mold cast material. This is because I used the same wax positive to create two identical negatives from oomoo.

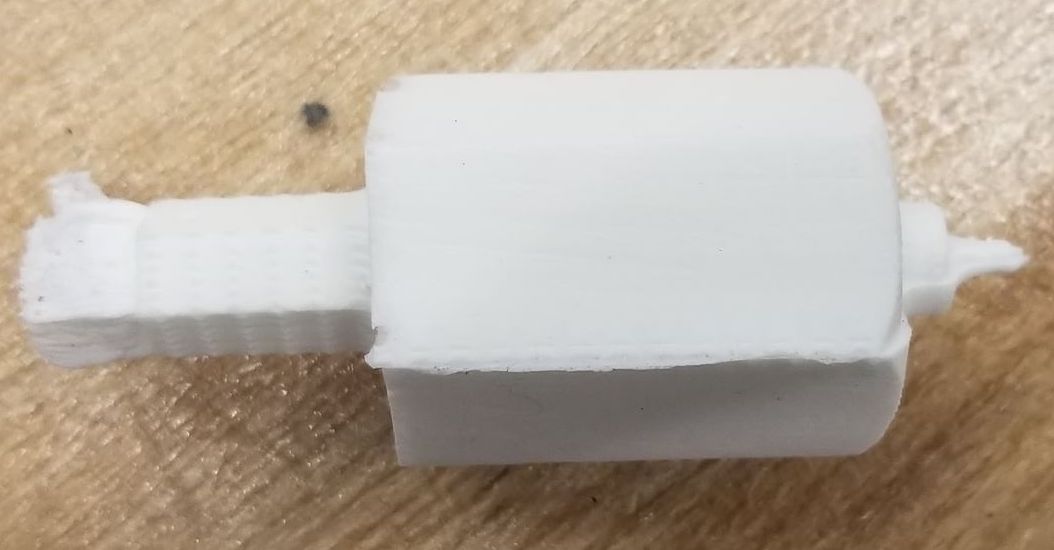

The 305 white plastic was my casting material. It took about 30 minuted to dry and give me a nice solid top. My molds were just slightly misaligned so I sanded the top down once more to get cleaner surfaces and sharper edges. The result was very close to my design. However, the tip is too pointy. I need to smoothen it out so the top spins longer.

I also 3D printed the same top. It is much lighter and spins more because there are less details on the tip that spins, so it is smoother.

From left to right, 3D printed, casted 305, original wooden.