Contribution in Machine Week

I unfortuantely, had to be out of town on Thursday and Friday this week. By the time I came back, all the roles of machine building were pretty much divided among other people on the team. I could have helped with software, my strongest area, however a bunch of people were already on it and had already made some progress in it. Therefore, I mostly helped with stuff whose need came immediately.

Soldering Squidworks Moduleboard

I soldered the Squidworks Moduleboard provided by Jake on to a PCB that Premila gave me. This soldering seemed simple, however, I ended up making a short. The short was due to solder under the board touching two adjacent pins. This was very difficult to fix because the short was under the board. Also because the chip had so many pins which I had already soldered, it was difficult to remove the chip off the PCB board. Anthony helped me remove the module board. And indeed there was the short. I had used solder paste, and some solder paste had solidified. The unmelted solder paste had then creeped into the adjacent pin and had created a short. I removed the solder, and finally soldered the moduleboard without any shorts, this time using solder from the soldering wire.

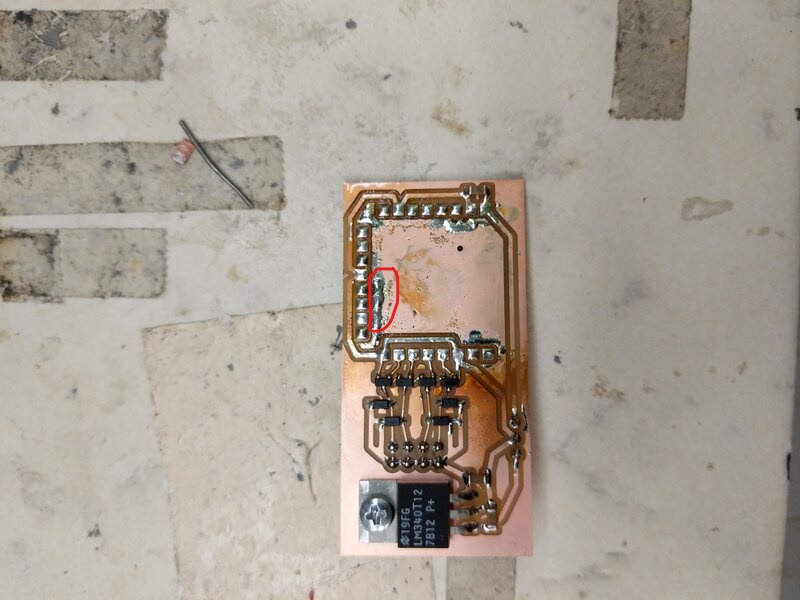

Red enclosure marking un-solidified solder

Red enclosure marking un-solidified solder

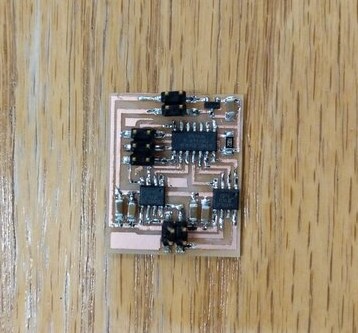

Soldered Module Board

Soldered Module Board

Stepper Motor Board

On Tuesday evening, the board which controlled the stepper motor was not working. To cope with that, we decided we could make our own board for the stepper motor. On the class website, there alreay existed a design for the stepper motor board. I went ahead and milled the board and soldered all the components on it. We had our custom stepper motor board. However, our group members later successfully made the stepper board that Jake had given us work, so the custom board was not put to use.

Stepper Motor Board

Stepper Motor Board