Week 04

3D Scanning and Printing

3D Scanning

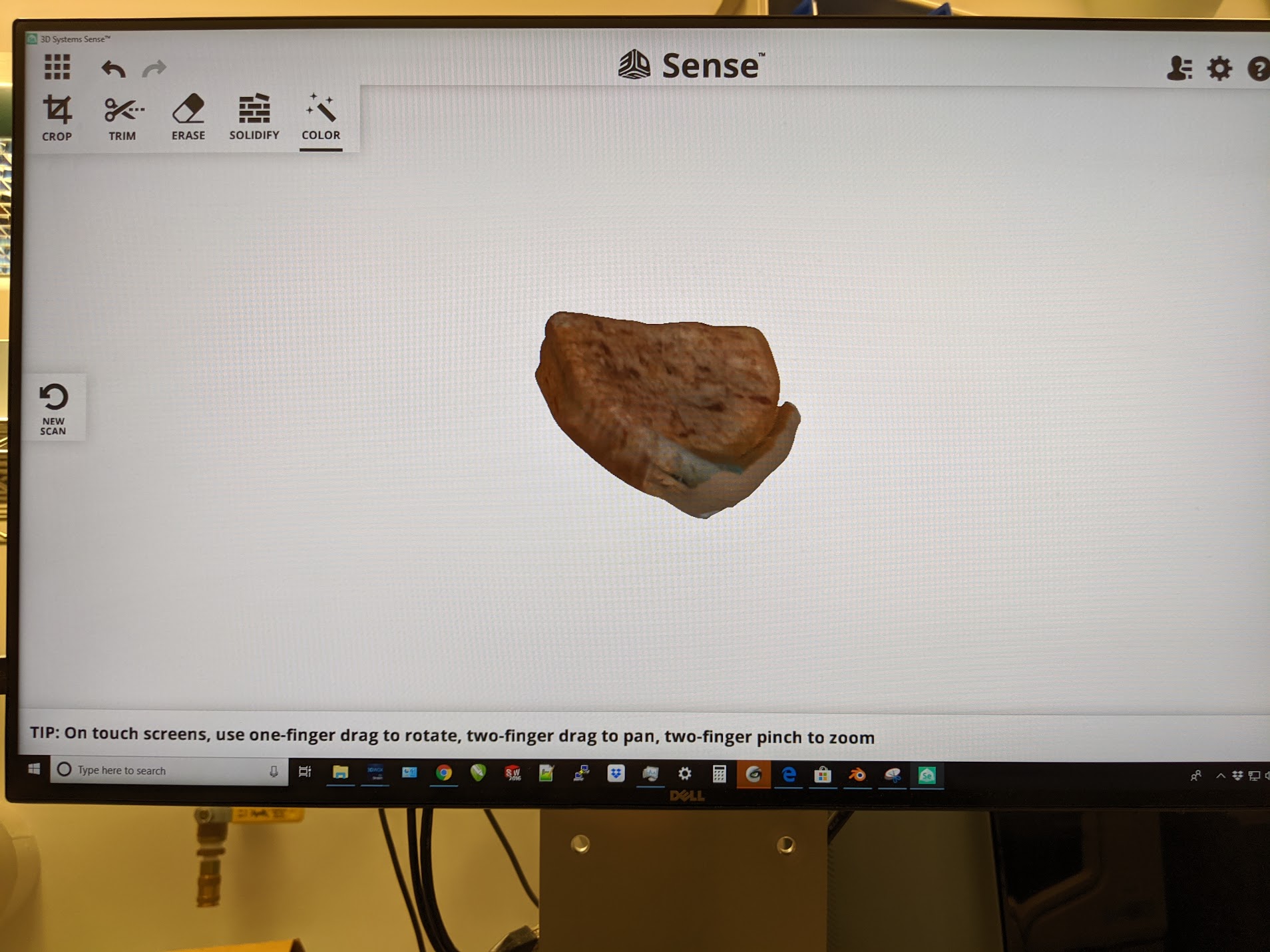

I wasn't too sure what I wanted to 3D scan. To minimize the decisions I had to make,

I picked up the item that was closest to me. It just so happened to be a rouge sponge

that had made it's escape from the soldering iron station.

Oh here is that little rascal!

Oh here is that little rascal!

I used the iSense in the EDS shop for this portion of the week.

I am still working on remembering to get photos of the process, but alas I have failed to get a

sufficient number of photos for this assignment.

I am still working on remembering to get photos of the process, but alas I have failed to get a

sufficient number of photos for this assignment.

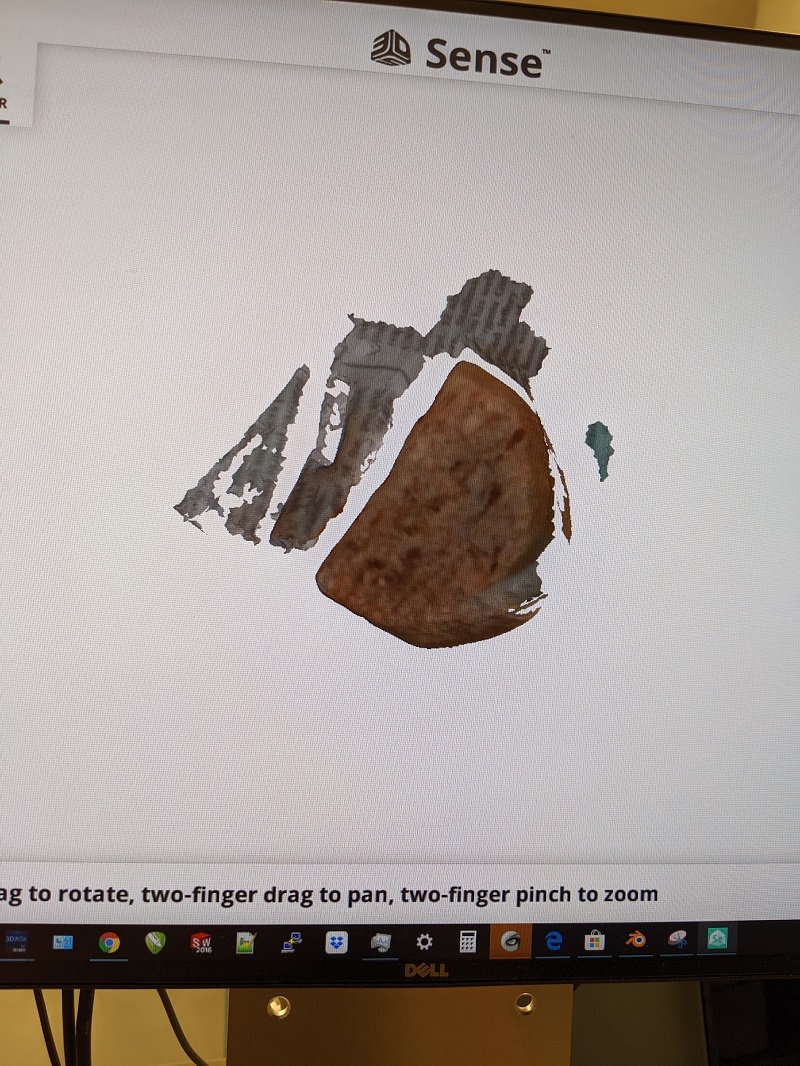

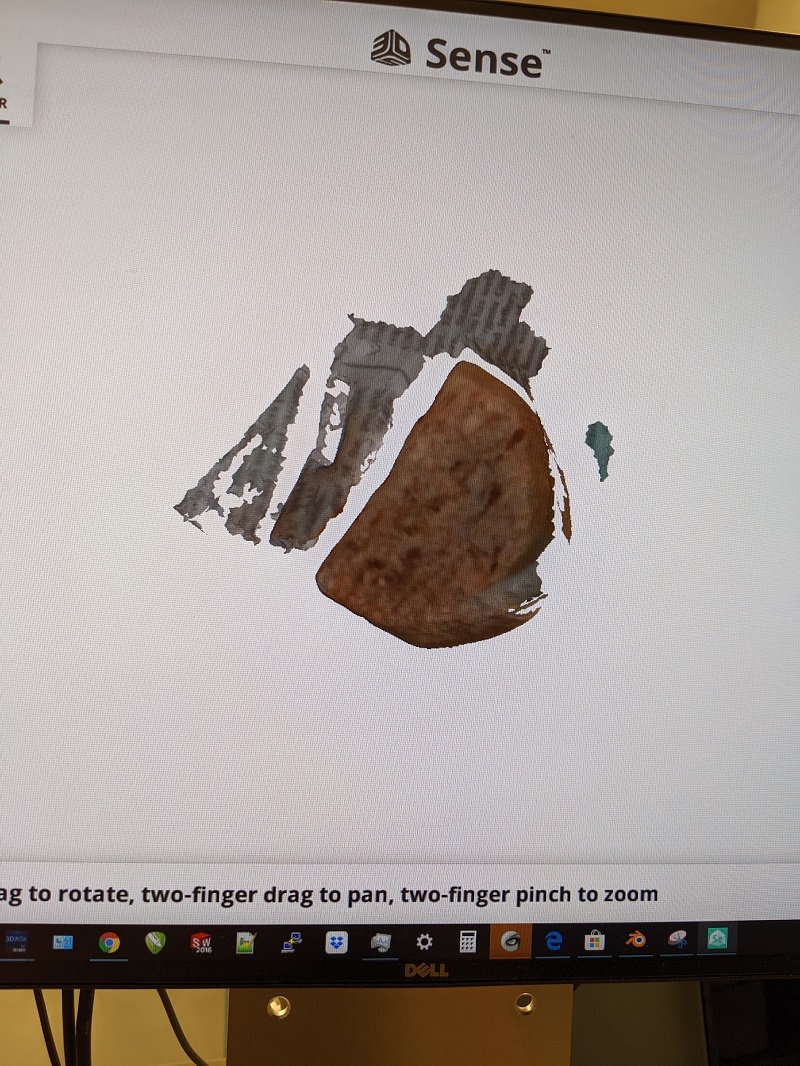

Fortunately for me, the newspaper that I had placed the sponge on came through to the scan.

Fortunately for me, the newspaper that I had placed the sponge on came through to the scan.

I wasn't sure how the newspaper was part of the sccan, but maybe it was lifted ever so slightly in that

area. Not a problem, I found a trimming tool on the software and continued on my merry way towards an "okay"

3D scan.

I was fairly surprised to see what the iSense had picked up and placed in the final scan.

I was fairly surprised to see what the iSense had picked up and placed in the final scan.

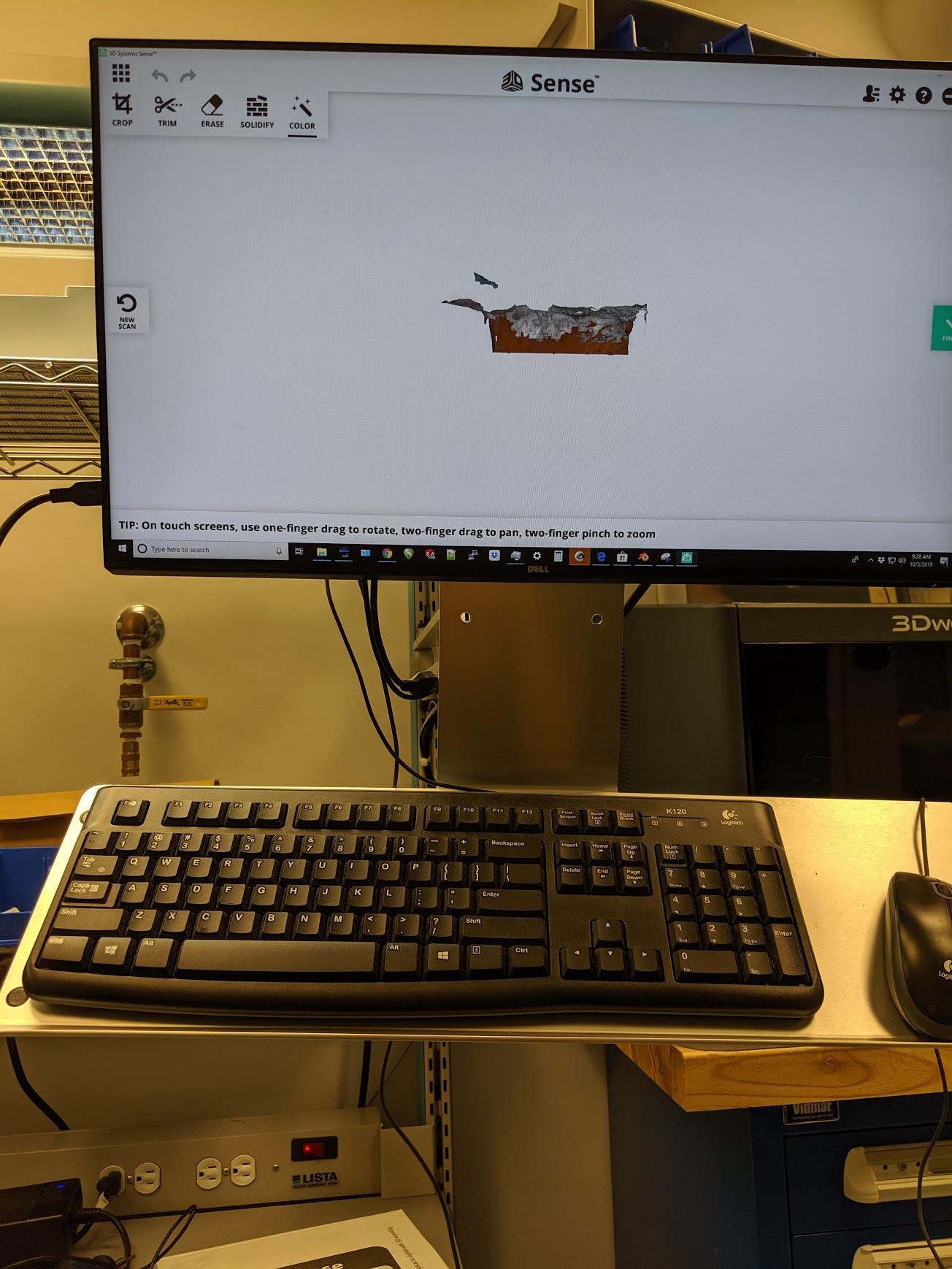

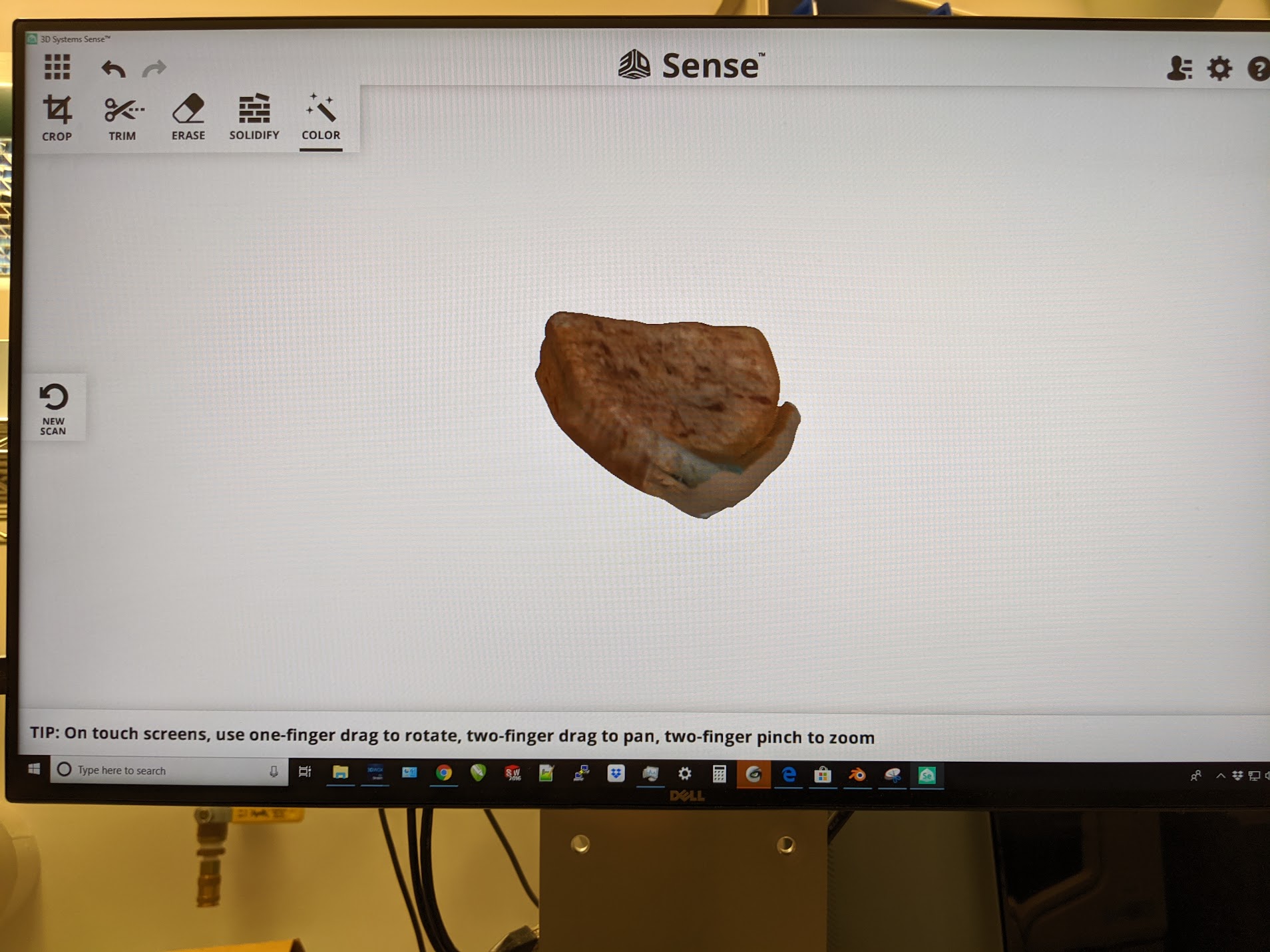

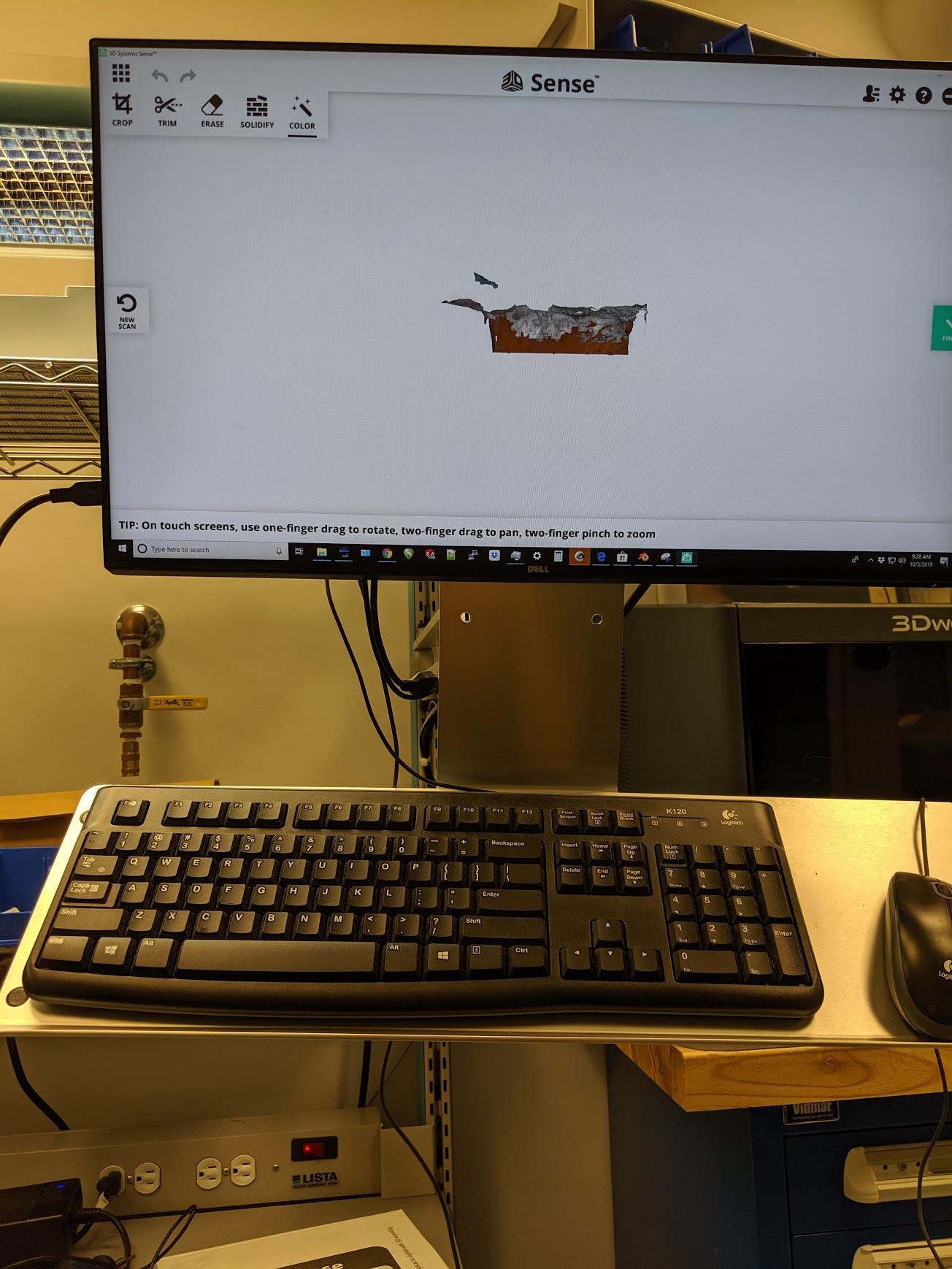

Ultimately, my scan didn't come out too horribly. Really since a sponge isn't a "solid" item I probably

should have considered using a different item. I will have to look into some type of sponge MRI machine to

figure out how to incorporate the porosity. That would ultimately be a more accurate scan.

Once all the trimming was complete, I was fairly satisfied with my scan.

Once all the trimming was complete, I was fairly satisfied with my scan.

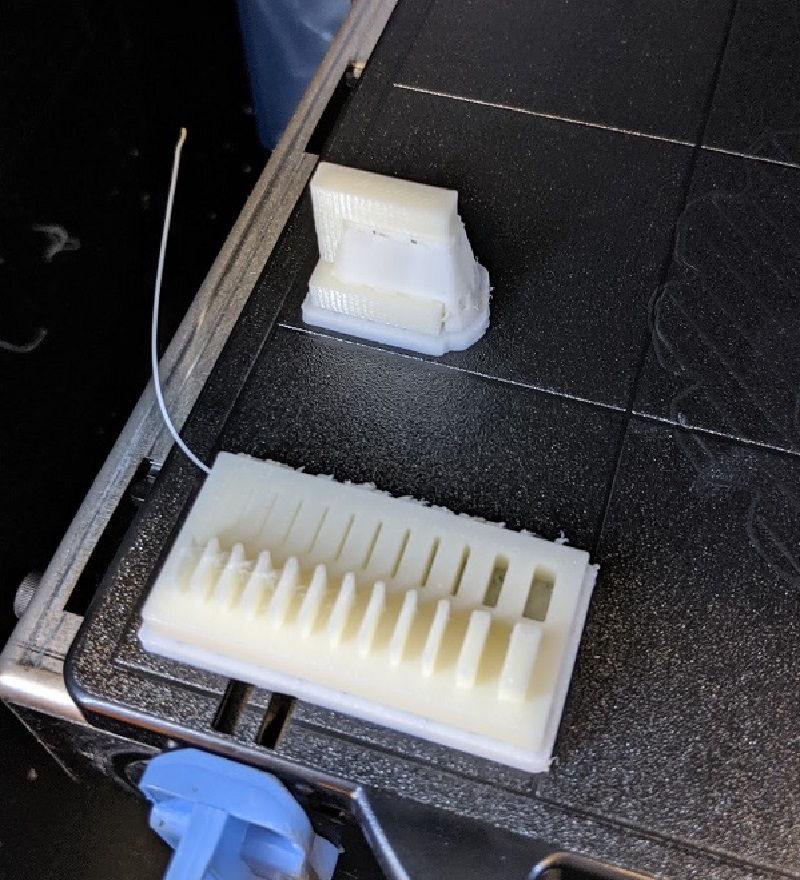

3D Printing Group

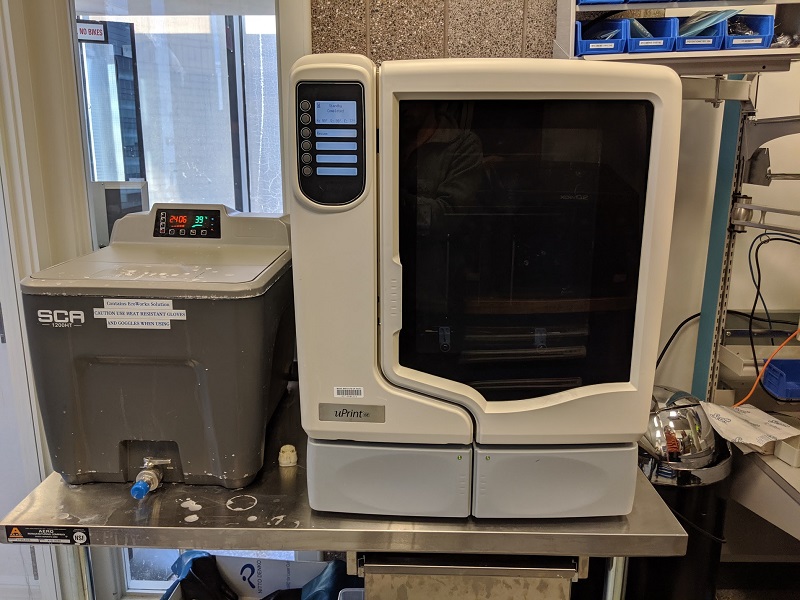

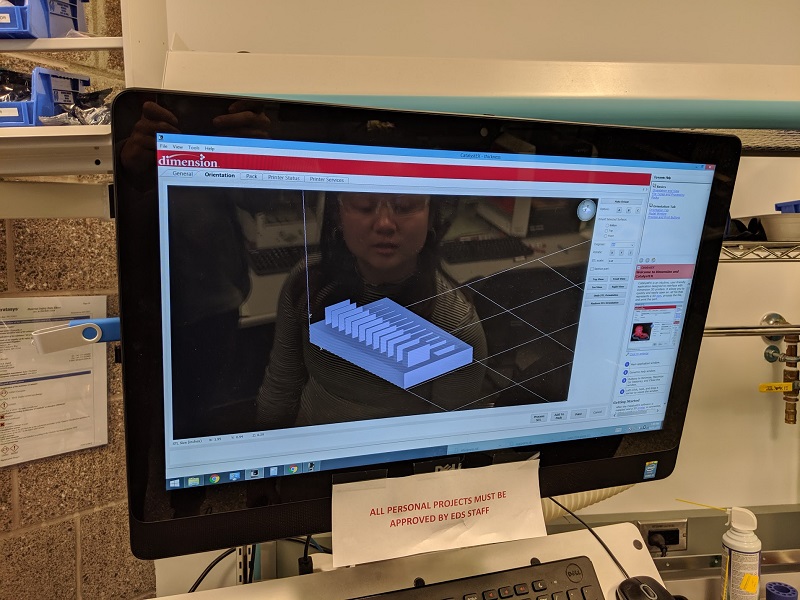

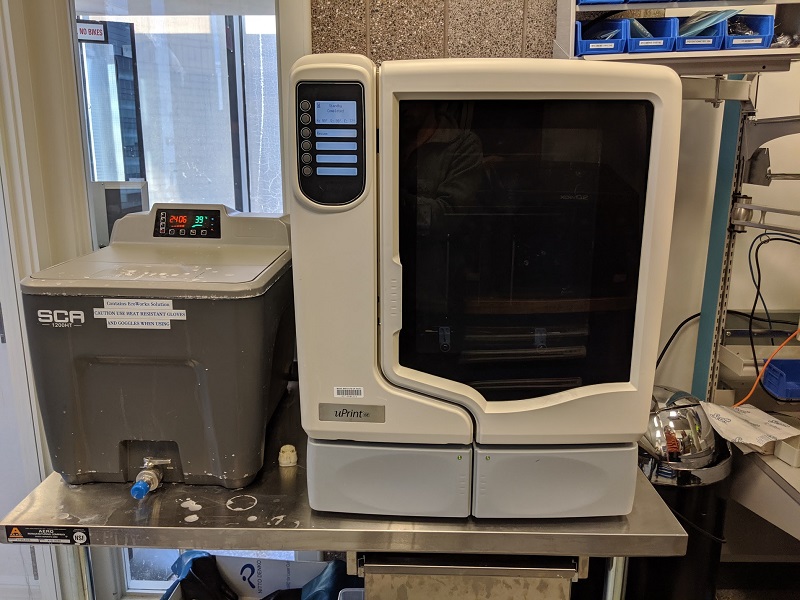

As always, the characterization is a very helpful step to working towards a final product. The EECS section

decided to divide and conquer. Not only did this reduce the time that the printer was operating, but it also reduced

the amount of material used overall. First as a small group we had to figure out what was to be printed. Honestly,

the printer did a really decent job. I don't have much to compare it to, but I was pretty happy with the results. Overall

it performed as it said it would and consistently put out parts within tolerances.

We probably should have gone in order, but why not make life a little more interesting.

We probably should have gone in order, but why not make life a little more interesting.

The 3D printer is such a neat tool. It aides in rapid prototyping, while reducing costs and resource use.

The 3D printer is such a neat tool. It aides in rapid prototyping, while reducing costs and resource use.

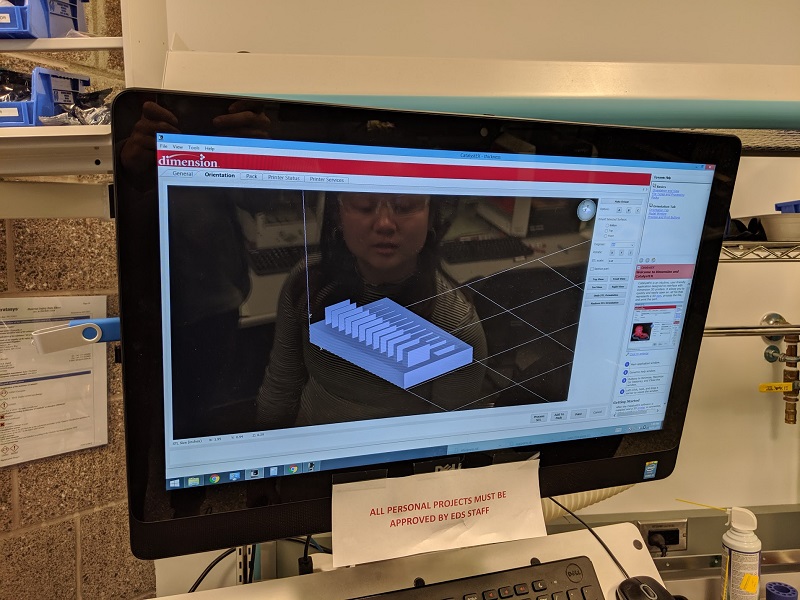

We took some good looks at the prints we were about to print. Did we need to scale them? Should we change anything else

about them?

We took some good looks at the prints we were about to print. Did we need to scale them? Should we change anything else

about them?

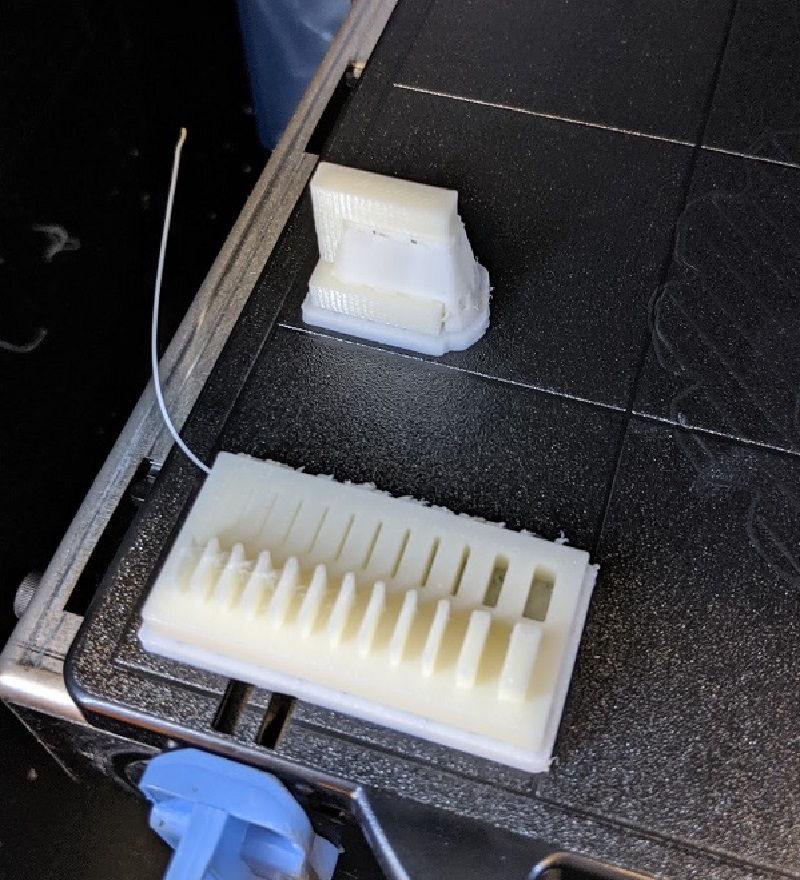

The support was a wonderful tool. This support really was nice being able to dissolve it (but we will get to that later.

The support was a wonderful tool. This support really was nice being able to dissolve it (but we will get to that later.

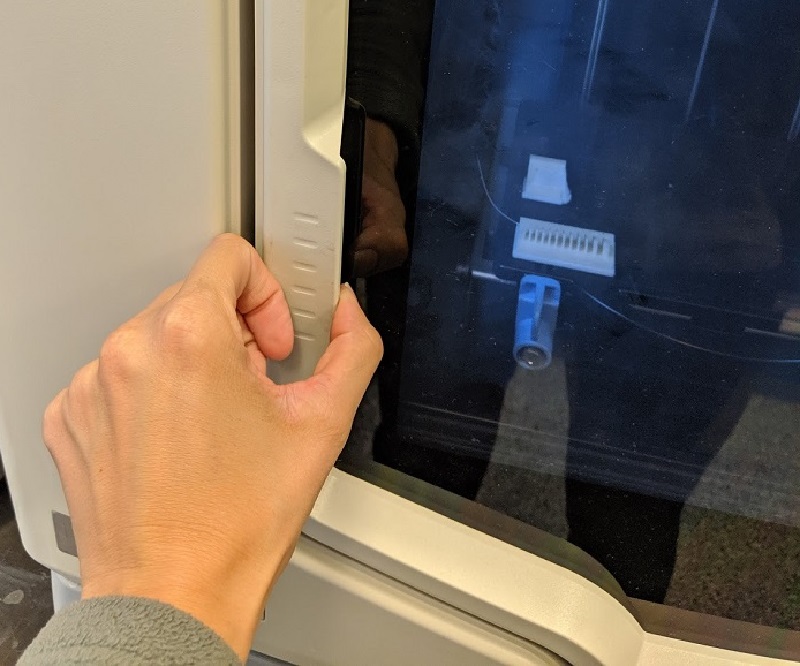

And so it begins!

And so it begins!

The moment of truth. I had other projects that I was working on, so I waited for the print.

The moment of truth. I had other projects that I was working on, so I waited for the print.

Honestly, this looks nice and tidy. I was happy with the outcome.

Honestly, this looks nice and tidy. I was happy with the outcome.

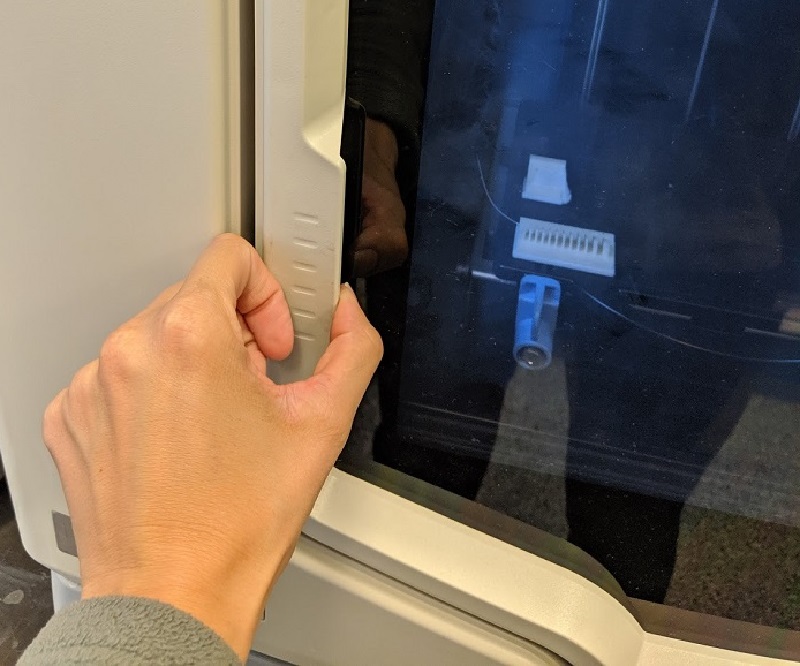

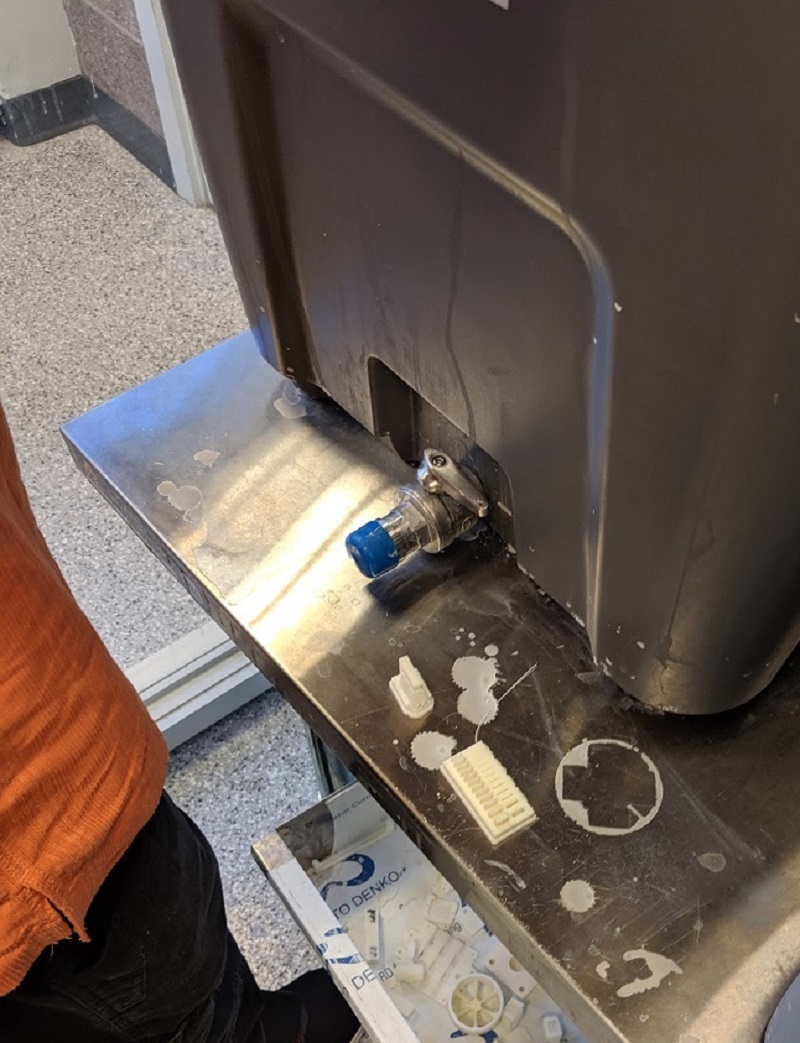

In the hand goes to draw out the basket!

In the hand goes to draw out the basket!

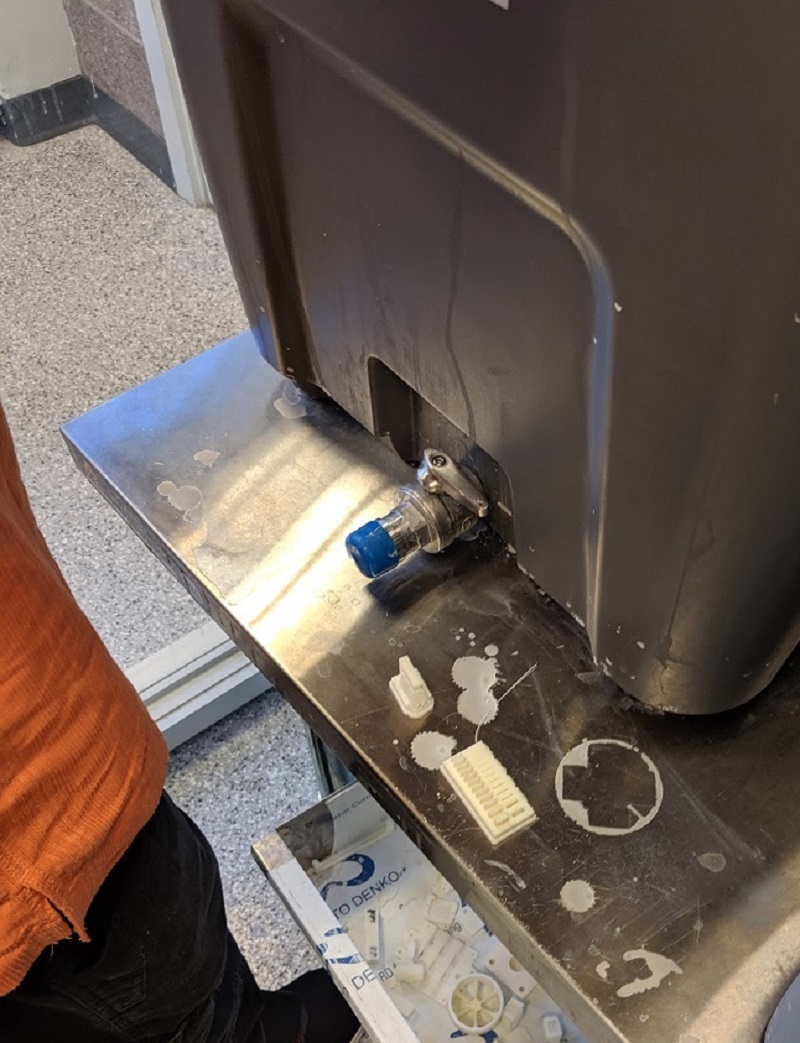

I know they are tiny, but at the very bottom of the bath, you can just make out our pieces.

I know they are tiny, but at the very bottom of the bath, you can just make out our pieces.

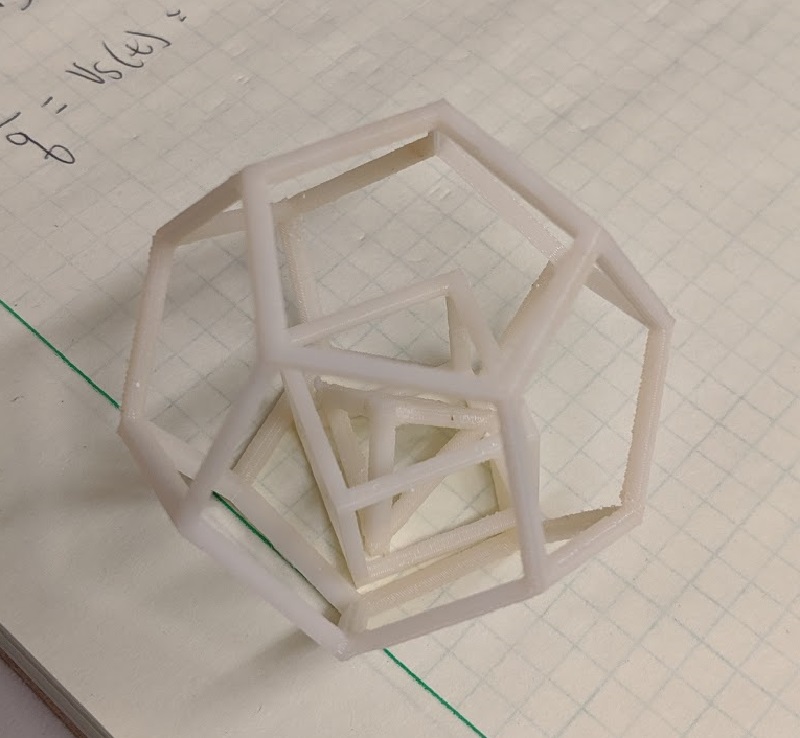

3D Printing Inception

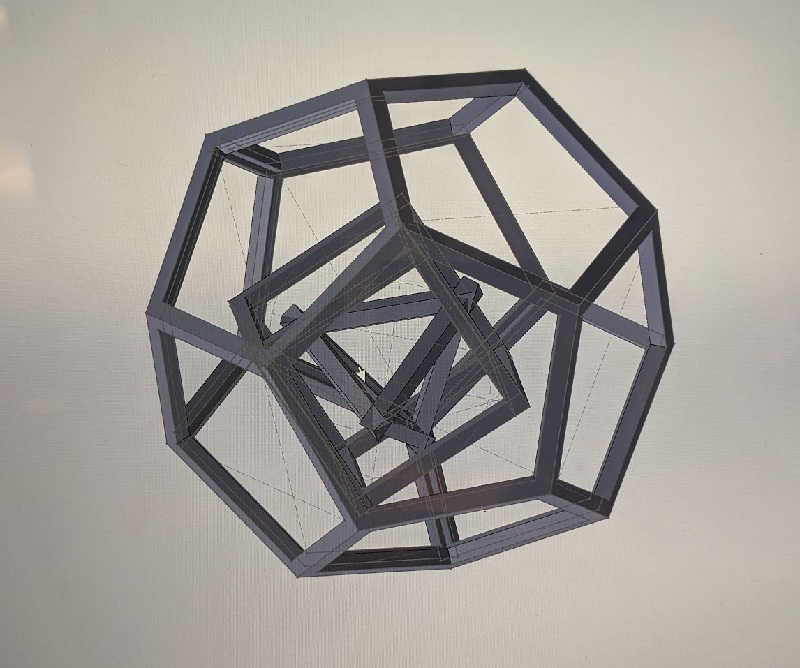

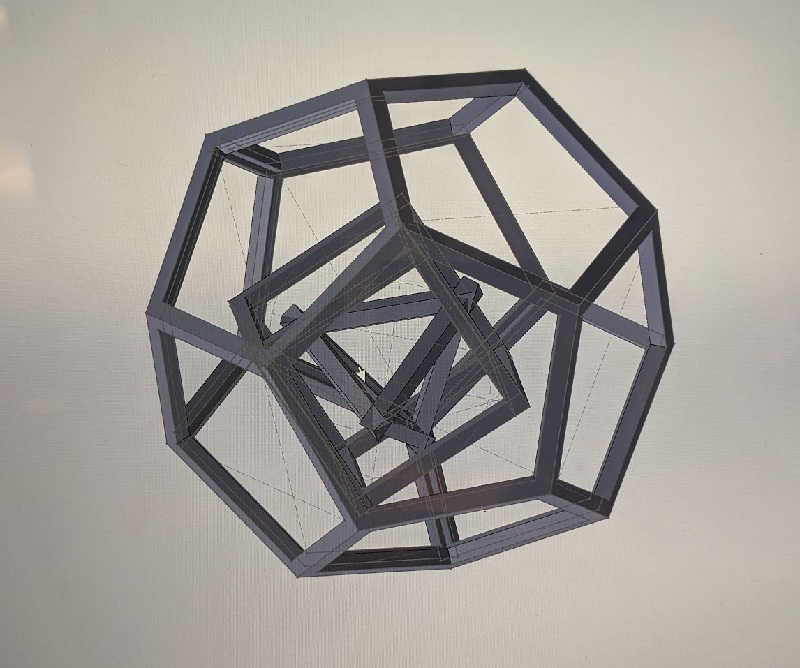

I honestly had a hard time thinking of something that could not be made subtractively. But eventually, I decided

on a pyramid, inside a cube, inside a sphere made with five-sided shapes. I was really excited for this. We were

able to find a cube inside a cube inside a cube that had been milled, but with consideration for the different shapes

I was given the green light.

I had forgotten the 3-sided picture, but at some point you just gotta call it.

All of my pieces started separatly and then I combined them as an assembly.

I had forgotten the 3-sided picture, but at some point you just gotta call it.

All of my pieces started separatly and then I combined them as an assembly.

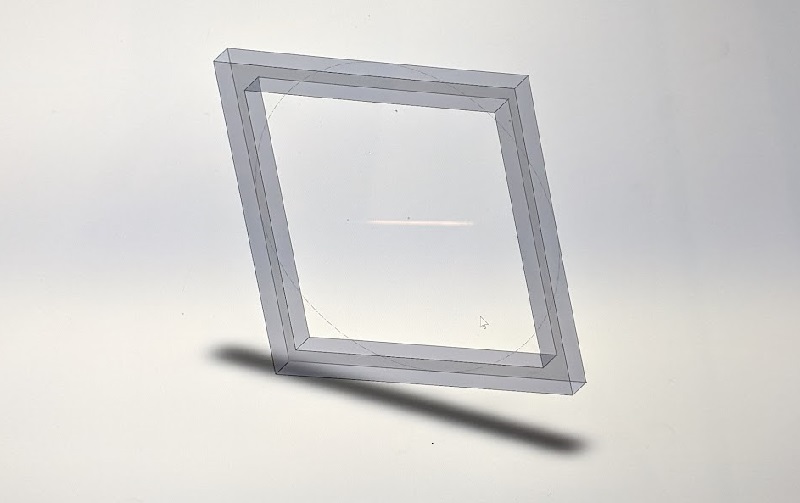

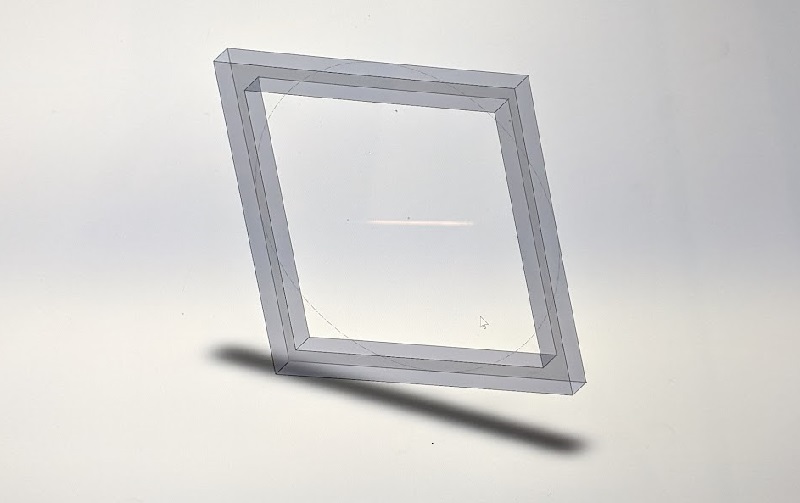

My five-sided base.

My five-sided base.

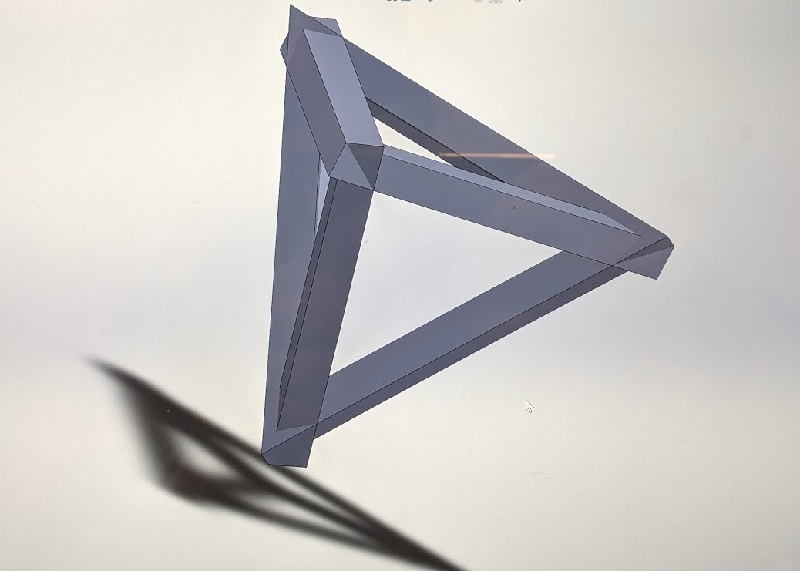

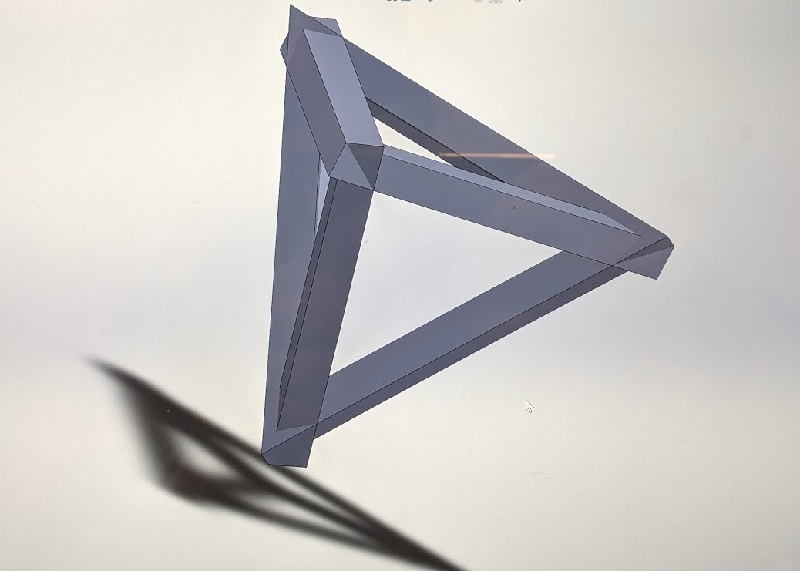

All the three-sided shapes placed together. Since the shape's angles were acute, I ended up with

little spurs on each corner. I liked them, so I kept them.

All the three-sided shapes placed together. Since the shape's angles were acute, I ended up with

little spurs on each corner. I liked them, so I kept them.

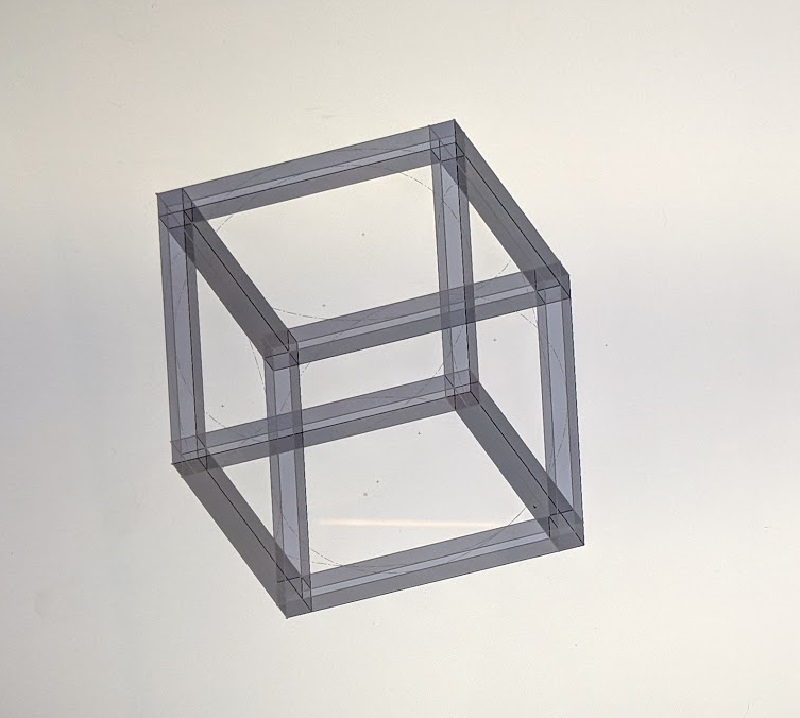

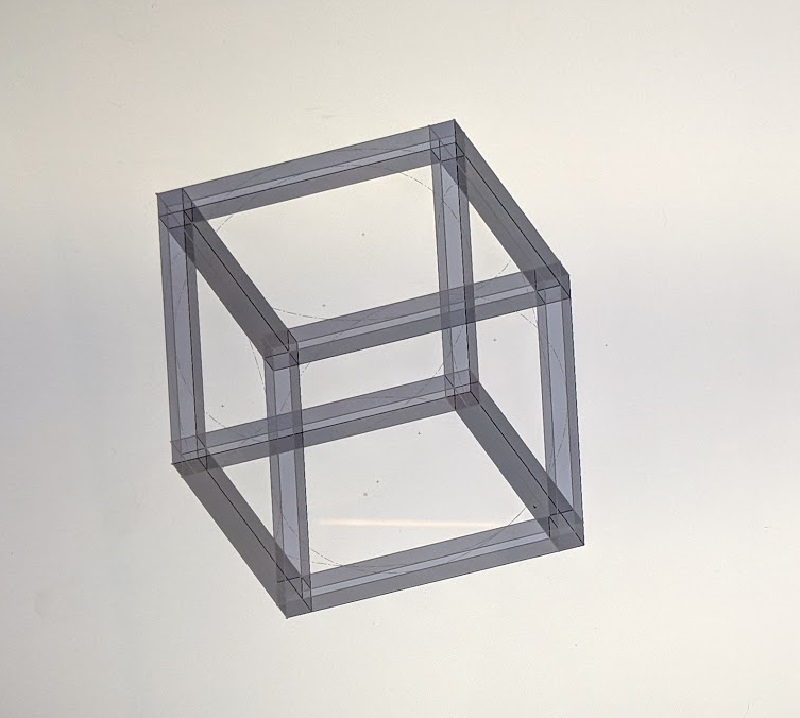

Here is my cube all put together. I basically took the outside edges of the extruded "2D" version and merged them

together. The end result was this.

Here is my cube all put together. I basically took the outside edges of the extruded "2D" version and merged them

together. The end result was this.

Once all my 3D shapes were created, the challenge was placing them all on the same plane with the same origin. I got there eventually

with some patience and stubborness.

Once all my 3D shapes were created, the challenge was placing them all on the same plane with the same origin. I got there eventually

with some patience and stubborness.

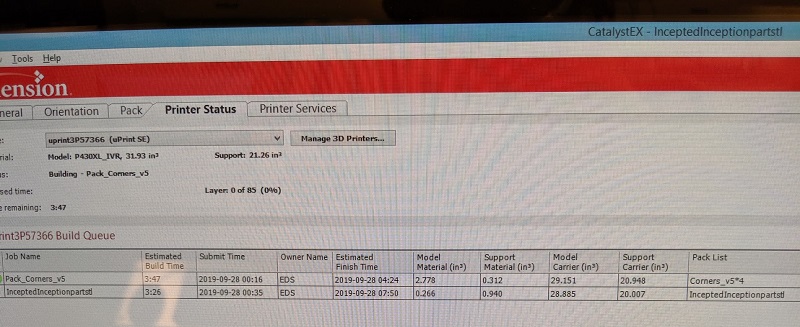

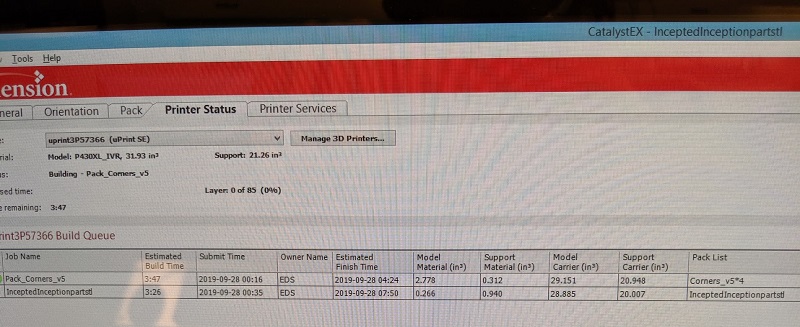

I then loaded my shape into the 3D printing software. It was a breeze. My footprint of support looked a little like this.

I then loaded my shape into the 3D printing software. It was a breeze. My footprint of support looked a little like this.

The support material seemed like a lot, but upon inspection it wasn't as much as I had expected.

The support material seemed like a lot, but upon inspection it wasn't as much as I had expected.

I almost timed it right to be first, but I wasn't quite quick enough. That's alright, I found out that you can queue your prints.

What a luxury!

I almost timed it right to be first, but I wasn't quite quick enough. That's alright, I found out that you can queue your prints.

What a luxury!

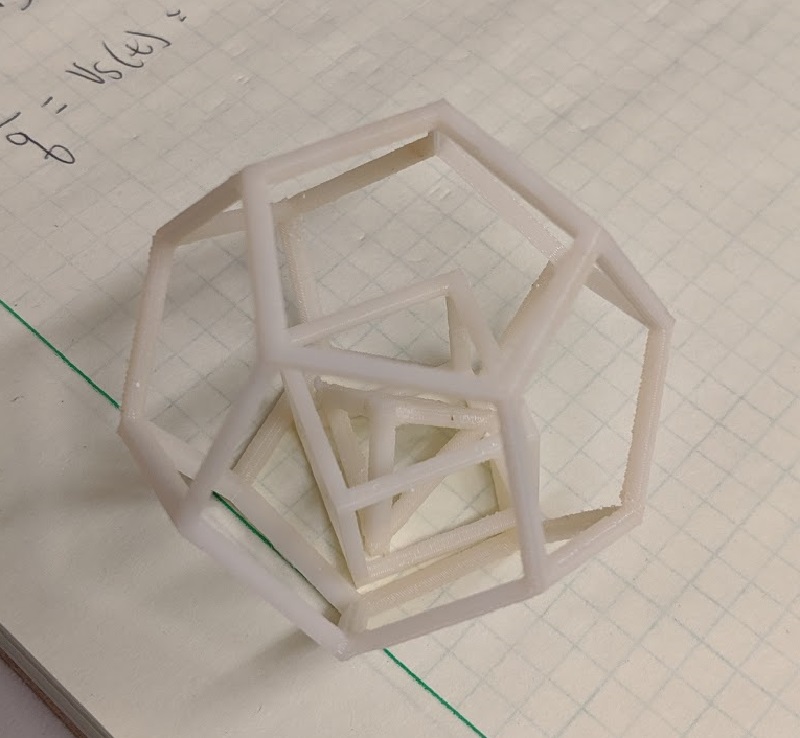

And TADAH! The final outcome! It was almost perfect. I had done the math wrong and occasionally my triangle would sidebarCollapse

out, but honestly I enjoyed the minor flaw.

And TADAH! The final outcome! It was almost perfect. I had done the math wrong and occasionally my triangle would sidebarCollapse

out, but honestly I enjoyed the minor flaw.

Roadtrips with friends are the best!

Roadtrips with friends are the best!