Week 05

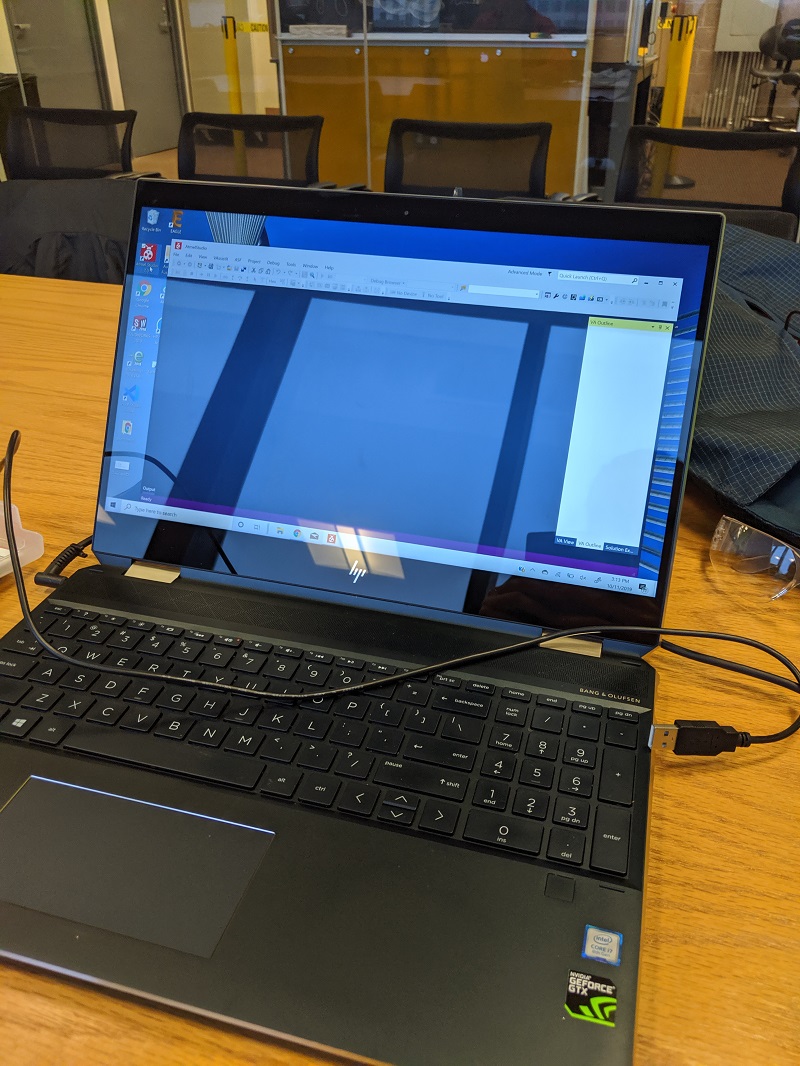

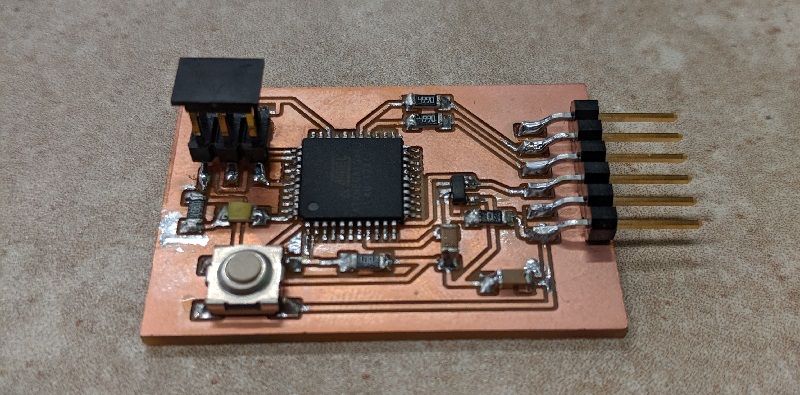

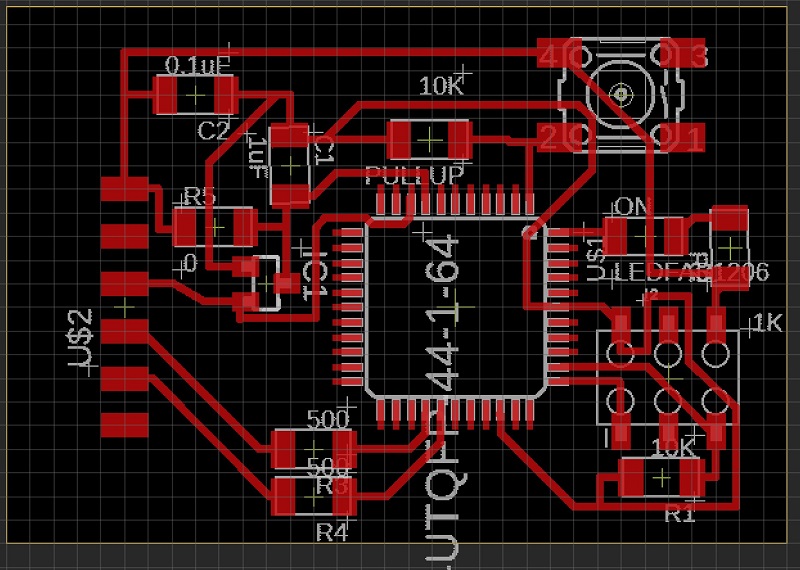

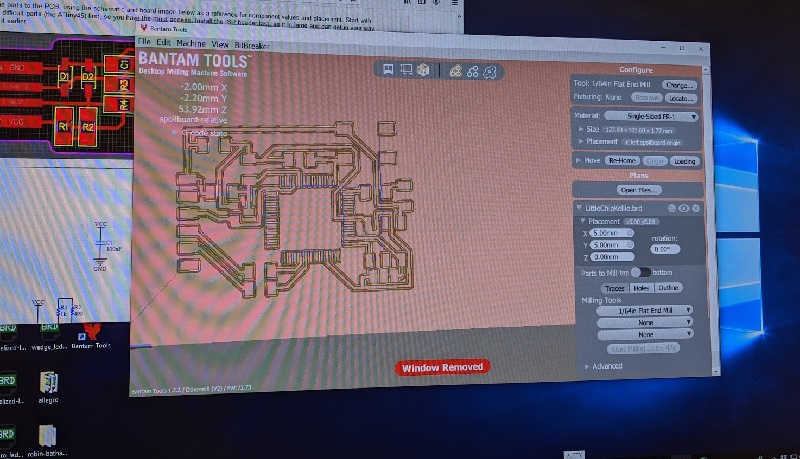

Electronics Design

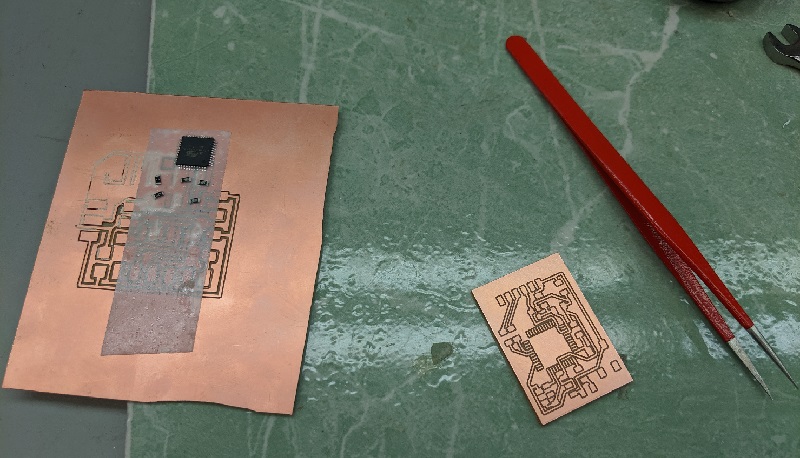

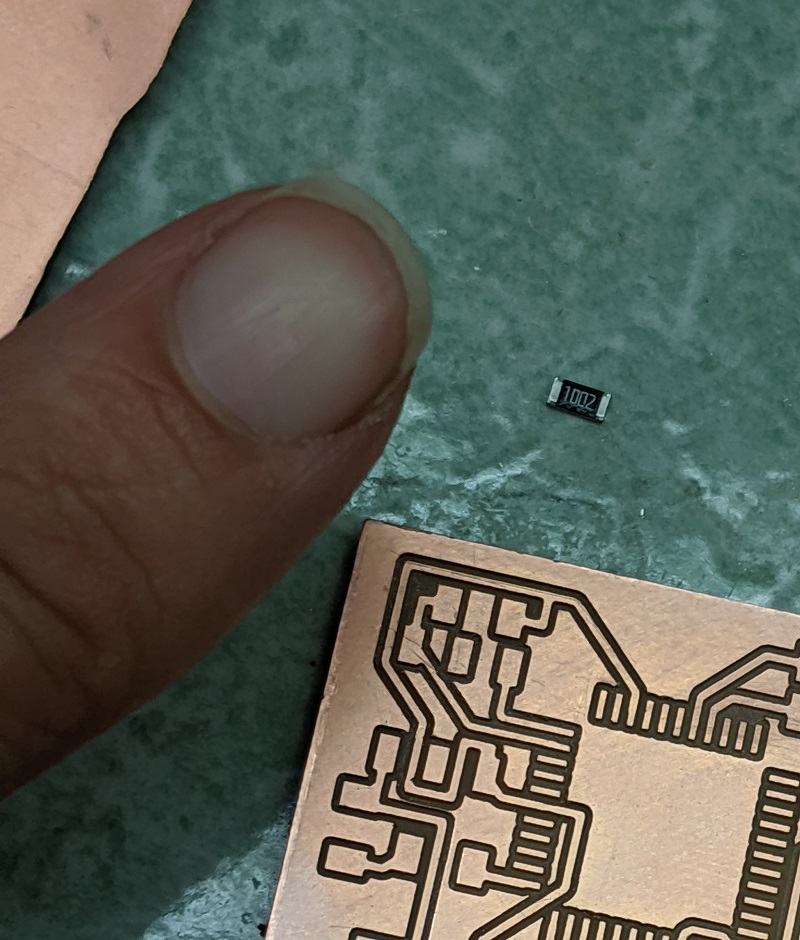

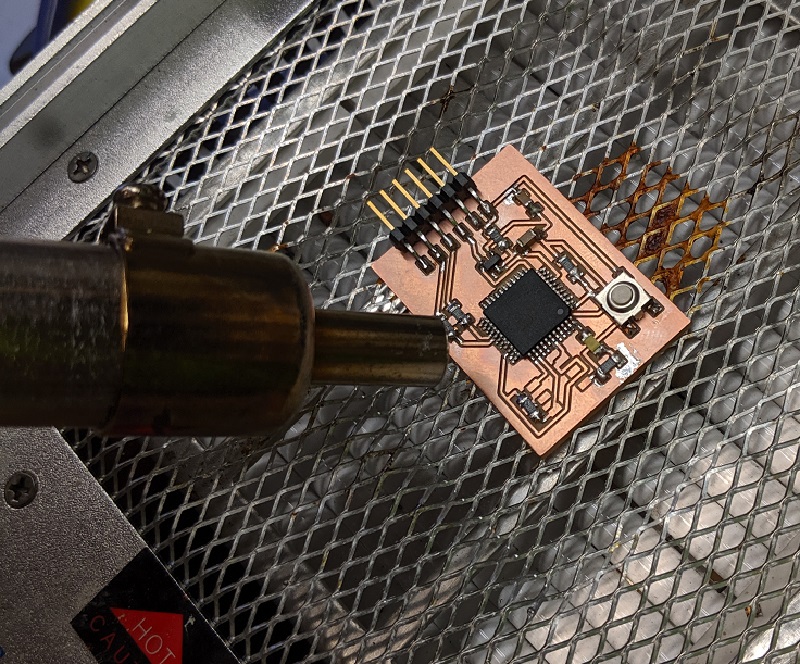

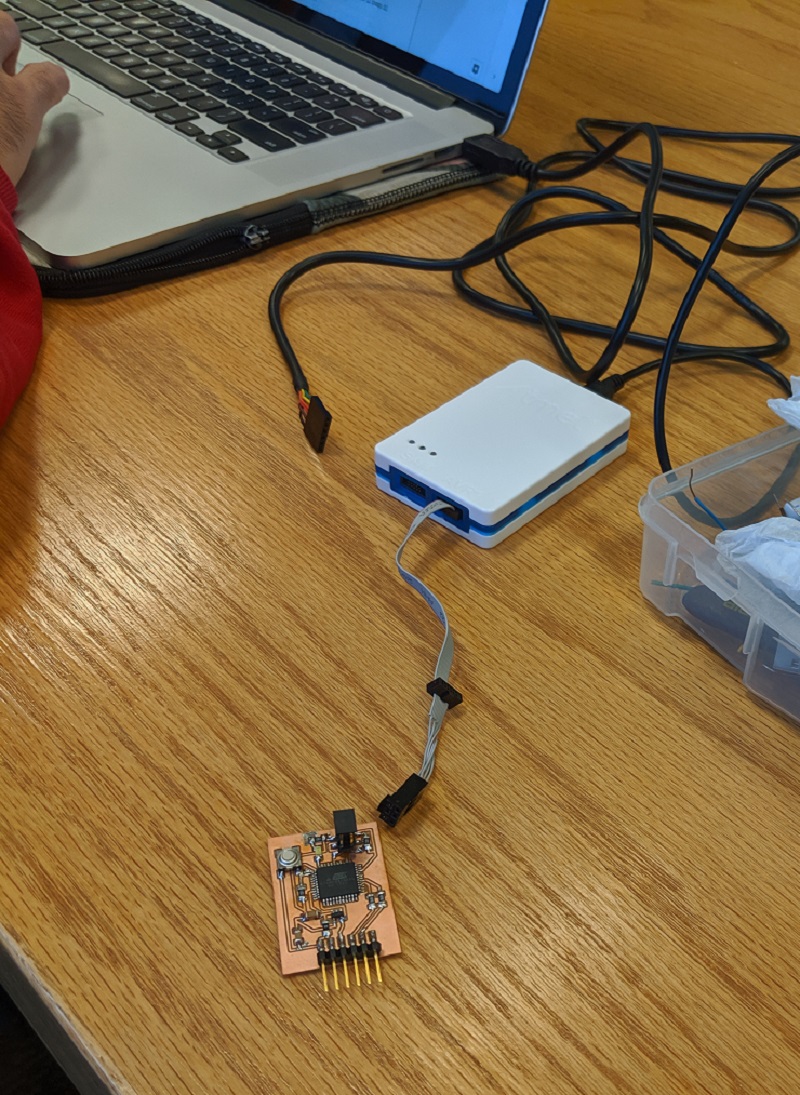

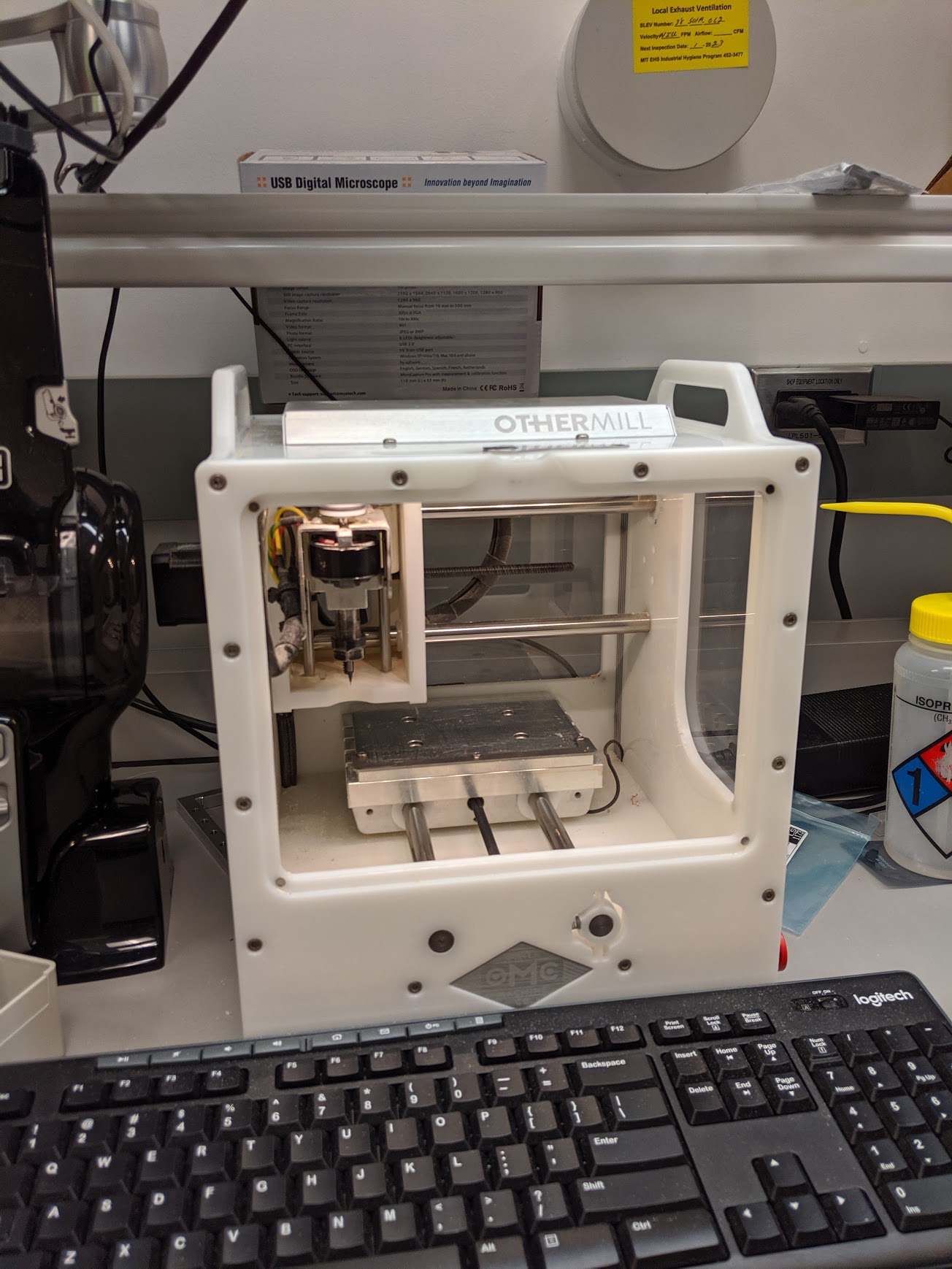

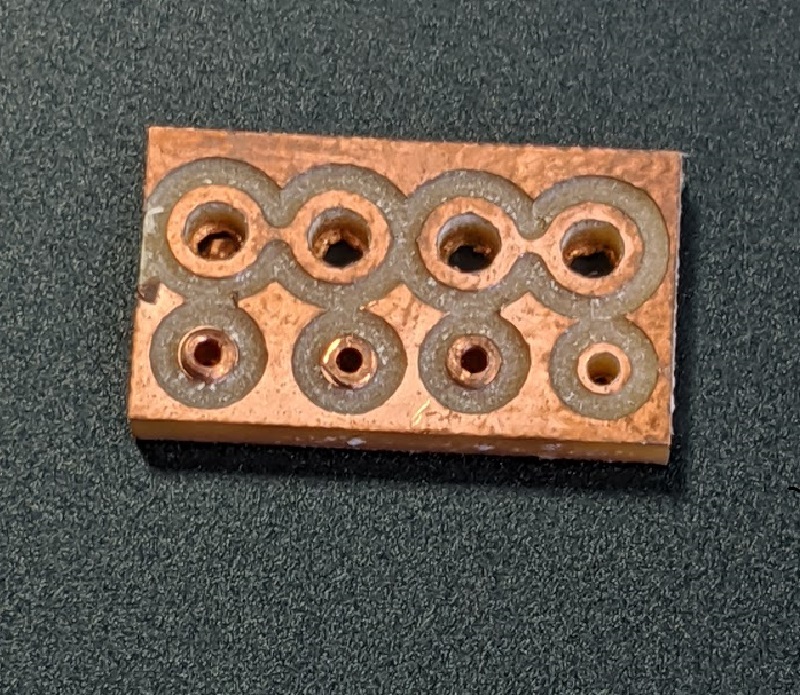

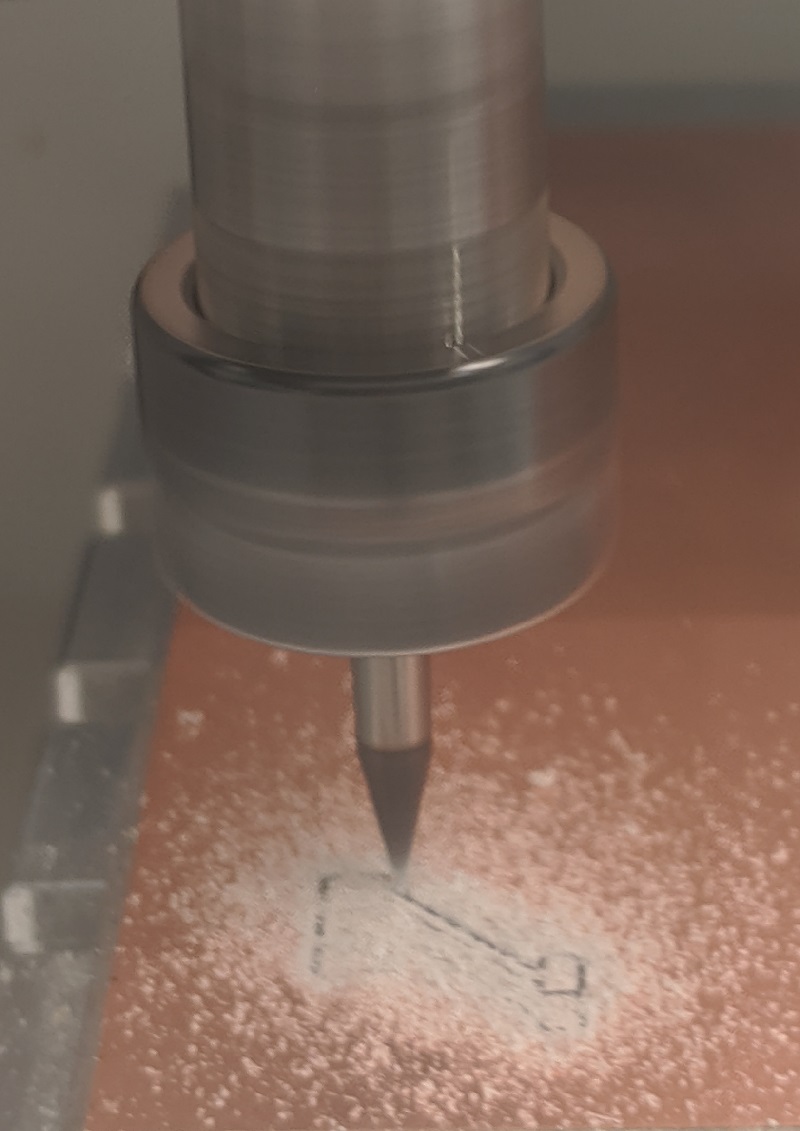

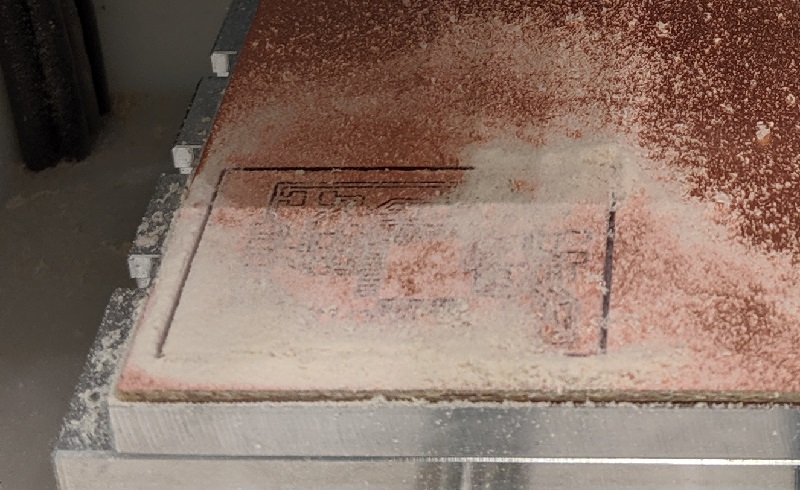

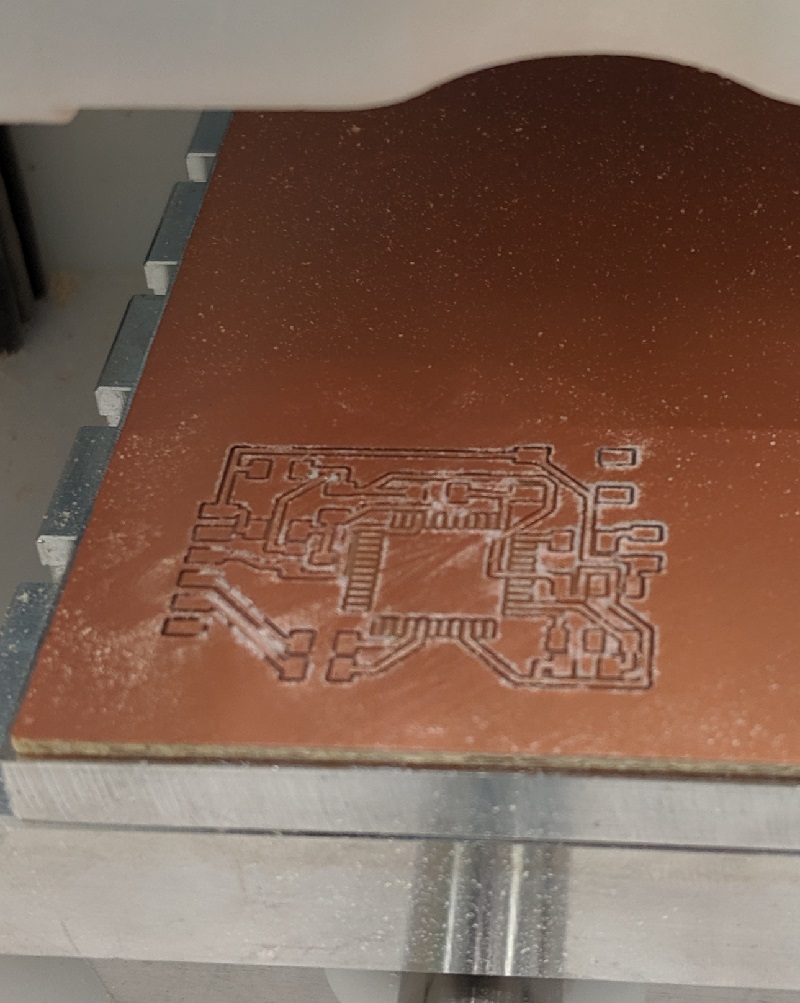

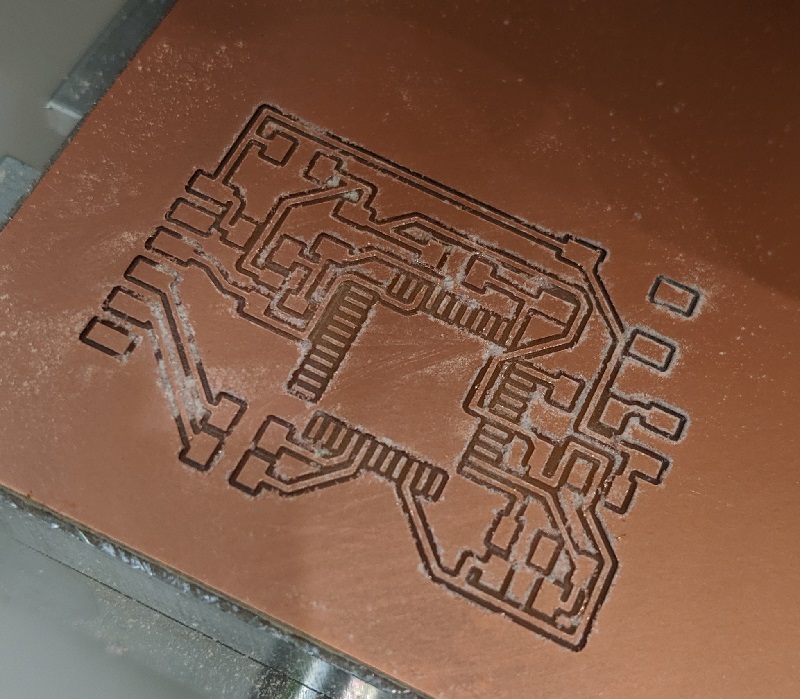

Milling Copper

I use to play with fairly expensive boards ($10K per board), so it was neat being able to work with a board that I wasn't afraid to mess up. Obviously wasting time was not on my agenda, but I did want to see and learn all that I could.

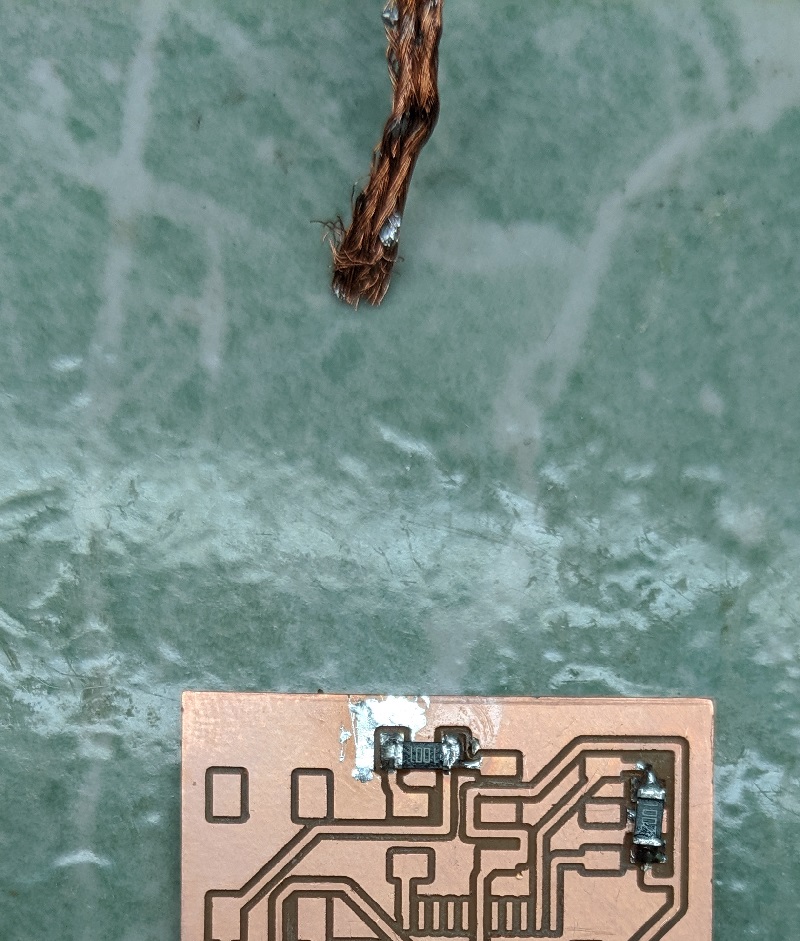

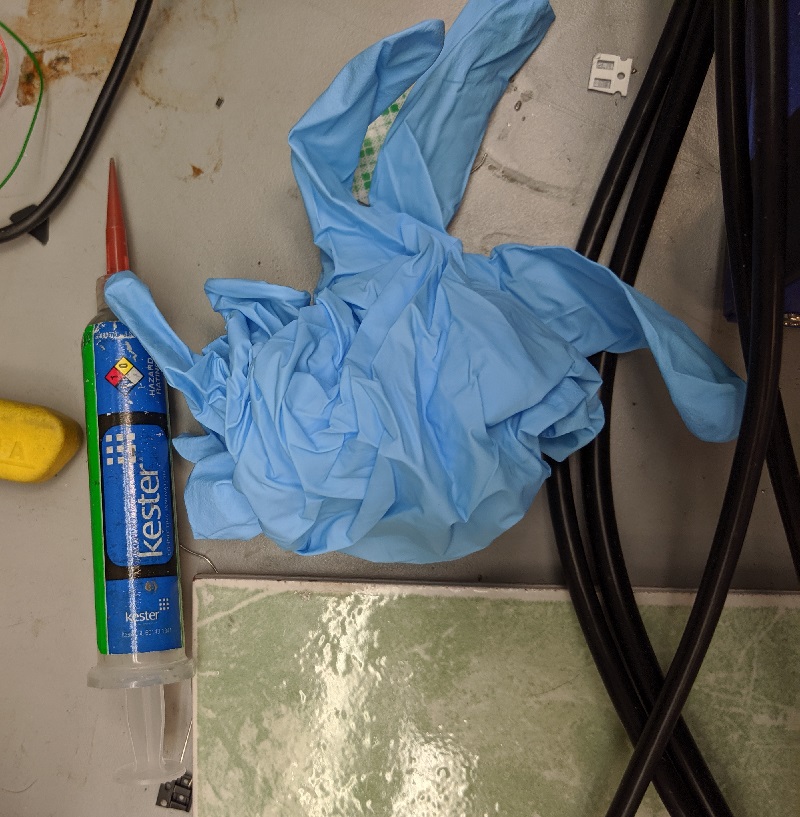

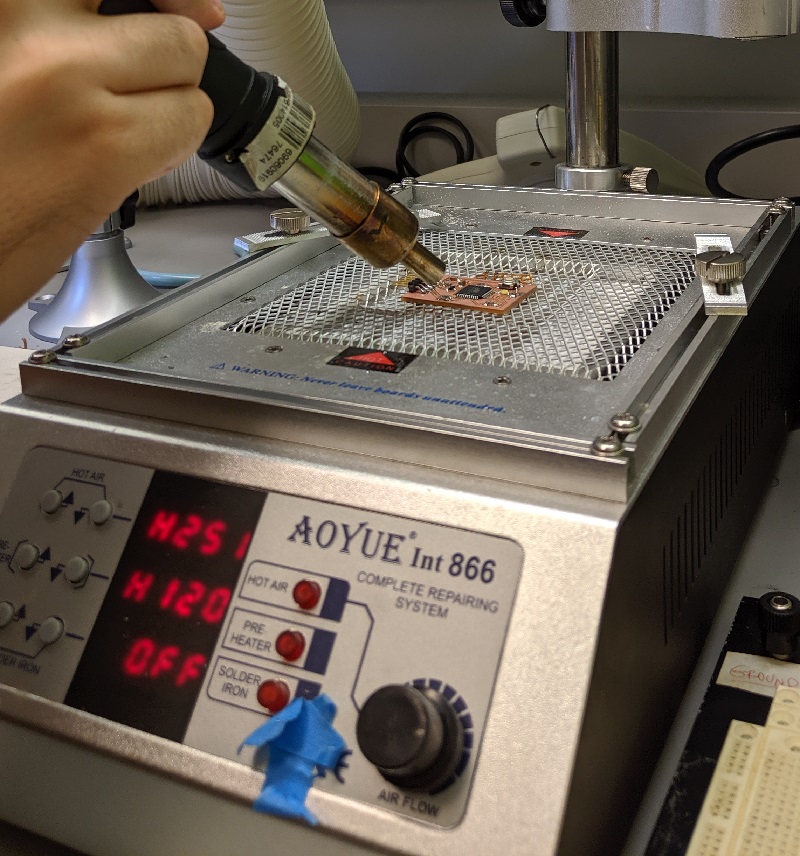

Solder Adventures