Week 06

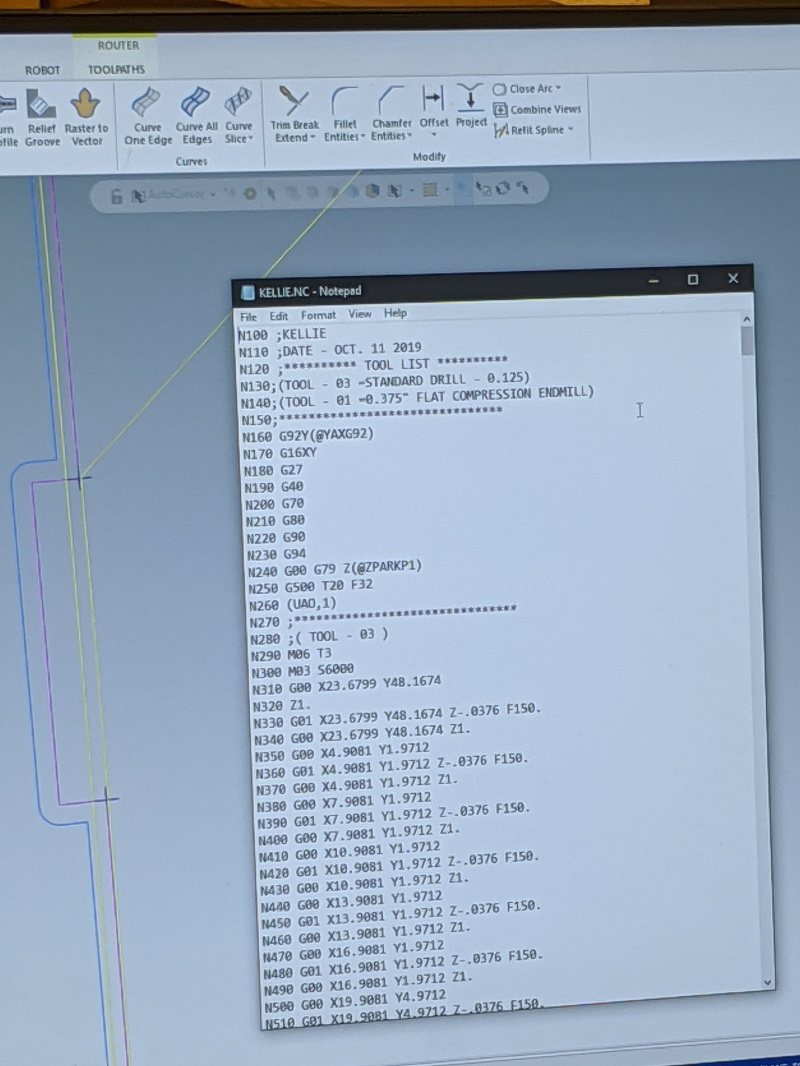

Computer-Controlled Machining

Basic Thoughts and Sketches

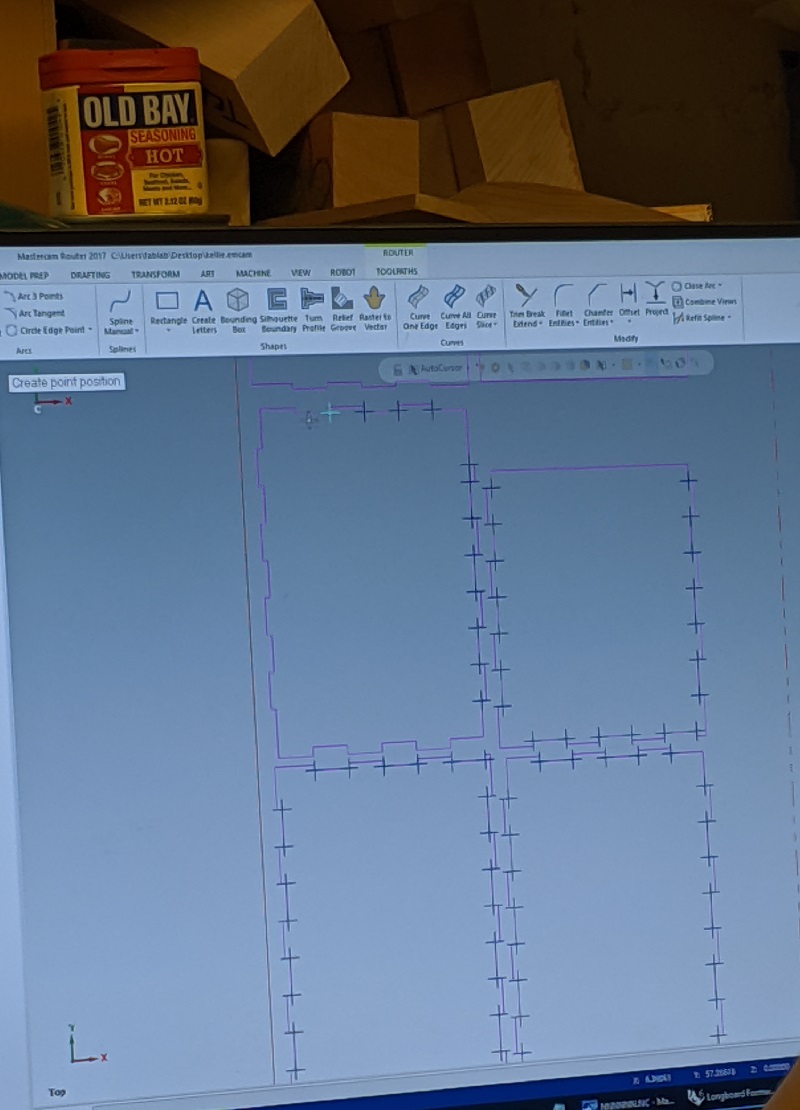

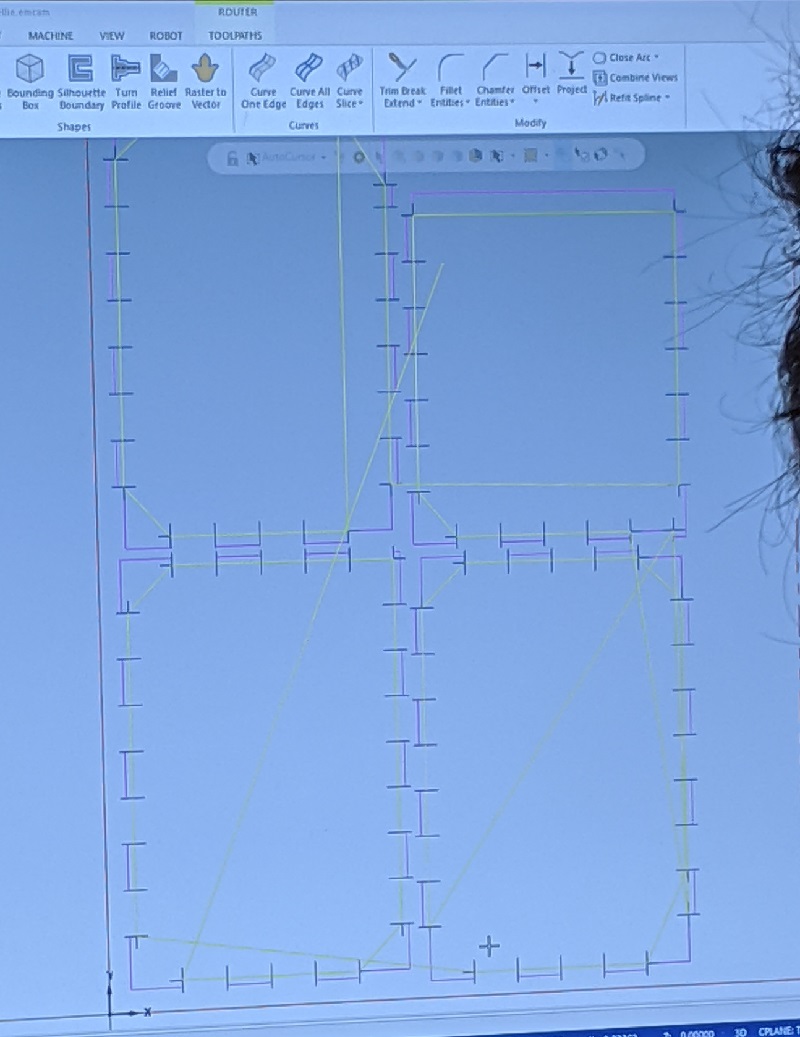

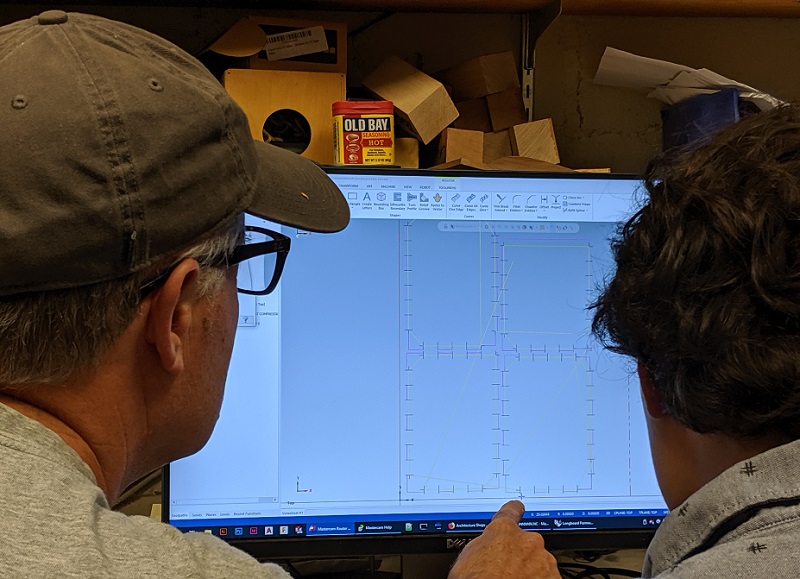

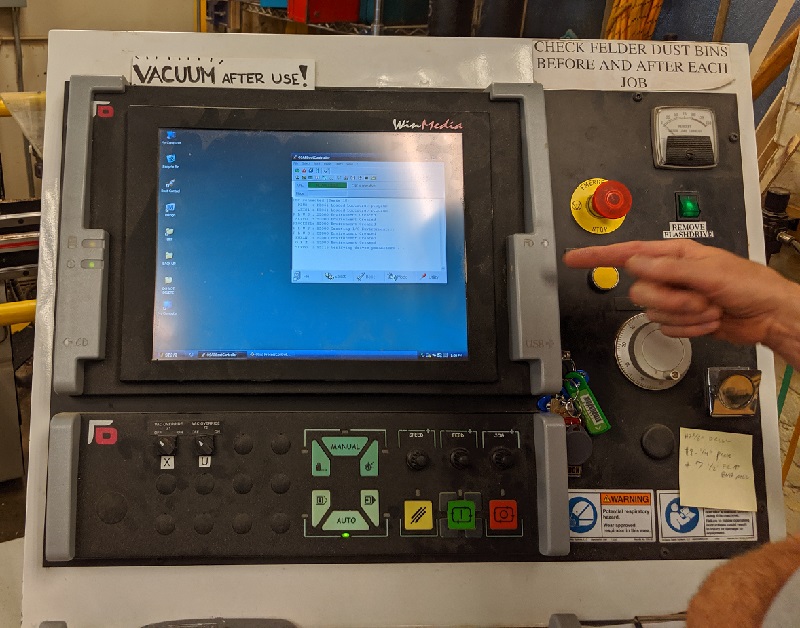

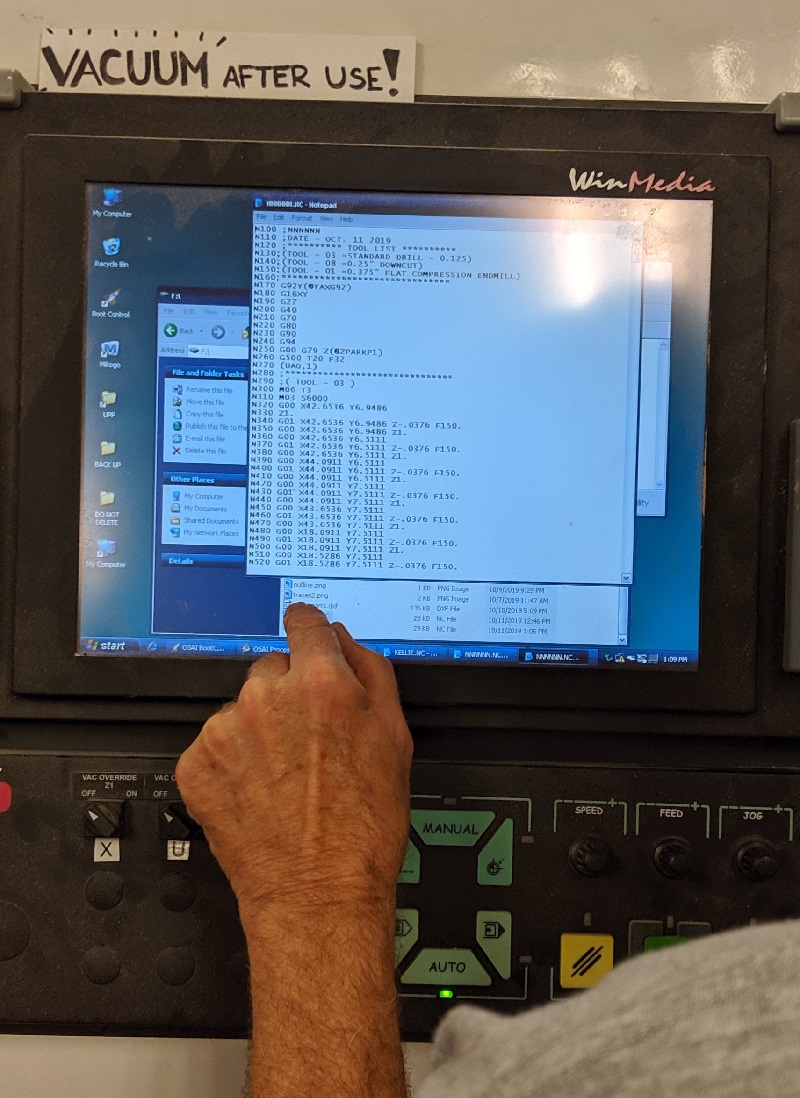

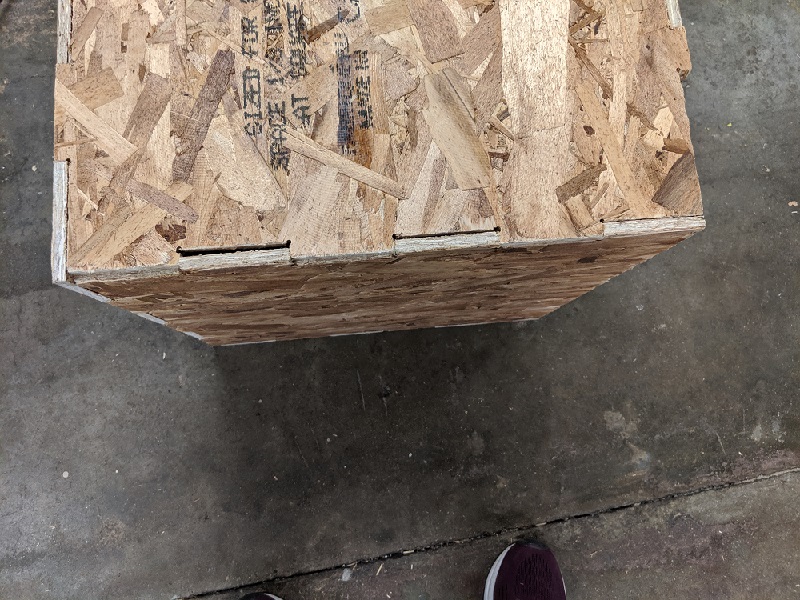

Going over to the Architecture Shop was a blast. It was intriguing to see a different type of shop. Of course it ran slightly differently than the EECS shop that I am use to. But that is ok. Upon asking to characterize the equipment it was sorta shrugged off. It seemed as if the shop caretaker knew what was best for the machine and didn't want to run a bunch of potentially hazardous projects on it. Instead, we were taught what the proper setup was and guided. (I really cannot blame him, that is an expensive piece of equipment.)

Fluff RIP 14OCT2019