Assignment:

Tasks:

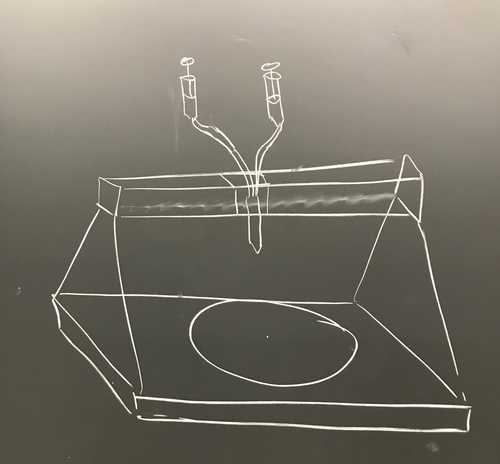

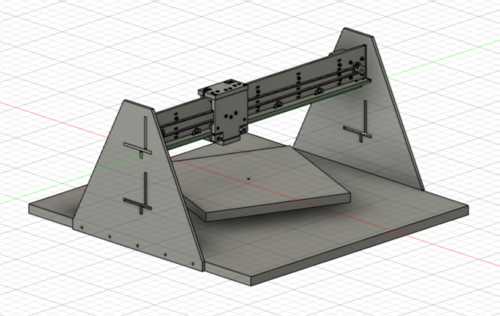

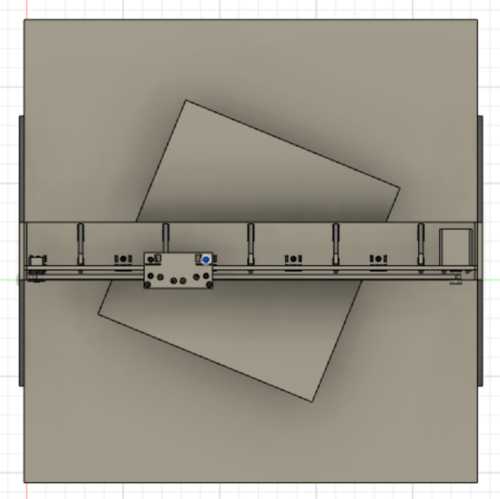

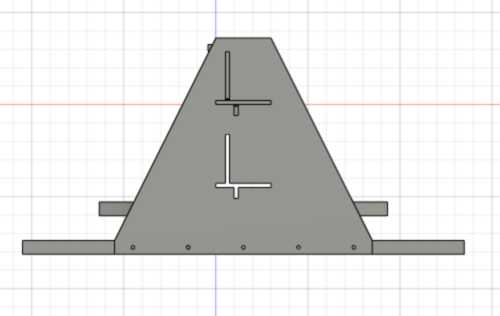

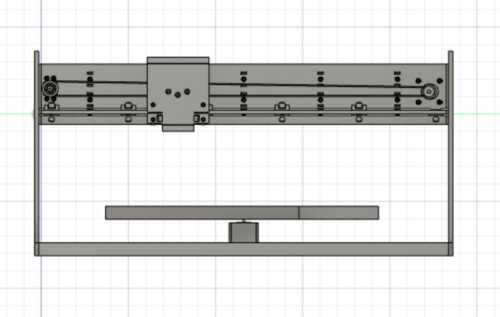

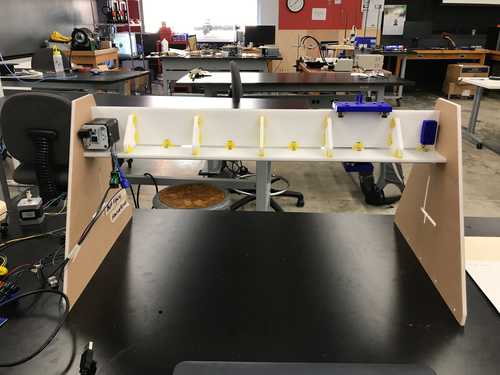

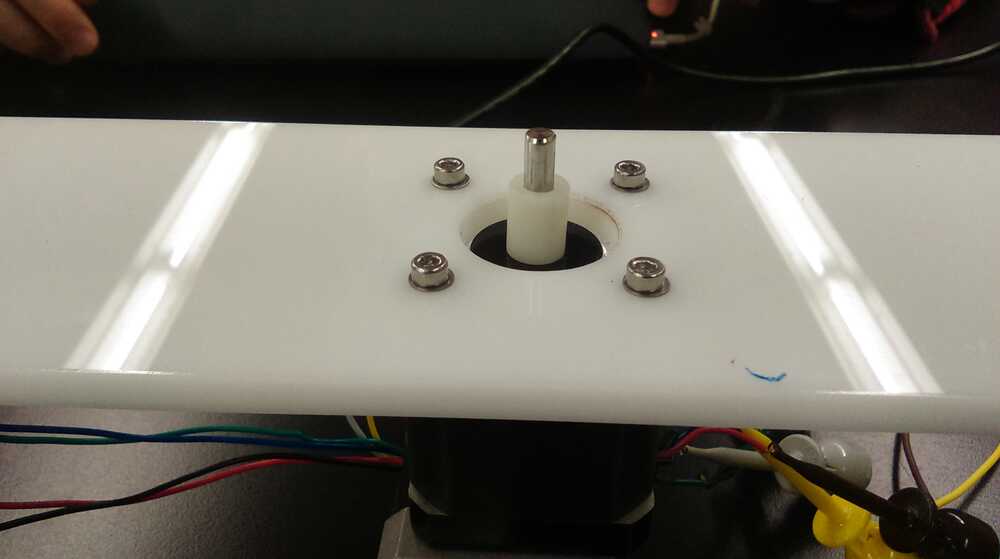

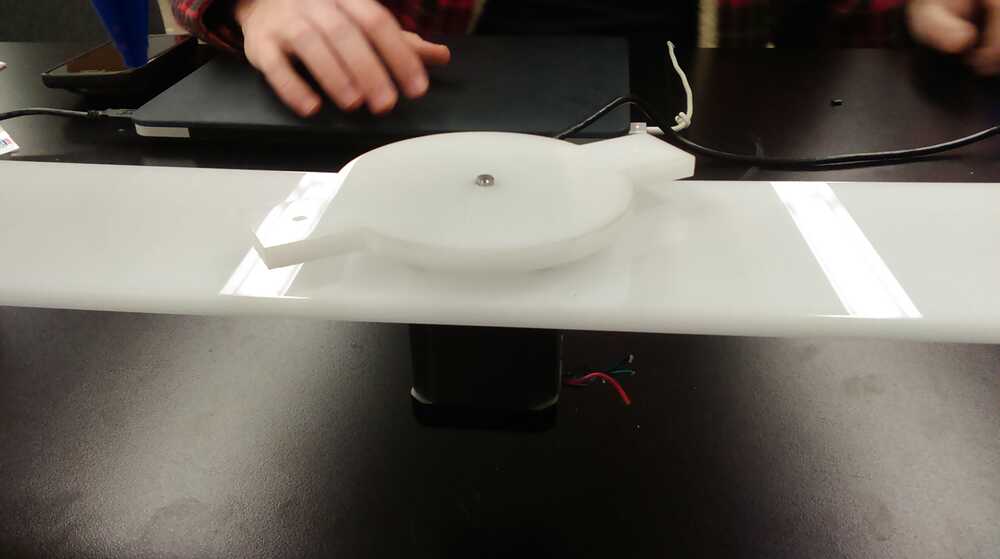

After the linear stage had been assembled and a team had begun work on the software interface to the axis, another team began work on the rotary axis underneath. We decided to mount a stepper underneath the linear stage and then to attach a turntable directly to the stepper shaft. We used a small plastic bushing drilled out to the right size to give the turntable clearance from the support bracket.

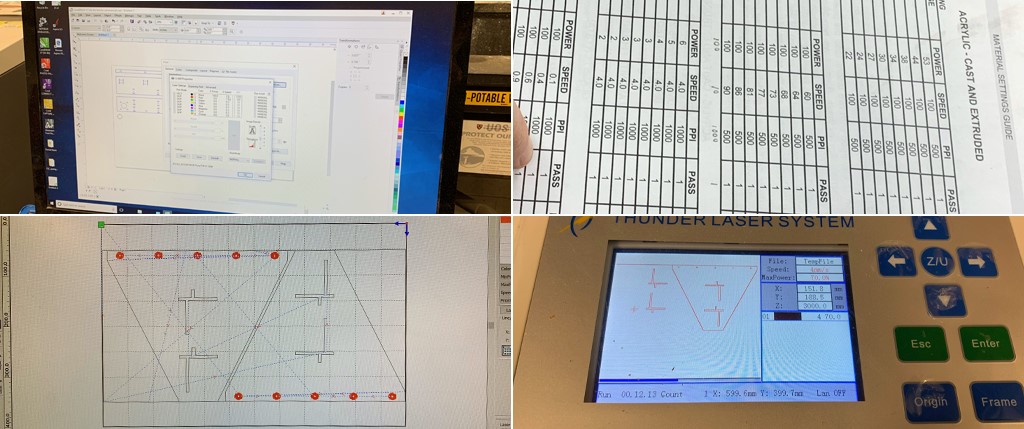

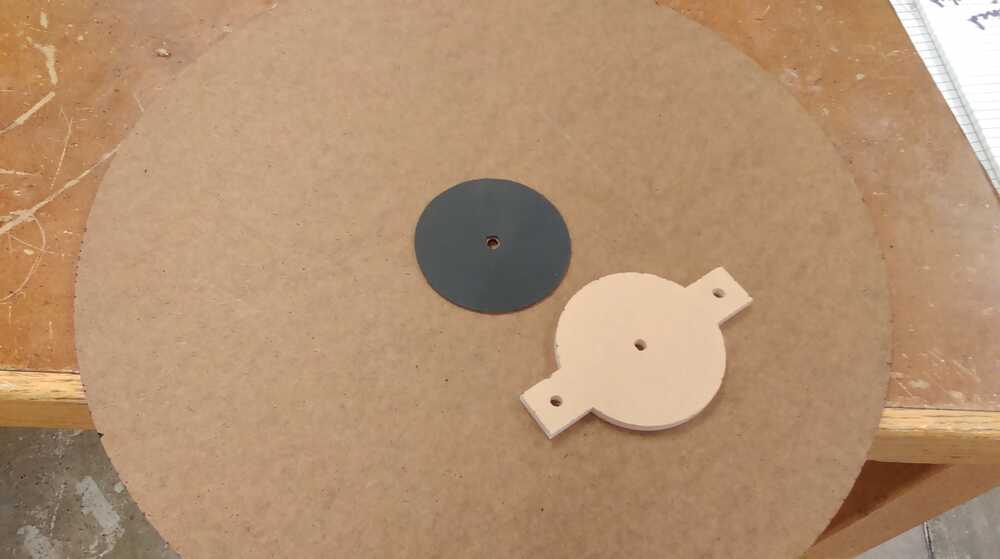

We laser cut an acrylic bracket to mount the turntable to the motor shaft. It turns out that the laser cutter does not do a good job at cutting holes with precisely vertical edges, so we cut the holes a bit small on the laser cutter and then drilled them to fit the shaft snugly with a drill press.

We thought it would be convenient to be able to remove the turntable easily to mount a new sheet of paper or canvas, so we mounted a circular pad from a sticky rubber sheet on the turntable to provide a friction clutch against the acrylic bracket.

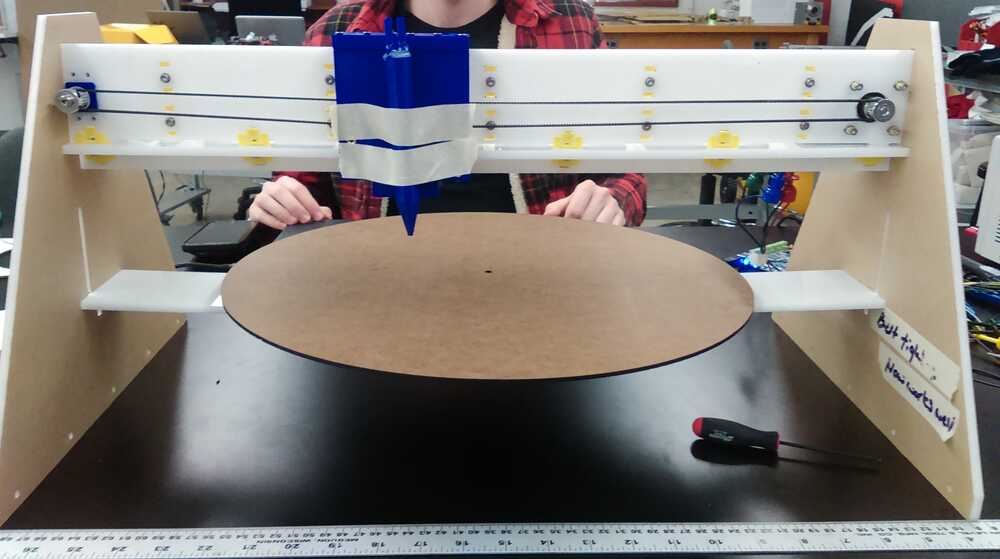

With the rotary turntable assembled, the machine was ready to test!

<<<<<<< HEAD

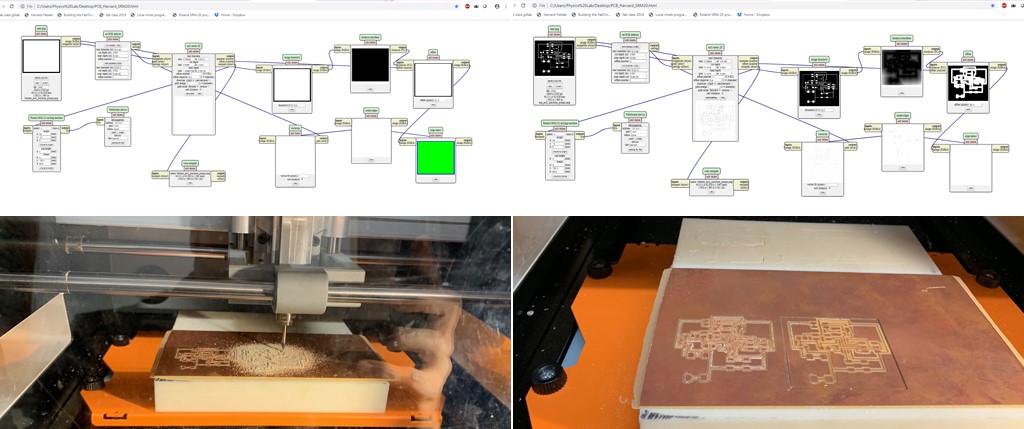

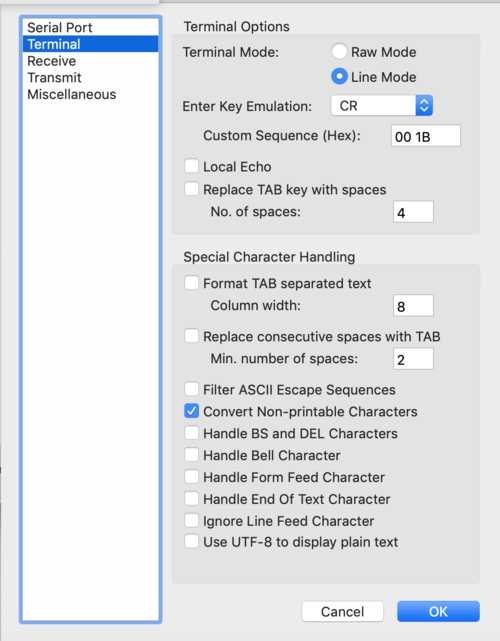

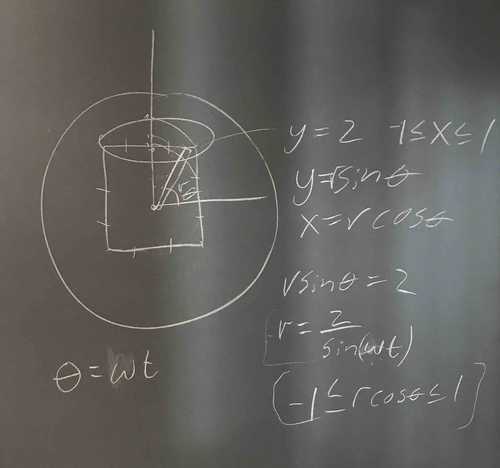

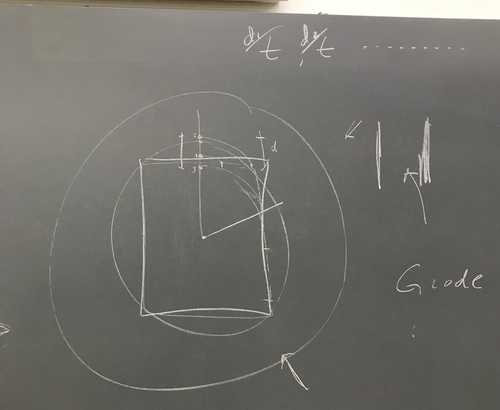

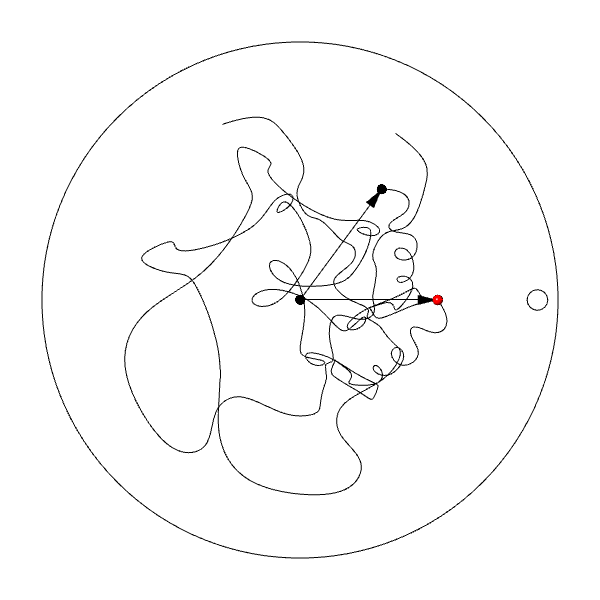

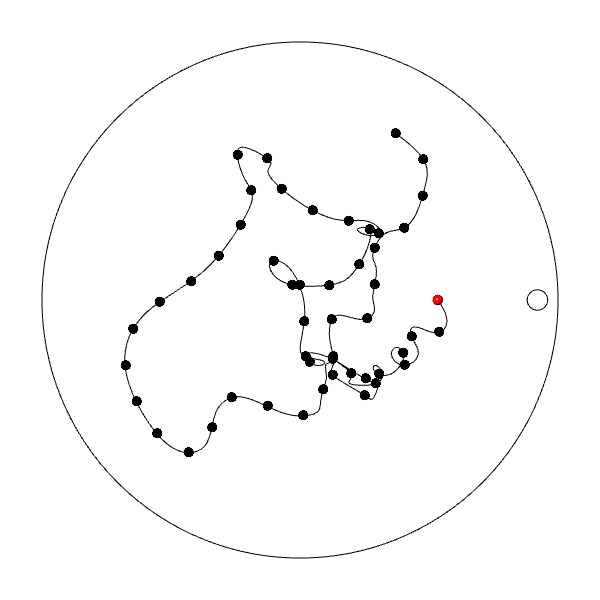

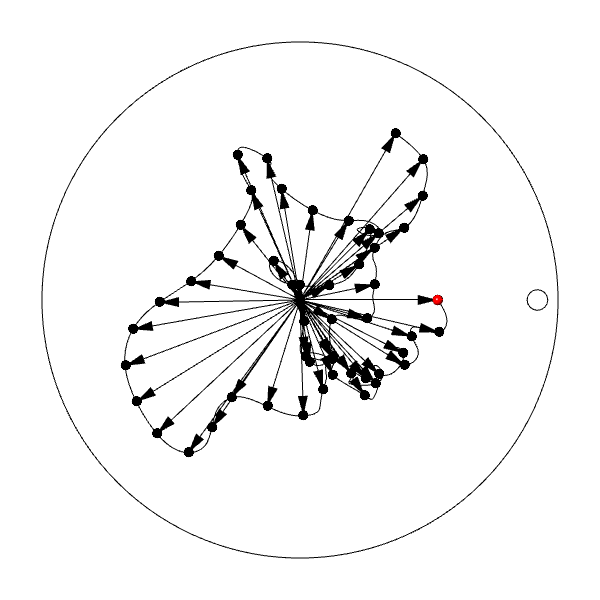

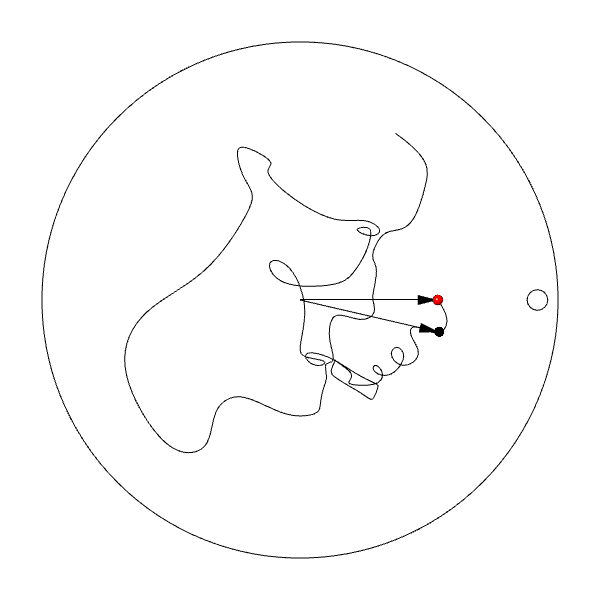

Calculation-rotation movement and linear movment

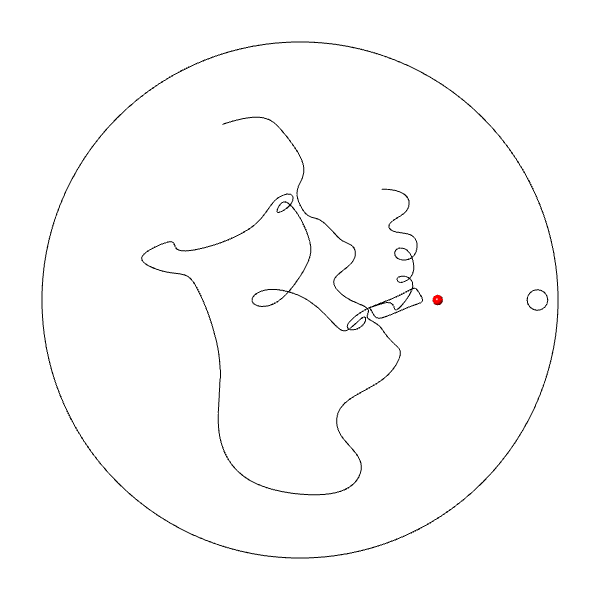

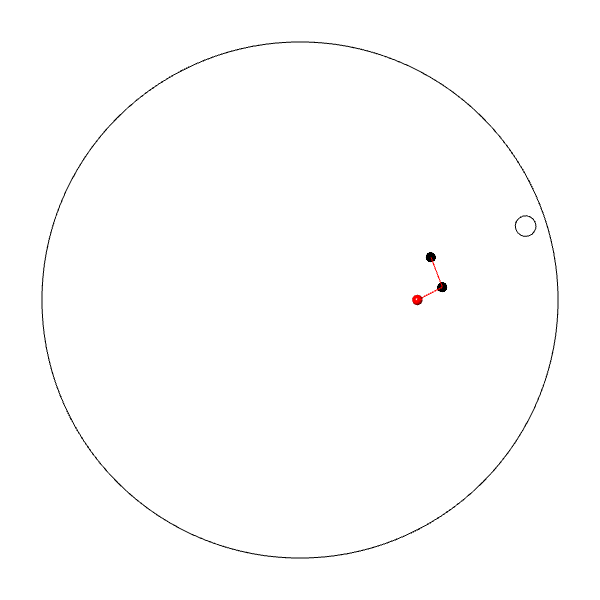

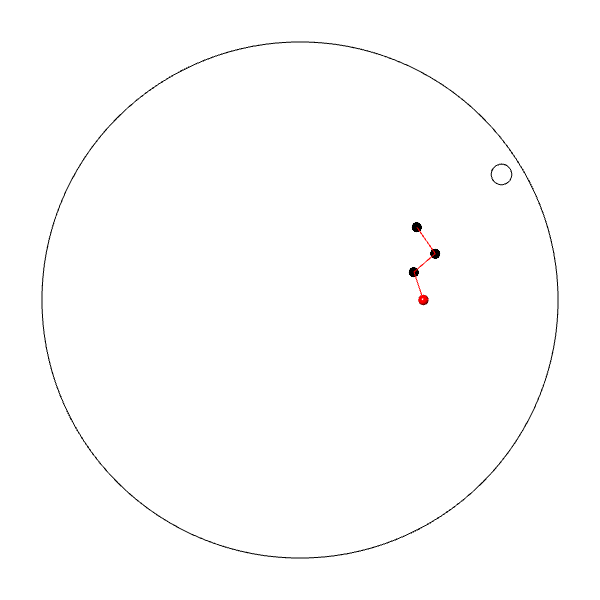

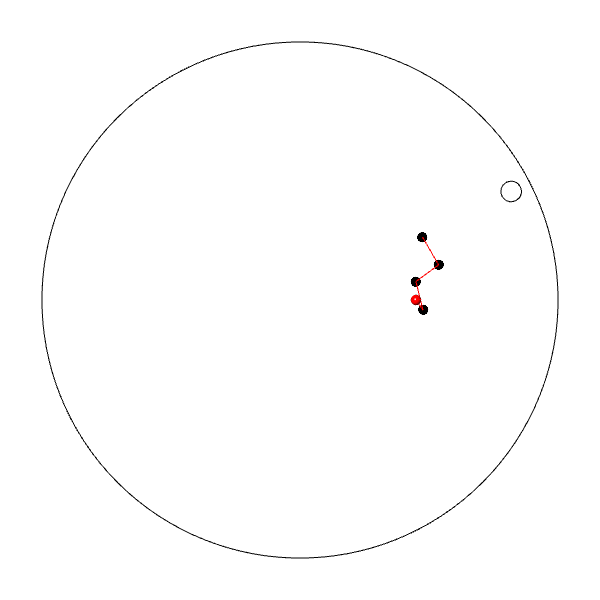

Simulation of pen drawing.

>>>>>>> 5b992d2d017ba677d2f2f1e75b3e1b20d67b86af

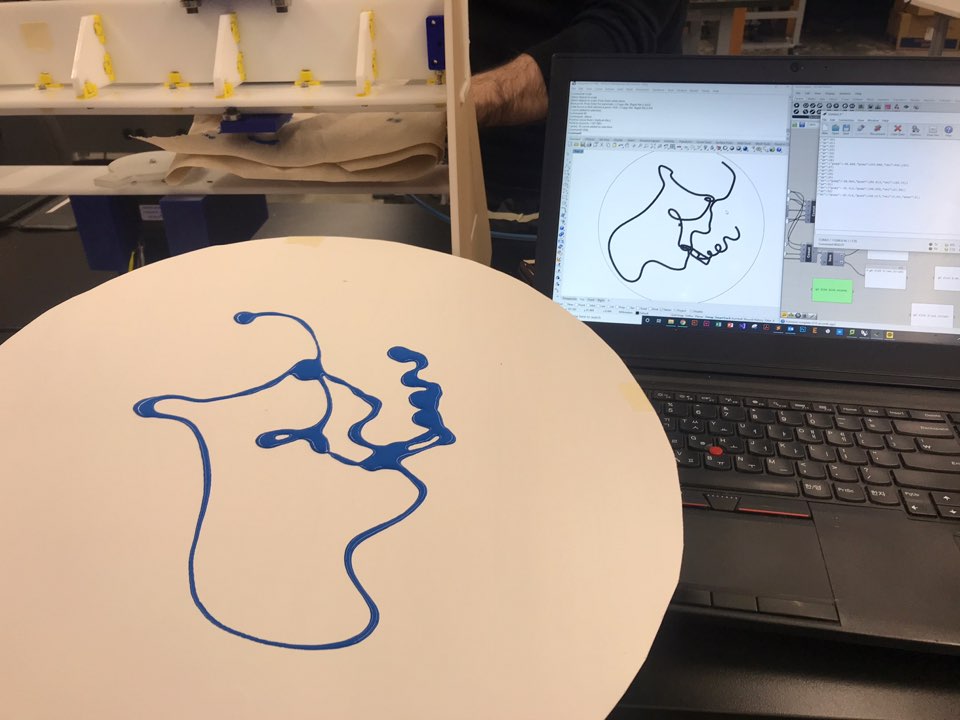

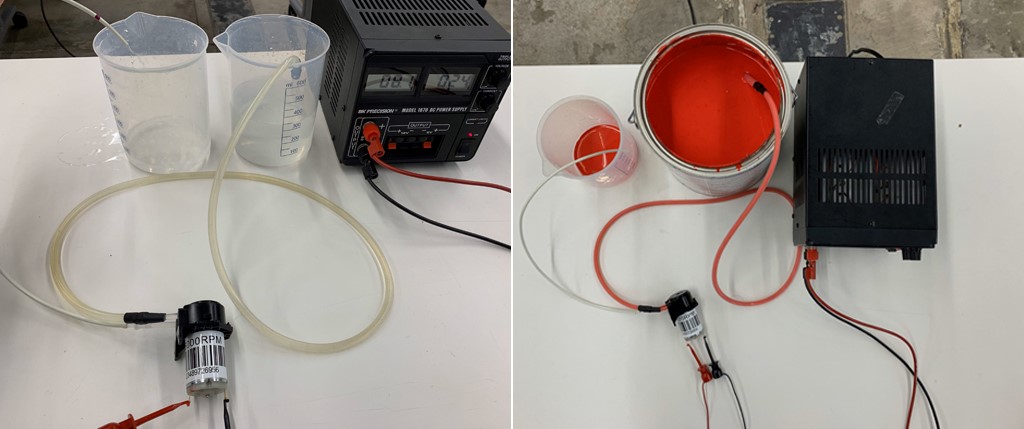

The first goal was to draw a rectangle using a sharpie. We loaded paper and a sharpie and started up the machine.

Not very rectangular...

Second Attempt

After some more tweaks to the algorithm: