Week 14

Let's go home

Composites

For this week, I was deciding between working on soft robotics with Ali or Composites with Rob and ended up sticking with composites. The composite we were going to create would be a mixture of burlap/fabric and a resin that is light-weight, but would add a lot of rigidity and hardness to the burlap.

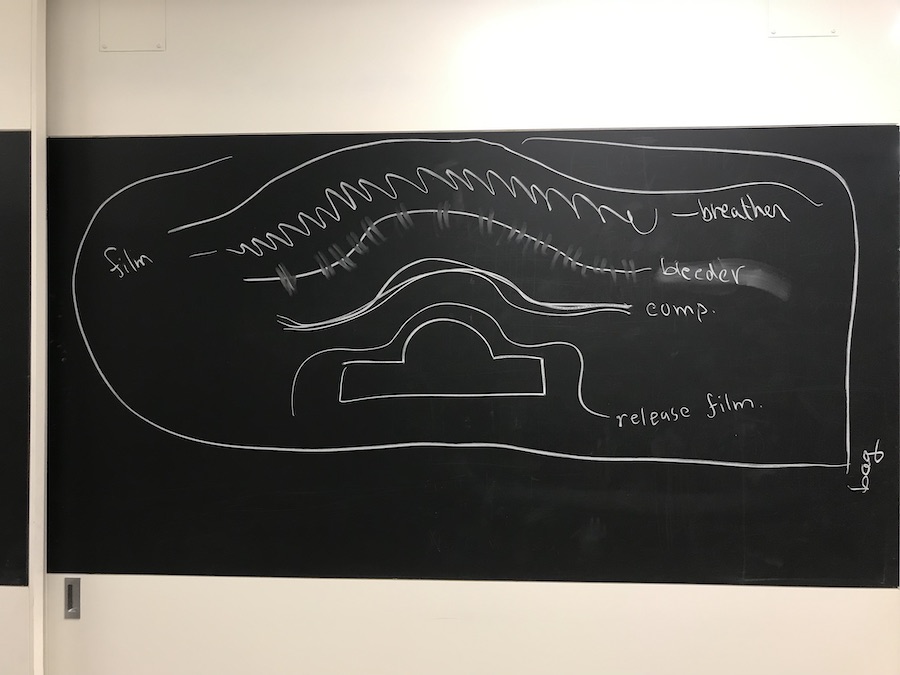

Rob first took the time to explain the process by which composites are prepared and made. First you design some physical mold for your design to take the shape of. You add a layer above that as a release film. Then you can lay down your composite, followed by bleeder layer, a breather layer, and one last layer of film to enclose it all.

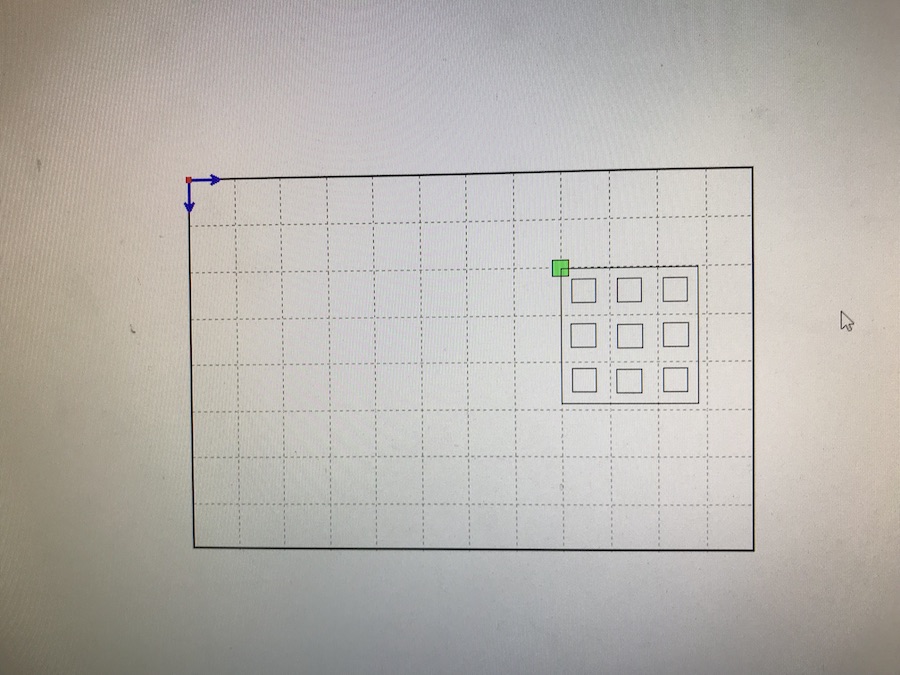

I wanted to make a hard composite of the sierpinski carpet.

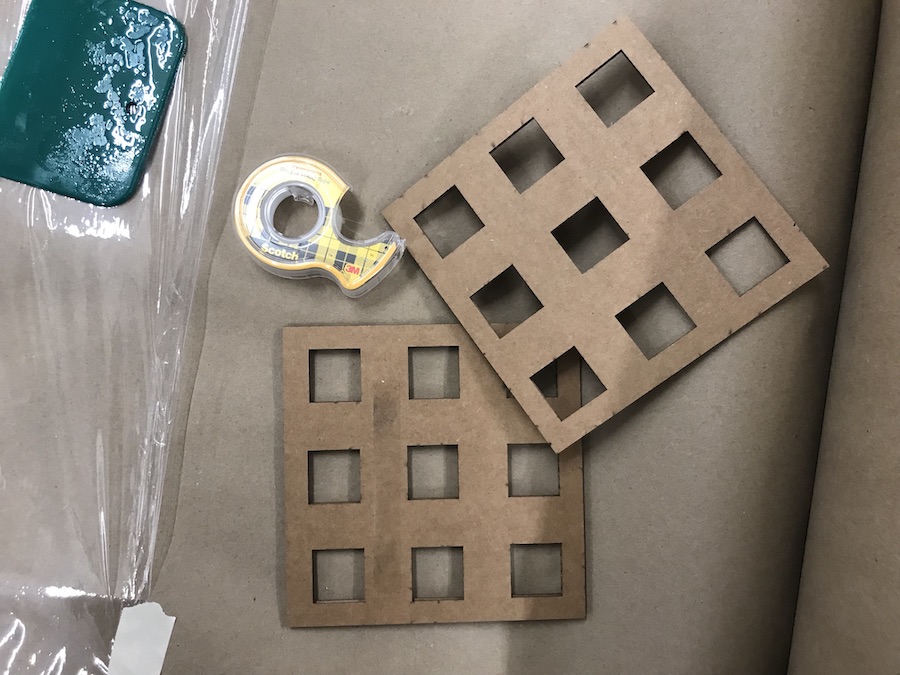

However, because of the maximum size structure I could fit in our lab's vacuum sealer, I was only able to make a small square with one iteration of the carpet. I designed it with Aspire and laser cut it using our lab's Thunder Laser Cutter.

I ended up cutting two pieces and sticking them together with double-sided tape. This way, the negative space would serve as a thick enough depression for the burlap once the vacuuming took place.

Matt Schrage and I worked at the same time, so we made a single batch of epoxy and hardener.

And we mixed it together.

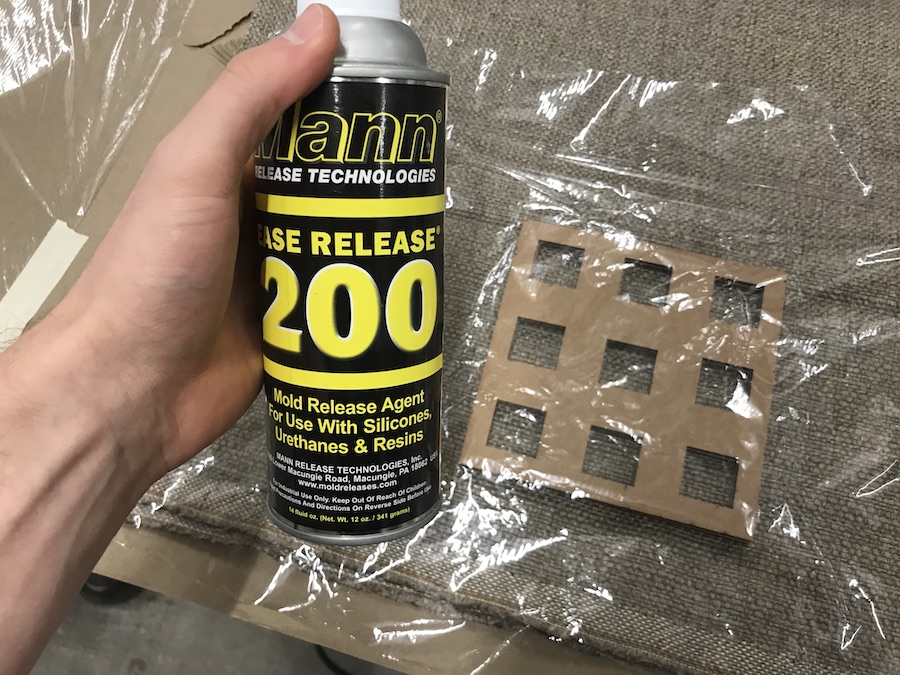

I covered my design with a piece of seran wrap and sprayed it with some Mann Ease Release 200.

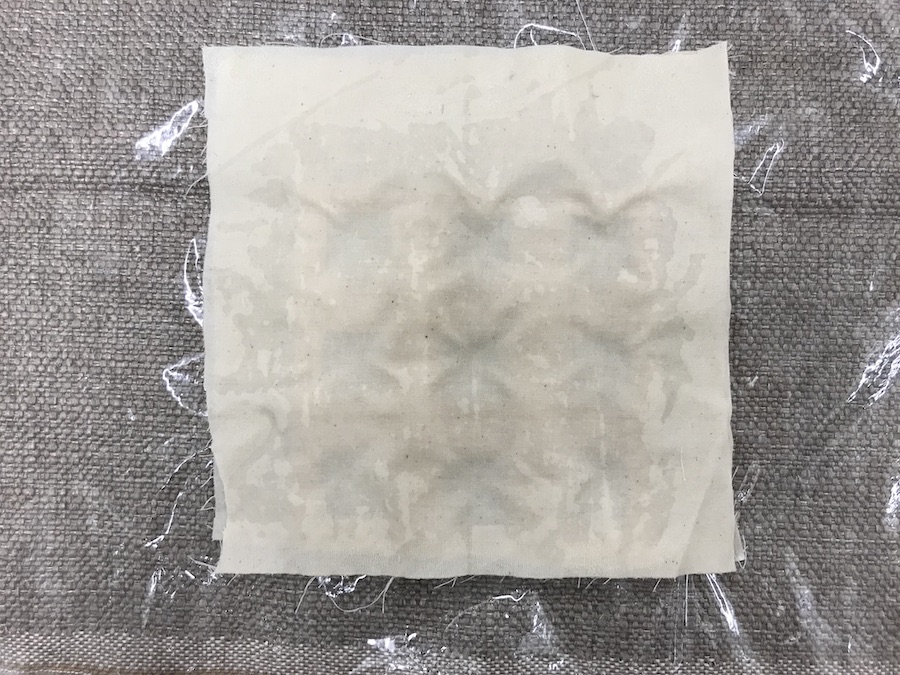

After spreading the epoxy mix on a square piece of burlap, I placed the burlap over my release layer.

Then, we prepared a bleeder layer by puncturing holes into another piece of seran wrap using this medieval torture device.

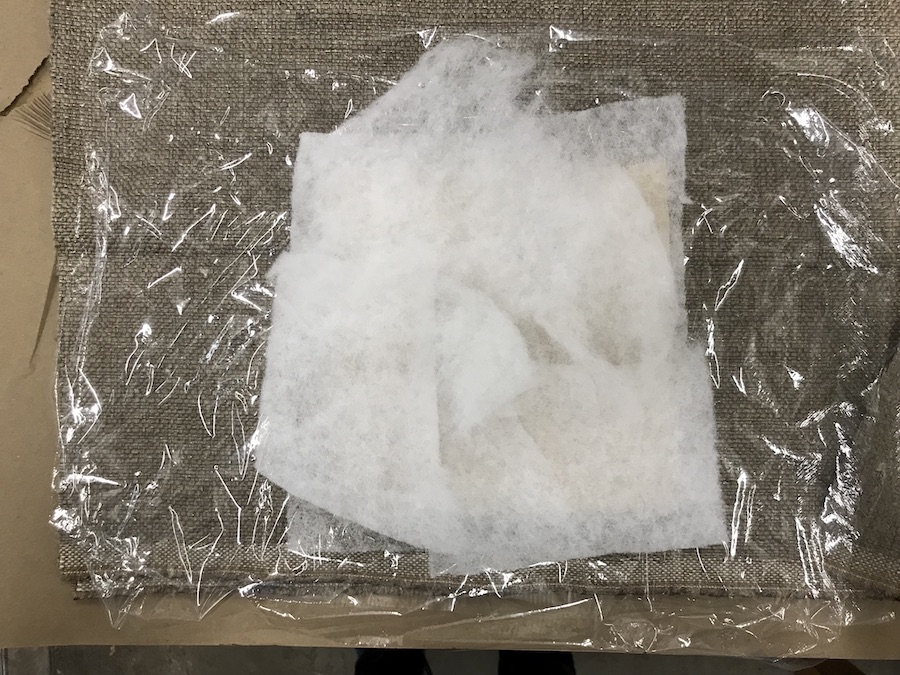

We added some breather in t he form of ripped apart cotton.

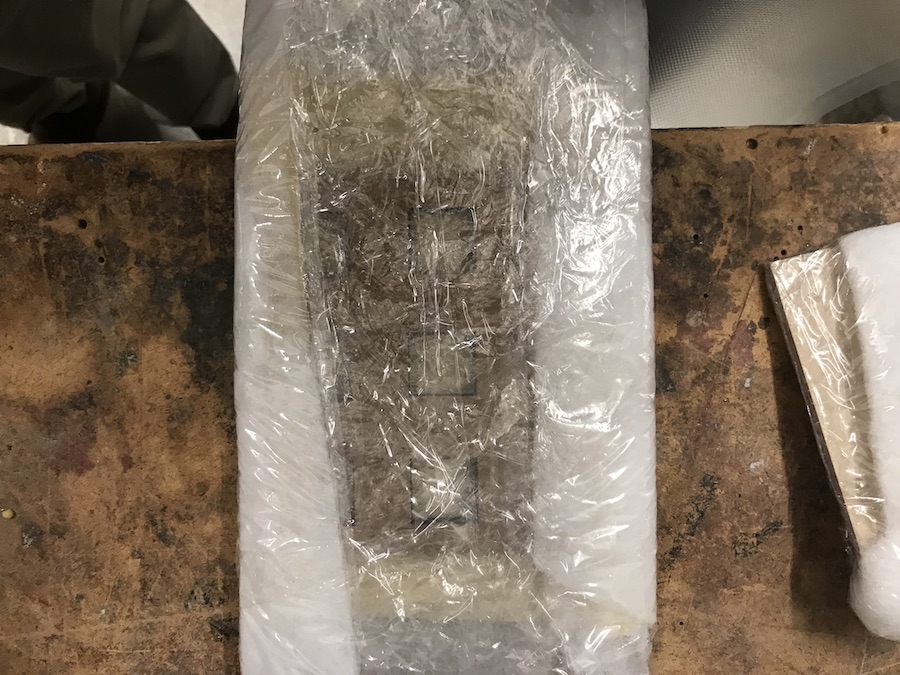

And then I added one more layer of seran wrap and sealed everything together so that it would fit within the width of the vacuum machine.

I placed everything into a plastic package for the vacuum machine, and then I let it suck the air out.

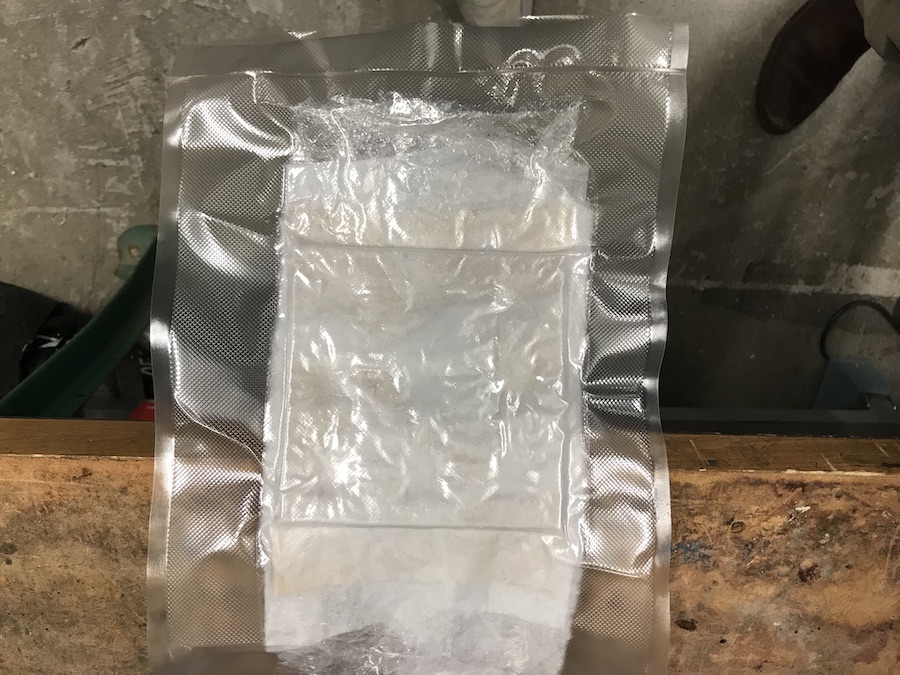

Here it is all vacuumed up nice and tight.

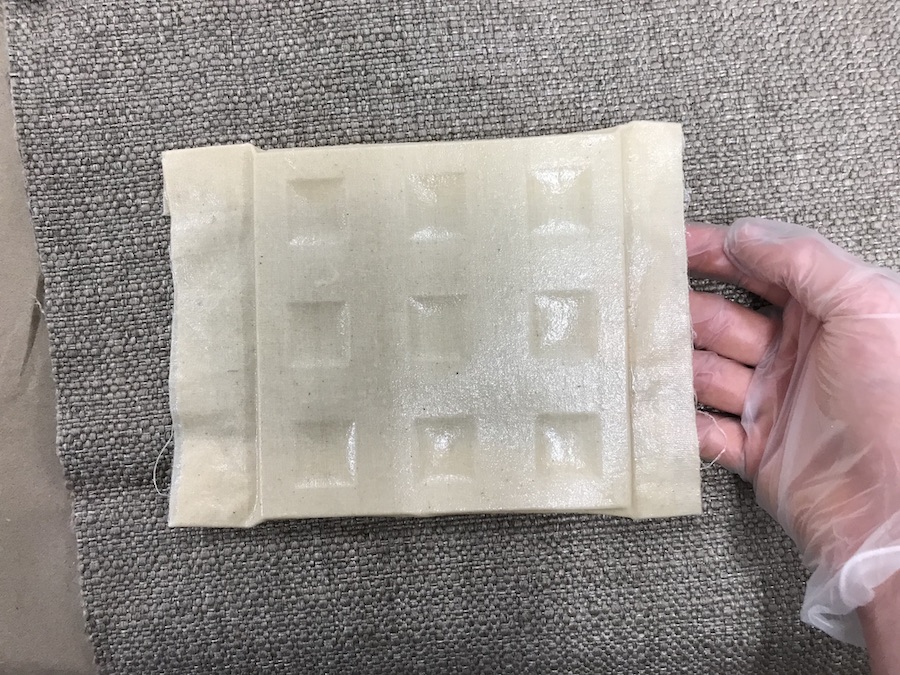

I let it sit for 24 hours and then opened up the piece.

Uh oh! This should have been hard as a rock. What happened? We messed up the epoxy and hardner ratios. It should have been 2:1 but out solution was made with equal parts of each. Let this be a lesson for next time.