Week 04 - Molding and Casting

This week's assignment was: design a mold around the stock and tooling that you'll be using,

mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

I was having some trouble thinking of what I could make out of casted hydrostone that I could use frequently. Sometimes when I eat lunch, I like to watch videos on my phone. I decided to cast an adjustable stand that could support my phone upright either horizontally or vertically. I also wanted to leave room for the charger, and I also wanted this stand to be usable as a wet paint brush holder as well.

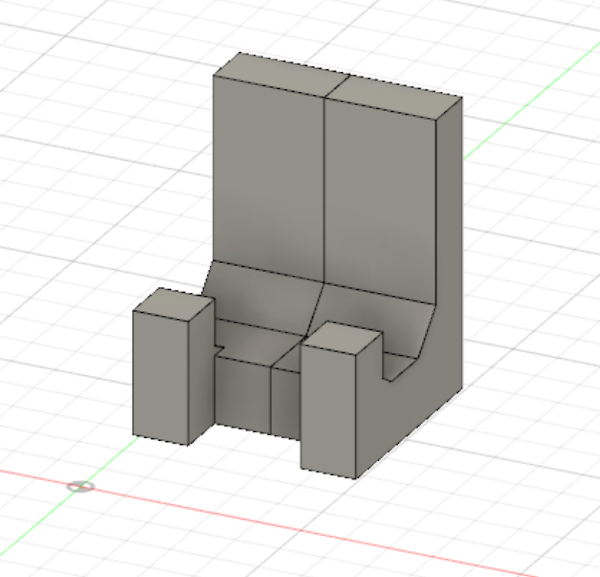

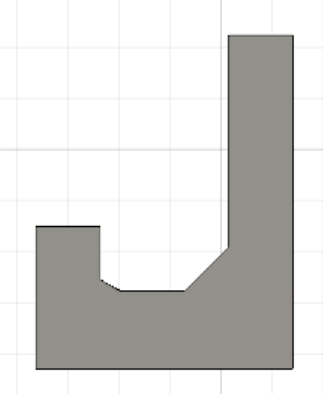

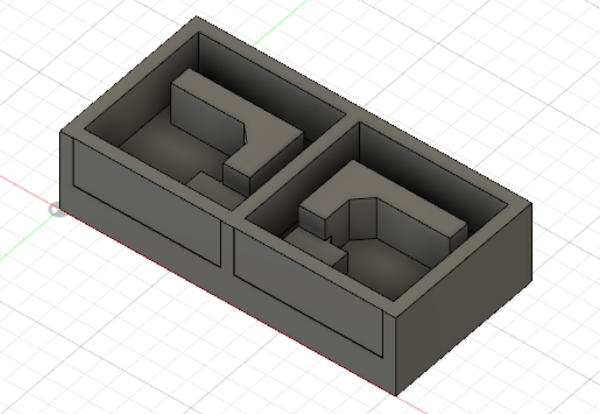

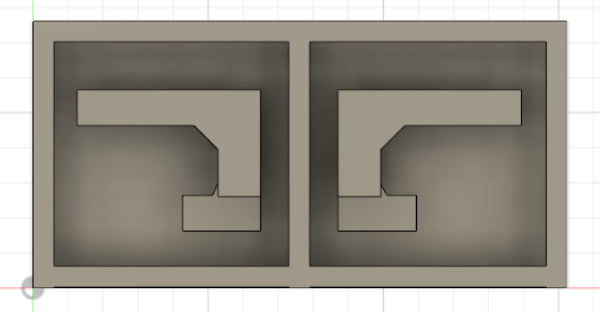

I went into Fusion to start modeling! I took some measurements of my phone and came up with this design as the holder:

I made sure there weren't any 90 degree corners to make the piece more difficult to accidentally break apart. I then cut it in half to lay out and fit in the wax block and to make the holder adjustable to things of different widths. I think it should work okay with my phone laying horizontally, but I'm worried it's too short to work for my phone laying vertically since I had to fit in in the block. I originally intended the design to be casted in a way that combined the two sides into one holder, but I think the two separate components will allow more flexibility. This also meant I didn't have to add a pouring hole or notches that kept two sides of the mold together. Despite the fact that this design is pretty simple, adding a pouring hole turned out to be pretty nontrivial, so being able to separate the two sides and omit the pour hole step helped me out a lot. I also wanted to make sure that however deep I decided to go I would be able to reach with the tools and bits availble. Here is the final plan for the wax block cut out:

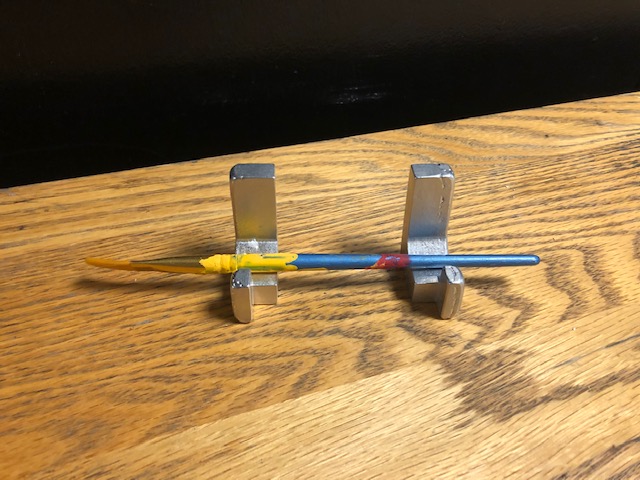

I met on Zoom with Zain to set up my mastercam. I ended up using these two bits (1/4 flat, 1/8 ball):

The larger was for the initial cuts and the smaller one for the finer details. The tool path worked in layers by starting at the top and working downwards in increments. I used the ProtoTrak in N51 for the milling. On the mill, we first had to center the block so that zero was in the middle of the wax.

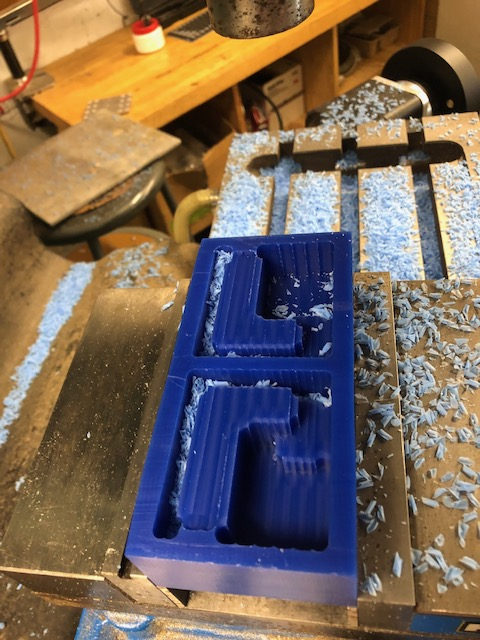

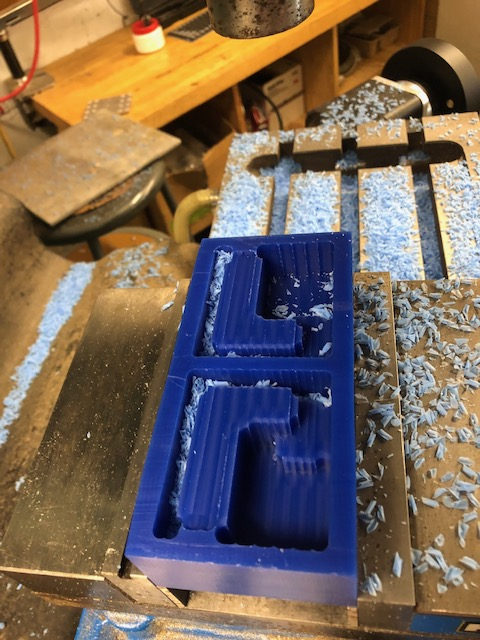

Here's what the cutting process looked like! The first cuts with the large bit:

Finished with the larger bit:

Cutting with the smaller bit:

And the wax cutting all finished:

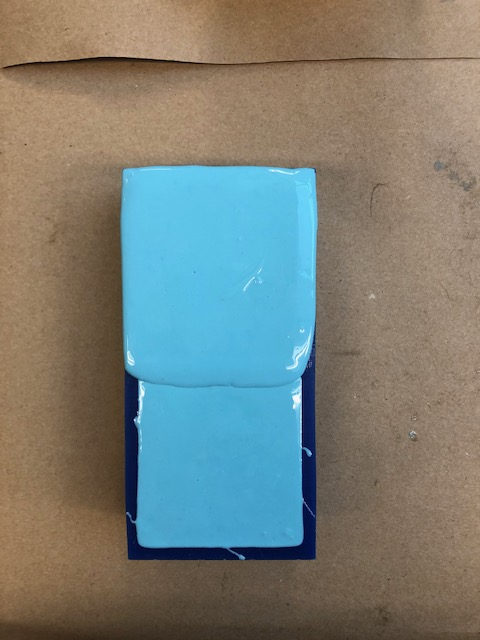

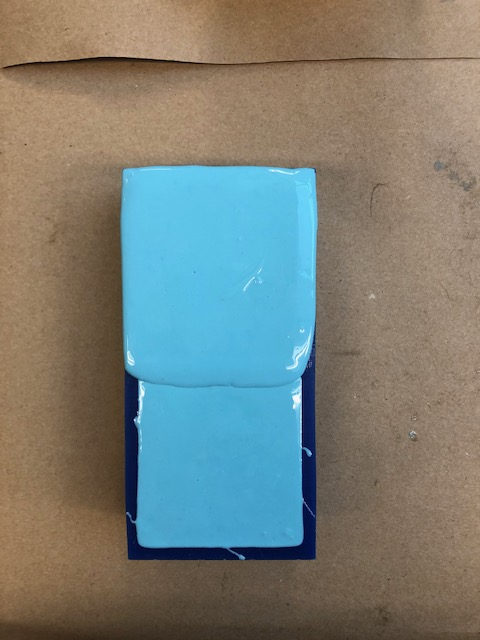

Then, I headed back over to the arch shops in building 3 to start with the OOMOO. Like during the group assignment, I mixed the two OOMOO components in a 1:1 volume ratio. After mixing well and slowly to minimize bubbles as much as I could, I then poured the mixture into my wax mold. I did not do the best pouring job:

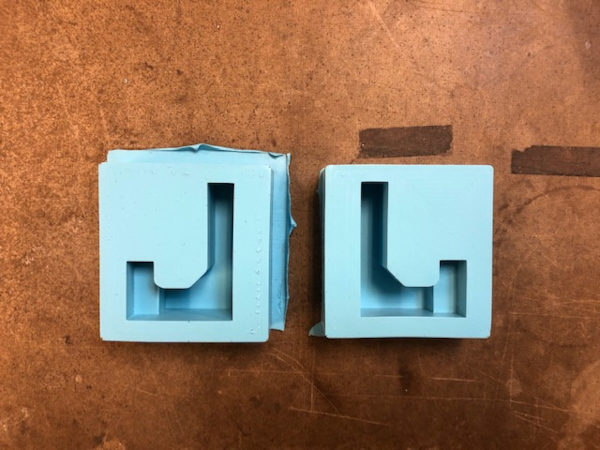

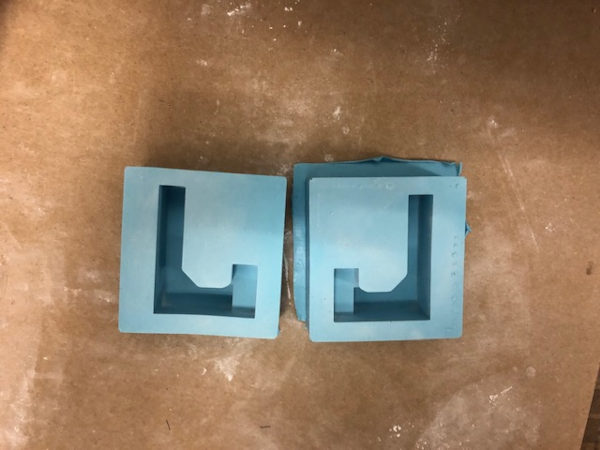

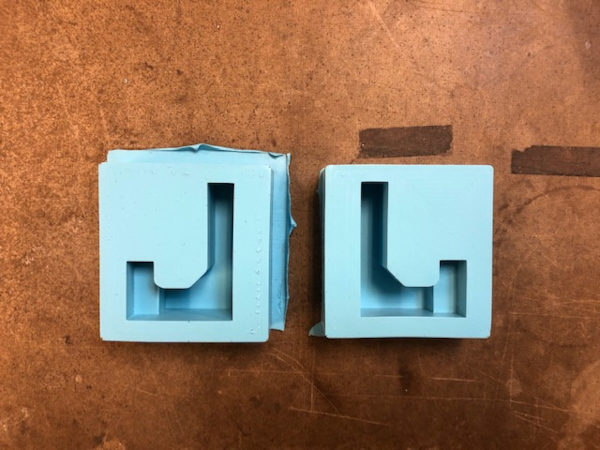

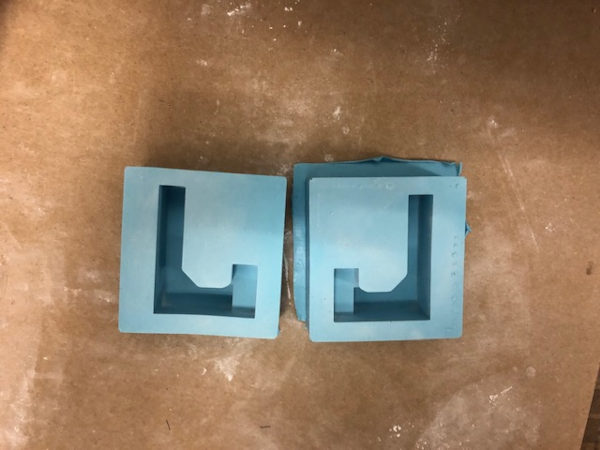

I waited about an hour and twenty minutes for the oomoo to cure before removing it from the wax. The final mold turned out pretty well, and there wasn't any severe bubble damage. The walls were smooth and the molds luckily did not tear when I took them out of the wax. I had a lot of 90 degree walls and they definitely did make it a bit harder to remove. Adding a taper probably would've helped. Here's how the final molds turned out:

During our group assignment we did test casts with the hydrostone, but the arch labs also had a metallic material available and I wanted to try it out. We heated it until it melted, and in the meantime I painted baby powder around the sides of my mold to minimize sticking:

Then it was time to pour into the mold! The metal hardens pretty quickly (although it will still be pretty hot) and I tried putting baby powder on the top to see if it would minimize the surface tension and create a flatter surface but it didn't seem to make too much of a difference.

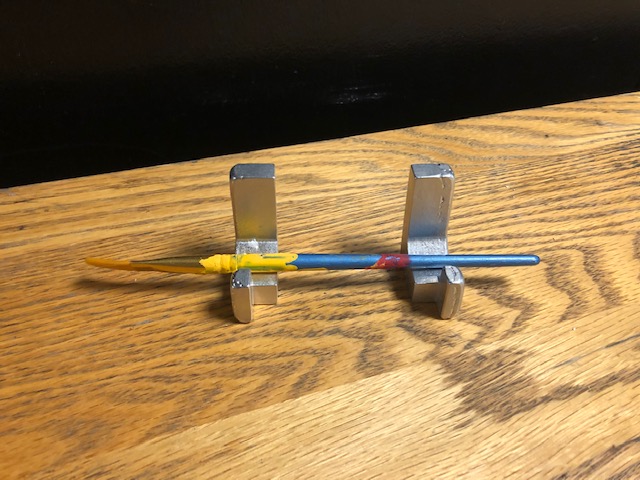

The baby powder worked and the pieces were super easy to remove from the mold. Overall, I'm pretty happy with how it came out.

It ended up still working for my phone stood up vertically even though I thought it might be too short. Here's the stand in action: