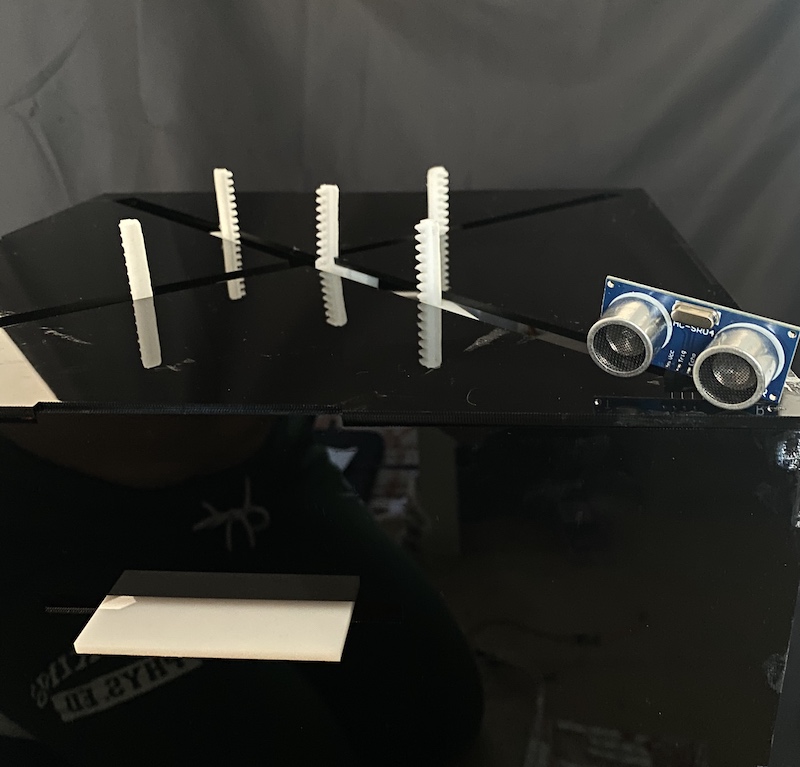

Ideally I would like to test this on many people to get their impressions on the installation and to understand how it could be improved. Due to the current situation, I am the only person that could evaluate it. The only major problem that still need to be solved is the ultrasonic sensor giving out fuzzy readings from time to time. I tried using different libraries and changing the timing of pings which did decrease some of the fuzziness but it is still there.

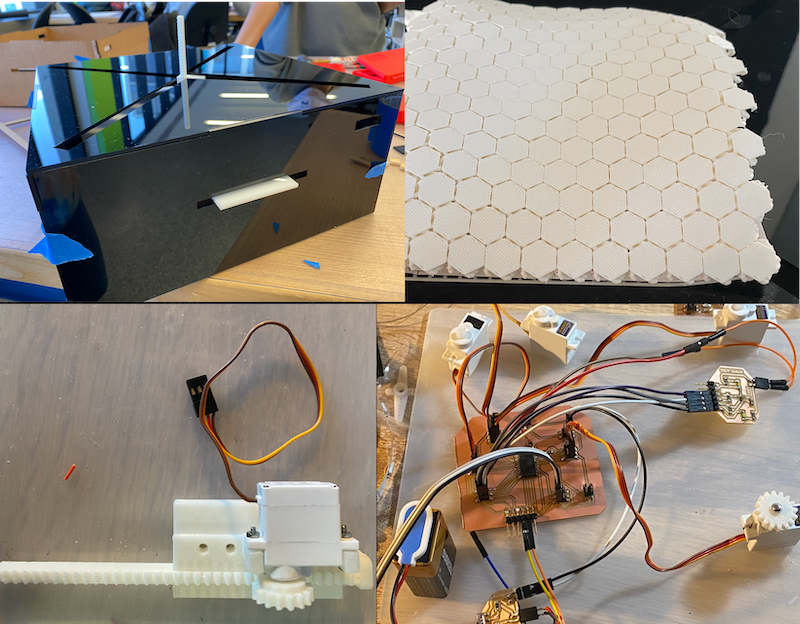

I would also look into 3D printing a larger size chain to cover all the surface area.

I also found the sound coming from the servos quite loud, which mean it is not practical to have it on all the time. In the future, I would look into ways to minize the noise or use alternative mechanical parts.

Finally, I would like to iterate on this installation to includ the color sensor as well.