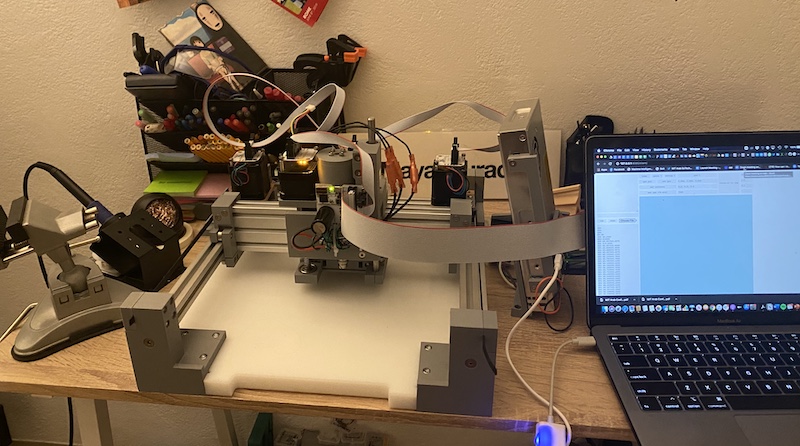

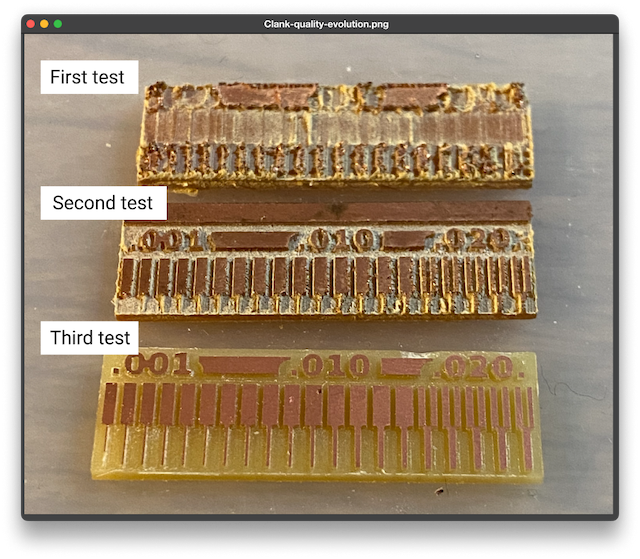

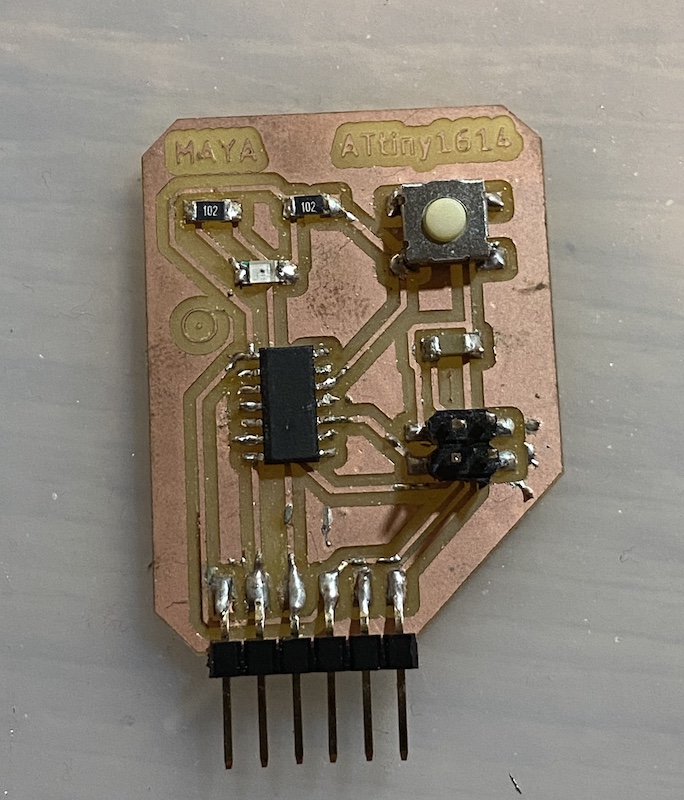

The first boards I milled with Clank were quite bad, I was able to fix some of them with a virtual troubleshooting session with Jake.

I was able to get better results after using the V-shaped bits (instead of 1/64'' flute bit), tightening the belts and updating the z-motor firmware.

However the results were still not good enough to produce board reliable enough for the upcoming assignments. For the upcoming assignments, I used the Roland Modela in the Arch Shop and OtherMills in EECS (I enjoyed using OtherMills the most as it's fastest and most user friendly).

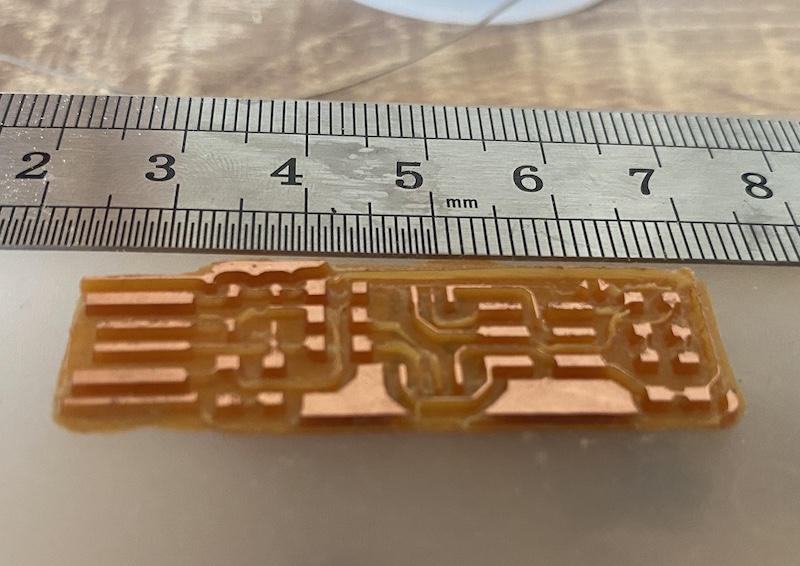

I was finally able to get reliable results from Clank after doing an in-person troubleshooting session with Anthony. Some of the issues we fixed include, further tightening the belts, changing the spindle direction of the z-motor, and using 2.5 inch/sec speeds when setting the G-code.

Based on the test results, 0.016-0.017 is the right wire and gap thickness.

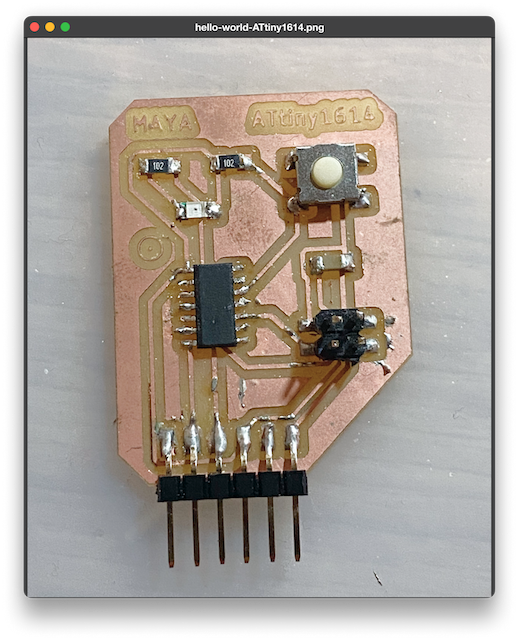

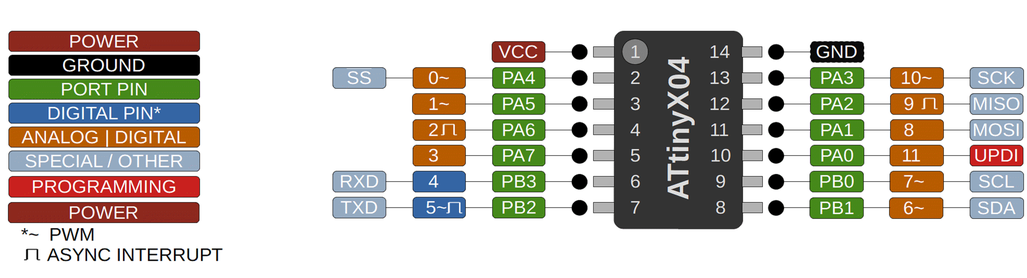

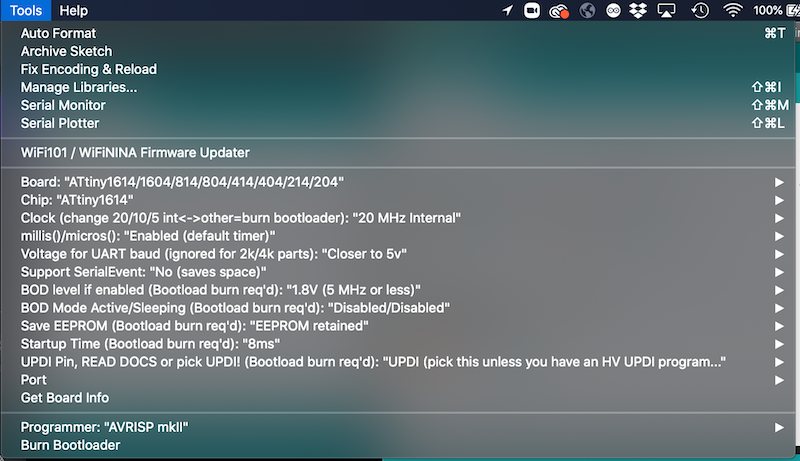

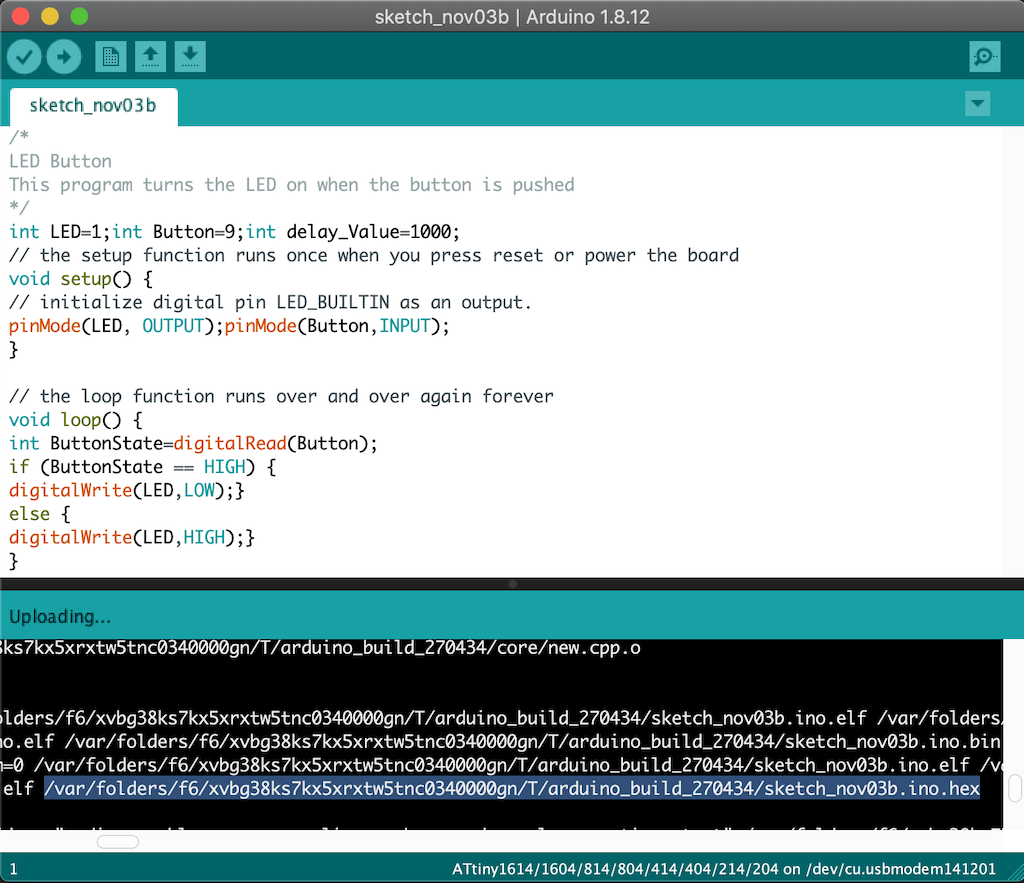

ATtiny is a family of 8-bit AVR mircrocontrollers. The 1614 is a recent model in the series with 14 pins which can run at up to 20MHz and has a low power architecture.

The datasheet details the ATtiny's pinout, which is very useful when designing boards to make sure we are connecting to right pins. It also includes important information on its memory, peripherals, clock, and more.