week 2

3D Printing & Scanning

Sept 22, 2020

This weeks assignments were to 3d print something that cant be made throught a subtractive machining process and 3d scan something.

3D Printing

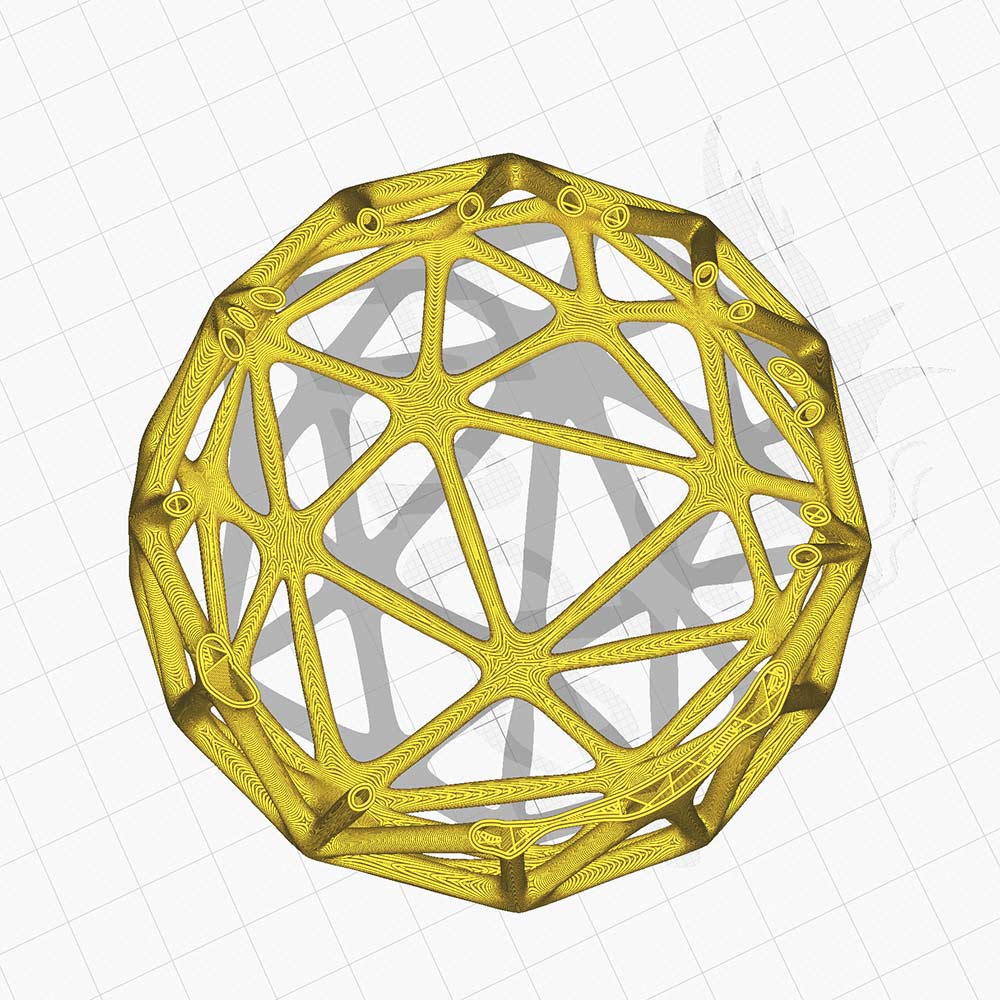

I wanted to print something that would have a very organic shape that would be difficult to machine, In the past I have come across 3D organic meshes that resemble bone mesh structures.

While trying to figure out how to create an organic shape in Fusion 360 I came across an useful youtube tutorial https://www.youtube.com/watch?v=1D-YR_IUps8

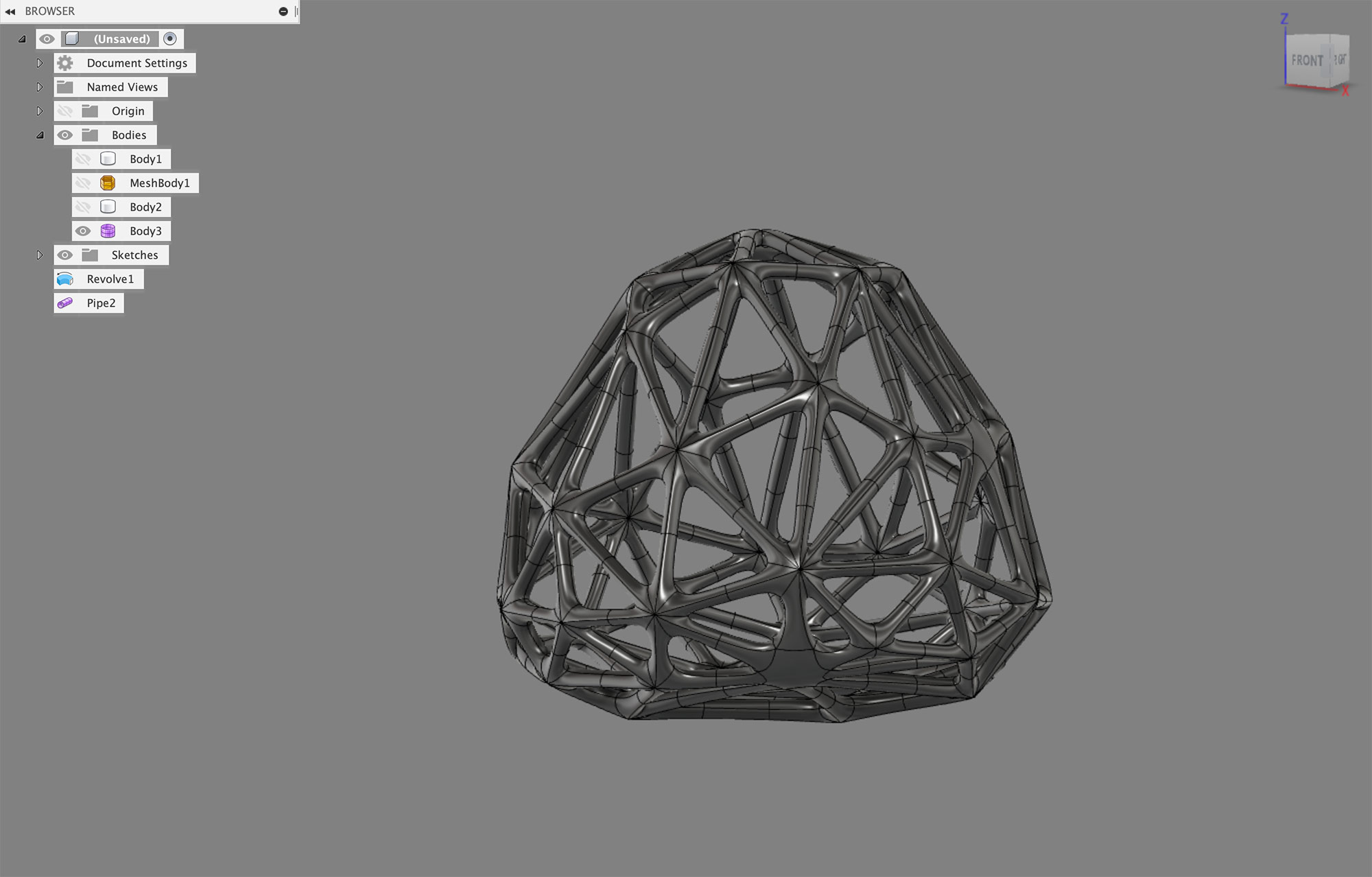

I started with a blob shape and followed the tutorial to make it into a mesh, then reduce the points in the mesh, then turn the mesh into a pipe structure. I then rendered the mesh to see how it would look.

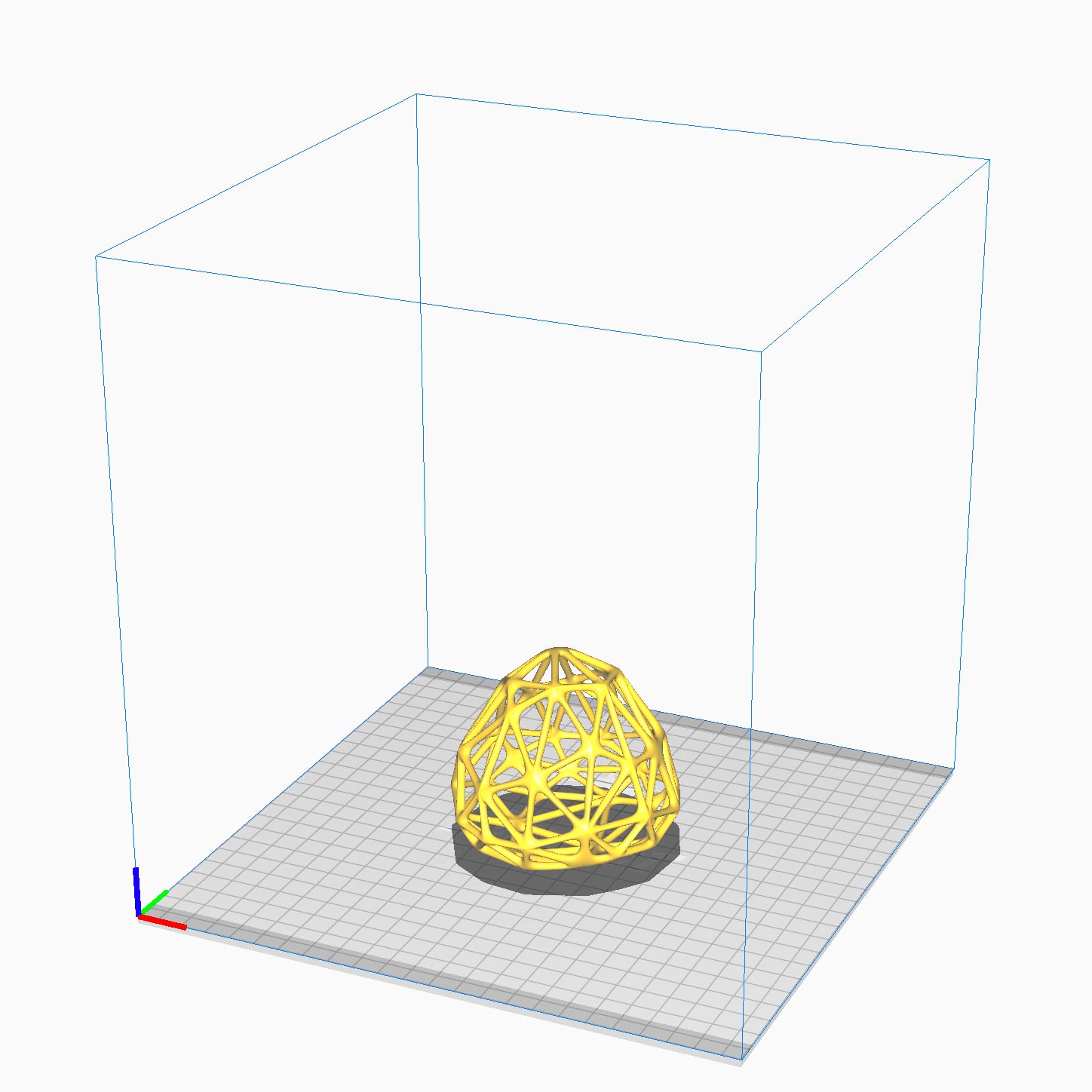

After this I then moved on to printing. First I opened the stl file in Ultimaker Cura to convert the stl file to g-code, I had purchased a 3d printer a few months back, I chose to print the model on that machine. It is a Creality Ender 3 Pro machine. I used pink PLA as the material. I initially tried printing without support but the print failed and so I resorted to using supports for overhangs beyond 70 degrees. After cleanup and a bit of sanding I ended up with a decently finished mesh

3D Scanning

For 3d scanning I decided to use one of the objects available in the workshop, I chose cho scan a glue bottle. I used an Artec Leo 3D scanner for the process.

I placed the glue bottle on a flat sheet of newspaper and scanned it by walking around the bottle in a circle while pointing the scanner at the bottle in order to capture the bottle from multiple angles. I then opened the scanned object file in Artec studio application for processing