week 3

CNC Machining

Sept 29, 2020

This weeks assignment was to make something big with the CNC Router machines and OSB sheets

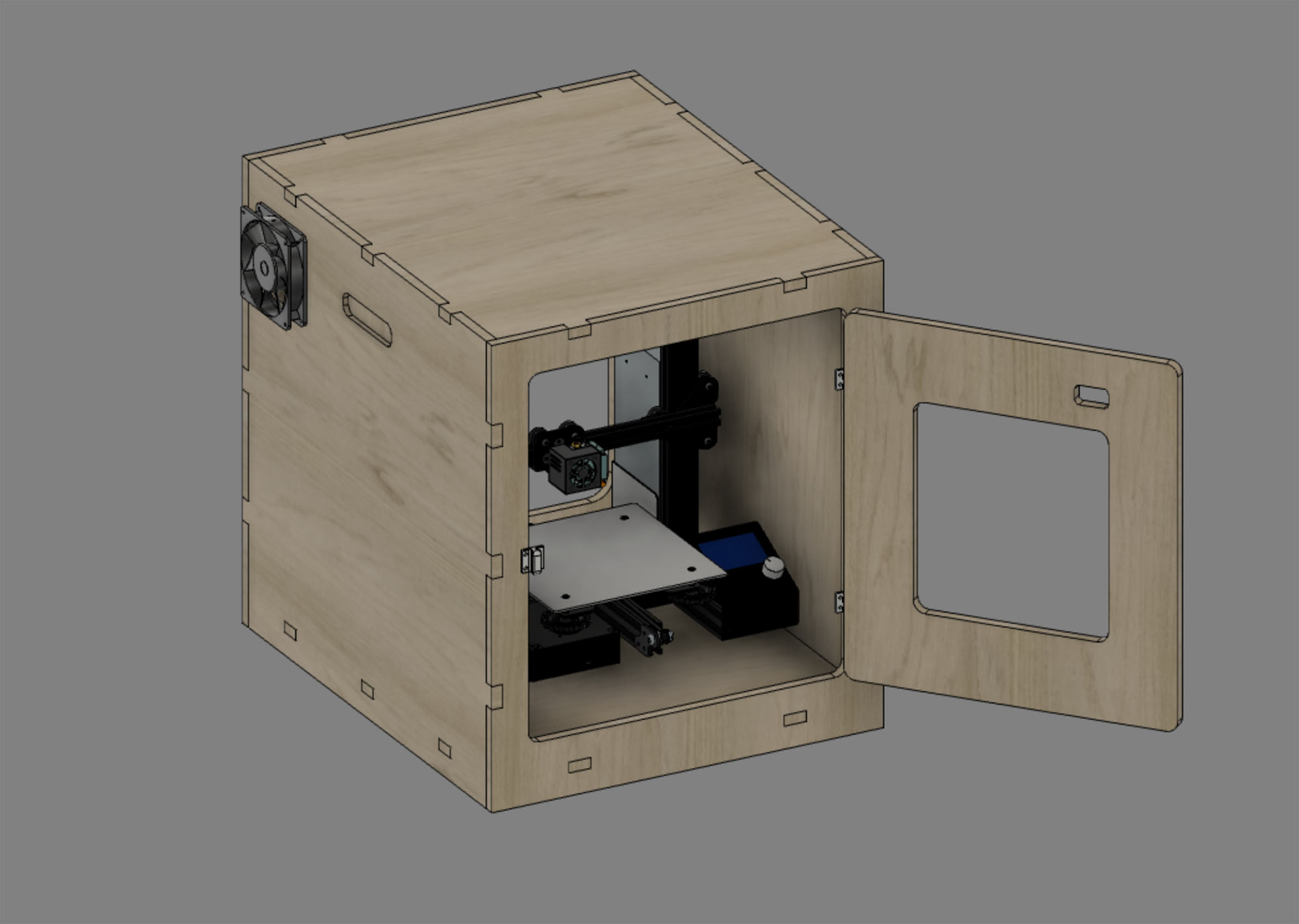

I have a 3D printer in my living room and I have been thinking about building an enclousure for it for a while. The enclousure would serve three purposes.

- Keep the printer and filament dustfree

- Reduce the noise a little

- If I put in a suction fan along with an air duct that opens outside the apartment, I can use it to pull away any VOC's released during the printing process.

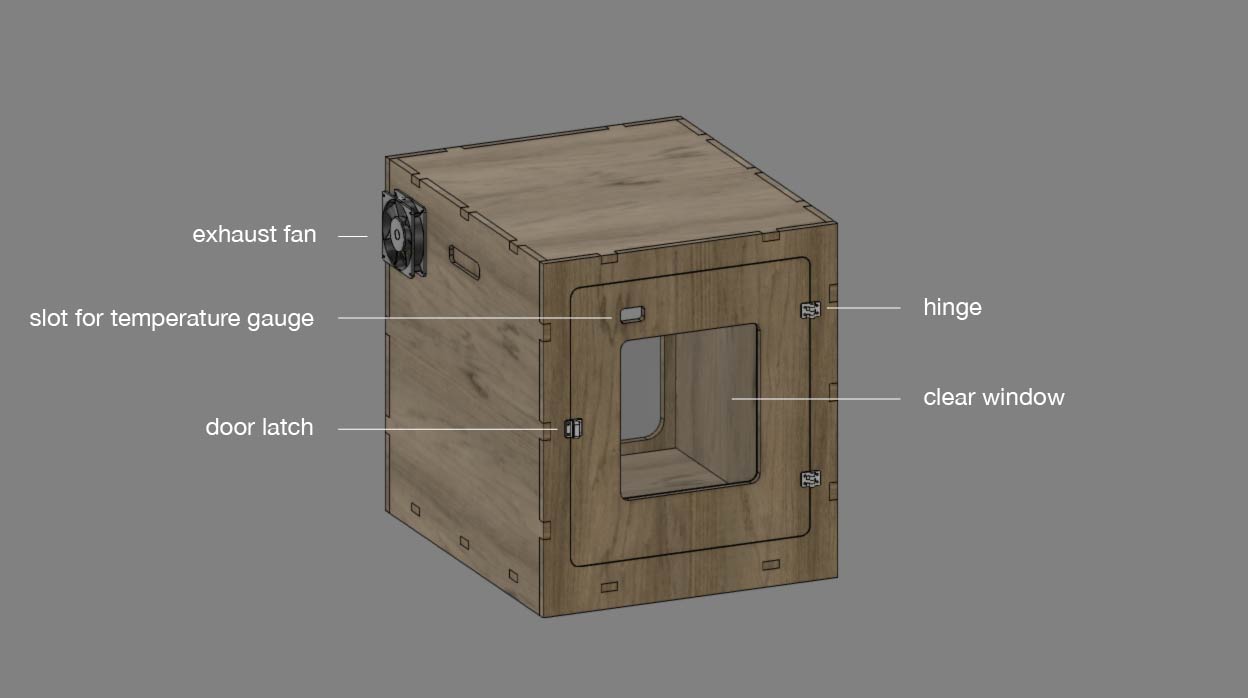

The features I wanted in the enclousure were:

- easy to assemble and fabricate

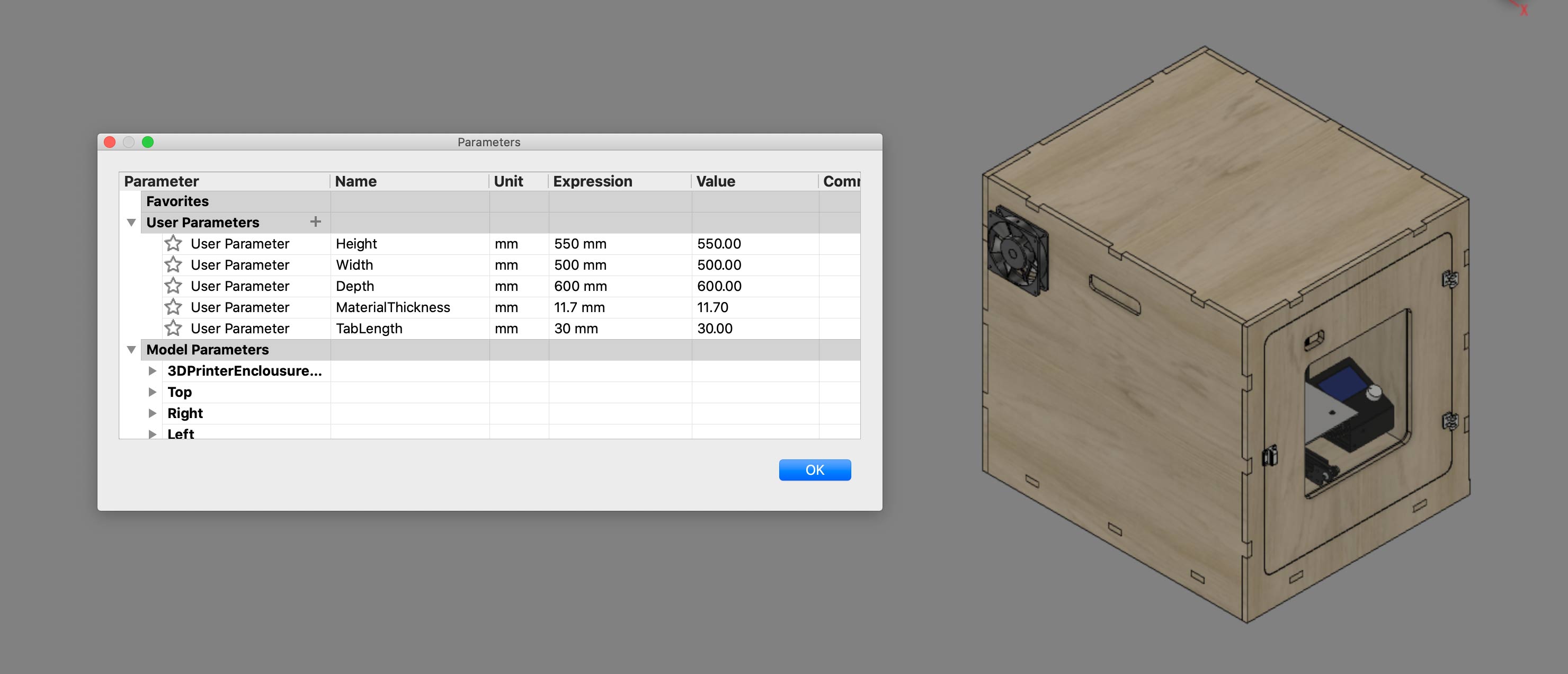

- parametric design to be able to print other enclousures in future

- not too heavy, not too light

- rigid construction

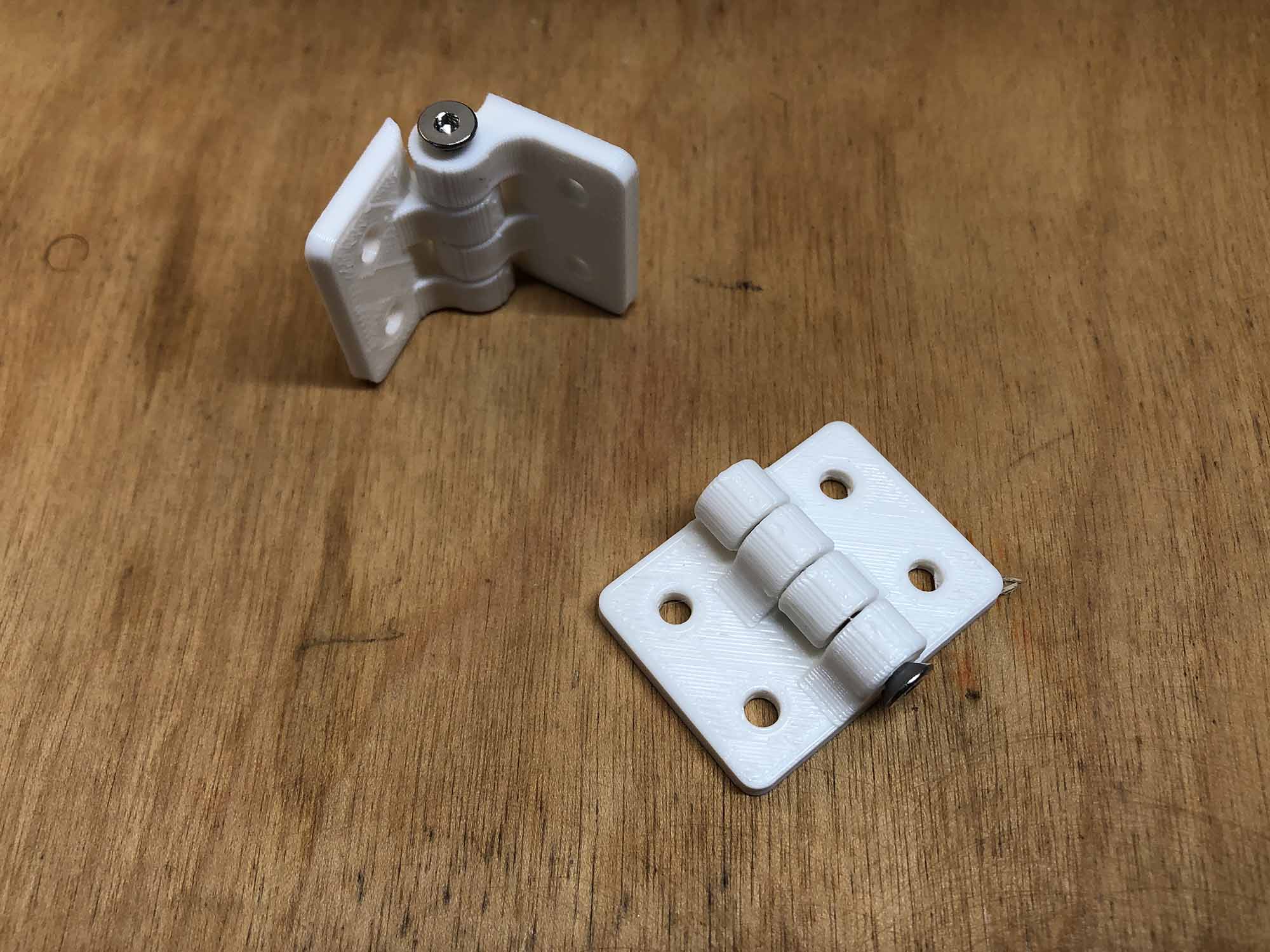

- hinged door with a transparent window

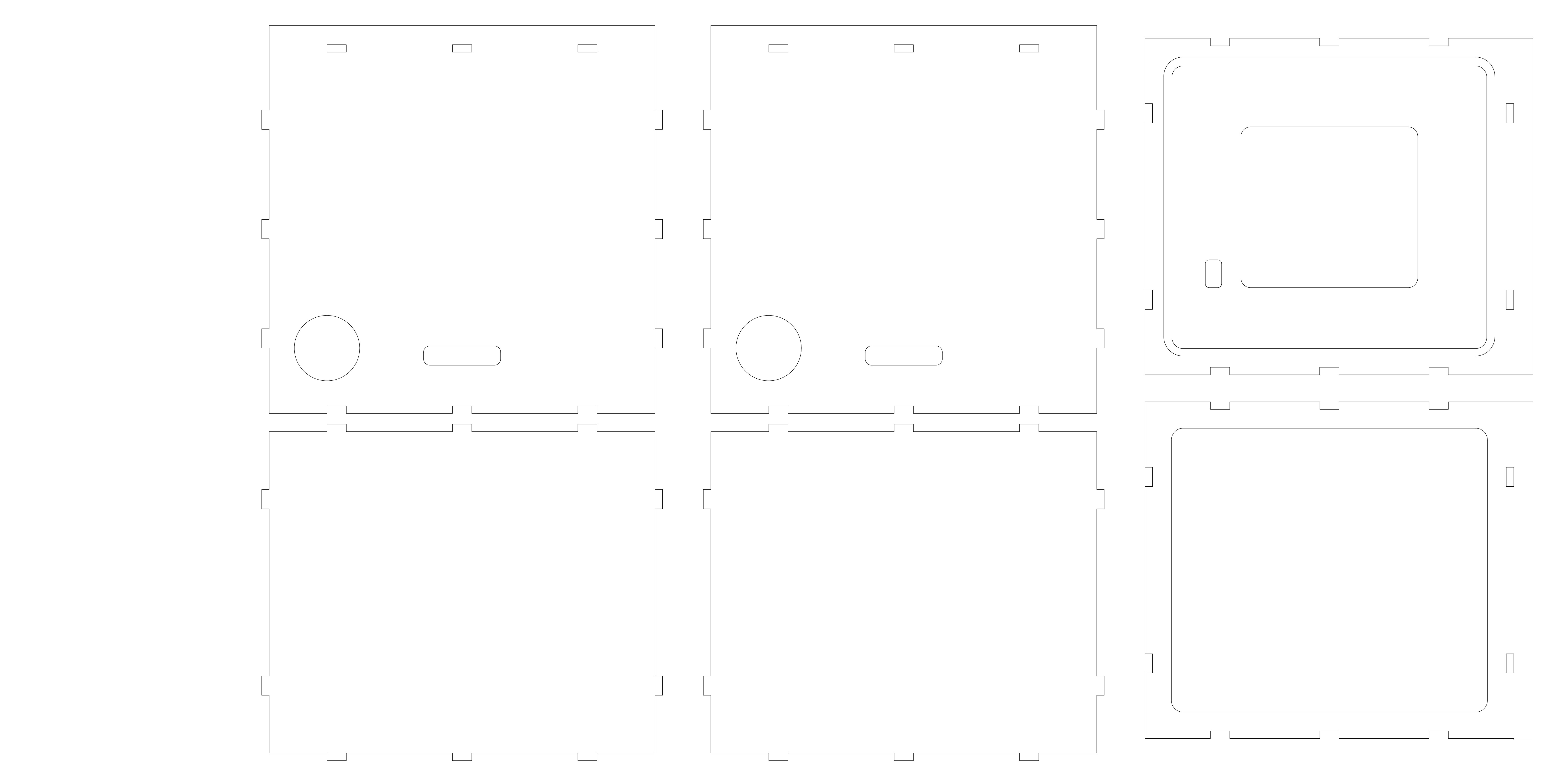

After this I went to the shop in the morning to use the shopbot, I checked the thickness of the stock, changed the thickness parameter in the model accordingly, then laid out the shapes on a canvas and used the shopbot machine to cut all pieces from a 8x4 sheet of OSB.

After this I will be finishing the pieces, assmble the door and hinges and paint the enclosure.