Charaterization of a 3D printer requires tests to determint the outer limits of the following parameters:

We wanted to characterize both the Prusa and the Objet, but with limited time, we decided to fully characterize the Prusa and to do a single print characterization on the Objet along with using our own prints to fill in some blanks.

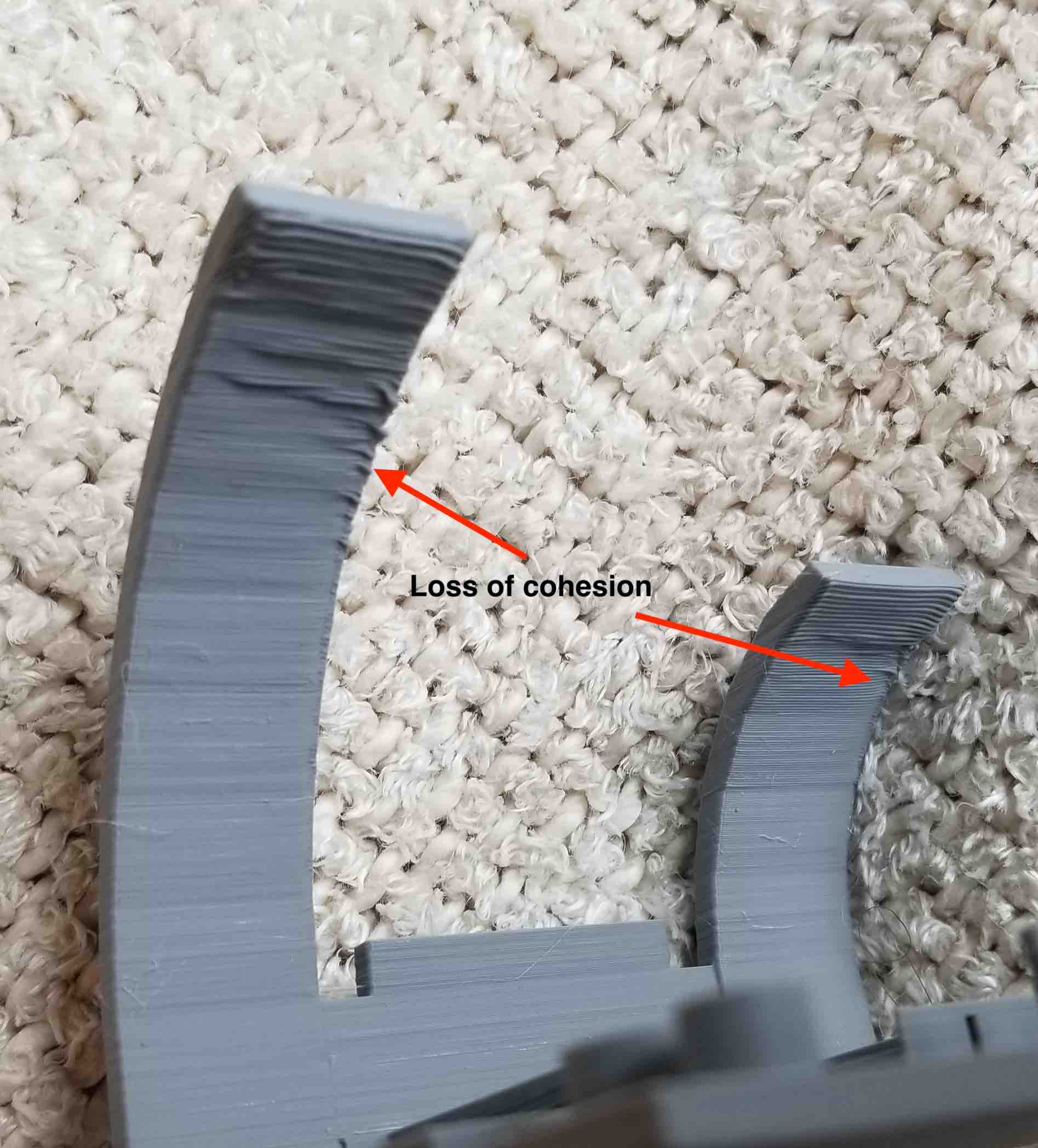

We used a pre-made printer test that incorporated an overhang test (with and without supports), bridging and angle tests (unsupported), and multiple dimensions tests. We found the following restrictions:

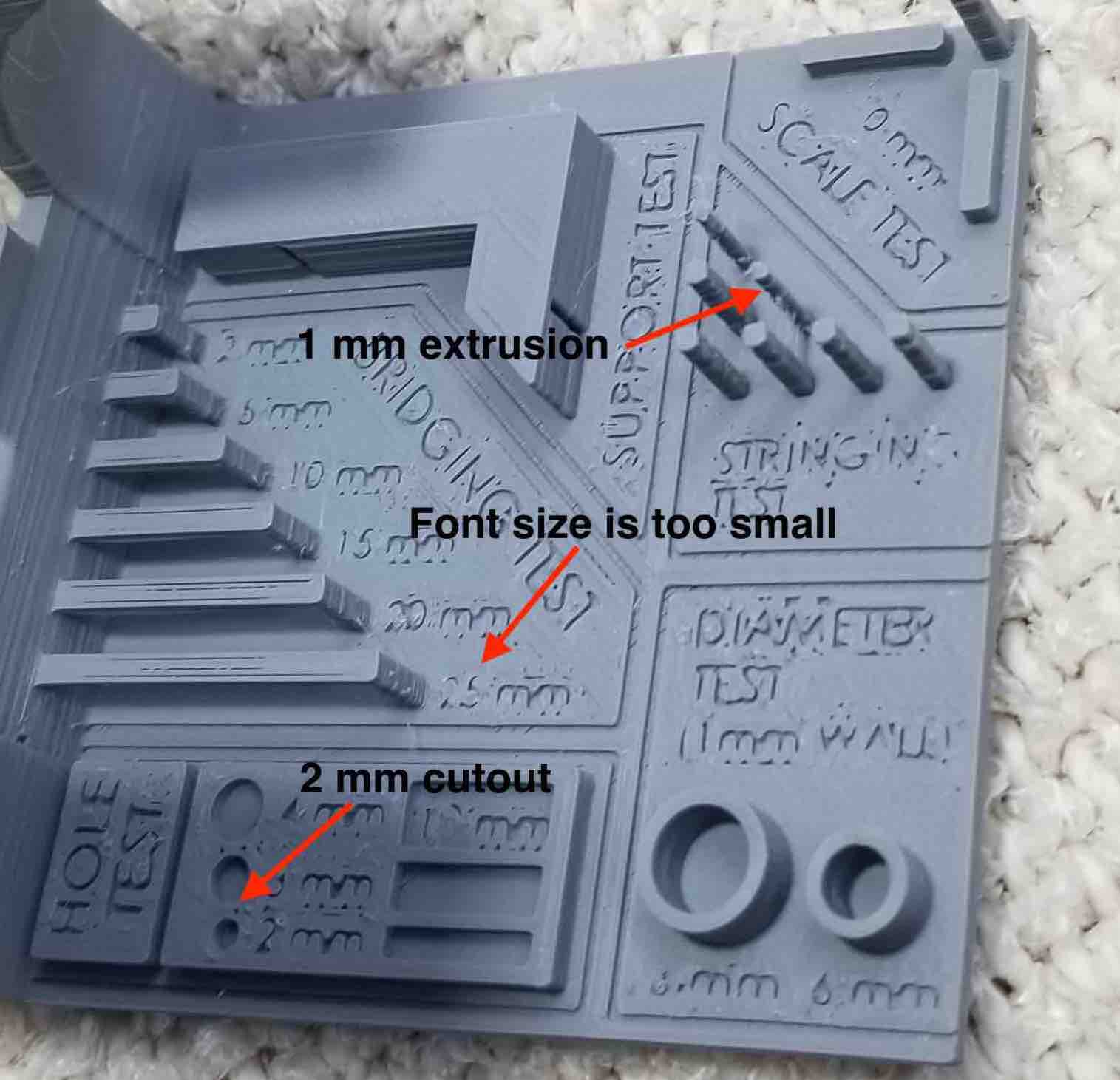

The clearance, anisotropy and infill tests were done using our own printed parts and variations of these parts.

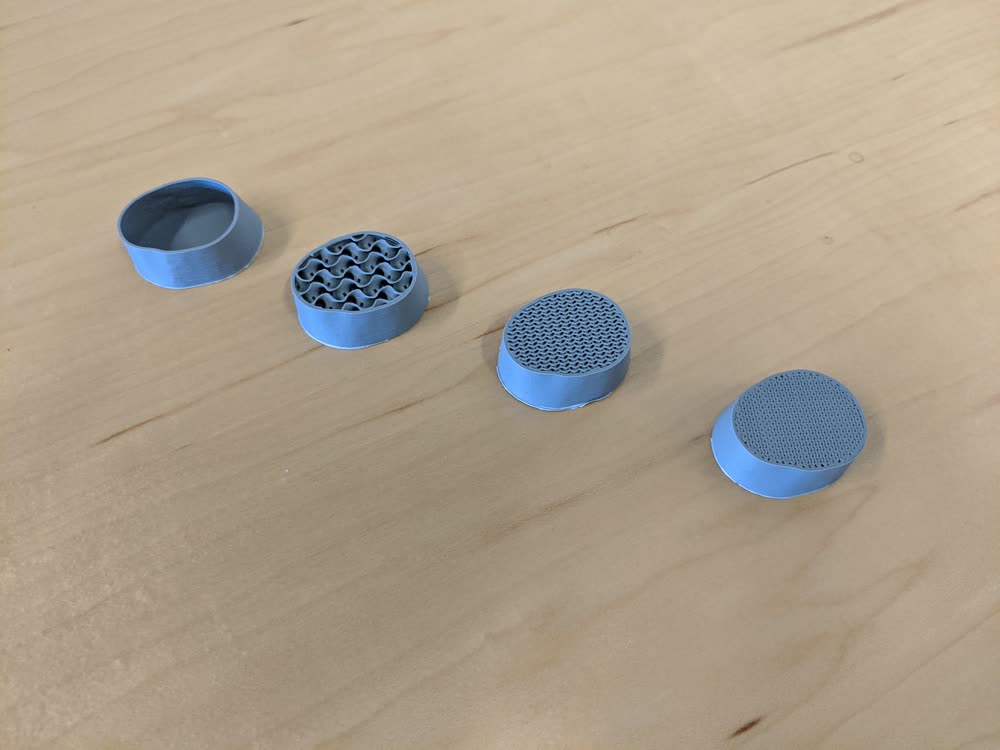

Clearance: the gyroscope made by Andres Rico served as a clearance test by varying the gap between the ball and track from 0.1mm to 0.3mm. Anything greater than 0.2mm provided sufficient clearance for the joint to function.

The anisotropy was demonstrated by Justin Christensen with the surface texture of the hand he printed. As the surface flattened over the top of the bent fingers, the layering became more evident providing restrictions on the allowable surface angle.

The infill tests were done by taking a cut profile of the same hand print. These were infilled with 0%, 15%, 50% and 80%. The 15%, which is typical for Prusa infill, was sufficient structurally.

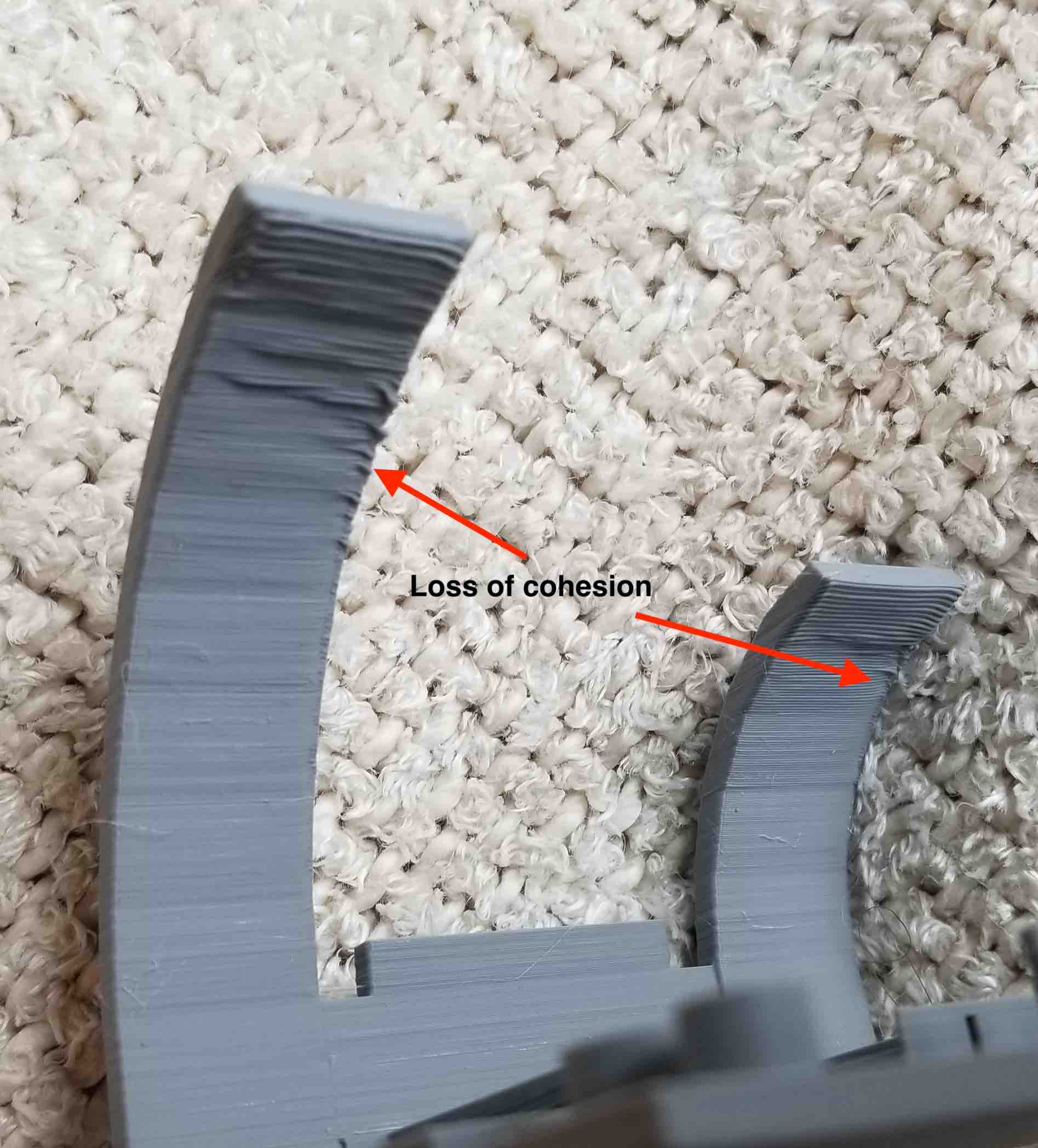

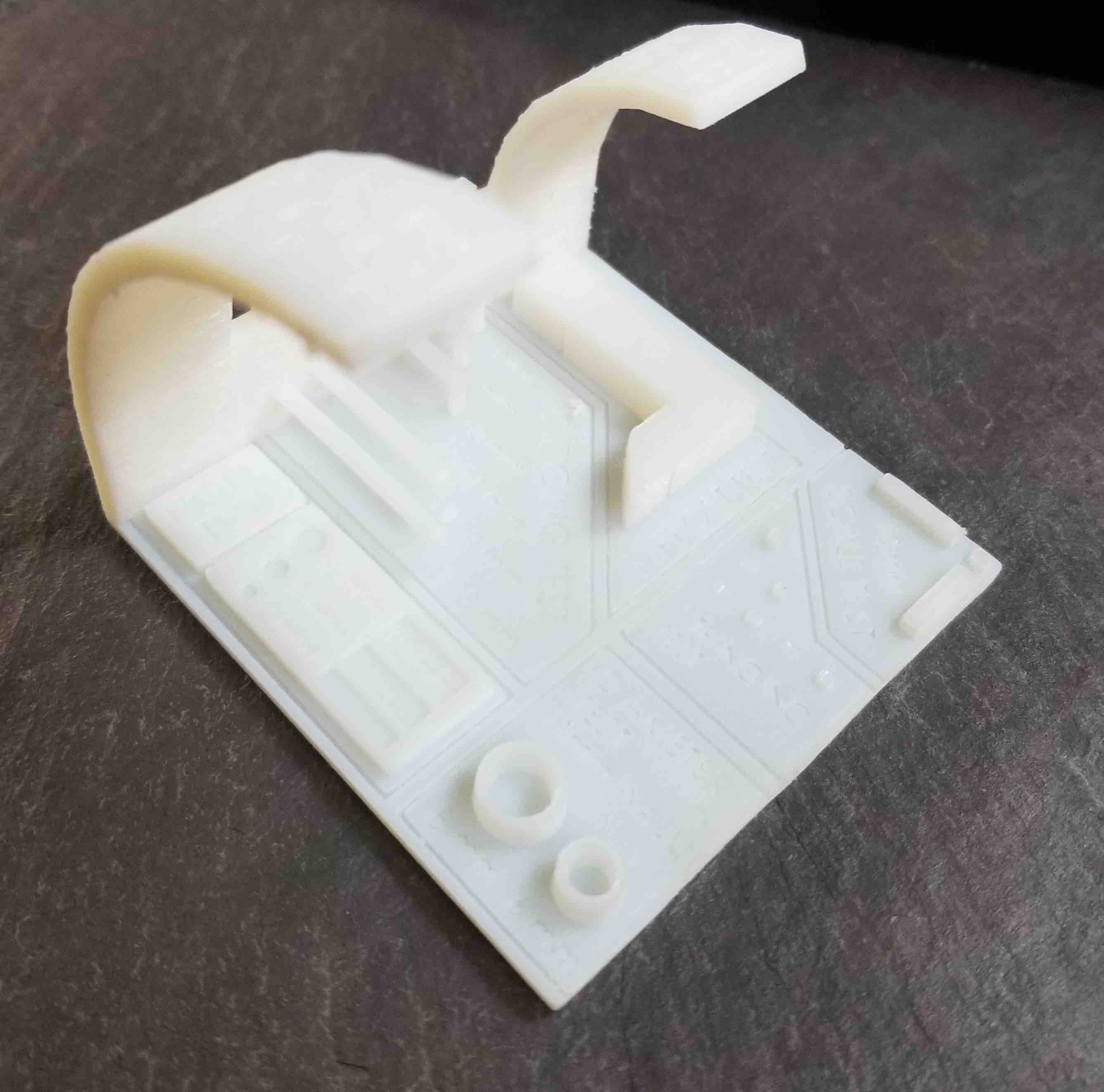

Here we printed the same test block, however, this was done using support material. Interestingly, cleaning the support material actually removed the bridge supports as well as the thin extrusions. This demontrated that the supports could actually be damaging for very fine components.

We were also able to test the clearance for the prusa through Andres Rico's gyroscope and through Cody Paige's caterpillar. The gyroscope was done with a 0.2 mm clearance, the caterpillar with a 0.3 mm clearance. The gyroscope had a slightly tighter feel to the joint making it a more tactile movement.

Design Rules Test